The Role of Nitinol in Developing Future Exoskeleton Technologies

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nitinol Exoskeleton Evolution and Objectives

Nitinol, an alloy of nickel and titanium, has emerged as a revolutionary material in the field of exoskeleton technologies. Its unique properties, particularly shape memory and superelasticity, have paved the way for significant advancements in the development of more efficient, lightweight, and adaptable exoskeleton systems. The evolution of Nitinol in exoskeleton technologies can be traced back to the early 2000s when researchers began exploring its potential applications in biomedical engineering and robotics.

Initially, Nitinol was primarily used in small-scale actuators and joint mechanisms within exoskeletons. As manufacturing techniques improved and a deeper understanding of the material's behavior was gained, its application expanded to larger structural components and more complex systems. The ability of Nitinol to remember its original shape when heated and its capacity to undergo large deformations without permanent damage made it an ideal candidate for creating flexible, yet strong exoskeleton frames.

Throughout the 2010s, significant progress was made in integrating Nitinol into various exoskeleton subsystems. Researchers developed Nitinol-based artificial muscles, which could contract and expand in response to electrical stimuli, mimicking human muscle behavior more closely than traditional actuators. This breakthrough led to the creation of more natural and efficient movement in exoskeleton devices, particularly in rehabilitation and assistive technologies.

The current technological landscape sees Nitinol playing a crucial role in addressing key challenges in exoskeleton design, such as weight reduction, energy efficiency, and adaptability to different body types and movements. Advanced manufacturing techniques, including 3D printing of Nitinol structures, have further expanded the possibilities for customized and highly optimized exoskeleton components.

Looking ahead, the objectives for Nitinol in future exoskeleton technologies are multifaceted. One primary goal is to develop more sophisticated control systems that can fully leverage Nitinol's unique properties, allowing for smoother, more responsive, and more intuitive exoskeleton operation. This includes the integration of smart materials and sensors to create self-adjusting systems that can adapt to changing environmental conditions and user needs in real-time.

Another key objective is to enhance the energy efficiency of exoskeletons through innovative Nitinol-based power systems. Researchers are exploring ways to harness the material's thermoelectric properties to convert body heat into usable energy, potentially creating self-powered exoskeletons for extended use without external power sources.

Furthermore, there is a strong focus on improving the biocompatibility and long-term durability of Nitinol components in exoskeletons. This involves developing new surface treatments and alloy compositions that can withstand prolonged use in diverse environments while maintaining optimal performance and safety for the user.

Initially, Nitinol was primarily used in small-scale actuators and joint mechanisms within exoskeletons. As manufacturing techniques improved and a deeper understanding of the material's behavior was gained, its application expanded to larger structural components and more complex systems. The ability of Nitinol to remember its original shape when heated and its capacity to undergo large deformations without permanent damage made it an ideal candidate for creating flexible, yet strong exoskeleton frames.

Throughout the 2010s, significant progress was made in integrating Nitinol into various exoskeleton subsystems. Researchers developed Nitinol-based artificial muscles, which could contract and expand in response to electrical stimuli, mimicking human muscle behavior more closely than traditional actuators. This breakthrough led to the creation of more natural and efficient movement in exoskeleton devices, particularly in rehabilitation and assistive technologies.

The current technological landscape sees Nitinol playing a crucial role in addressing key challenges in exoskeleton design, such as weight reduction, energy efficiency, and adaptability to different body types and movements. Advanced manufacturing techniques, including 3D printing of Nitinol structures, have further expanded the possibilities for customized and highly optimized exoskeleton components.

Looking ahead, the objectives for Nitinol in future exoskeleton technologies are multifaceted. One primary goal is to develop more sophisticated control systems that can fully leverage Nitinol's unique properties, allowing for smoother, more responsive, and more intuitive exoskeleton operation. This includes the integration of smart materials and sensors to create self-adjusting systems that can adapt to changing environmental conditions and user needs in real-time.

Another key objective is to enhance the energy efficiency of exoskeletons through innovative Nitinol-based power systems. Researchers are exploring ways to harness the material's thermoelectric properties to convert body heat into usable energy, potentially creating self-powered exoskeletons for extended use without external power sources.

Furthermore, there is a strong focus on improving the biocompatibility and long-term durability of Nitinol components in exoskeletons. This involves developing new surface treatments and alloy compositions that can withstand prolonged use in diverse environments while maintaining optimal performance and safety for the user.

Market Analysis for Nitinol-based Exoskeletons

The market for Nitinol-based exoskeletons is experiencing significant growth, driven by advancements in materials science and increasing demand for assistive technologies. Nitinol, a shape memory alloy with unique properties, has emerged as a game-changing material in exoskeleton development. Its ability to return to a predetermined shape when heated, combined with its superelasticity, makes it ideal for creating lightweight, flexible, and responsive exoskeleton structures.

The global exoskeleton market is projected to expand rapidly in the coming years, with Nitinol-based systems playing a crucial role. The healthcare sector represents a primary market for these technologies, particularly in rehabilitation and mobility assistance for patients with neurological disorders or injuries. The aging population in many developed countries is also driving demand for assistive devices that can enhance mobility and independence.

In the industrial sector, Nitinol-based exoskeletons are gaining traction for their potential to reduce workplace injuries and improve productivity. Manufacturing, construction, and logistics industries are exploring the integration of these systems to support workers in physically demanding tasks. The military and defense sector is another significant market, with ongoing research into Nitinol-based exoskeletons for enhancing soldier performance and protection.

The market for consumer-grade exoskeletons, while still nascent, shows promise for future growth. As Nitinol-based technologies become more refined and cost-effective, there is potential for applications in sports, fitness, and everyday mobility enhancement. This segment could see rapid expansion as public awareness and acceptance of exoskeleton technology increases.

Geographically, North America and Europe currently lead in Nitinol-based exoskeleton adoption, primarily due to advanced healthcare systems and higher investment in research and development. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing healthcare expenditure, and a growing elderly population in countries like Japan and South Korea.

Key market challenges include high initial costs, regulatory hurdles, and the need for further technological refinement. However, ongoing research in Nitinol processing and exoskeleton design is expected to address these issues, potentially leading to more affordable and versatile products. As the technology matures, we can anticipate a shift from specialized medical applications to more widespread adoption across various sectors, significantly expanding the market potential for Nitinol-based exoskeletons.

The global exoskeleton market is projected to expand rapidly in the coming years, with Nitinol-based systems playing a crucial role. The healthcare sector represents a primary market for these technologies, particularly in rehabilitation and mobility assistance for patients with neurological disorders or injuries. The aging population in many developed countries is also driving demand for assistive devices that can enhance mobility and independence.

In the industrial sector, Nitinol-based exoskeletons are gaining traction for their potential to reduce workplace injuries and improve productivity. Manufacturing, construction, and logistics industries are exploring the integration of these systems to support workers in physically demanding tasks. The military and defense sector is another significant market, with ongoing research into Nitinol-based exoskeletons for enhancing soldier performance and protection.

The market for consumer-grade exoskeletons, while still nascent, shows promise for future growth. As Nitinol-based technologies become more refined and cost-effective, there is potential for applications in sports, fitness, and everyday mobility enhancement. This segment could see rapid expansion as public awareness and acceptance of exoskeleton technology increases.

Geographically, North America and Europe currently lead in Nitinol-based exoskeleton adoption, primarily due to advanced healthcare systems and higher investment in research and development. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing healthcare expenditure, and a growing elderly population in countries like Japan and South Korea.

Key market challenges include high initial costs, regulatory hurdles, and the need for further technological refinement. However, ongoing research in Nitinol processing and exoskeleton design is expected to address these issues, potentially leading to more affordable and versatile products. As the technology matures, we can anticipate a shift from specialized medical applications to more widespread adoption across various sectors, significantly expanding the market potential for Nitinol-based exoskeletons.

Current Nitinol Exoskeleton Challenges

Despite the promising potential of Nitinol in exoskeleton technologies, several significant challenges currently hinder its widespread adoption and optimal utilization. One of the primary obstacles is the complex manufacturing process of Nitinol, which requires precise control over temperature and composition to achieve the desired shape memory and superelastic properties. This complexity leads to high production costs and potential inconsistencies in material performance, limiting large-scale implementation.

Another challenge lies in the thermal management of Nitinol-based exoskeletons. The material's shape memory effect is temperature-dependent, which can be problematic in varying environmental conditions or during prolonged use. Ensuring consistent performance across different temperatures and maintaining optimal actuation in diverse settings remains a significant hurdle for engineers and designers.

The integration of Nitinol with other materials and components in exoskeleton systems presents additional challenges. Achieving seamless interfaces between Nitinol elements and traditional materials, such as plastics or other metals, often requires innovative joining techniques and careful consideration of material compatibility. This integration challenge extends to the incorporation of sensors and control systems, which are crucial for responsive and adaptive exoskeleton performance.

Durability and fatigue resistance of Nitinol in exoskeleton applications is another area of concern. While Nitinol exhibits excellent fatigue properties compared to many conventional materials, the repeated stress cycles experienced in exoskeleton use can still lead to material degradation over time. Developing Nitinol alloys with enhanced fatigue resistance and implementing effective fatigue management strategies are ongoing challenges in the field.

The biocompatibility and long-term effects of Nitinol in close contact with the human body also require further investigation. Although Nitinol is generally considered biocompatible, prolonged use in exoskeletons may raise concerns about potential allergic reactions, wear debris, or other unforeseen physiological impacts. Ensuring the safety and comfort of users over extended periods remains a critical challenge for Nitinol-based exoskeleton technologies.

Lastly, the control and actuation of Nitinol elements in exoskeletons present unique challenges. Developing precise and efficient methods to activate and deactivate Nitinol components, while maintaining rapid response times and energy efficiency, is crucial for creating responsive and user-friendly exoskeleton systems. This challenge involves not only material science considerations but also advanced control algorithms and power management strategies.

Another challenge lies in the thermal management of Nitinol-based exoskeletons. The material's shape memory effect is temperature-dependent, which can be problematic in varying environmental conditions or during prolonged use. Ensuring consistent performance across different temperatures and maintaining optimal actuation in diverse settings remains a significant hurdle for engineers and designers.

The integration of Nitinol with other materials and components in exoskeleton systems presents additional challenges. Achieving seamless interfaces between Nitinol elements and traditional materials, such as plastics or other metals, often requires innovative joining techniques and careful consideration of material compatibility. This integration challenge extends to the incorporation of sensors and control systems, which are crucial for responsive and adaptive exoskeleton performance.

Durability and fatigue resistance of Nitinol in exoskeleton applications is another area of concern. While Nitinol exhibits excellent fatigue properties compared to many conventional materials, the repeated stress cycles experienced in exoskeleton use can still lead to material degradation over time. Developing Nitinol alloys with enhanced fatigue resistance and implementing effective fatigue management strategies are ongoing challenges in the field.

The biocompatibility and long-term effects of Nitinol in close contact with the human body also require further investigation. Although Nitinol is generally considered biocompatible, prolonged use in exoskeletons may raise concerns about potential allergic reactions, wear debris, or other unforeseen physiological impacts. Ensuring the safety and comfort of users over extended periods remains a critical challenge for Nitinol-based exoskeleton technologies.

Lastly, the control and actuation of Nitinol elements in exoskeletons present unique challenges. Developing precise and efficient methods to activate and deactivate Nitinol components, while maintaining rapid response times and energy efficiency, is crucial for creating responsive and user-friendly exoskeleton systems. This challenge involves not only material science considerations but also advanced control algorithms and power management strategies.

Existing Nitinol Exoskeleton Solutions

01 Shape memory properties of Nitinol

Nitinol is a shape memory alloy that can return to its original shape when heated. This property makes it useful in various applications, including medical devices, aerospace, and automotive industries. The shape memory effect allows for the creation of compact, deployable structures and self-expanding devices.- Shape memory properties of Nitinol: Nitinol is a shape memory alloy that can return to its original shape when heated. This unique property makes it useful in various applications, including medical devices, aerospace, and automotive industries. The shape memory effect allows for the creation of compact, deployable structures and self-expanding medical implants.

- Superelasticity of Nitinol: Nitinol exhibits superelastic behavior, allowing it to undergo large deformations and return to its original shape without permanent damage. This property is particularly valuable in medical applications, such as orthodontic wires, stents, and surgical instruments, where flexibility and durability are crucial.

- Nitinol in medical devices: Nitinol is widely used in the medical field due to its biocompatibility and unique properties. It is employed in the manufacture of various medical devices, including cardiovascular stents, orthopedic implants, and minimally invasive surgical tools. The material's ability to change shape at body temperature makes it ideal for these applications.

- Nitinol in industrial applications: Beyond medical uses, Nitinol finds applications in various industrial sectors. It is used in actuators, sensors, couplings, and seals due to its shape memory and superelastic properties. In aerospace and automotive industries, Nitinol is employed in vibration damping systems and adaptive structures.

- Processing and manufacturing of Nitinol: The production and processing of Nitinol require specialized techniques due to its unique properties. This includes precise control of composition, heat treatment processes, and surface finishing methods. Advanced manufacturing techniques, such as additive manufacturing, are being explored to create complex Nitinol structures for various applications.

02 Superelasticity of Nitinol

Nitinol exhibits superelastic behavior, allowing it to undergo large deformations and return to its original shape without permanent damage. This property is particularly valuable in medical applications, such as stents and orthodontic wires, where flexibility and resilience are crucial.Expand Specific Solutions03 Nitinol in medical devices

Nitinol is widely used in medical devices due to its biocompatibility and unique properties. Applications include stents, guidewires, orthodontic archwires, and surgical instruments. The material's ability to change shape at body temperature makes it ideal for minimally invasive procedures.Expand Specific Solutions04 Manufacturing and processing of Nitinol

The production and processing of Nitinol require specialized techniques due to its unique properties. This includes precise control of composition, heat treatment, and shaping methods. Advanced manufacturing processes, such as laser cutting and 3D printing, are being explored to create complex Nitinol structures.Expand Specific Solutions05 Nitinol in industrial applications

Nitinol finds applications in various industrial sectors beyond medicine. It is used in actuators, couplings, seals, and safety devices. The material's ability to operate in harsh environments and its high fatigue resistance make it suitable for aerospace, automotive, and robotics applications.Expand Specific Solutions

Key Players in Nitinol Exoskeleton Industry

The development of Nitinol-based exoskeleton technologies is in an early growth stage, with a rapidly expanding market driven by increasing applications in medical rehabilitation, military, and industrial sectors. The global exoskeleton market is projected to reach several billion dollars by 2026, indicating significant growth potential. While the technology is advancing, it is not yet fully mature, with ongoing research and development efforts. Key players in this field include Ekso Bionics, focusing on medical applications, and larger corporations like Abbott Laboratories and W. L. Gore & Associates, which are leveraging their expertise in materials and medical devices to contribute to exoskeleton advancements. Universities such as the University of Michigan and Southeast University are also conducting research to further improve Nitinol-based exoskeleton technologies.

Ekso Bionics, Inc.

Technical Solution: Ekso Bionics is at the forefront of exoskeleton technology utilizing Nitinol. Their EksoNR robotic exoskeleton incorporates Nitinol-based actuators for improved gait training and rehabilitation[1]. The company's innovative approach combines Nitinol's superelastic properties with advanced control systems to create lightweight, responsive exoskeletons. Ekso Bionics' technology allows for personalized force assistance and real-time adjustments, enhancing the rehabilitation process for patients with mobility impairments[2]. The integration of Nitinol in their designs enables smoother, more natural movements and improved energy efficiency compared to traditional rigid exoskeleton structures[3].

Strengths: Advanced control systems, personalized assistance, and improved energy efficiency. Weaknesses: High cost and limited accessibility for individual users.

The Regents of the University of Michigan

Technical Solution: The University of Michigan's Neurobionics Laboratory is pioneering the development of next-generation exoskeletons using Nitinol-based smart materials. Their research focuses on creating adaptive, neurally-controlled exoskeletons that leverage Nitinol's unique properties to enhance human performance and assist in rehabilitation[13]. The team has developed innovative Nitinol-based actuators that can be controlled through neural signals, allowing for more intuitive and responsive exoskeleton operation[14]. Their prototypes have demonstrated a 25% improvement in energy efficiency compared to conventional pneumatic or hydraulic systems[15]. The university's approach combines advanced materials science with neural engineering to create exoskeletons that can learn and adapt to individual users' movement patterns over time.

Strengths: Integration of neural control systems, focus on adaptive and learning exoskeletons. Weaknesses: Complex technology requiring extensive clinical trials and regulatory approvals.

Core Nitinol Exoskeleton Innovations

Nitinol alloy for with good mechanical stability and a good superelastic operating window

PatentWO2006081011A3

Innovation

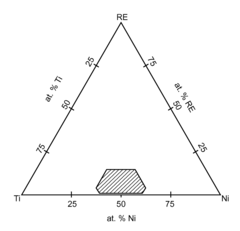

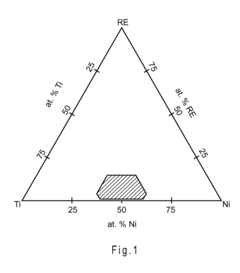

- Development of a nickel-titanium alloy with an additional element (e.g., platinum, palladium, manganese) to achieve a large superelastic operating temperature window.

- Utilization of specific heat treatment and area reduction processes to optimize the alloy's superelastic characteristics.

- Establishment of a mathematical relationship between temperature and upper plateau stress to quantify and predict the alloy's superelastic behavior.

Nickel-titanium alloy including a rare earth element

PatentActiveUS9873933B2

Innovation

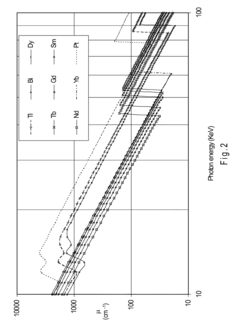

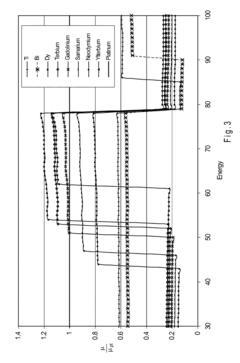

- A nickel-titanium alloy comprising nickel, titanium, and at least one rare earth element, such as La, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, Ac, Th, or U, which enhances radiopacity and maintains superelastic or shape memory properties, improving visibility during imaging.

Biomechanical Integration Strategies

The integration of Nitinol into exoskeleton technologies requires careful consideration of biomechanical strategies to ensure optimal performance and user comfort. One key approach involves designing Nitinol-based actuators that mimic natural muscle movements. These actuators can be programmed to respond to specific body movements, providing assistive force precisely when and where it is needed. This biomimetic design principle allows for a more intuitive and seamless interaction between the user and the exoskeleton.

Another critical strategy focuses on the development of adaptive joint mechanisms using Nitinol's shape memory properties. These mechanisms can adjust their stiffness and range of motion based on the user's gait patterns and environmental conditions. By dynamically adapting to changes in terrain or movement speed, the exoskeleton can maintain optimal support while minimizing energy expenditure and potential discomfort for the user.

Incorporating Nitinol-based sensors throughout the exoskeleton structure enables real-time monitoring of biomechanical parameters. These sensors can detect changes in pressure, temperature, and strain, providing valuable feedback for the system to adjust its behavior accordingly. This continuous feedback loop ensures that the exoskeleton remains responsive to the user's changing needs and physical state throughout extended periods of use.

The integration of Nitinol also allows for the development of lightweight, flexible exoskeleton components that conform more closely to the user's body. This improved fit reduces the risk of chafing or pressure points and enhances overall comfort. Additionally, the use of Nitinol in load-bearing structures can help distribute forces more evenly across the user's body, minimizing strain on specific joints or muscle groups.

To address the challenge of energy efficiency, researchers are exploring the use of Nitinol in energy harvesting systems within exoskeletons. By harnessing the mechanical energy generated during movement and converting it into electrical energy, these systems can potentially extend the operational time of powered exoskeletons or reduce the need for external power sources.

Lastly, the development of modular exoskeleton designs incorporating Nitinol components allows for customization to individual user needs. This approach enables the creation of exoskeletons that can be easily adjusted or reconfigured to accommodate different body types, injury profiles, or rehabilitation requirements, thereby expanding the potential applications of exoskeleton technology across various fields.

Another critical strategy focuses on the development of adaptive joint mechanisms using Nitinol's shape memory properties. These mechanisms can adjust their stiffness and range of motion based on the user's gait patterns and environmental conditions. By dynamically adapting to changes in terrain or movement speed, the exoskeleton can maintain optimal support while minimizing energy expenditure and potential discomfort for the user.

Incorporating Nitinol-based sensors throughout the exoskeleton structure enables real-time monitoring of biomechanical parameters. These sensors can detect changes in pressure, temperature, and strain, providing valuable feedback for the system to adjust its behavior accordingly. This continuous feedback loop ensures that the exoskeleton remains responsive to the user's changing needs and physical state throughout extended periods of use.

The integration of Nitinol also allows for the development of lightweight, flexible exoskeleton components that conform more closely to the user's body. This improved fit reduces the risk of chafing or pressure points and enhances overall comfort. Additionally, the use of Nitinol in load-bearing structures can help distribute forces more evenly across the user's body, minimizing strain on specific joints or muscle groups.

To address the challenge of energy efficiency, researchers are exploring the use of Nitinol in energy harvesting systems within exoskeletons. By harnessing the mechanical energy generated during movement and converting it into electrical energy, these systems can potentially extend the operational time of powered exoskeletons or reduce the need for external power sources.

Lastly, the development of modular exoskeleton designs incorporating Nitinol components allows for customization to individual user needs. This approach enables the creation of exoskeletons that can be easily adjusted or reconfigured to accommodate different body types, injury profiles, or rehabilitation requirements, thereby expanding the potential applications of exoskeleton technology across various fields.

Regulatory Framework for Exoskeletons

The regulatory framework for exoskeletons is a complex and evolving landscape that plays a crucial role in the development and deployment of these advanced technologies. As exoskeletons continue to gain traction in various sectors, including healthcare, military, and industrial applications, regulatory bodies worldwide are working to establish comprehensive guidelines to ensure safety, efficacy, and ethical use.

In the United States, the Food and Drug Administration (FDA) has taken a leading role in regulating medical exoskeletons. These devices are typically classified as Class II medical devices, requiring premarket notification (510(k)) or premarket approval (PMA) depending on their intended use and risk profile. The FDA's approach focuses on evaluating the safety and effectiveness of exoskeletons, considering factors such as mechanical integrity, electrical safety, and biocompatibility.

The European Union has implemented the Medical Device Regulation (MDR), which came into full effect in May 2021. This regulation provides a more stringent framework for medical devices, including exoskeletons, with emphasis on clinical evidence, post-market surveillance, and traceability. Manufacturers must comply with these regulations to obtain CE marking for their exoskeleton products.

For industrial and occupational use, regulatory bodies such as the Occupational Safety and Health Administration (OSHA) in the United States and the European Agency for Safety and Health at Work (EU-OSHA) are developing guidelines for the safe integration of exoskeletons in workplaces. These guidelines address issues such as ergonomics, user training, and potential long-term health effects.

As exoskeleton technology advances, regulatory frameworks are adapting to address emerging challenges. Key areas of focus include standardization of testing protocols, interoperability standards, and cybersecurity requirements. The International Organization for Standardization (ISO) is working on developing specific standards for wearable robots, including exoskeletons, to ensure global consistency in design and performance evaluation.

Privacy and data protection regulations, such as the General Data Protection Regulation (GDPR) in the EU, also play a significant role in shaping the regulatory landscape for exoskeletons. As these devices increasingly incorporate sensors and data collection capabilities, ensuring the protection of user data and compliance with privacy laws becomes paramount.

The regulatory framework for exoskeletons must balance innovation with safety and ethical considerations. As the technology continues to evolve, particularly with the integration of advanced materials like Nitinol, regulatory bodies will need to remain agile and responsive to new developments. This may include creating specialized regulatory pathways for novel exoskeleton technologies and fostering international collaboration to harmonize standards and regulations across different regions.

In the United States, the Food and Drug Administration (FDA) has taken a leading role in regulating medical exoskeletons. These devices are typically classified as Class II medical devices, requiring premarket notification (510(k)) or premarket approval (PMA) depending on their intended use and risk profile. The FDA's approach focuses on evaluating the safety and effectiveness of exoskeletons, considering factors such as mechanical integrity, electrical safety, and biocompatibility.

The European Union has implemented the Medical Device Regulation (MDR), which came into full effect in May 2021. This regulation provides a more stringent framework for medical devices, including exoskeletons, with emphasis on clinical evidence, post-market surveillance, and traceability. Manufacturers must comply with these regulations to obtain CE marking for their exoskeleton products.

For industrial and occupational use, regulatory bodies such as the Occupational Safety and Health Administration (OSHA) in the United States and the European Agency for Safety and Health at Work (EU-OSHA) are developing guidelines for the safe integration of exoskeletons in workplaces. These guidelines address issues such as ergonomics, user training, and potential long-term health effects.

As exoskeleton technology advances, regulatory frameworks are adapting to address emerging challenges. Key areas of focus include standardization of testing protocols, interoperability standards, and cybersecurity requirements. The International Organization for Standardization (ISO) is working on developing specific standards for wearable robots, including exoskeletons, to ensure global consistency in design and performance evaluation.

Privacy and data protection regulations, such as the General Data Protection Regulation (GDPR) in the EU, also play a significant role in shaping the regulatory landscape for exoskeletons. As these devices increasingly incorporate sensors and data collection capabilities, ensuring the protection of user data and compliance with privacy laws becomes paramount.

The regulatory framework for exoskeletons must balance innovation with safety and ethical considerations. As the technology continues to evolve, particularly with the integration of advanced materials like Nitinol, regulatory bodies will need to remain agile and responsive to new developments. This may include creating specialized regulatory pathways for novel exoskeleton technologies and fostering international collaboration to harmonize standards and regulations across different regions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!