The Influence of Alloying Elements on Nitinol's Snap Action Behavior

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nitinol Alloying Background and Objectives

Nitinol, an equiatomic alloy of nickel and titanium, has been a subject of intense research and development since its discovery in the 1960s. This shape memory alloy (SMA) exhibits unique properties, including superelasticity and the shape memory effect, which have made it invaluable in various industries, from medical devices to aerospace applications. The snap action behavior of Nitinol, characterized by its ability to rapidly change shape in response to temperature or stress, is a critical aspect of its functionality.

The evolution of Nitinol technology has been marked by continuous efforts to enhance its performance characteristics through alloying. Researchers have explored the addition of various elements to the basic NiTi composition to tailor its properties for specific applications. The primary objectives of alloying Nitinol are to modify its transformation temperatures, improve its mechanical properties, and enhance its corrosion resistance.

Early studies focused on ternary additions such as copper, which was found to narrow the hysteresis of the phase transformation and stabilize the transformation temperatures. This led to the development of NiTiCu alloys with improved fatigue life and more precise control over the actuation temperature range. Subsequently, the addition of elements like niobium, palladium, and platinum has been investigated to raise the transformation temperatures for high-temperature applications.

The influence of alloying elements on Nitinol's snap action behavior is of particular interest due to its implications for actuator design and performance. Alloying can affect the kinetics of the martensitic transformation, which directly impacts the speed and force of the shape change. For instance, the addition of hafnium has been shown to increase the transformation temperatures and modify the lattice parameters, potentially altering the snap action characteristics.

Recent research has also explored the use of quaternary alloys, combining multiple alloying elements to achieve synergistic effects. These complex alloys aim to fine-tune the snap action behavior while simultaneously addressing other performance criteria such as biocompatibility for medical applications or resistance to hydrogen embrittlement in industrial settings.

The ongoing technological goal is to develop Nitinol alloys with precisely controlled snap action behavior, allowing for the design of actuators and devices with optimal performance in diverse operating conditions. This includes achieving faster actuation speeds, higher work output, and greater stability over repeated cycles. Additionally, there is a push towards expanding the temperature range in which Nitinol can exhibit its unique properties, opening up new application possibilities in extreme environments.

The evolution of Nitinol technology has been marked by continuous efforts to enhance its performance characteristics through alloying. Researchers have explored the addition of various elements to the basic NiTi composition to tailor its properties for specific applications. The primary objectives of alloying Nitinol are to modify its transformation temperatures, improve its mechanical properties, and enhance its corrosion resistance.

Early studies focused on ternary additions such as copper, which was found to narrow the hysteresis of the phase transformation and stabilize the transformation temperatures. This led to the development of NiTiCu alloys with improved fatigue life and more precise control over the actuation temperature range. Subsequently, the addition of elements like niobium, palladium, and platinum has been investigated to raise the transformation temperatures for high-temperature applications.

The influence of alloying elements on Nitinol's snap action behavior is of particular interest due to its implications for actuator design and performance. Alloying can affect the kinetics of the martensitic transformation, which directly impacts the speed and force of the shape change. For instance, the addition of hafnium has been shown to increase the transformation temperatures and modify the lattice parameters, potentially altering the snap action characteristics.

Recent research has also explored the use of quaternary alloys, combining multiple alloying elements to achieve synergistic effects. These complex alloys aim to fine-tune the snap action behavior while simultaneously addressing other performance criteria such as biocompatibility for medical applications or resistance to hydrogen embrittlement in industrial settings.

The ongoing technological goal is to develop Nitinol alloys with precisely controlled snap action behavior, allowing for the design of actuators and devices with optimal performance in diverse operating conditions. This includes achieving faster actuation speeds, higher work output, and greater stability over repeated cycles. Additionally, there is a push towards expanding the temperature range in which Nitinol can exhibit its unique properties, opening up new application possibilities in extreme environments.

Market Analysis for Nitinol Applications

The Nitinol market has experienced significant growth in recent years, driven by the material's unique properties and expanding applications across various industries. The global Nitinol market size was valued at approximately $1.5 billion in 2020 and is projected to reach $2.7 billion by 2026, growing at a CAGR of 10.2% during the forecast period.

The medical devices sector dominates the Nitinol market, accounting for over 70% of the total market share. This is primarily due to Nitinol's biocompatibility, superelasticity, and shape memory properties, which make it ideal for minimally invasive surgical instruments, stents, orthodontic wires, and other medical implants. The growing prevalence of cardiovascular diseases and the increasing adoption of minimally invasive procedures are key factors driving the demand for Nitinol in the medical field.

The aerospace and automotive industries are emerging as significant growth sectors for Nitinol applications. In aerospace, Nitinol is used in adaptive wing structures, vibration damping systems, and actuators. The automotive sector utilizes Nitinol in various components, including engine valves, sensors, and adaptive headlight systems. These industries are expected to contribute to the market's growth, with a projected CAGR of 12% and 9% respectively over the next five years.

Consumer electronics and robotics are also showing promising growth potential for Nitinol applications. The material's shape memory properties are being leveraged in smartphone antennas, wearable devices, and robotic actuators. The consumer electronics segment is anticipated to grow at a CAGR of 11% through 2026, driven by the increasing demand for smart devices and wearable technology.

Geographically, North America holds the largest market share, accounting for approximately 40% of the global Nitinol market. This is attributed to the region's advanced healthcare infrastructure and high adoption rate of innovative medical technologies. Europe follows closely, with a market share of around 30%, driven by the presence of major medical device manufacturers and stringent regulatory standards promoting the use of advanced materials.

The Asia-Pacific region is expected to witness the fastest growth, with a projected CAGR of 12.5% during the forecast period. This growth is fueled by the rapidly expanding healthcare sector in countries like China and India, increasing investments in aerospace and automotive industries, and the growing demand for consumer electronics.

The medical devices sector dominates the Nitinol market, accounting for over 70% of the total market share. This is primarily due to Nitinol's biocompatibility, superelasticity, and shape memory properties, which make it ideal for minimally invasive surgical instruments, stents, orthodontic wires, and other medical implants. The growing prevalence of cardiovascular diseases and the increasing adoption of minimally invasive procedures are key factors driving the demand for Nitinol in the medical field.

The aerospace and automotive industries are emerging as significant growth sectors for Nitinol applications. In aerospace, Nitinol is used in adaptive wing structures, vibration damping systems, and actuators. The automotive sector utilizes Nitinol in various components, including engine valves, sensors, and adaptive headlight systems. These industries are expected to contribute to the market's growth, with a projected CAGR of 12% and 9% respectively over the next five years.

Consumer electronics and robotics are also showing promising growth potential for Nitinol applications. The material's shape memory properties are being leveraged in smartphone antennas, wearable devices, and robotic actuators. The consumer electronics segment is anticipated to grow at a CAGR of 11% through 2026, driven by the increasing demand for smart devices and wearable technology.

Geographically, North America holds the largest market share, accounting for approximately 40% of the global Nitinol market. This is attributed to the region's advanced healthcare infrastructure and high adoption rate of innovative medical technologies. Europe follows closely, with a market share of around 30%, driven by the presence of major medical device manufacturers and stringent regulatory standards promoting the use of advanced materials.

The Asia-Pacific region is expected to witness the fastest growth, with a projected CAGR of 12.5% during the forecast period. This growth is fueled by the rapidly expanding healthcare sector in countries like China and India, increasing investments in aerospace and automotive industries, and the growing demand for consumer electronics.

Current Challenges in Nitinol Alloying

Despite the remarkable properties of Nitinol, the current challenges in alloying this shape memory alloy present significant hurdles for researchers and engineers. One of the primary difficulties lies in maintaining the delicate balance of nickel and titanium composition, which is crucial for preserving the alloy's unique characteristics. Even slight deviations in the Ni-Ti ratio can dramatically alter the transformation temperatures and mechanical properties of Nitinol.

The introduction of tertiary elements, while offering potential benefits, further complicates the alloying process. Elements such as copper, iron, or niobium can enhance certain properties but may simultaneously compromise others. For instance, adding copper can improve the stability of transformation temperatures, but it may also reduce the overall strength of the alloy. This trade-off between different properties poses a significant challenge in optimizing Nitinol for specific applications.

Another major hurdle is the control of impurities during the alloying process. Oxygen, carbon, and nitrogen are particularly problematic, as they can form unwanted precipitates that affect the alloy's performance. These impurities can lead to a loss of shape memory effect, reduced fatigue life, and increased brittleness. Achieving and maintaining high purity levels during melting and processing remains a constant challenge for manufacturers.

The scalability of precise alloying techniques is also a significant concern. While laboratory-scale production can achieve tight compositional control, translating this precision to industrial-scale manufacturing is problematic. Variations in composition across large batches can lead to inconsistent performance in final products, which is particularly critical in medical and aerospace applications where reliability is paramount.

Furthermore, the influence of alloying elements on Nitinol's snap action behavior is not fully understood. The complex interplay between composition, microstructure, and thermomechanical properties makes it challenging to predict and fine-tune the snap action characteristics. This knowledge gap hinders the development of Nitinol alloys with tailored snap action behaviors for specific applications.

Lastly, the high cost associated with the precise control of alloying elements and processing parameters presents an economic challenge. The need for specialized equipment, stringent quality control measures, and often proprietary techniques drives up production costs, limiting the widespread adoption of Nitinol in cost-sensitive applications.

The introduction of tertiary elements, while offering potential benefits, further complicates the alloying process. Elements such as copper, iron, or niobium can enhance certain properties but may simultaneously compromise others. For instance, adding copper can improve the stability of transformation temperatures, but it may also reduce the overall strength of the alloy. This trade-off between different properties poses a significant challenge in optimizing Nitinol for specific applications.

Another major hurdle is the control of impurities during the alloying process. Oxygen, carbon, and nitrogen are particularly problematic, as they can form unwanted precipitates that affect the alloy's performance. These impurities can lead to a loss of shape memory effect, reduced fatigue life, and increased brittleness. Achieving and maintaining high purity levels during melting and processing remains a constant challenge for manufacturers.

The scalability of precise alloying techniques is also a significant concern. While laboratory-scale production can achieve tight compositional control, translating this precision to industrial-scale manufacturing is problematic. Variations in composition across large batches can lead to inconsistent performance in final products, which is particularly critical in medical and aerospace applications where reliability is paramount.

Furthermore, the influence of alloying elements on Nitinol's snap action behavior is not fully understood. The complex interplay between composition, microstructure, and thermomechanical properties makes it challenging to predict and fine-tune the snap action characteristics. This knowledge gap hinders the development of Nitinol alloys with tailored snap action behaviors for specific applications.

Lastly, the high cost associated with the precise control of alloying elements and processing parameters presents an economic challenge. The need for specialized equipment, stringent quality control measures, and often proprietary techniques drives up production costs, limiting the widespread adoption of Nitinol in cost-sensitive applications.

Existing Alloying Techniques for Nitinol

01 Shape memory properties of Nitinol

Nitinol exhibits unique shape memory properties, allowing it to return to a predetermined shape when heated. This characteristic is fundamental to its snap action behavior, enabling the material to rapidly change shape or position in response to temperature changes. The shape memory effect is utilized in various applications, including actuators and medical devices.- Shape memory properties of Nitinol: Nitinol exhibits unique shape memory properties that allow it to return to a predetermined shape when heated. This characteristic enables the material to produce snap action behavior, which can be utilized in various applications such as actuators, switches, and temperature-sensitive devices.

- Thermal actuation mechanisms: The snap action behavior of Nitinol can be triggered by thermal actuation. When the material reaches its transition temperature, it rapidly changes shape, producing a sudden and forceful movement. This principle is used in thermal switches, circuit breakers, and other temperature-controlled devices.

- Bistable mechanisms using Nitinol: Nitinol's snap action behavior can be utilized to create bistable mechanisms, where the material can switch between two stable states. This property is valuable in the design of latching mechanisms, toggle switches, and other devices requiring distinct on/off positions.

- Electrical applications of Nitinol snap action: The snap action behavior of Nitinol is particularly useful in electrical applications. It can be employed in the design of electrical switches, circuit breakers, and relays, where rapid and reliable switching is required. The material's unique properties allow for the creation of compact and efficient electrical components.

- Design considerations for Nitinol snap action devices: When designing devices that utilize Nitinol's snap action behavior, several factors must be considered. These include the material composition, heat treatment processes, and the specific geometry of the Nitinol element. Proper design ensures optimal performance, reliability, and longevity of the snap action mechanism in various applications.

02 Superelasticity of Nitinol

Nitinol's superelastic properties contribute to its snap action behavior. This allows the material to undergo large deformations and return to its original shape without permanent damage. The superelasticity of Nitinol is crucial in applications requiring repeated snap action or where high flexibility and recovery are needed.Expand Specific Solutions03 Temperature-dependent phase transformation

The snap action behavior of Nitinol is closely related to its temperature-dependent phase transformation between austenite and martensite. This transformation occurs at specific transition temperatures, which can be tailored during the manufacturing process. The rapid change in crystal structure during this transformation is responsible for the material's quick and forceful shape change.Expand Specific Solutions04 Application in actuators and switches

Nitinol's snap action behavior makes it ideal for use in actuators and switches. The material can be designed to rapidly change shape or position in response to electrical or thermal stimuli, providing a reliable and repeatable switching mechanism. This property is utilized in various industries, including automotive, aerospace, and consumer electronics.Expand Specific Solutions05 Design considerations for Nitinol snap action devices

Designing devices that utilize Nitinol's snap action behavior requires careful consideration of factors such as material composition, heat treatment, and mechanical constraints. The geometry of the Nitinol component, its transition temperatures, and the applied stress all play crucial roles in achieving the desired snap action performance. Proper design ensures optimal functionality and longevity of the device.Expand Specific Solutions

Key Players in Nitinol Industry

The influence of alloying elements on Nitinol's snap action behavior is a niche area within shape memory alloy technology, currently in its growth phase. The market size is expanding as industries like aerospace, automotive, and medical devices increasingly adopt Nitinol-based solutions. Technologically, the field is moderately mature, with ongoing research to optimize performance. Companies like Ningbo Boway Alloy Material Co., Ltd. and Carpenter Technology Corp. are at the forefront, developing advanced Nitinol alloys. Academic institutions such as Wuhan University of Science & Technology and South China University of Technology contribute significantly to fundamental research, while industry players like Komatsu Ltd. and Siemens AG explore practical applications, driving the technology towards commercialization.

NIPPON STEEL CORP.

Technical Solution: NIPPON STEEL CORP. has developed advanced Nitinol alloys with improved snap action behavior through precise control of alloying elements. Their research focuses on optimizing the composition of nickel-titanium alloys by adding ternary elements such as copper, iron, or niobium. These additions can significantly alter the transformation temperatures and hysteresis of the alloy, enhancing its snap action characteristics[1]. The company has implemented a sophisticated heat treatment process that allows for fine-tuning of the microstructure, resulting in Nitinol alloys with more consistent and reliable shape memory effects[3]. Their proprietary manufacturing techniques ensure high purity and homogeneity of the alloy composition, which is crucial for achieving precise control over the snap action behavior[5].

Strengths: Precise control over alloy composition and microstructure, leading to enhanced snap action performance. Weaknesses: Potentially higher production costs due to the need for specialized manufacturing processes and high-purity raw materials.

Carpenter Technology Corp.

Technical Solution: Carpenter Technology Corp. has developed a range of Nitinol alloys with tailored snap action behaviors for various applications. Their approach involves careful manipulation of the Ni-Ti ratio and the addition of specific alloying elements to modify the transformation temperatures and mechanical properties. The company has invested in advanced melting and processing techniques, including vacuum induction melting and vacuum arc remelting, to ensure high purity and homogeneity of their Nitinol alloys[2]. Carpenter's research has shown that small additions of elements such as hafnium or zirconium can significantly improve the stability of the snap action behavior over repeated cycles[4]. They have also developed proprietary thermomechanical treatments that optimize the microstructure for enhanced snap action performance, particularly in thin-walled components and fine wires used in medical devices[6].

Strengths: Wide range of tailored Nitinol alloys for specific applications, advanced manufacturing processes ensuring high purity. Weaknesses: Potentially limited flexibility in rapidly adapting alloy compositions for emerging applications.

Innovative Alloying Elements for Snap Action

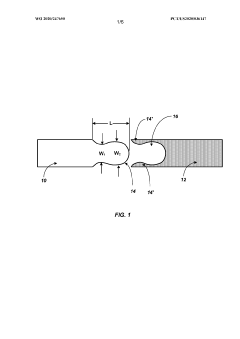

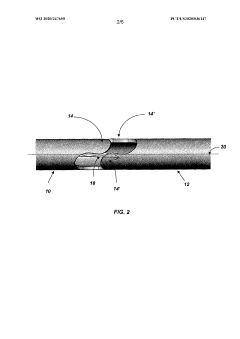

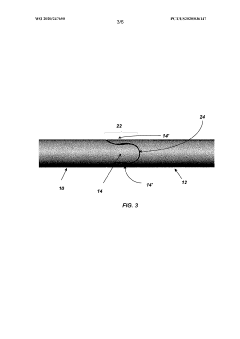

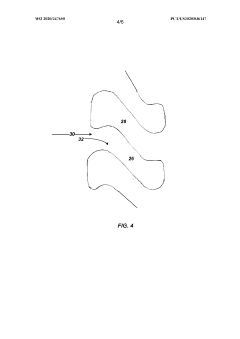

Mechanical joining of nitinol tubes

PatentWO2020247650A1

Innovation

- The method involves creating Nitinol tubes with protruding lobes that interlock with corresponding lobes on other metallic tubes, utilizing superelasticity or shape memory properties to form a mechanical joint through translation, rotation, or hinging motions, eliminating the need for welding and intermediate components.

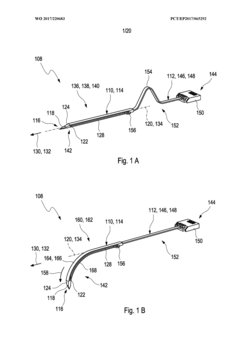

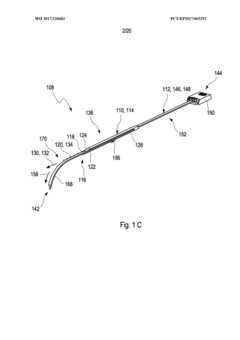

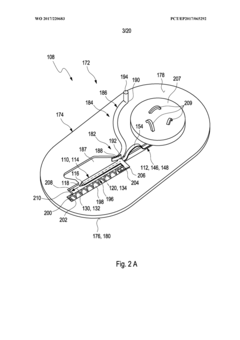

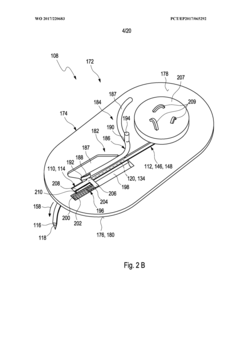

Medical device for transcutaneously inserting an insertable element into a body tissue

PatentWO2017220683A1

Innovation

- A medical device featuring an insertion cannula made of shape memory alloy, transformable from a straight to an arch shape for easy insertion and removal, integrated with a patch and electronics unit for simplified assembly and operation, reducing the need for additional components and assembly steps.

Material Characterization Methods

The characterization of Nitinol alloys and the influence of alloying elements on their snap action behavior requires a comprehensive set of material analysis techniques. X-ray diffraction (XRD) is a fundamental method used to identify the crystalline structure and phase composition of Nitinol alloys. This technique provides crucial information about the austenite and martensite phases, as well as any precipitates formed due to alloying elements. Differential scanning calorimetry (DSC) is essential for determining the transformation temperatures and latent heat of the phase transitions, which are directly affected by alloying elements.

Scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDS) allows for high-resolution imaging of the microstructure and elemental mapping, revealing the distribution of alloying elements within the Nitinol matrix. Transmission electron microscopy (TEM) provides even higher resolution for observing the atomic structure and any nanoscale precipitates formed by alloying elements.

Mechanical testing methods are crucial for evaluating the snap action behavior. Dynamic mechanical analysis (DMA) can measure the temperature-dependent modulus and damping properties, which are indicative of the martensitic transformation. Tensile testing with in-situ temperature control allows for the observation of stress-strain behavior across different temperatures, revealing the influence of alloying elements on the superelastic properties and shape memory effect.

Thermomechanical analysis (TMA) is particularly useful for measuring the dimensional changes associated with the phase transformation, providing insights into how alloying elements affect the shape recovery characteristics. Nanoindentation can be employed to map the local mechanical properties across different phases and grain boundaries, offering a nanoscale perspective on the alloy's behavior.

Atom probe tomography (APT) provides three-dimensional atomic-scale compositional mapping, which is invaluable for understanding the precise distribution of alloying elements and their role in the formation of precipitates or local compositional variations that influence the snap action behavior. Synchrotron-based techniques, such as high-energy X-ray diffraction and X-ray absorption spectroscopy, offer in-situ capabilities for observing structural changes during the martensitic transformation under various conditions.

These characterization methods, when used in combination, provide a comprehensive understanding of how alloying elements influence the microstructure, phase transformation, and ultimately the snap action behavior of Nitinol alloys. The data obtained from these techniques can be correlated to develop structure-property relationships, guiding the optimization of alloy compositions for specific applications requiring precise control over the snap action characteristics.

Scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDS) allows for high-resolution imaging of the microstructure and elemental mapping, revealing the distribution of alloying elements within the Nitinol matrix. Transmission electron microscopy (TEM) provides even higher resolution for observing the atomic structure and any nanoscale precipitates formed by alloying elements.

Mechanical testing methods are crucial for evaluating the snap action behavior. Dynamic mechanical analysis (DMA) can measure the temperature-dependent modulus and damping properties, which are indicative of the martensitic transformation. Tensile testing with in-situ temperature control allows for the observation of stress-strain behavior across different temperatures, revealing the influence of alloying elements on the superelastic properties and shape memory effect.

Thermomechanical analysis (TMA) is particularly useful for measuring the dimensional changes associated with the phase transformation, providing insights into how alloying elements affect the shape recovery characteristics. Nanoindentation can be employed to map the local mechanical properties across different phases and grain boundaries, offering a nanoscale perspective on the alloy's behavior.

Atom probe tomography (APT) provides three-dimensional atomic-scale compositional mapping, which is invaluable for understanding the precise distribution of alloying elements and their role in the formation of precipitates or local compositional variations that influence the snap action behavior. Synchrotron-based techniques, such as high-energy X-ray diffraction and X-ray absorption spectroscopy, offer in-situ capabilities for observing structural changes during the martensitic transformation under various conditions.

These characterization methods, when used in combination, provide a comprehensive understanding of how alloying elements influence the microstructure, phase transformation, and ultimately the snap action behavior of Nitinol alloys. The data obtained from these techniques can be correlated to develop structure-property relationships, guiding the optimization of alloy compositions for specific applications requiring precise control over the snap action characteristics.

Environmental Impact of Nitinol Production

The production of Nitinol, a shape memory alloy composed of nickel and titanium, has significant environmental implications that warrant careful consideration. The manufacturing process involves energy-intensive steps and the use of potentially hazardous materials, which can lead to various environmental impacts.

One of the primary concerns is the high energy consumption associated with Nitinol production. The melting and alloying of nickel and titanium require extremely high temperatures, typically achieved through vacuum arc remelting or vacuum induction melting. These processes consume substantial amounts of electricity, contributing to greenhouse gas emissions and increasing the carbon footprint of Nitinol manufacturing.

The extraction and processing of raw materials, particularly nickel and titanium, also pose environmental challenges. Mining operations for these metals can lead to habitat destruction, soil erosion, and water pollution. Additionally, the refining processes for both metals involve chemical treatments that may generate hazardous waste and emissions if not properly managed.

Water usage is another critical factor in Nitinol production. The material undergoes multiple heat treatments and cooling cycles, often requiring significant quantities of water for quenching and temperature control. This can strain local water resources, especially in water-scarce regions.

The production of Nitinol also generates various waste streams that need careful management. These include metal scraps, slag from melting processes, and chemical waste from surface treatments and cleaning operations. Proper disposal or recycling of these materials is essential to minimize environmental impact and comply with regulations.

Air emissions are a concern during Nitinol manufacturing, particularly during melting and heat treatment stages. These processes can release particulate matter and potentially harmful gases, necessitating effective air pollution control measures to protect air quality and worker health.

Despite these challenges, there are ongoing efforts to improve the environmental sustainability of Nitinol production. Research is being conducted on more energy-efficient melting techniques, such as electron beam melting, which could reduce energy consumption. Additionally, advancements in recycling technologies are enabling better recovery and reuse of Nitinol scrap, reducing the demand for virgin raw materials.

Implementing cleaner production techniques and adopting circular economy principles can significantly mitigate the environmental impact of Nitinol manufacturing. This includes optimizing process efficiency, utilizing renewable energy sources, improving waste management practices, and developing closed-loop water systems to minimize resource consumption and environmental pollution.

One of the primary concerns is the high energy consumption associated with Nitinol production. The melting and alloying of nickel and titanium require extremely high temperatures, typically achieved through vacuum arc remelting or vacuum induction melting. These processes consume substantial amounts of electricity, contributing to greenhouse gas emissions and increasing the carbon footprint of Nitinol manufacturing.

The extraction and processing of raw materials, particularly nickel and titanium, also pose environmental challenges. Mining operations for these metals can lead to habitat destruction, soil erosion, and water pollution. Additionally, the refining processes for both metals involve chemical treatments that may generate hazardous waste and emissions if not properly managed.

Water usage is another critical factor in Nitinol production. The material undergoes multiple heat treatments and cooling cycles, often requiring significant quantities of water for quenching and temperature control. This can strain local water resources, especially in water-scarce regions.

The production of Nitinol also generates various waste streams that need careful management. These include metal scraps, slag from melting processes, and chemical waste from surface treatments and cleaning operations. Proper disposal or recycling of these materials is essential to minimize environmental impact and comply with regulations.

Air emissions are a concern during Nitinol manufacturing, particularly during melting and heat treatment stages. These processes can release particulate matter and potentially harmful gases, necessitating effective air pollution control measures to protect air quality and worker health.

Despite these challenges, there are ongoing efforts to improve the environmental sustainability of Nitinol production. Research is being conducted on more energy-efficient melting techniques, such as electron beam melting, which could reduce energy consumption. Additionally, advancements in recycling technologies are enabling better recovery and reuse of Nitinol scrap, reducing the demand for virgin raw materials.

Implementing cleaner production techniques and adopting circular economy principles can significantly mitigate the environmental impact of Nitinol manufacturing. This includes optimizing process efficiency, utilizing renewable energy sources, improving waste management practices, and developing closed-loop water systems to minimize resource consumption and environmental pollution.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!