The Science Behind PLA's Biodegradability

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PLA Biodegradability Background and Objectives

Polylactic acid (PLA) has emerged as a promising biodegradable polymer, garnering significant attention in recent years due to its potential to address environmental concerns associated with conventional plastics. The science behind PLA's biodegradability is rooted in its unique chemical structure and the natural processes that facilitate its decomposition.

PLA is derived from renewable resources such as corn starch, cassava roots, or sugarcane, making it an attractive alternative to petroleum-based plastics. The biodegradability of PLA is primarily attributed to its ester linkages, which are susceptible to hydrolysis under specific environmental conditions. This characteristic sets PLA apart from traditional plastics, which can persist in the environment for hundreds of years.

The evolution of PLA technology can be traced back to the 1930s when Wallace Carothers first synthesized a low molecular weight PLA. However, it wasn't until the 1990s that breakthroughs in polymerization techniques allowed for the production of high molecular weight PLA suitable for commercial applications. Since then, research and development efforts have focused on enhancing PLA's properties and expanding its potential uses.

The primary objective in studying PLA's biodegradability is to understand the mechanisms and factors that influence its decomposition in various environments. This knowledge is crucial for optimizing PLA formulations and developing appropriate disposal methods to ensure efficient biodegradation. Additionally, researchers aim to explore ways to control the rate of biodegradation, as different applications may require varying lifespans for PLA-based products.

Another key goal is to assess the environmental impact of PLA throughout its lifecycle, from production to disposal. This includes evaluating the carbon footprint of PLA manufacturing processes, as well as the potential effects of PLA degradation products on ecosystems. Understanding these aspects is essential for positioning PLA as a truly sustainable alternative to conventional plastics.

The scientific community is also focused on addressing current limitations of PLA, such as its relatively low heat resistance and brittleness. Ongoing research aims to develop PLA composites and blends that maintain biodegradability while improving mechanical and thermal properties. This work is critical for expanding PLA's applications across various industries, from packaging to medical devices.

As environmental regulations become more stringent and consumer demand for eco-friendly products grows, the importance of advancing PLA technology cannot be overstated. The ultimate goal is to create a circular economy where PLA-based products can be efficiently produced, used, and biodegraded, minimizing waste and environmental impact. This ambitious objective drives ongoing research into PLA's biodegradability and its potential to revolutionize the plastics industry.

PLA is derived from renewable resources such as corn starch, cassava roots, or sugarcane, making it an attractive alternative to petroleum-based plastics. The biodegradability of PLA is primarily attributed to its ester linkages, which are susceptible to hydrolysis under specific environmental conditions. This characteristic sets PLA apart from traditional plastics, which can persist in the environment for hundreds of years.

The evolution of PLA technology can be traced back to the 1930s when Wallace Carothers first synthesized a low molecular weight PLA. However, it wasn't until the 1990s that breakthroughs in polymerization techniques allowed for the production of high molecular weight PLA suitable for commercial applications. Since then, research and development efforts have focused on enhancing PLA's properties and expanding its potential uses.

The primary objective in studying PLA's biodegradability is to understand the mechanisms and factors that influence its decomposition in various environments. This knowledge is crucial for optimizing PLA formulations and developing appropriate disposal methods to ensure efficient biodegradation. Additionally, researchers aim to explore ways to control the rate of biodegradation, as different applications may require varying lifespans for PLA-based products.

Another key goal is to assess the environmental impact of PLA throughout its lifecycle, from production to disposal. This includes evaluating the carbon footprint of PLA manufacturing processes, as well as the potential effects of PLA degradation products on ecosystems. Understanding these aspects is essential for positioning PLA as a truly sustainable alternative to conventional plastics.

The scientific community is also focused on addressing current limitations of PLA, such as its relatively low heat resistance and brittleness. Ongoing research aims to develop PLA composites and blends that maintain biodegradability while improving mechanical and thermal properties. This work is critical for expanding PLA's applications across various industries, from packaging to medical devices.

As environmental regulations become more stringent and consumer demand for eco-friendly products grows, the importance of advancing PLA technology cannot be overstated. The ultimate goal is to create a circular economy where PLA-based products can be efficiently produced, used, and biodegraded, minimizing waste and environmental impact. This ambitious objective drives ongoing research into PLA's biodegradability and its potential to revolutionize the plastics industry.

Market Analysis for Biodegradable Plastics

The biodegradable plastics market has experienced significant growth in recent years, driven by increasing environmental concerns and regulatory pressures to reduce plastic waste. Polylactic acid (PLA), a biodegradable polymer derived from renewable resources, has emerged as a key player in this market. The global biodegradable plastics market was valued at approximately $4.2 billion in 2020 and is projected to reach $7.8 billion by 2025, growing at a CAGR of 13.3% during the forecast period.

PLA, in particular, has gained substantial market share due to its versatility and relatively low production costs compared to other biodegradable alternatives. The PLA market is expected to grow from $698 million in 2020 to $2.1 billion by 2025, representing a CAGR of 24.6%. This growth is primarily attributed to the increasing adoption of PLA in packaging, textiles, and medical applications.

The packaging industry remains the largest consumer of biodegradable plastics, accounting for over 60% of the total market share. PLA's biodegradability and compostability make it an attractive option for food packaging, disposable cutlery, and other single-use items. The textile industry is also showing increased interest in PLA fibers, with applications in clothing, upholstery, and non-woven fabrics.

Geographically, Europe leads the biodegradable plastics market, followed by North America and Asia-Pacific. European countries have implemented stringent regulations on single-use plastics, driving the demand for biodegradable alternatives. The Asia-Pacific region is expected to witness the highest growth rate in the coming years, fueled by rapid industrialization, increasing environmental awareness, and government initiatives to promote sustainable materials.

Despite the positive market outlook, challenges remain for widespread adoption of biodegradable plastics, including PLA. Higher production costs compared to conventional plastics, limited waste management infrastructure for proper composting, and consumer confusion about proper disposal methods are significant barriers to market growth. Additionally, the performance limitations of PLA in certain applications, such as high-temperature resistance and barrier properties, continue to be areas of ongoing research and development.

The competitive landscape of the biodegradable plastics market is characterized by a mix of large chemical companies and specialized bioplastics manufacturers. Key players in the PLA market include NatureWorks LLC, Total Corbion PLA, and Futerro, among others. These companies are investing heavily in research and development to improve PLA's properties and expand its applications, which is expected to drive further market growth and innovation in the coming years.

PLA, in particular, has gained substantial market share due to its versatility and relatively low production costs compared to other biodegradable alternatives. The PLA market is expected to grow from $698 million in 2020 to $2.1 billion by 2025, representing a CAGR of 24.6%. This growth is primarily attributed to the increasing adoption of PLA in packaging, textiles, and medical applications.

The packaging industry remains the largest consumer of biodegradable plastics, accounting for over 60% of the total market share. PLA's biodegradability and compostability make it an attractive option for food packaging, disposable cutlery, and other single-use items. The textile industry is also showing increased interest in PLA fibers, with applications in clothing, upholstery, and non-woven fabrics.

Geographically, Europe leads the biodegradable plastics market, followed by North America and Asia-Pacific. European countries have implemented stringent regulations on single-use plastics, driving the demand for biodegradable alternatives. The Asia-Pacific region is expected to witness the highest growth rate in the coming years, fueled by rapid industrialization, increasing environmental awareness, and government initiatives to promote sustainable materials.

Despite the positive market outlook, challenges remain for widespread adoption of biodegradable plastics, including PLA. Higher production costs compared to conventional plastics, limited waste management infrastructure for proper composting, and consumer confusion about proper disposal methods are significant barriers to market growth. Additionally, the performance limitations of PLA in certain applications, such as high-temperature resistance and barrier properties, continue to be areas of ongoing research and development.

The competitive landscape of the biodegradable plastics market is characterized by a mix of large chemical companies and specialized bioplastics manufacturers. Key players in the PLA market include NatureWorks LLC, Total Corbion PLA, and Futerro, among others. These companies are investing heavily in research and development to improve PLA's properties and expand its applications, which is expected to drive further market growth and innovation in the coming years.

Current PLA Biodegradation Challenges

Despite the promising potential of Polylactic Acid (PLA) as a biodegradable alternative to conventional plastics, several challenges currently hinder its widespread adoption and effective biodegradation. One of the primary issues is the slow degradation rate of PLA under natural environmental conditions. While PLA can theoretically break down into harmless components, this process often takes much longer than anticipated, sometimes spanning several years.

The biodegradation of PLA is highly dependent on specific environmental conditions, particularly temperature and humidity. In most natural settings, these conditions are not optimal for rapid PLA degradation. This leads to a significant discrepancy between laboratory results and real-world performance, where PLA may persist in the environment for extended periods.

Another challenge is the lack of widespread industrial composting facilities capable of efficiently processing PLA waste. These facilities require controlled conditions, including high temperatures and specific microbial environments, to effectively break down PLA. The scarcity of such facilities limits the practical end-of-life options for PLA products, often resulting in their disposal in conventional landfills where biodegradation is even slower.

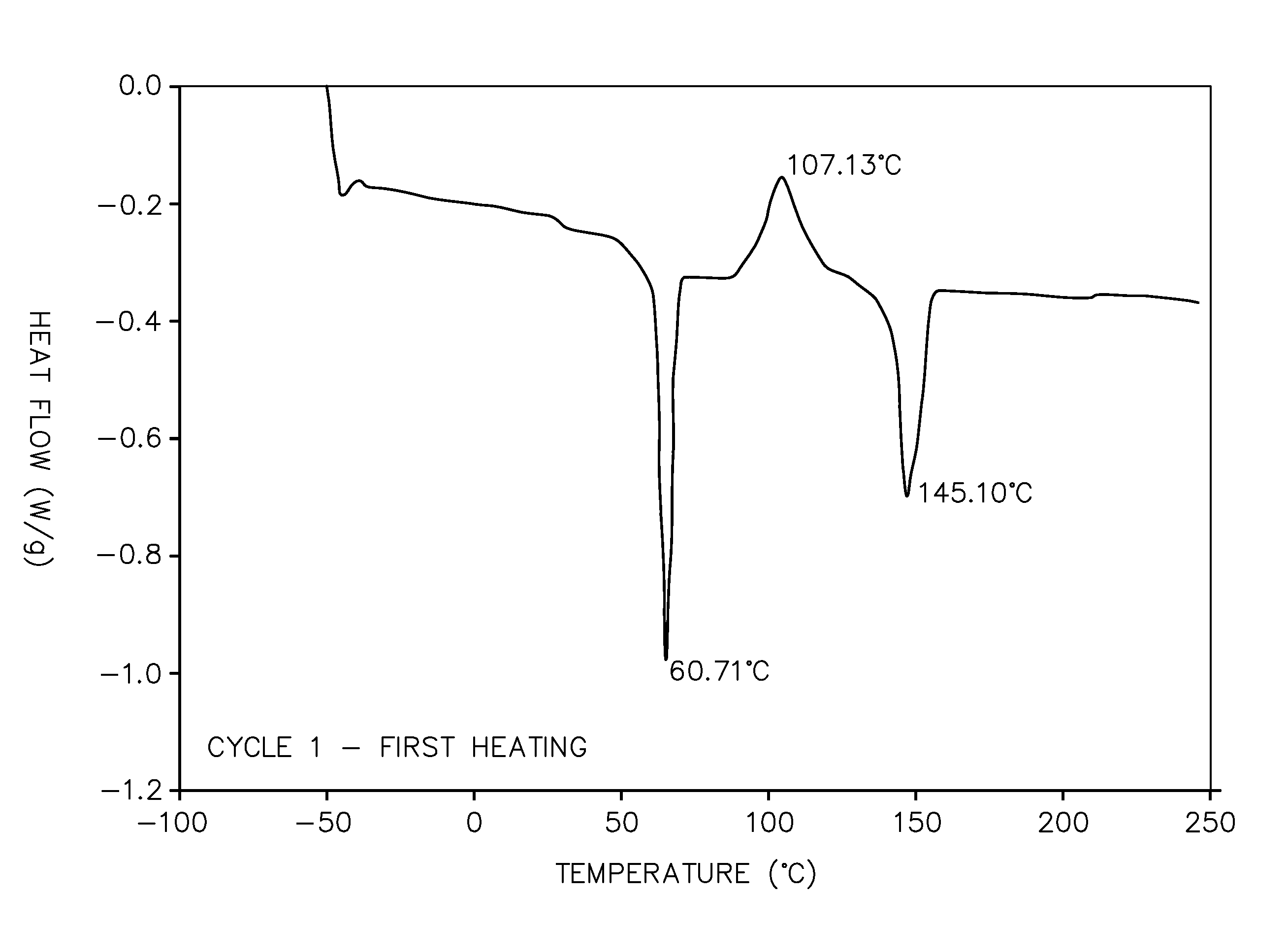

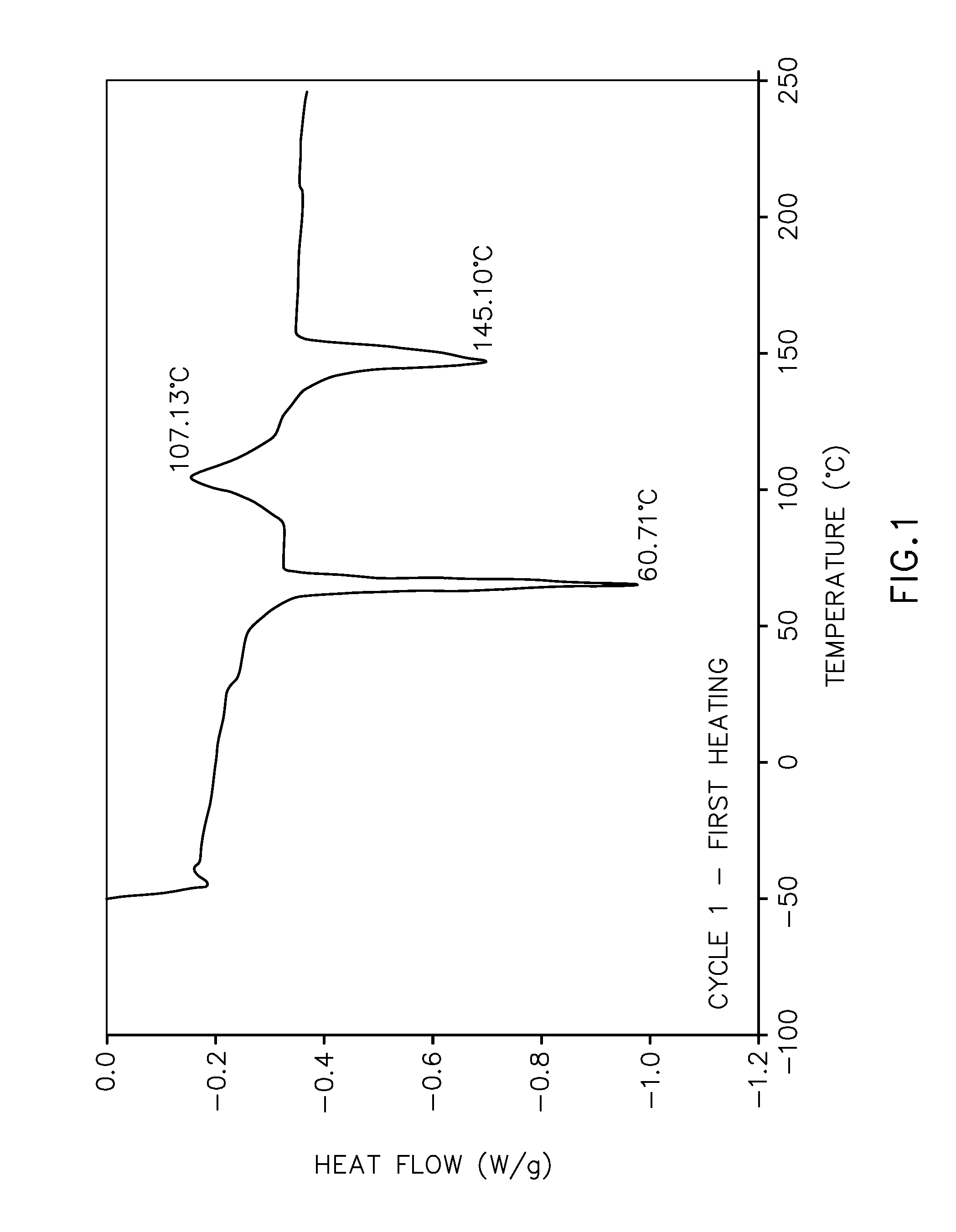

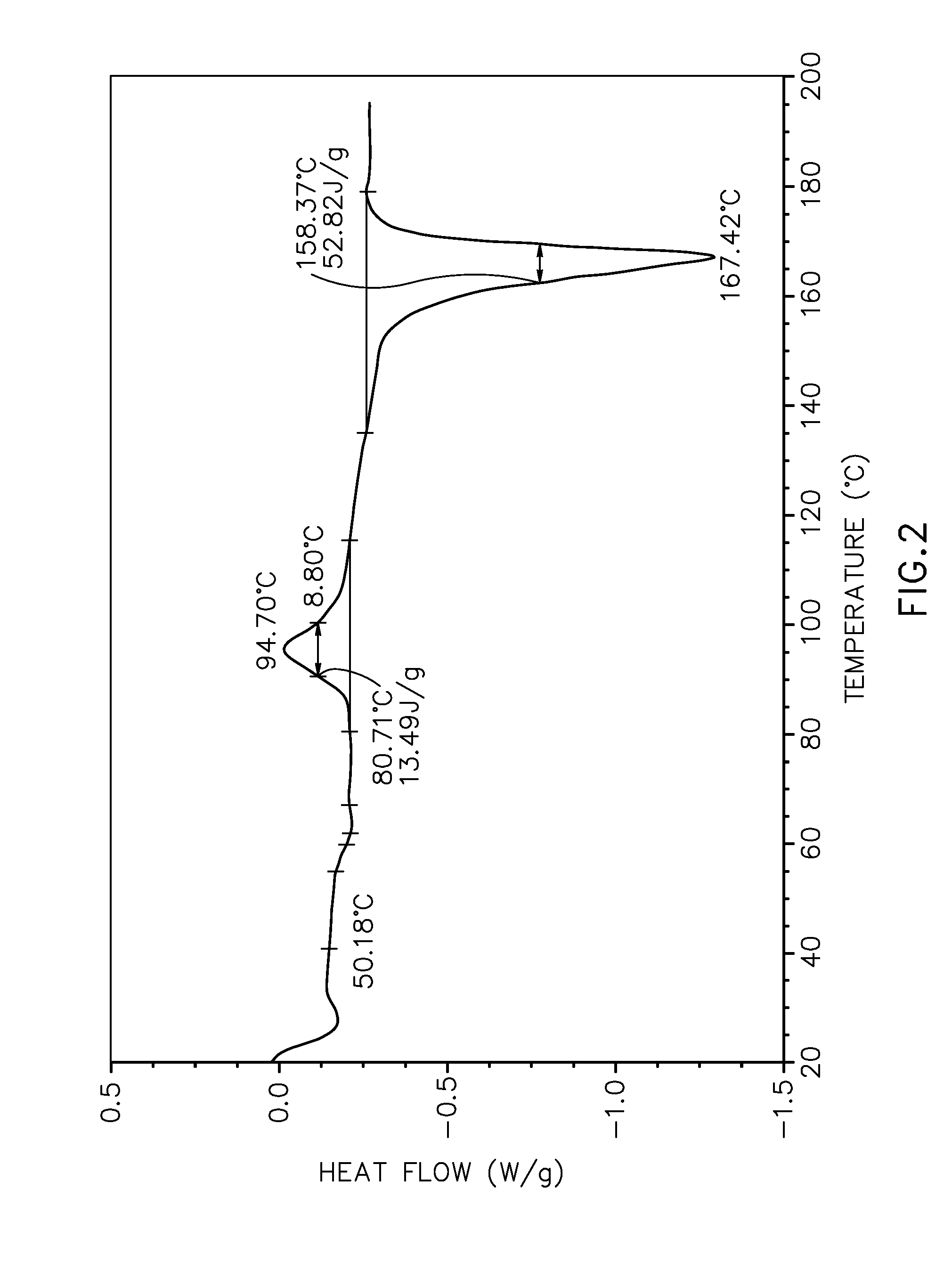

The molecular weight and crystallinity of PLA also play crucial roles in its biodegradability. Higher molecular weight and increased crystallinity, while beneficial for certain material properties, can significantly slow down the biodegradation process. This creates a challenging balance between achieving desired material performance and ensuring efficient biodegradability.

Furthermore, the presence of additives and blends in PLA products can complicate the biodegradation process. Many commercial PLA products contain various additives to enhance their properties, and these additives may not be biodegradable themselves or may interfere with the biodegradation of PLA.

There is also a growing concern about the potential ecological impact of PLA degradation products. While lactic acid, the primary breakdown product of PLA, is generally considered safe, the long-term effects of large-scale PLA biodegradation on soil and aquatic ecosystems are not yet fully understood.

Lastly, there is a need for standardized testing methods and regulations for PLA biodegradability. Current testing protocols often do not accurately reflect real-world conditions, leading to discrepancies in biodegradability claims and consumer confusion. Developing more accurate and universally accepted testing standards remains a significant challenge in the field.

The biodegradation of PLA is highly dependent on specific environmental conditions, particularly temperature and humidity. In most natural settings, these conditions are not optimal for rapid PLA degradation. This leads to a significant discrepancy between laboratory results and real-world performance, where PLA may persist in the environment for extended periods.

Another challenge is the lack of widespread industrial composting facilities capable of efficiently processing PLA waste. These facilities require controlled conditions, including high temperatures and specific microbial environments, to effectively break down PLA. The scarcity of such facilities limits the practical end-of-life options for PLA products, often resulting in their disposal in conventional landfills where biodegradation is even slower.

The molecular weight and crystallinity of PLA also play crucial roles in its biodegradability. Higher molecular weight and increased crystallinity, while beneficial for certain material properties, can significantly slow down the biodegradation process. This creates a challenging balance between achieving desired material performance and ensuring efficient biodegradability.

Furthermore, the presence of additives and blends in PLA products can complicate the biodegradation process. Many commercial PLA products contain various additives to enhance their properties, and these additives may not be biodegradable themselves or may interfere with the biodegradation of PLA.

There is also a growing concern about the potential ecological impact of PLA degradation products. While lactic acid, the primary breakdown product of PLA, is generally considered safe, the long-term effects of large-scale PLA biodegradation on soil and aquatic ecosystems are not yet fully understood.

Lastly, there is a need for standardized testing methods and regulations for PLA biodegradability. Current testing protocols often do not accurately reflect real-world conditions, leading to discrepancies in biodegradability claims and consumer confusion. Developing more accurate and universally accepted testing standards remains a significant challenge in the field.

Existing PLA Biodegradation Enhancement Methods

01 Biodegradation mechanisms of PLA

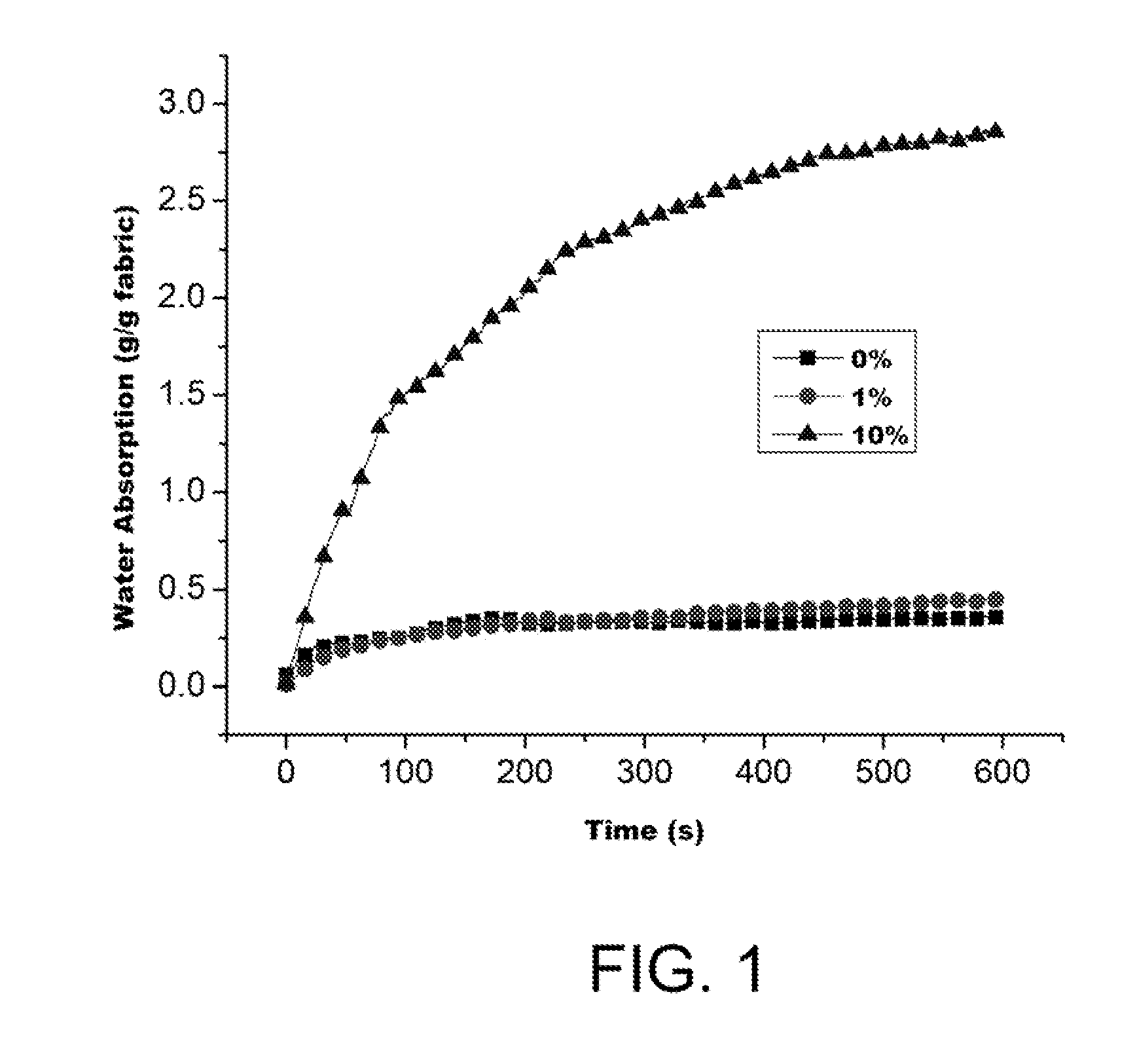

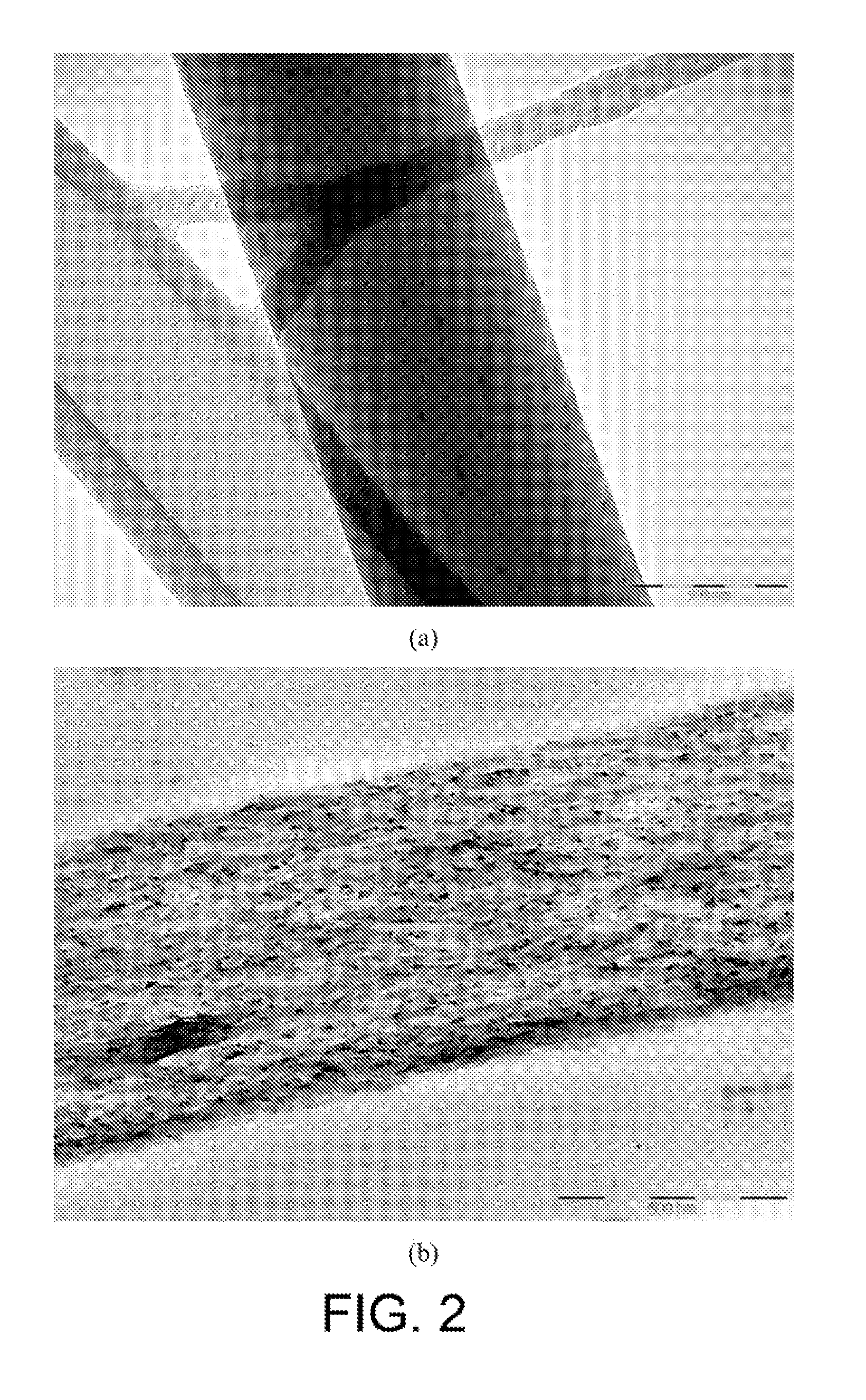

PLA biodegradation occurs through hydrolysis and microbial action. The process begins with water absorption, leading to hydrolytic chain scission. Microorganisms then metabolize the resulting oligomers and monomers. Factors such as temperature, humidity, and microbial population influence the rate of biodegradation.- Biodegradation mechanisms of PLA: PLA biodegradation occurs through hydrolysis and microbial action. The process begins with water absorption, leading to chain scission and molecular weight reduction. Microorganisms then consume the smaller molecules, converting them into carbon dioxide, water, and biomass. Factors such as temperature, humidity, and microbial activity influence the rate of biodegradation.

- Enhancing PLA biodegradability: Various methods are employed to improve PLA biodegradability, including blending with other biodegradable polymers, incorporating additives, and modifying the polymer structure. These techniques aim to increase hydrophilicity, reduce crystallinity, or introduce more easily degradable segments, thereby accelerating the biodegradation process.

- Environmental factors affecting PLA biodegradation: The biodegradation rate of PLA is significantly influenced by environmental conditions. Factors such as temperature, pH, moisture content, and the presence of specific microorganisms play crucial roles. Optimal conditions can accelerate biodegradation, while unfavorable environments may slow down or inhibit the process.

- Industrial applications considering PLA biodegradability: PLA's biodegradability is leveraged in various industries, including packaging, agriculture, and biomedical fields. Products are designed to balance functionality with controlled biodegradation rates, ensuring they maintain integrity during use but degrade efficiently after disposal. This approach contributes to reducing environmental impact and promoting sustainable material use.

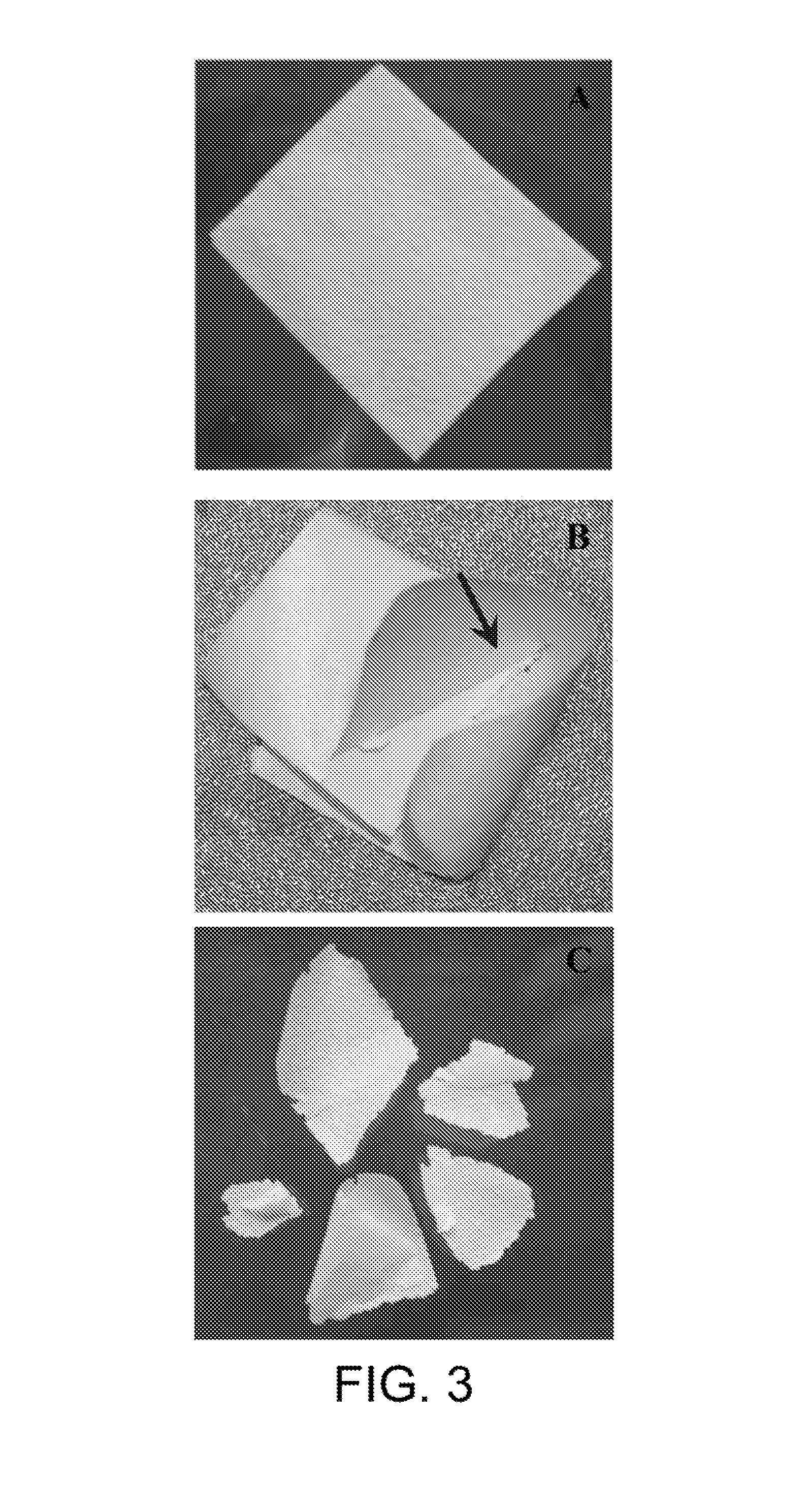

- Composting and waste management of PLA products: Proper disposal and composting of PLA products are essential for realizing their biodegradability benefits. Industrial composting facilities provide optimal conditions for PLA degradation, including controlled temperature and humidity. Research focuses on developing PLA formulations that can biodegrade effectively in various composting environments, from industrial facilities to home compost bins.

02 Enhancing PLA biodegradability

Various methods are employed to improve PLA biodegradability, including blending with other biodegradable polymers, incorporating additives, and modifying the polymer structure. These techniques aim to increase the material's susceptibility to environmental degradation while maintaining its desirable properties during use.Expand Specific Solutions03 Environmental impact of PLA biodegradation

The biodegradation of PLA offers potential environmental benefits, such as reduced plastic waste accumulation and lower carbon footprint compared to conventional plastics. However, proper waste management and composting facilities are crucial for realizing these benefits. The end-products of PLA biodegradation are primarily carbon dioxide and water.Expand Specific Solutions04 Industrial applications of biodegradable PLA

Biodegradable PLA finds applications in various industries, including packaging, agriculture, and biomedical fields. Its use in disposable items, mulch films, and drug delivery systems leverages its biodegradability. Ongoing research focuses on expanding PLA's application range while optimizing its biodegradation properties.Expand Specific Solutions05 Measuring and standardizing PLA biodegradability

Standardized testing methods and protocols are essential for assessing PLA biodegradability. These include composting tests, soil burial tests, and enzymatic degradation assays. Efforts are ongoing to develop and refine international standards for evaluating and certifying the biodegradability of PLA and other bioplastics.Expand Specific Solutions

Key Players in PLA Industry

The biodegradability of PLA (Polylactic Acid) is a rapidly evolving field in the bioplastics industry, currently in its growth phase. The market for biodegradable plastics is expanding, driven by environmental concerns and regulatory pressures. Technological maturity varies among key players, with companies like 3M Innovative Properties Co. and International Paper Co. leading in innovation. Academic institutions such as Changzhou University and Cornell University contribute significantly to research advancements. Collaborations between industry and academia, exemplified by partnerships involving TotalEnergies OneTech SAS and the University of Rennes, are accelerating progress in PLA biodegradability science. The involvement of diverse entities, from established corporations to specialized biotech firms like Galatea Biotech SRL, indicates a competitive and dynamic landscape in this emerging field.

Sulapac Oy

Technical Solution: Sulapac Oy has developed a biodegradable material made from wood chips and natural binders. Their technology focuses on creating a plastic-like material that biodegrades without leaving behind microplastics. The material is designed to break down in various environments, including industrial composting facilities and marine conditions. Sulapac's innovation lies in its ability to mimic the properties of traditional plastics while ensuring complete biodegradability, addressing both functionality and environmental concerns.

Strengths: Versatile application in packaging, fully biodegradable, leaves no microplastics. Weaknesses: May have higher production costs compared to traditional plastics, limited scalability in some applications.

Arctic Biomaterials Oy

Technical Solution: Arctic Biomaterials Oy specializes in developing biodegradable plastics reinforced with natural fibers. Their technology combines PLA with their proprietary fiber reinforcement to create materials with enhanced mechanical properties and biodegradability. The company's approach focuses on improving the performance of PLA while maintaining its biodegradable characteristics. Their materials are designed to degrade in industrial composting conditions, offering a balance between durability during use and environmental friendliness at end-of-life.

Strengths: Enhanced mechanical properties compared to standard PLA, maintains biodegradability. Weaknesses: May require specific composting conditions for optimal degradation, potentially higher cost than non-reinforced PLA.

Core Innovations in PLA Biodegradability

Biodegradable chemical delivery system

PatentActiveUS20110275520A1

Innovation

- A polymeric material system comprising a hydrophobic polymeric matrix and a hydrophilic second polymeric material, where the latter forms nanocomposite fibers with PLA, enhancing degradation rates and allowing controlled release of compounds like pesticides through varying the composition and form of the polymeric material.

Thermoformed articles made from reactive extrusion products of biobased materials

PatentActiveUS8231954B2

Innovation

- Development of thermoformable composite materials comprising blends of PLA and polyhydroxyalkanoates (PHAs) with specific additives, processed via extrusion, to enhance thermal and mechanical performance, achieving a Vicat softening point up to 180°C and heat distortion index up to 160°C, thereby improving resistance to deformation at higher temperatures.

Environmental Impact Assessment of PLA

The environmental impact assessment of PLA (Polylactic Acid) is a critical aspect of understanding its biodegradability and overall sustainability. PLA, derived from renewable resources such as corn starch or sugarcane, has gained significant attention as a potential alternative to conventional petroleum-based plastics.

One of the primary environmental benefits of PLA is its reduced carbon footprint during production. Compared to traditional plastics, PLA manufacturing requires less energy and generates fewer greenhouse gas emissions. This advantage stems from the use of renewable feedstocks and more efficient production processes. However, it is essential to consider the entire life cycle of PLA products, including cultivation of raw materials, processing, and end-of-life management.

The biodegradability of PLA is a key factor in its environmental impact. Under specific conditions, PLA can break down into water, carbon dioxide, and biomass. This process typically occurs in industrial composting facilities, where controlled temperature, humidity, and microbial activity facilitate decomposition. However, it is crucial to note that PLA does not readily biodegrade in natural environments or landfills, which can lead to misconceptions about its environmental benefits.

The end-of-life management of PLA products plays a significant role in their overall environmental impact. Proper disposal through industrial composting systems can maximize the benefits of PLA's biodegradability. However, the limited availability of such facilities in many regions poses a challenge to realizing these benefits on a large scale. Improper disposal of PLA in conventional waste streams may negate its potential environmental advantages.

Land use and agricultural practices associated with PLA production also warrant consideration. The cultivation of crops for PLA feedstock may compete with food production or lead to land-use changes, potentially impacting biodiversity and ecosystem services. Sustainable agricultural practices and efficient use of land resources are crucial to mitigating these concerns.

Water consumption and pollution are additional factors to evaluate in PLA's environmental impact assessment. While PLA production generally requires less water compared to some conventional plastics, the agricultural phase of feedstock production can be water-intensive. Proper water management practices and technologies are essential to minimize the overall water footprint of PLA.

In conclusion, the environmental impact assessment of PLA reveals a complex interplay of factors. While PLA offers potential benefits in terms of reduced carbon emissions and biodegradability, its overall environmental performance depends heavily on responsible production, efficient use, and proper end-of-life management. Continued research and development in PLA technology, coupled with improvements in waste management infrastructure, will be crucial in maximizing its positive environmental impact and addressing current limitations.

One of the primary environmental benefits of PLA is its reduced carbon footprint during production. Compared to traditional plastics, PLA manufacturing requires less energy and generates fewer greenhouse gas emissions. This advantage stems from the use of renewable feedstocks and more efficient production processes. However, it is essential to consider the entire life cycle of PLA products, including cultivation of raw materials, processing, and end-of-life management.

The biodegradability of PLA is a key factor in its environmental impact. Under specific conditions, PLA can break down into water, carbon dioxide, and biomass. This process typically occurs in industrial composting facilities, where controlled temperature, humidity, and microbial activity facilitate decomposition. However, it is crucial to note that PLA does not readily biodegrade in natural environments or landfills, which can lead to misconceptions about its environmental benefits.

The end-of-life management of PLA products plays a significant role in their overall environmental impact. Proper disposal through industrial composting systems can maximize the benefits of PLA's biodegradability. However, the limited availability of such facilities in many regions poses a challenge to realizing these benefits on a large scale. Improper disposal of PLA in conventional waste streams may negate its potential environmental advantages.

Land use and agricultural practices associated with PLA production also warrant consideration. The cultivation of crops for PLA feedstock may compete with food production or lead to land-use changes, potentially impacting biodiversity and ecosystem services. Sustainable agricultural practices and efficient use of land resources are crucial to mitigating these concerns.

Water consumption and pollution are additional factors to evaluate in PLA's environmental impact assessment. While PLA production generally requires less water compared to some conventional plastics, the agricultural phase of feedstock production can be water-intensive. Proper water management practices and technologies are essential to minimize the overall water footprint of PLA.

In conclusion, the environmental impact assessment of PLA reveals a complex interplay of factors. While PLA offers potential benefits in terms of reduced carbon emissions and biodegradability, its overall environmental performance depends heavily on responsible production, efficient use, and proper end-of-life management. Continued research and development in PLA technology, coupled with improvements in waste management infrastructure, will be crucial in maximizing its positive environmental impact and addressing current limitations.

Regulatory Framework for Biodegradable Plastics

The regulatory framework for biodegradable plastics plays a crucial role in shaping the development, production, and disposal of materials like PLA (Polylactic Acid). As environmental concerns continue to grow, governments and international organizations have been establishing guidelines and standards to ensure the proper management of these innovative materials.

In the European Union, the EN 13432 standard sets the requirements for packaging recoverable through composting and biodegradation. This standard specifies the characteristics that a material must have to be considered "compostable" within industrial composting facilities. It requires that at least 90% of the material should biodegrade within 180 days under controlled composting conditions.

The United States has its own set of regulations, primarily governed by the ASTM D6400 standard. This standard specifies the requirements for labeling materials and products as "compostable in municipal and industrial composting facilities." Similar to the EU standard, it requires that the material must biodegrade at a rate comparable to known compostable materials.

Japan has implemented the GreenPla certification system, which evaluates biodegradable plastics based on their biodegradability, safety, and absence of harmful substances. This system aims to promote the use of environmentally friendly plastics and provides consumers with clear information about product characteristics.

On a global scale, the International Organization for Standardization (ISO) has developed several standards related to biodegradable plastics. ISO 17088 specifies the requirements for compostable plastics, while ISO 14855 provides methods for determining the ultimate aerobic biodegradability of plastic materials under controlled composting conditions.

These regulatory frameworks not only set standards for biodegradability but also address issues such as ecotoxicity, heavy metal content, and the overall environmental impact of the materials. They play a vital role in preventing "greenwashing" and ensuring that products labeled as biodegradable truly meet specific environmental criteria.

However, the regulatory landscape for biodegradable plastics is still evolving. As new materials and technologies emerge, policymakers and standards organizations are working to update and refine existing regulations. There is an ongoing debate about the need for more standardized global regulations to facilitate international trade and ensure consistent environmental protection across different regions.

The implementation of these regulations has significant implications for manufacturers, retailers, and consumers. Companies producing or using biodegradable plastics must invest in research and development to meet these standards, while also navigating the complex landscape of certifications and labeling requirements across different markets.

In the European Union, the EN 13432 standard sets the requirements for packaging recoverable through composting and biodegradation. This standard specifies the characteristics that a material must have to be considered "compostable" within industrial composting facilities. It requires that at least 90% of the material should biodegrade within 180 days under controlled composting conditions.

The United States has its own set of regulations, primarily governed by the ASTM D6400 standard. This standard specifies the requirements for labeling materials and products as "compostable in municipal and industrial composting facilities." Similar to the EU standard, it requires that the material must biodegrade at a rate comparable to known compostable materials.

Japan has implemented the GreenPla certification system, which evaluates biodegradable plastics based on their biodegradability, safety, and absence of harmful substances. This system aims to promote the use of environmentally friendly plastics and provides consumers with clear information about product characteristics.

On a global scale, the International Organization for Standardization (ISO) has developed several standards related to biodegradable plastics. ISO 17088 specifies the requirements for compostable plastics, while ISO 14855 provides methods for determining the ultimate aerobic biodegradability of plastic materials under controlled composting conditions.

These regulatory frameworks not only set standards for biodegradability but also address issues such as ecotoxicity, heavy metal content, and the overall environmental impact of the materials. They play a vital role in preventing "greenwashing" and ensuring that products labeled as biodegradable truly meet specific environmental criteria.

However, the regulatory landscape for biodegradable plastics is still evolving. As new materials and technologies emerge, policymakers and standards organizations are working to update and refine existing regulations. There is an ongoing debate about the need for more standardized global regulations to facilitate international trade and ensure consistent environmental protection across different regions.

The implementation of these regulations has significant implications for manufacturers, retailers, and consumers. Companies producing or using biodegradable plastics must invest in research and development to meet these standards, while also navigating the complex landscape of certifications and labeling requirements across different markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!