The Role of PLA in Advancing Sustainable Innovation

JUN 25, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PLA Technology Evolution

Polylactic acid (PLA) has undergone significant technological evolution since its inception, marking key milestones in the advancement of sustainable innovation. The journey of PLA began in the 1930s when it was first synthesized by Wallace Carothers at DuPont. However, it wasn't until the 1960s that serious research into PLA as a biodegradable polymer gained momentum.

The 1980s saw a breakthrough in PLA production when Patrick R. Gruber at Cargill developed a more cost-effective method to produce lactic acid, the building block of PLA. This innovation paved the way for commercial-scale production of PLA, making it a viable alternative to traditional petroleum-based plastics.

In the 1990s, PLA technology took a significant leap forward with the development of high-molecular-weight PLA suitable for various applications. This advancement expanded PLA's potential beyond medical uses to packaging, textiles, and other consumer goods. The decade also witnessed the establishment of the first commercial-scale PLA production plant by Cargill Dow LLC (now NatureWorks).

The early 2000s marked the beginning of PLA's widespread adoption in various industries. Improved processing techniques and the development of PLA blends and composites enhanced its mechanical properties and versatility. This period also saw increased research into PLA's end-of-life options, including composting and chemical recycling.

From 2010 onwards, PLA technology has focused on addressing its limitations and expanding its applications. Innovations in PLA crystallization have improved its heat resistance, making it suitable for a broader range of products. Advancements in PLA modification techniques have led to the development of PLA with enhanced flexibility, impact resistance, and barrier properties.

Recent years have seen a surge in research on PLA-based materials for 3D printing, showcasing its potential in additive manufacturing. Additionally, the development of PLA from non-food sources, such as agricultural waste and algae, has addressed concerns about competition with food resources.

The latest frontier in PLA technology evolution is the exploration of closed-loop recycling systems. Researchers are developing efficient methods to depolymerize PLA back into lactic acid, enabling true circular economy solutions. This advancement, coupled with ongoing improvements in PLA's performance characteristics, continues to solidify its role as a key player in sustainable innovation.

The 1980s saw a breakthrough in PLA production when Patrick R. Gruber at Cargill developed a more cost-effective method to produce lactic acid, the building block of PLA. This innovation paved the way for commercial-scale production of PLA, making it a viable alternative to traditional petroleum-based plastics.

In the 1990s, PLA technology took a significant leap forward with the development of high-molecular-weight PLA suitable for various applications. This advancement expanded PLA's potential beyond medical uses to packaging, textiles, and other consumer goods. The decade also witnessed the establishment of the first commercial-scale PLA production plant by Cargill Dow LLC (now NatureWorks).

The early 2000s marked the beginning of PLA's widespread adoption in various industries. Improved processing techniques and the development of PLA blends and composites enhanced its mechanical properties and versatility. This period also saw increased research into PLA's end-of-life options, including composting and chemical recycling.

From 2010 onwards, PLA technology has focused on addressing its limitations and expanding its applications. Innovations in PLA crystallization have improved its heat resistance, making it suitable for a broader range of products. Advancements in PLA modification techniques have led to the development of PLA with enhanced flexibility, impact resistance, and barrier properties.

Recent years have seen a surge in research on PLA-based materials for 3D printing, showcasing its potential in additive manufacturing. Additionally, the development of PLA from non-food sources, such as agricultural waste and algae, has addressed concerns about competition with food resources.

The latest frontier in PLA technology evolution is the exploration of closed-loop recycling systems. Researchers are developing efficient methods to depolymerize PLA back into lactic acid, enabling true circular economy solutions. This advancement, coupled with ongoing improvements in PLA's performance characteristics, continues to solidify its role as a key player in sustainable innovation.

Sustainable Innovation Demand

The demand for sustainable innovation has grown significantly in recent years, driven by increasing environmental concerns, regulatory pressures, and consumer preferences. Polylactic acid (PLA), a biodegradable and renewable polymer, has emerged as a key player in advancing sustainable innovation across various industries.

Market analysis indicates a robust growth trajectory for PLA-based products, with the global PLA market expected to expand at a compound annual growth rate of over 15% in the coming years. This growth is primarily fueled by the rising adoption of eco-friendly materials in packaging, textiles, and consumer goods sectors. The packaging industry, in particular, has shown a strong inclination towards PLA due to its biodegradability and compostability, aligning with the increasing consumer demand for sustainable packaging solutions.

In the automotive and electronics industries, there is a growing interest in PLA as a potential substitute for conventional petroleum-based plastics. This shift is driven by stringent environmental regulations and the automotive sector's push towards lightweight, fuel-efficient vehicles. The medical field also presents a significant opportunity for PLA, with its biocompatibility making it an attractive material for implants, drug delivery systems, and tissue engineering applications.

The agricultural sector is another area where PLA is gaining traction, particularly in mulch films and controlled-release fertilizer coatings. These applications address the need for sustainable farming practices and reduced environmental impact in agriculture.

Consumer awareness and preference for eco-friendly products have been key drivers in the demand for PLA-based innovations. Surveys indicate that a majority of consumers are willing to pay a premium for products made from sustainable materials, creating a favorable market environment for PLA-based goods.

However, challenges remain in scaling up PLA production to meet the growing demand while maintaining cost competitiveness with traditional plastics. The development of more efficient production processes and the expansion of feedstock sources beyond corn are crucial areas of focus to address these challenges and further drive the adoption of PLA in sustainable innovation.

Government initiatives and policies promoting the use of biodegradable materials have also played a significant role in boosting the demand for PLA. Many countries have implemented or are considering regulations to reduce single-use plastics, creating opportunities for PLA as a sustainable alternative.

Market analysis indicates a robust growth trajectory for PLA-based products, with the global PLA market expected to expand at a compound annual growth rate of over 15% in the coming years. This growth is primarily fueled by the rising adoption of eco-friendly materials in packaging, textiles, and consumer goods sectors. The packaging industry, in particular, has shown a strong inclination towards PLA due to its biodegradability and compostability, aligning with the increasing consumer demand for sustainable packaging solutions.

In the automotive and electronics industries, there is a growing interest in PLA as a potential substitute for conventional petroleum-based plastics. This shift is driven by stringent environmental regulations and the automotive sector's push towards lightweight, fuel-efficient vehicles. The medical field also presents a significant opportunity for PLA, with its biocompatibility making it an attractive material for implants, drug delivery systems, and tissue engineering applications.

The agricultural sector is another area where PLA is gaining traction, particularly in mulch films and controlled-release fertilizer coatings. These applications address the need for sustainable farming practices and reduced environmental impact in agriculture.

Consumer awareness and preference for eco-friendly products have been key drivers in the demand for PLA-based innovations. Surveys indicate that a majority of consumers are willing to pay a premium for products made from sustainable materials, creating a favorable market environment for PLA-based goods.

However, challenges remain in scaling up PLA production to meet the growing demand while maintaining cost competitiveness with traditional plastics. The development of more efficient production processes and the expansion of feedstock sources beyond corn are crucial areas of focus to address these challenges and further drive the adoption of PLA in sustainable innovation.

Government initiatives and policies promoting the use of biodegradable materials have also played a significant role in boosting the demand for PLA. Many countries have implemented or are considering regulations to reduce single-use plastics, creating opportunities for PLA as a sustainable alternative.

PLA Technical Challenges

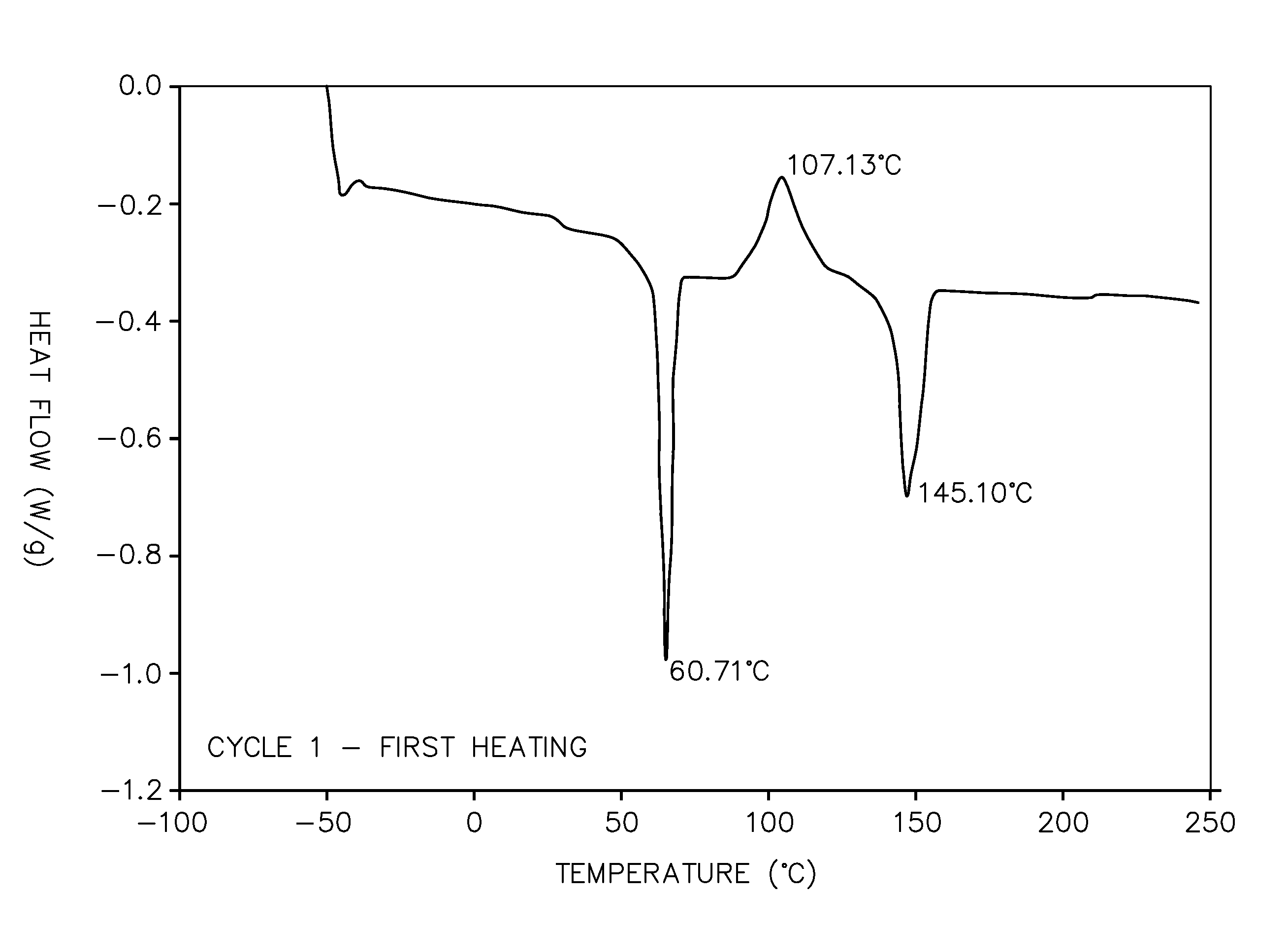

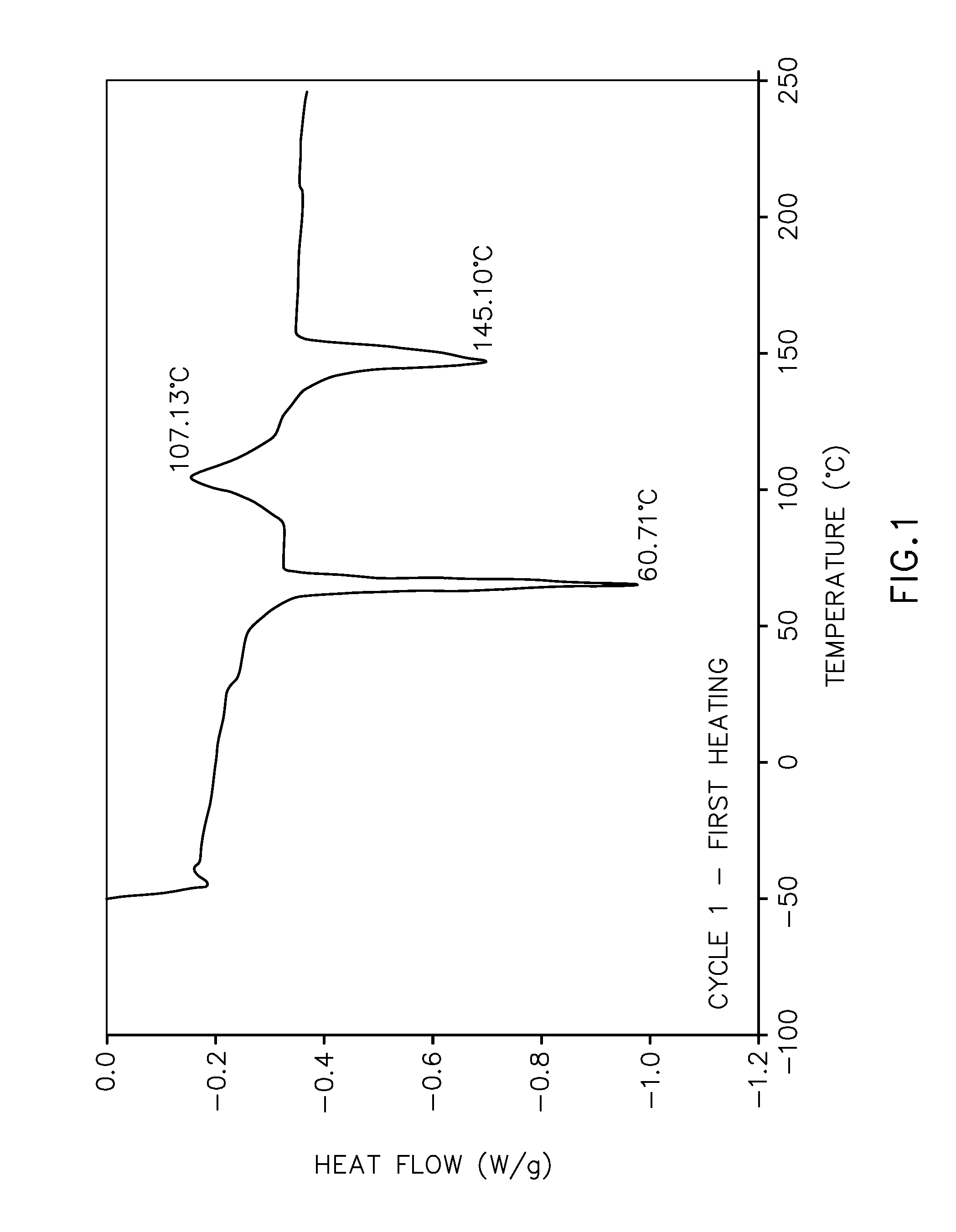

Polylactic acid (PLA) has emerged as a promising sustainable material, but its widespread adoption faces several technical challenges. One of the primary issues is the material's inherent brittleness, which limits its application in products requiring high impact resistance or flexibility. This characteristic stems from PLA's high glass transition temperature and low crystallization rate, resulting in a rigid structure that can easily fracture under stress.

Another significant challenge lies in PLA's thermal stability. The material tends to degrade at relatively low temperatures compared to conventional plastics, which restricts its use in high-temperature applications and complicates processing methods. This thermal sensitivity also affects PLA's long-term durability, as prolonged exposure to heat or UV radiation can lead to premature degradation and loss of mechanical properties.

The moisture sensitivity of PLA presents additional hurdles. The material readily absorbs water from the environment, which can lead to hydrolysis and a consequent reduction in molecular weight. This not only affects the material's mechanical properties but also complicates storage and processing conditions, requiring careful control of humidity levels throughout the production and use phases.

PLA's biodegradability, while generally considered an advantage, also poses challenges in certain applications. The rate and conditions of degradation can be difficult to control, potentially leading to premature breakdown in some environments while persisting longer than desired in others. This variability in degradation behavior complicates the material's use in products with specific lifetime requirements or in applications where consistent long-term performance is crucial.

From a processing standpoint, PLA exhibits a narrow processing window compared to traditional thermoplastics. This characteristic makes it more challenging to achieve consistent quality in manufacturing processes such as injection molding or extrusion. Additionally, PLA's relatively high cost of production compared to petroleum-based plastics remains a barrier to widespread adoption, particularly in price-sensitive markets.

The development of high-performance PLA composites and blends presents another set of technical challenges. While these approaches offer potential solutions to some of PLA's limitations, achieving optimal compatibility between PLA and other materials or additives without compromising its biodegradability or sustainability credentials is complex. Researchers continue to explore novel compatibilization techniques and environmentally friendly additives to enhance PLA's performance while maintaining its eco-friendly profile.

Another significant challenge lies in PLA's thermal stability. The material tends to degrade at relatively low temperatures compared to conventional plastics, which restricts its use in high-temperature applications and complicates processing methods. This thermal sensitivity also affects PLA's long-term durability, as prolonged exposure to heat or UV radiation can lead to premature degradation and loss of mechanical properties.

The moisture sensitivity of PLA presents additional hurdles. The material readily absorbs water from the environment, which can lead to hydrolysis and a consequent reduction in molecular weight. This not only affects the material's mechanical properties but also complicates storage and processing conditions, requiring careful control of humidity levels throughout the production and use phases.

PLA's biodegradability, while generally considered an advantage, also poses challenges in certain applications. The rate and conditions of degradation can be difficult to control, potentially leading to premature breakdown in some environments while persisting longer than desired in others. This variability in degradation behavior complicates the material's use in products with specific lifetime requirements or in applications where consistent long-term performance is crucial.

From a processing standpoint, PLA exhibits a narrow processing window compared to traditional thermoplastics. This characteristic makes it more challenging to achieve consistent quality in manufacturing processes such as injection molding or extrusion. Additionally, PLA's relatively high cost of production compared to petroleum-based plastics remains a barrier to widespread adoption, particularly in price-sensitive markets.

The development of high-performance PLA composites and blends presents another set of technical challenges. While these approaches offer potential solutions to some of PLA's limitations, achieving optimal compatibility between PLA and other materials or additives without compromising its biodegradability or sustainability credentials is complex. Researchers continue to explore novel compatibilization techniques and environmentally friendly additives to enhance PLA's performance while maintaining its eco-friendly profile.

Current PLA Applications

01 PLA composites and blends

PLA can be combined with other materials to form composites or blends, enhancing its properties. These combinations can improve mechanical strength, thermal stability, or biodegradability. Various fillers, fibers, or other polymers may be incorporated to tailor the material for specific applications.- PLA-based composite materials: Development of composite materials using PLA as a base polymer, incorporating various additives or fillers to enhance properties such as strength, durability, or biodegradability. These composites can be used in a wide range of applications, from packaging to medical devices.

- PLA processing techniques: Innovative methods for processing PLA, including extrusion, injection molding, and 3D printing. These techniques aim to improve the material's performance, reduce production costs, and expand its potential applications in various industries.

- PLA modification for improved properties: Chemical or physical modification of PLA to enhance its properties such as thermal stability, mechanical strength, or barrier properties. This includes blending with other polymers, adding plasticizers, or modifying the molecular structure of PLA.

- Biodegradable PLA applications: Development of biodegradable products using PLA, focusing on environmentally friendly alternatives to traditional plastics. Applications include packaging materials, disposable items, and agricultural films that can decompose naturally in the environment.

- PLA in medical and pharmaceutical applications: Utilization of PLA in medical and pharmaceutical fields, including drug delivery systems, tissue engineering scaffolds, and bioabsorbable implants. The biocompatibility and controlled degradation properties of PLA make it suitable for various medical applications.

02 PLA processing techniques

Different processing techniques can be applied to PLA to create various forms and products. These may include extrusion, injection molding, 3D printing, or film blowing. Each technique can affect the final properties and structure of the PLA-based product.Expand Specific Solutions03 PLA modifications for improved properties

Chemical or physical modifications can be made to PLA to enhance its properties. These modifications may include plasticization, crosslinking, or grafting of functional groups. Such changes can improve flexibility, heat resistance, or barrier properties of PLA materials.Expand Specific Solutions04 PLA in packaging applications

PLA is widely used in packaging applications due to its biodegradability and renewability. It can be used to create food packaging, disposable containers, or films. Research focuses on improving barrier properties and shelf life of PLA-based packaging materials.Expand Specific Solutions05 PLA in biomedical applications

PLA finds applications in the biomedical field due to its biocompatibility and biodegradability. It can be used for tissue engineering scaffolds, drug delivery systems, or surgical implants. Research in this area focuses on controlling degradation rates and enhancing bioactivity of PLA-based materials.Expand Specific Solutions

Key PLA Industry Players

The development of Polylactic Acid (PLA) in advancing sustainable innovation is in a growth phase, with increasing market size and technological maturity. The global PLA market is expanding rapidly, driven by growing demand for eco-friendly materials across various industries. Technologically, PLA has progressed significantly, with companies like Total Research Corp, 3M Innovative Properties Co., and NatureWorks LLC leading innovation. Universities such as Harvard College and Cornell University are contributing to research advancements. The involvement of diverse players, including industrial giants like International Paper Co. and specialized firms like Arctic Biomaterials Oy, indicates a competitive and evolving landscape. This multi-faceted development suggests PLA's potential for further growth and application in sustainable solutions.

International Paper Co.

Technical Solution: International Paper Co. has developed a sustainable innovation approach using PLA (Polylactic Acid) in paper packaging. Their technology involves incorporating PLA fibers into traditional paper pulp, creating a hybrid material that combines the biodegradability of paper with the enhanced barrier properties of PLA. This composite material offers improved moisture resistance and grease-proofing, making it suitable for food packaging applications. The company has also developed a proprietary coating process using PLA to create fully compostable paper products with enhanced functionality.

Strengths: Combines paper's recyclability with PLA's barrier properties, enhancing product performance. Fully compostable solution aligns with circular economy principles. Weaknesses: May have higher production costs compared to traditional paper products. Limited high-temperature applications due to PLA's thermal properties.

Arctic Biomaterials Oy

Technical Solution: Arctic Biomaterials Oy has pioneered the development of PLA-based biocomposites for sustainable innovation. Their technology focuses on enhancing PLA's mechanical properties by incorporating natural fibers and minerals. They have developed a proprietary process to create PLA compounds with improved heat resistance and durability, addressing some of the material's traditional limitations. Their innovation extends to the creation of biodegradable flame-retardant PLA composites, opening up new applications in electronics and automotive industries where sustainability and safety are paramount.

Strengths: Addresses PLA's limitations in heat resistance and mechanical properties. Expands PLA's application range to more demanding industries. Weaknesses: Higher cost compared to conventional plastics. May require specialized processing equipment for manufacturing.

PLA Material Innovations

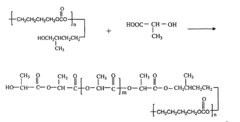

Producing method for polylactic acid-based copolymer

PatentActiveEP2184307A1

Innovation

- A method for preparing poly (lactic acid)-based copolymers by introducing flexible chain segments through copolymerization with polycaprolactone and aliphatic polycarbonate diols, enhancing molecular weight and mechanical properties, and incorporating chain extension processes to improve toughness, elasticity, and biodegradability.

Thermoformed articles made from reactive extrusion products of biobased materials

PatentActiveUS8231954B2

Innovation

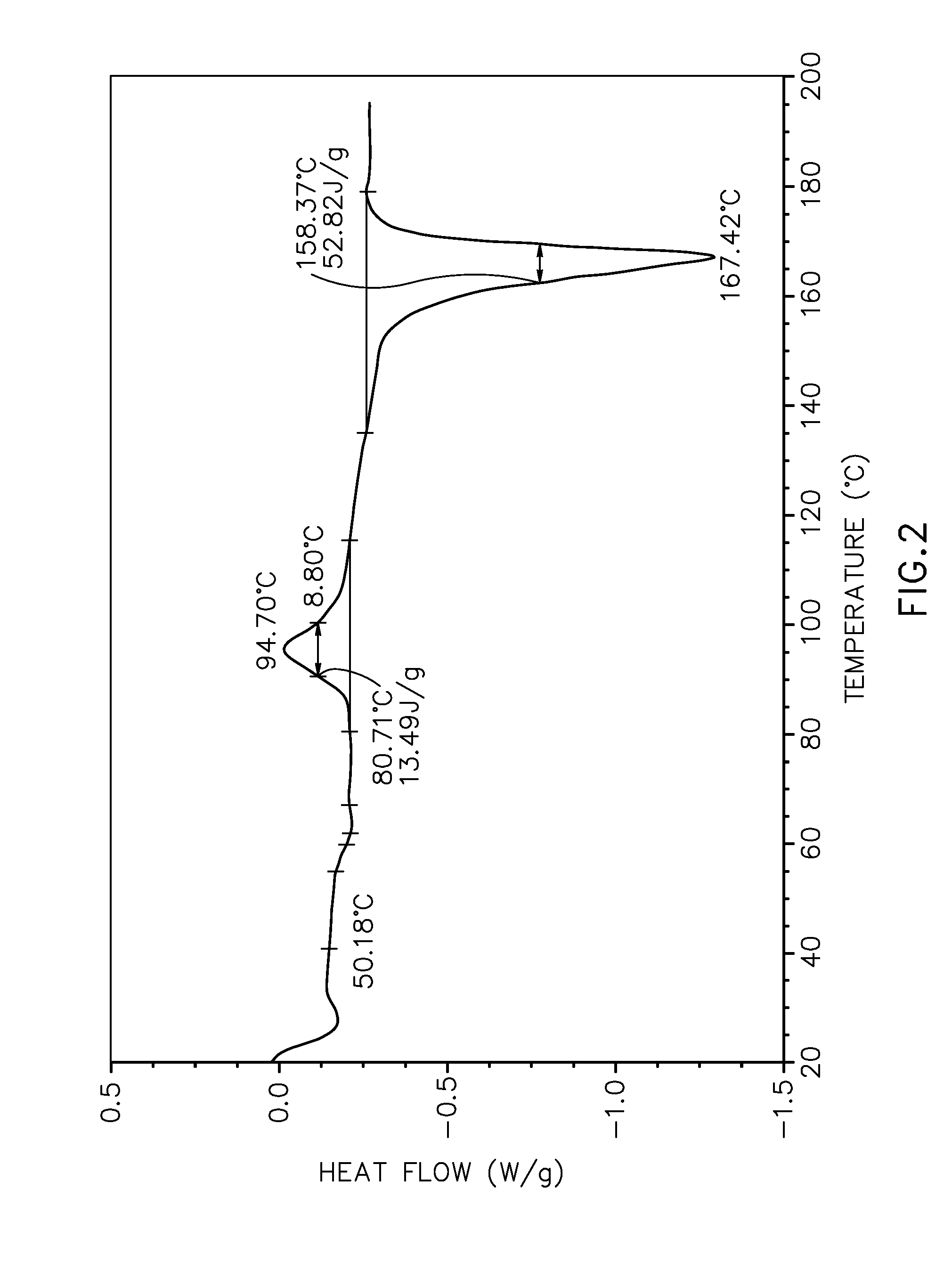

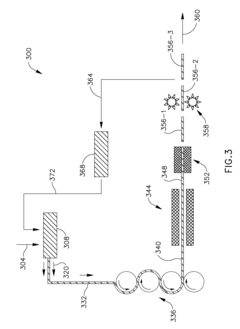

- Development of thermoformable composite materials comprising blends of PLA and polyhydroxyalkanoates (PHAs) with specific additives, processed via extrusion, to enhance thermal and mechanical performance, achieving a Vicat softening point up to 180°C and heat distortion index up to 160°C, thereby improving resistance to deformation at higher temperatures.

Environmental Impact of PLA

Polylactic acid (PLA) has emerged as a promising sustainable alternative to conventional plastics, offering significant environmental benefits throughout its lifecycle. The production of PLA requires less energy compared to petroleum-based plastics, resulting in reduced greenhouse gas emissions. PLA is derived from renewable resources such as corn starch or sugarcane, which can be replenished annually, unlike finite fossil fuel resources used in traditional plastic production.

One of the most notable environmental advantages of PLA is its biodegradability. Under proper composting conditions, PLA can break down into water, carbon dioxide, and biomass within a few months to two years, significantly reducing the long-term environmental impact associated with plastic waste. This characteristic is particularly valuable in addressing the global plastic pollution crisis, as PLA products can be safely returned to the environment without leaving persistent microplastics.

PLA also contributes to reduced carbon footprint in various applications. In packaging, PLA-based materials can replace single-use plastics, offering a more environmentally friendly option for food containers, disposable cutlery, and other short-lived products. The use of PLA in 3D printing has gained traction, providing a more sustainable alternative for rapid prototyping and small-scale manufacturing.

However, it is important to note that the environmental benefits of PLA are contingent upon proper disposal and processing. While PLA is compostable, it requires industrial composting facilities to break down efficiently. Improper disposal in regular waste streams can lead to PLA persisting in the environment, albeit for a shorter duration than conventional plastics. Additionally, the agricultural practices used to produce PLA feedstocks must be carefully managed to ensure overall sustainability.

The production of PLA also raises concerns about land use and potential competition with food crops. As demand for PLA increases, there is a need to balance the allocation of agricultural resources between food production and bioplastic feedstocks. Research into alternative feedstocks, such as agricultural waste or algae, is ongoing to address these concerns and further improve the environmental profile of PLA.

In conclusion, while PLA offers significant environmental advantages over traditional plastics, its impact is complex and multifaceted. Continued research and development in PLA technology, coupled with improvements in waste management infrastructure, will be crucial in maximizing its potential as a sustainable innovation in materials science.

One of the most notable environmental advantages of PLA is its biodegradability. Under proper composting conditions, PLA can break down into water, carbon dioxide, and biomass within a few months to two years, significantly reducing the long-term environmental impact associated with plastic waste. This characteristic is particularly valuable in addressing the global plastic pollution crisis, as PLA products can be safely returned to the environment without leaving persistent microplastics.

PLA also contributes to reduced carbon footprint in various applications. In packaging, PLA-based materials can replace single-use plastics, offering a more environmentally friendly option for food containers, disposable cutlery, and other short-lived products. The use of PLA in 3D printing has gained traction, providing a more sustainable alternative for rapid prototyping and small-scale manufacturing.

However, it is important to note that the environmental benefits of PLA are contingent upon proper disposal and processing. While PLA is compostable, it requires industrial composting facilities to break down efficiently. Improper disposal in regular waste streams can lead to PLA persisting in the environment, albeit for a shorter duration than conventional plastics. Additionally, the agricultural practices used to produce PLA feedstocks must be carefully managed to ensure overall sustainability.

The production of PLA also raises concerns about land use and potential competition with food crops. As demand for PLA increases, there is a need to balance the allocation of agricultural resources between food production and bioplastic feedstocks. Research into alternative feedstocks, such as agricultural waste or algae, is ongoing to address these concerns and further improve the environmental profile of PLA.

In conclusion, while PLA offers significant environmental advantages over traditional plastics, its impact is complex and multifaceted. Continued research and development in PLA technology, coupled with improvements in waste management infrastructure, will be crucial in maximizing its potential as a sustainable innovation in materials science.

PLA Regulatory Framework

The regulatory framework surrounding Polylactic Acid (PLA) plays a crucial role in advancing sustainable innovation. As a biodegradable and renewable polymer, PLA has gained significant attention in various industries, particularly in packaging and medical applications. The regulatory landscape for PLA is complex and evolving, with different regions and countries implementing their own sets of rules and standards.

In the United States, the Food and Drug Administration (FDA) regulates the use of PLA in food contact materials and medical devices. The FDA has approved PLA for use in various applications, including food packaging and implantable medical devices. The Environmental Protection Agency (EPA) also oversees the environmental impact of PLA production and disposal.

The European Union has established a comprehensive regulatory framework for bioplastics, including PLA. The European Food Safety Authority (EFSA) evaluates the safety of PLA for food contact applications, while the European Chemicals Agency (ECHA) regulates its production and use under the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation.

In Asia, countries like Japan and China have developed their own regulatory frameworks for PLA. Japan's Ministry of Health, Labour and Welfare has approved PLA for food contact applications, while China's National Medical Products Administration regulates its use in medical devices.

International standards organizations, such as ASTM International and the International Organization for Standardization (ISO), have developed specific standards for PLA testing and characterization. These standards help ensure consistency and quality in PLA production and applications across different regions.

The regulatory framework for PLA also addresses end-of-life considerations. Many countries have implemented regulations to promote the proper disposal and recycling of PLA products. For instance, the EU's Waste Framework Directive and Packaging and Packaging Waste Directive provide guidelines for the management of bioplastic waste, including PLA.

As sustainability becomes an increasingly important focus for governments and industries worldwide, the regulatory framework for PLA continues to evolve. New regulations are being developed to address emerging applications of PLA, such as 3D printing and advanced medical devices. Additionally, there is a growing emphasis on life cycle assessment and circular economy principles in PLA regulations, aiming to maximize the material's environmental benefits throughout its entire lifecycle.

In the United States, the Food and Drug Administration (FDA) regulates the use of PLA in food contact materials and medical devices. The FDA has approved PLA for use in various applications, including food packaging and implantable medical devices. The Environmental Protection Agency (EPA) also oversees the environmental impact of PLA production and disposal.

The European Union has established a comprehensive regulatory framework for bioplastics, including PLA. The European Food Safety Authority (EFSA) evaluates the safety of PLA for food contact applications, while the European Chemicals Agency (ECHA) regulates its production and use under the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation.

In Asia, countries like Japan and China have developed their own regulatory frameworks for PLA. Japan's Ministry of Health, Labour and Welfare has approved PLA for food contact applications, while China's National Medical Products Administration regulates its use in medical devices.

International standards organizations, such as ASTM International and the International Organization for Standardization (ISO), have developed specific standards for PLA testing and characterization. These standards help ensure consistency and quality in PLA production and applications across different regions.

The regulatory framework for PLA also addresses end-of-life considerations. Many countries have implemented regulations to promote the proper disposal and recycling of PLA products. For instance, the EU's Waste Framework Directive and Packaging and Packaging Waste Directive provide guidelines for the management of bioplastic waste, including PLA.

As sustainability becomes an increasingly important focus for governments and industries worldwide, the regulatory framework for PLA continues to evolve. New regulations are being developed to address emerging applications of PLA, such as 3D printing and advanced medical devices. Additionally, there is a growing emphasis on life cycle assessment and circular economy principles in PLA regulations, aiming to maximize the material's environmental benefits throughout its entire lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!