The Role of Smart Wastegate Designs in Optimizing B58 Boost

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

B58 Boost Optimization Background and Objectives

The B58 engine, developed by BMW, represents a significant advancement in turbocharged inline-six engine technology. This engine has gained prominence for its impressive power output and efficiency, particularly in its application across various BMW models and other vehicles within the BMW Group. The optimization of boost pressure in the B58 engine is a critical factor in enhancing its performance and efficiency.

Smart wastegate designs play a crucial role in this optimization process. Traditionally, wastegates have been used to regulate turbocharger boost pressure by diverting excess exhaust gases away from the turbine wheel. However, the introduction of smart wastegate technology has revolutionized this aspect of engine management, allowing for more precise control and dynamic adjustment of boost pressure.

The primary objective of implementing smart wastegate designs in the B58 engine is to achieve a delicate balance between maximizing power output and maintaining engine reliability. This involves carefully managing boost pressure across various operating conditions, from low-speed city driving to high-speed highway cruising and performance-oriented scenarios.

Another key goal is to improve the engine's responsiveness and reduce turbo lag. Smart wastegates can potentially provide quicker boost response by allowing for more rapid changes in boost pressure based on real-time driving conditions and driver inputs. This can result in a more engaging driving experience and improved overall vehicle performance.

Fuel efficiency and emissions reduction are also critical objectives in the development of smart wastegate technology for the B58 engine. By optimizing boost pressure, engineers aim to achieve better combustion efficiency, potentially leading to reduced fuel consumption and lower emissions without compromising on power output.

The evolution of smart wastegate designs is closely tied to advancements in engine control units (ECUs) and sensor technology. Modern ECUs can process vast amounts of data in real-time, allowing for more sophisticated boost control strategies. This integration of smart wastegates with advanced engine management systems opens up new possibilities for fine-tuning engine performance and efficiency.

As automotive technology continues to evolve, particularly with the increasing focus on electrification and hybrid powertrains, the role of smart wastegate designs in optimizing the B58 boost becomes even more significant. These advancements may pave the way for innovative boost control strategies that can further enhance the engine's performance while meeting increasingly stringent emissions regulations.

Smart wastegate designs play a crucial role in this optimization process. Traditionally, wastegates have been used to regulate turbocharger boost pressure by diverting excess exhaust gases away from the turbine wheel. However, the introduction of smart wastegate technology has revolutionized this aspect of engine management, allowing for more precise control and dynamic adjustment of boost pressure.

The primary objective of implementing smart wastegate designs in the B58 engine is to achieve a delicate balance between maximizing power output and maintaining engine reliability. This involves carefully managing boost pressure across various operating conditions, from low-speed city driving to high-speed highway cruising and performance-oriented scenarios.

Another key goal is to improve the engine's responsiveness and reduce turbo lag. Smart wastegates can potentially provide quicker boost response by allowing for more rapid changes in boost pressure based on real-time driving conditions and driver inputs. This can result in a more engaging driving experience and improved overall vehicle performance.

Fuel efficiency and emissions reduction are also critical objectives in the development of smart wastegate technology for the B58 engine. By optimizing boost pressure, engineers aim to achieve better combustion efficiency, potentially leading to reduced fuel consumption and lower emissions without compromising on power output.

The evolution of smart wastegate designs is closely tied to advancements in engine control units (ECUs) and sensor technology. Modern ECUs can process vast amounts of data in real-time, allowing for more sophisticated boost control strategies. This integration of smart wastegates with advanced engine management systems opens up new possibilities for fine-tuning engine performance and efficiency.

As automotive technology continues to evolve, particularly with the increasing focus on electrification and hybrid powertrains, the role of smart wastegate designs in optimizing the B58 boost becomes even more significant. These advancements may pave the way for innovative boost control strategies that can further enhance the engine's performance while meeting increasingly stringent emissions regulations.

Market Demand for Enhanced Engine Performance

The demand for enhanced engine performance in the automotive market has been steadily increasing, driven by consumer expectations for more powerful, efficient, and responsive vehicles. This trend is particularly evident in the premium and sports car segments, where the BMW B58 engine has gained significant popularity. The market for high-performance engines like the B58 is characterized by a growing emphasis on turbocharging technology, which allows manufacturers to extract more power from smaller displacement engines while maintaining fuel efficiency.

Smart wastegate designs play a crucial role in optimizing boost pressure in turbocharged engines, directly impacting performance, fuel economy, and emissions. As environmental regulations become more stringent and consumers demand better fuel economy without sacrificing power, the market for advanced turbocharging solutions, including smart wastegates, has expanded considerably.

The automotive industry has witnessed a shift towards downsized, turbocharged engines to meet both performance and efficiency targets. This trend has created a substantial market for innovative boost control technologies, with smart wastegates emerging as a key component in achieving optimal engine performance. The demand for these advanced systems is driven by several factors, including the need for precise boost control, improved throttle response, and reduced turbo lag.

In the context of the BMW B58 engine, the market demand for enhanced performance is particularly strong among enthusiasts and tuners. These consumers are constantly seeking ways to unlock additional power and torque from their vehicles, creating a thriving aftermarket for performance upgrades. Smart wastegate designs offer a promising avenue for achieving these goals without compromising reliability or drivability.

The commercial vehicle sector also contributes to the market demand for smart wastegate technologies. As fleet operators seek to improve fuel efficiency and reduce operating costs, the adoption of advanced turbocharging systems in commercial engines has increased. This trend extends the potential market for smart wastegate designs beyond personal vehicles, encompassing a broader range of applications in the transportation industry.

Furthermore, the racing and motorsport sectors represent a significant niche market for cutting-edge turbocharging technologies. The extreme performance requirements in these fields drive innovation in boost control systems, often leading to advancements that eventually trickle down to production vehicles. This symbiotic relationship between motorsport and consumer automotive technology continues to fuel the demand for sophisticated wastegate designs and other boost optimization solutions.

Smart wastegate designs play a crucial role in optimizing boost pressure in turbocharged engines, directly impacting performance, fuel economy, and emissions. As environmental regulations become more stringent and consumers demand better fuel economy without sacrificing power, the market for advanced turbocharging solutions, including smart wastegates, has expanded considerably.

The automotive industry has witnessed a shift towards downsized, turbocharged engines to meet both performance and efficiency targets. This trend has created a substantial market for innovative boost control technologies, with smart wastegates emerging as a key component in achieving optimal engine performance. The demand for these advanced systems is driven by several factors, including the need for precise boost control, improved throttle response, and reduced turbo lag.

In the context of the BMW B58 engine, the market demand for enhanced performance is particularly strong among enthusiasts and tuners. These consumers are constantly seeking ways to unlock additional power and torque from their vehicles, creating a thriving aftermarket for performance upgrades. Smart wastegate designs offer a promising avenue for achieving these goals without compromising reliability or drivability.

The commercial vehicle sector also contributes to the market demand for smart wastegate technologies. As fleet operators seek to improve fuel efficiency and reduce operating costs, the adoption of advanced turbocharging systems in commercial engines has increased. This trend extends the potential market for smart wastegate designs beyond personal vehicles, encompassing a broader range of applications in the transportation industry.

Furthermore, the racing and motorsport sectors represent a significant niche market for cutting-edge turbocharging technologies. The extreme performance requirements in these fields drive innovation in boost control systems, often leading to advancements that eventually trickle down to production vehicles. This symbiotic relationship between motorsport and consumer automotive technology continues to fuel the demand for sophisticated wastegate designs and other boost optimization solutions.

Smart Wastegate Technology: Current State and Challenges

Smart wastegate technology has become a crucial component in optimizing the performance of modern turbocharged engines, particularly in the case of BMW's B58 engine. The current state of smart wastegate designs represents a significant advancement in turbocharger control systems, offering precise boost management and improved engine efficiency.

One of the primary challenges in smart wastegate technology is achieving optimal boost control across a wide range of operating conditions. Traditional wastegates often struggle to maintain consistent boost pressure, especially during rapid throttle changes or varying atmospheric conditions. Smart wastegates address this issue by incorporating advanced sensors and electronic actuators, allowing for real-time adjustments to boost pressure based on engine load, ambient conditions, and driver input.

Another significant challenge lies in the integration of smart wastegate systems with engine management software. As turbocharger technology becomes more sophisticated, the complexity of control algorithms increases, requiring more processing power and finer-tuned calibration. This integration challenge extends to ensuring seamless communication between the wastegate actuator, engine control unit (ECU), and other powertrain components.

Durability and reliability remain ongoing concerns in smart wastegate design. The harsh operating environment of a turbocharger, with extreme temperatures and high-speed moving parts, puts significant stress on electronic components and actuators. Engineers must develop robust solutions that can withstand these conditions while maintaining precise control over extended periods.

Material selection presents another challenge in smart wastegate development. The components must be lightweight to minimize inertia and improve response times, yet durable enough to withstand the harsh turbocharger environment. Advanced alloys and composite materials are being explored to strike the right balance between weight, strength, and thermal resistance.

Packaging constraints pose a significant challenge, particularly in compact engine bays. Smart wastegate designs must be compact and efficiently integrated into the turbocharger assembly without compromising performance or accessibility for maintenance. This often requires innovative approaches to component layout and miniaturization of electronic controls.

Cost-effectiveness remains a key consideration in the widespread adoption of smart wastegate technology. While the performance benefits are clear, manufacturers must balance the additional complexity and cost against the gains in efficiency and power output. This challenge drives ongoing research into more cost-effective production methods and materials.

As emissions regulations become increasingly stringent, smart wastegates play a crucial role in optimizing engine performance while minimizing environmental impact. The challenge lies in fine-tuning boost control to achieve the ideal balance between power output and emissions reduction across all operating conditions.

One of the primary challenges in smart wastegate technology is achieving optimal boost control across a wide range of operating conditions. Traditional wastegates often struggle to maintain consistent boost pressure, especially during rapid throttle changes or varying atmospheric conditions. Smart wastegates address this issue by incorporating advanced sensors and electronic actuators, allowing for real-time adjustments to boost pressure based on engine load, ambient conditions, and driver input.

Another significant challenge lies in the integration of smart wastegate systems with engine management software. As turbocharger technology becomes more sophisticated, the complexity of control algorithms increases, requiring more processing power and finer-tuned calibration. This integration challenge extends to ensuring seamless communication between the wastegate actuator, engine control unit (ECU), and other powertrain components.

Durability and reliability remain ongoing concerns in smart wastegate design. The harsh operating environment of a turbocharger, with extreme temperatures and high-speed moving parts, puts significant stress on electronic components and actuators. Engineers must develop robust solutions that can withstand these conditions while maintaining precise control over extended periods.

Material selection presents another challenge in smart wastegate development. The components must be lightweight to minimize inertia and improve response times, yet durable enough to withstand the harsh turbocharger environment. Advanced alloys and composite materials are being explored to strike the right balance between weight, strength, and thermal resistance.

Packaging constraints pose a significant challenge, particularly in compact engine bays. Smart wastegate designs must be compact and efficiently integrated into the turbocharger assembly without compromising performance or accessibility for maintenance. This often requires innovative approaches to component layout and miniaturization of electronic controls.

Cost-effectiveness remains a key consideration in the widespread adoption of smart wastegate technology. While the performance benefits are clear, manufacturers must balance the additional complexity and cost against the gains in efficiency and power output. This challenge drives ongoing research into more cost-effective production methods and materials.

As emissions regulations become increasingly stringent, smart wastegates play a crucial role in optimizing engine performance while minimizing environmental impact. The challenge lies in fine-tuning boost control to achieve the ideal balance between power output and emissions reduction across all operating conditions.

Existing Smart Wastegate Solutions for B58 Engines

01 Electronic control of wastegate

Smart wastegate systems utilize electronic control to precisely regulate boost pressure. This involves using sensors and actuators to dynamically adjust the wastegate position based on engine conditions, improving overall performance and efficiency.- Electronic control of wastegate: Smart wastegate systems utilize electronic control to precisely regulate boost pressure. These systems employ sensors and actuators to dynamically adjust the wastegate position based on engine conditions, improving overall performance and efficiency.

- Variable geometry turbocharger integration: Integration of variable geometry turbochargers with smart wastegate systems allows for more precise control of boost pressure across a wider range of engine speeds. This combination enhances engine responsiveness and fuel efficiency.

- Multi-stage turbocharging with smart wastegate: Smart wastegate systems in multi-stage turbocharging setups enable optimized boost control across different turbochargers. This arrangement allows for improved low-end torque and high-end power, while maintaining efficiency throughout the engine's operating range.

- Adaptive boost control algorithms: Advanced algorithms are employed in smart wastegate systems to adaptively control boost pressure based on various parameters such as engine load, ambient conditions, and driver input. These algorithms continuously optimize turbocharger performance for improved efficiency and power delivery.

- Integration with engine management systems: Smart wastegate boost systems are tightly integrated with overall engine management systems. This integration allows for coordinated control of boost pressure, fuel injection, and ignition timing, resulting in optimized engine performance, emissions reduction, and fuel economy improvements.

02 Integration with turbocharger systems

Smart wastegate boost technology is integrated into advanced turbocharger systems. This integration allows for better coordination between the wastegate and turbocharger, optimizing boost pressure across various operating conditions and enhancing engine responsiveness.Expand Specific Solutions03 Adaptive boost control strategies

Implementing adaptive control strategies enables smart wastegate systems to learn and adjust boost parameters over time. This approach takes into account factors such as driving style, environmental conditions, and engine wear to continuously optimize boost performance.Expand Specific Solutions04 Multi-stage wastegate designs

Advanced wastegate designs incorporate multiple stages or valves to provide finer control over boost pressure. These multi-stage systems allow for more precise boost regulation across a wider range of engine speeds and loads, improving overall engine efficiency and performance.Expand Specific Solutions05 Integration with engine management systems

Smart wastegate boost technology is closely integrated with broader engine management systems. This integration allows for coordinated control of boost pressure, fuel injection, ignition timing, and other engine parameters to optimize performance, fuel efficiency, and emissions across various operating conditions.Expand Specific Solutions

Key Players in Automotive Turbocharging Industry

The smart wastegate design optimization for B58 boost is in a mature stage of development, with a competitive market dominated by established automotive and technology companies. The industry is characterized by ongoing innovation and refinement, driven by the demand for improved engine performance and fuel efficiency. Key players like BorgWarner, Garrett Motion, and Continental Automotive are at the forefront, leveraging their extensive experience in turbocharger technology. The market size is substantial, given the widespread adoption of turbocharged engines in modern vehicles. Companies such as BMW, Ford, and Honda are also actively involved in developing proprietary solutions, indicating the technology's strategic importance in the automotive sector.

BorgWarner, Inc.

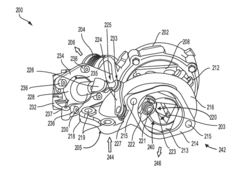

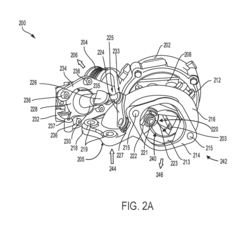

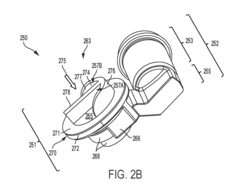

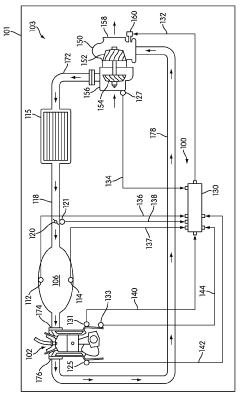

Technical Solution: BorgWarner has developed advanced smart wastegate designs for optimizing boost in turbochargers, including those used in BMW's B58 engine. Their technology incorporates electronic actuation and precise control algorithms to manage boost pressure more effectively. BorgWarner's smart wastegate system uses a compact electric actuator that responds quickly to engine management signals, allowing for rapid adjustments to boost pressure based on driving conditions[1]. The system also integrates sensors for real-time monitoring of wastegate position and exhaust gas temperature, enabling more accurate boost control and improved engine efficiency[2]. BorgWarner's smart wastegate design features a dual-valve configuration that provides finer control over exhaust gas flow, allowing for better low-end torque and high-end power optimization[3].

Strengths: Precise boost control, rapid response times, and improved engine efficiency. Weaknesses: Potentially higher cost and complexity compared to traditional mechanical wastegates.

Garrett Transportation I, Inc.

Technical Solution: Garrett has introduced innovative smart wastegate designs for turbochargers, applicable to engines like BMW's B58. Their technology focuses on electric actuation and advanced control strategies for optimal boost management. Garrett's smart wastegate system utilizes a high-precision electric actuator capable of making millisecond adjustments to wastegate position[4]. The system incorporates advanced sensors and predictive algorithms to anticipate boost requirements based on driving conditions and engine load[5]. Garrett's design also features a variable geometry mechanism that allows for dynamic adjustment of the exhaust gas flow path, enabling better boost control across a wider range of engine speeds[6]. Additionally, their smart wastegate integrates with the engine's ECU to provide adaptive boost control, optimizing performance and fuel efficiency in real-time[7].

Strengths: High-precision control, adaptive boost management, and improved overall engine performance. Weaknesses: May require more complex integration with engine management systems.

Core Innovations in Smart Wastegate Technology

Wastegate for an engine system

PatentActiveUS20180128162A1

Innovation

- A wastegate design featuring a valve plate with a multiplane curved surface and a bifurcated passage divided by a central wall, which guides exhaust flow to minimize contact with turbocharger walls and enhance velocity, thereby reducing energy losses and improving catalyst lightoff.

Wastegate control system and method

PatentWO2010039816A2

Innovation

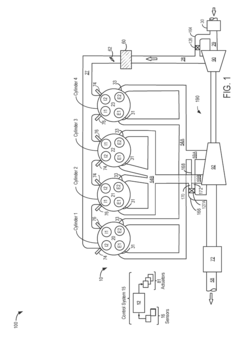

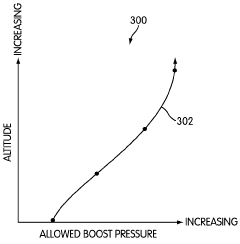

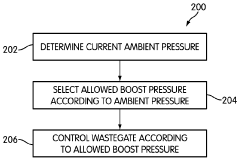

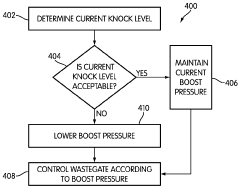

- A wastegate control system that incorporates a control unit communicating with throttle angle, intake charge humidity, engine speed, ambient pressure, ignition timing, and knock sensors to dynamically adjust the wastegate operation, ensuring optimal boost pressure and engine performance across different operating conditions.

Environmental Impact of Advanced Boost Technologies

The environmental impact of advanced boost technologies, particularly smart wastegate designs in the B58 engine, is a crucial consideration in the automotive industry's pursuit of efficiency and sustainability. These technologies play a significant role in optimizing engine performance while simultaneously addressing environmental concerns.

Smart wastegate designs contribute to reduced fuel consumption and lower emissions by precisely controlling boost pressure. This enhanced control allows the engine to operate more efficiently across various driving conditions, resulting in improved fuel economy. As a consequence, vehicles equipped with these advanced boost technologies typically produce fewer greenhouse gas emissions per mile driven, aligning with global efforts to combat climate change.

The materials used in smart wastegate designs also have environmental implications. Many components are made from lightweight, durable materials that can withstand high temperatures and pressures. While these materials often have a higher initial environmental cost in terms of production, their longevity and contribution to overall engine efficiency can offset this impact over the vehicle's lifetime.

Furthermore, smart wastegate designs enable more precise engine management, which can lead to reduced wear and tear on engine components. This increased durability potentially extends the lifespan of engines, reducing the frequency of replacements and the associated environmental costs of manufacturing new engines.

The technology's ability to optimize boost across a wide range of operating conditions also contributes to cleaner combustion. By ensuring the right amount of air is delivered to the engine at all times, smart wastegates help minimize incomplete combustion, which can lead to the production of harmful pollutants such as carbon monoxide and unburned hydrocarbons.

However, it is important to note that the environmental benefits of these technologies are not without challenges. The complexity of smart wastegate systems may require more specialized maintenance and potentially more frequent replacements of certain components. This could lead to increased waste if not managed properly through effective recycling and remanufacturing programs.

Additionally, the production of advanced electronic components used in smart wastegate control systems may involve rare earth elements and other materials with significant environmental footprints. Balancing the benefits of improved engine performance against the environmental costs of producing these components remains an ongoing challenge for manufacturers.

In conclusion, while smart wastegate designs in B58 boost optimization offer substantial environmental benefits through improved efficiency and reduced emissions, a holistic approach is necessary to fully assess their environmental impact. This includes considering the entire lifecycle of the technology, from production and use to eventual recycling or disposal.

Smart wastegate designs contribute to reduced fuel consumption and lower emissions by precisely controlling boost pressure. This enhanced control allows the engine to operate more efficiently across various driving conditions, resulting in improved fuel economy. As a consequence, vehicles equipped with these advanced boost technologies typically produce fewer greenhouse gas emissions per mile driven, aligning with global efforts to combat climate change.

The materials used in smart wastegate designs also have environmental implications. Many components are made from lightweight, durable materials that can withstand high temperatures and pressures. While these materials often have a higher initial environmental cost in terms of production, their longevity and contribution to overall engine efficiency can offset this impact over the vehicle's lifetime.

Furthermore, smart wastegate designs enable more precise engine management, which can lead to reduced wear and tear on engine components. This increased durability potentially extends the lifespan of engines, reducing the frequency of replacements and the associated environmental costs of manufacturing new engines.

The technology's ability to optimize boost across a wide range of operating conditions also contributes to cleaner combustion. By ensuring the right amount of air is delivered to the engine at all times, smart wastegates help minimize incomplete combustion, which can lead to the production of harmful pollutants such as carbon monoxide and unburned hydrocarbons.

However, it is important to note that the environmental benefits of these technologies are not without challenges. The complexity of smart wastegate systems may require more specialized maintenance and potentially more frequent replacements of certain components. This could lead to increased waste if not managed properly through effective recycling and remanufacturing programs.

Additionally, the production of advanced electronic components used in smart wastegate control systems may involve rare earth elements and other materials with significant environmental footprints. Balancing the benefits of improved engine performance against the environmental costs of producing these components remains an ongoing challenge for manufacturers.

In conclusion, while smart wastegate designs in B58 boost optimization offer substantial environmental benefits through improved efficiency and reduced emissions, a holistic approach is necessary to fully assess their environmental impact. This includes considering the entire lifecycle of the technology, from production and use to eventual recycling or disposal.

Integration with Engine Management Systems

The integration of smart wastegate designs with engine management systems is a critical aspect of optimizing boost control in the B58 engine. This integration allows for precise control of boost pressure, enhancing overall engine performance and efficiency. The engine control unit (ECU) plays a central role in this integration, continuously monitoring various engine parameters and adjusting the wastegate position accordingly.

Smart wastegate designs in the B58 engine utilize electronic actuators that can respond rapidly to ECU commands. These actuators are typically controlled through pulse-width modulation (PWM) signals, allowing for fine-tuned adjustments of the wastegate position. The ECU processes data from multiple sensors, including manifold absolute pressure (MAP) sensors, mass airflow (MAF) sensors, and engine speed sensors, to determine the optimal boost pressure for any given operating condition.

The integration also involves sophisticated software algorithms within the ECU. These algorithms take into account factors such as engine load, ambient temperature, and altitude to calculate the ideal boost pressure. The ECU then sends appropriate signals to the smart wastegate actuator to achieve and maintain this pressure. This dynamic control allows for better transient response and more consistent boost across varying driving conditions.

Advanced engine management systems may incorporate predictive control strategies for wastegate operation. By anticipating changes in engine load based on driver input and vehicle dynamics, the system can preemptively adjust the wastegate position to minimize turbo lag and improve overall responsiveness. This predictive capability is particularly beneficial in scenarios such as rapid acceleration or gear changes.

The integration of smart wastegates with engine management systems also facilitates adaptive learning capabilities. Over time, the ECU can refine its control strategies based on actual engine performance data, optimizing boost control for the specific characteristics of each individual engine. This adaptability helps to maintain optimal performance as the engine ages or if modifications are made.

Furthermore, the integration enables more sophisticated diagnostic capabilities. The ECU can monitor wastegate performance and detect any deviations from expected behavior, allowing for early identification of potential issues. This diagnostic integration enhances reliability and simplifies maintenance procedures for the B58 engine.

In conclusion, the seamless integration of smart wastegate designs with engine management systems is fundamental to achieving optimal boost control in the B58 engine. This integration enables precise, dynamic, and adaptive boost management, contributing significantly to the engine's performance, efficiency, and reliability.

Smart wastegate designs in the B58 engine utilize electronic actuators that can respond rapidly to ECU commands. These actuators are typically controlled through pulse-width modulation (PWM) signals, allowing for fine-tuned adjustments of the wastegate position. The ECU processes data from multiple sensors, including manifold absolute pressure (MAP) sensors, mass airflow (MAF) sensors, and engine speed sensors, to determine the optimal boost pressure for any given operating condition.

The integration also involves sophisticated software algorithms within the ECU. These algorithms take into account factors such as engine load, ambient temperature, and altitude to calculate the ideal boost pressure. The ECU then sends appropriate signals to the smart wastegate actuator to achieve and maintain this pressure. This dynamic control allows for better transient response and more consistent boost across varying driving conditions.

Advanced engine management systems may incorporate predictive control strategies for wastegate operation. By anticipating changes in engine load based on driver input and vehicle dynamics, the system can preemptively adjust the wastegate position to minimize turbo lag and improve overall responsiveness. This predictive capability is particularly beneficial in scenarios such as rapid acceleration or gear changes.

The integration of smart wastegates with engine management systems also facilitates adaptive learning capabilities. Over time, the ECU can refine its control strategies based on actual engine performance data, optimizing boost control for the specific characteristics of each individual engine. This adaptability helps to maintain optimal performance as the engine ages or if modifications are made.

Furthermore, the integration enables more sophisticated diagnostic capabilities. The ECU can monitor wastegate performance and detect any deviations from expected behavior, allowing for early identification of potential issues. This diagnostic integration enhances reliability and simplifies maintenance procedures for the B58 engine.

In conclusion, the seamless integration of smart wastegate designs with engine management systems is fundamental to achieving optimal boost control in the B58 engine. This integration enables precise, dynamic, and adaptive boost management, contributing significantly to the engine's performance, efficiency, and reliability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!