The Strategic Importance of PLA in Sustainable Development

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PLA Background and Objectives

Polylactic acid (PLA) has emerged as a key player in the pursuit of sustainable development, offering a biodegradable alternative to traditional petroleum-based plastics. The evolution of PLA technology can be traced back to the 1930s when Wallace Carothers first polymerized lactic acid. However, it wasn't until the late 20th century that PLA gained significant attention as a potential solution to environmental challenges posed by conventional plastics.

The development of PLA has been driven by increasing global awareness of environmental issues, particularly plastic pollution and the depletion of fossil resources. As a renewable, plant-based polymer, PLA aligns with the principles of circular economy and sustainable resource management. Its biodegradability and compostability under specific conditions make it an attractive option for reducing plastic waste accumulation in landfills and oceans.

The strategic importance of PLA in sustainable development is multifaceted. It offers a pathway to reduce dependency on fossil fuels for plastic production, as it can be derived from renewable resources such as corn starch, cassava roots, or sugarcane. This shift not only addresses resource scarcity concerns but also contributes to the reduction of greenhouse gas emissions associated with plastic production.

In recent years, technological advancements have significantly improved PLA's properties and production efficiency. Research efforts have focused on enhancing its thermal stability, mechanical strength, and processability to expand its application range. The goal is to position PLA as a viable substitute for conventional plastics in various industries, including packaging, textiles, and biomedical applications.

The objectives of PLA development in the context of sustainable development are ambitious and far-reaching. They include scaling up production to meet growing demand, reducing production costs to compete with traditional plastics, and improving end-of-life management through better recycling and composting infrastructure. Additionally, there is a push to develop PLA variants with enhanced properties, such as increased heat resistance and flexibility, to broaden its applicability across different sectors.

Looking ahead, the strategic importance of PLA is expected to grow as governments and industries worldwide intensify their efforts to transition towards a more sustainable and circular economy. The technology's potential to mitigate environmental impacts while supporting economic growth positions it as a crucial component in achieving global sustainability goals. As research continues and production scales up, PLA is poised to play an increasingly significant role in shaping a more sustainable future for plastic use and waste management.

The development of PLA has been driven by increasing global awareness of environmental issues, particularly plastic pollution and the depletion of fossil resources. As a renewable, plant-based polymer, PLA aligns with the principles of circular economy and sustainable resource management. Its biodegradability and compostability under specific conditions make it an attractive option for reducing plastic waste accumulation in landfills and oceans.

The strategic importance of PLA in sustainable development is multifaceted. It offers a pathway to reduce dependency on fossil fuels for plastic production, as it can be derived from renewable resources such as corn starch, cassava roots, or sugarcane. This shift not only addresses resource scarcity concerns but also contributes to the reduction of greenhouse gas emissions associated with plastic production.

In recent years, technological advancements have significantly improved PLA's properties and production efficiency. Research efforts have focused on enhancing its thermal stability, mechanical strength, and processability to expand its application range. The goal is to position PLA as a viable substitute for conventional plastics in various industries, including packaging, textiles, and biomedical applications.

The objectives of PLA development in the context of sustainable development are ambitious and far-reaching. They include scaling up production to meet growing demand, reducing production costs to compete with traditional plastics, and improving end-of-life management through better recycling and composting infrastructure. Additionally, there is a push to develop PLA variants with enhanced properties, such as increased heat resistance and flexibility, to broaden its applicability across different sectors.

Looking ahead, the strategic importance of PLA is expected to grow as governments and industries worldwide intensify their efforts to transition towards a more sustainable and circular economy. The technology's potential to mitigate environmental impacts while supporting economic growth positions it as a crucial component in achieving global sustainability goals. As research continues and production scales up, PLA is poised to play an increasingly significant role in shaping a more sustainable future for plastic use and waste management.

Market Demand Analysis

The market demand for Polylactic Acid (PLA) has been experiencing significant growth in recent years, driven by increasing environmental concerns and the shift towards sustainable materials. As a biodegradable and compostable bioplastic derived from renewable resources, PLA has gained traction across various industries, particularly in packaging, textiles, and consumer goods.

In the packaging sector, PLA has emerged as a viable alternative to traditional petroleum-based plastics. The food and beverage industry has shown particular interest in PLA due to its biodegradability and food-contact safety. The demand for PLA in this sector is expected to grow as more companies commit to sustainable packaging solutions in response to consumer preferences and regulatory pressures.

The textile industry has also embraced PLA as a sustainable fiber option. PLA-based fabrics offer properties similar to polyester but with a lower environmental impact. This has led to increased adoption in apparel, home textiles, and non-woven applications. The growing consumer awareness of sustainable fashion is likely to further boost the demand for PLA in textiles.

In the consumer goods sector, PLA has found applications in disposable items such as cutlery, cups, and plates. The hospitality industry and event management sectors are increasingly opting for PLA-based products to reduce their environmental footprint. This trend is expected to continue as more businesses adopt sustainability initiatives.

The medical and pharmaceutical industries have also shown interest in PLA due to its biocompatibility and biodegradability. PLA is used in various medical applications, including sutures, implants, and drug delivery systems. The growing emphasis on sustainable healthcare solutions is likely to drive further demand in this sector.

Market analysis indicates that the global PLA market is projected to grow at a compound annual growth rate (CAGR) of over 15% in the coming years. This growth is attributed to the increasing adoption of biodegradable plastics, stringent environmental regulations, and the rising demand for sustainable packaging solutions.

Geographically, North America and Europe currently lead the PLA market, driven by strong environmental policies and consumer awareness. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, fueled by rapid industrialization, increasing environmental concerns, and government initiatives promoting sustainable materials.

Despite the positive outlook, challenges remain in the widespread adoption of PLA. These include higher production costs compared to conventional plastics, limited end-of-life infrastructure for proper composting, and the need for improved performance characteristics in certain applications. Addressing these challenges will be crucial for realizing the full market potential of PLA in sustainable development.

In the packaging sector, PLA has emerged as a viable alternative to traditional petroleum-based plastics. The food and beverage industry has shown particular interest in PLA due to its biodegradability and food-contact safety. The demand for PLA in this sector is expected to grow as more companies commit to sustainable packaging solutions in response to consumer preferences and regulatory pressures.

The textile industry has also embraced PLA as a sustainable fiber option. PLA-based fabrics offer properties similar to polyester but with a lower environmental impact. This has led to increased adoption in apparel, home textiles, and non-woven applications. The growing consumer awareness of sustainable fashion is likely to further boost the demand for PLA in textiles.

In the consumer goods sector, PLA has found applications in disposable items such as cutlery, cups, and plates. The hospitality industry and event management sectors are increasingly opting for PLA-based products to reduce their environmental footprint. This trend is expected to continue as more businesses adopt sustainability initiatives.

The medical and pharmaceutical industries have also shown interest in PLA due to its biocompatibility and biodegradability. PLA is used in various medical applications, including sutures, implants, and drug delivery systems. The growing emphasis on sustainable healthcare solutions is likely to drive further demand in this sector.

Market analysis indicates that the global PLA market is projected to grow at a compound annual growth rate (CAGR) of over 15% in the coming years. This growth is attributed to the increasing adoption of biodegradable plastics, stringent environmental regulations, and the rising demand for sustainable packaging solutions.

Geographically, North America and Europe currently lead the PLA market, driven by strong environmental policies and consumer awareness. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, fueled by rapid industrialization, increasing environmental concerns, and government initiatives promoting sustainable materials.

Despite the positive outlook, challenges remain in the widespread adoption of PLA. These include higher production costs compared to conventional plastics, limited end-of-life infrastructure for proper composting, and the need for improved performance characteristics in certain applications. Addressing these challenges will be crucial for realizing the full market potential of PLA in sustainable development.

PLA Technical Challenges

Despite its promising potential in sustainable development, Polylactic Acid (PLA) faces several technical challenges that hinder its widespread adoption and full realization of its strategic importance. These challenges span across various aspects of PLA production, processing, and application.

One of the primary technical hurdles is the high production cost of PLA compared to conventional petroleum-based plastics. The fermentation process used to produce lactic acid, the precursor to PLA, is energy-intensive and requires significant optimization to become economically competitive. Additionally, the polymerization process to convert lactic acid into PLA is complex and time-consuming, further contributing to the overall cost.

The mechanical properties of PLA present another set of challenges. While PLA exhibits good tensile strength and modulus, it suffers from brittleness and low impact resistance. This limits its application in sectors requiring durable and flexible materials. Efforts to improve PLA's toughness through blending with other polymers or adding plasticizers often come at the expense of other desirable properties or biodegradability.

Thermal stability is a significant concern for PLA, particularly in high-temperature applications. PLA has a relatively low glass transition temperature and heat deflection temperature, which restricts its use in hot-fill packaging or products exposed to elevated temperatures during use or storage. Improving PLA's heat resistance without compromising its biodegradability remains a technical challenge.

The biodegradation rate of PLA poses another technical issue. While PLA is compostable under industrial conditions, it degrades slowly in natural environments. This creates a dilemma where the material persists longer than desired in some disposal scenarios, yet degrades too quickly for certain long-term applications. Controlling and optimizing the degradation rate for different end-use requirements is an ongoing challenge.

Processing PLA also presents technical difficulties. Its narrow processing window and sensitivity to moisture during melt processing can lead to thermal degradation and hydrolysis, affecting the final product quality. Developing robust processing techniques that maintain PLA's properties while allowing for efficient manufacturing is crucial for its widespread industrial adoption.

Lastly, the end-of-life management of PLA products faces technical hurdles. While theoretically compostable, PLA requires specific conditions for efficient decomposition. The lack of widespread industrial composting facilities and the potential contamination of recycling streams with PLA pose challenges for effective waste management. Developing better sorting technologies and establishing dedicated PLA recycling streams are necessary steps to fully realize its circular economy potential.

One of the primary technical hurdles is the high production cost of PLA compared to conventional petroleum-based plastics. The fermentation process used to produce lactic acid, the precursor to PLA, is energy-intensive and requires significant optimization to become economically competitive. Additionally, the polymerization process to convert lactic acid into PLA is complex and time-consuming, further contributing to the overall cost.

The mechanical properties of PLA present another set of challenges. While PLA exhibits good tensile strength and modulus, it suffers from brittleness and low impact resistance. This limits its application in sectors requiring durable and flexible materials. Efforts to improve PLA's toughness through blending with other polymers or adding plasticizers often come at the expense of other desirable properties or biodegradability.

Thermal stability is a significant concern for PLA, particularly in high-temperature applications. PLA has a relatively low glass transition temperature and heat deflection temperature, which restricts its use in hot-fill packaging or products exposed to elevated temperatures during use or storage. Improving PLA's heat resistance without compromising its biodegradability remains a technical challenge.

The biodegradation rate of PLA poses another technical issue. While PLA is compostable under industrial conditions, it degrades slowly in natural environments. This creates a dilemma where the material persists longer than desired in some disposal scenarios, yet degrades too quickly for certain long-term applications. Controlling and optimizing the degradation rate for different end-use requirements is an ongoing challenge.

Processing PLA also presents technical difficulties. Its narrow processing window and sensitivity to moisture during melt processing can lead to thermal degradation and hydrolysis, affecting the final product quality. Developing robust processing techniques that maintain PLA's properties while allowing for efficient manufacturing is crucial for its widespread industrial adoption.

Lastly, the end-of-life management of PLA products faces technical hurdles. While theoretically compostable, PLA requires specific conditions for efficient decomposition. The lack of widespread industrial composting facilities and the potential contamination of recycling streams with PLA pose challenges for effective waste management. Developing better sorting technologies and establishing dedicated PLA recycling streams are necessary steps to fully realize its circular economy potential.

Current PLA Solutions

01 PLA-based composite materials

Development of composite materials using PLA as a base polymer, incorporating various additives or fillers to enhance properties such as strength, durability, or biodegradability. These composites can be used in a wide range of applications, from packaging to medical devices.- PLA-based composite materials: Development of composite materials using PLA as a base polymer, incorporating various additives or reinforcing agents to enhance properties such as strength, durability, and biodegradability. These composites can be used in a wide range of applications, from packaging to biomedical devices.

- PLA processing techniques: Innovative methods for processing PLA, including extrusion, injection molding, and 3D printing. These techniques aim to improve the material's performance, reduce production costs, and expand its potential applications in various industries.

- PLA blends and copolymers: Creation of PLA blends and copolymers with other biodegradable or synthetic polymers to overcome limitations of pure PLA, such as brittleness or low heat resistance. These modified materials offer improved properties for specific applications while maintaining biodegradability.

- PLA surface modifications: Development of surface modification techniques for PLA to enhance its properties such as hydrophilicity, adhesion, or biocompatibility. These modifications can improve the material's performance in specific applications, particularly in the biomedical field.

- PLA degradation and recycling: Research into PLA degradation mechanisms and development of efficient recycling processes. This includes studies on enzymatic degradation, composting conditions, and chemical recycling methods to address end-of-life issues and promote circular economy principles.

02 PLA processing techniques

Innovative methods for processing PLA, including extrusion, injection molding, and 3D printing. These techniques aim to improve the material's performance, reduce production costs, and expand its potential applications in various industries.Expand Specific Solutions03 PLA modification for improved properties

Chemical or physical modification of PLA to enhance its properties such as thermal stability, mechanical strength, or barrier properties. This includes techniques like blending with other polymers, crosslinking, or surface treatments to overcome limitations of pure PLA.Expand Specific Solutions04 Biodegradable PLA applications

Development of biodegradable products using PLA, focusing on environmentally friendly alternatives to traditional plastics. Applications include packaging materials, disposable items, and agricultural films that can decompose naturally without harming the environment.Expand Specific Solutions05 PLA in medical and pharmaceutical applications

Utilization of PLA in medical and pharmaceutical fields, including drug delivery systems, tissue engineering scaffolds, and bioabsorbable implants. The biocompatibility and controlled degradation properties of PLA make it suitable for various medical applications.Expand Specific Solutions

Key PLA Industry Players

The strategic importance of PLA in sustainable development is gaining momentum in a rapidly evolving market. The industry is in a growth phase, with increasing market size driven by environmental concerns and regulatory pressures. Technologically, PLA is maturing, but there's still room for innovation. Companies like Total Research Corp, 3M Innovative Properties Co., and Avantium Knowledge Centre BV are at the forefront, developing advanced PLA applications. Universities such as Cornell and Tongji are contributing significant research. The competitive landscape is diverse, with players from various sectors, including materials science (Arctic Biomaterials Oy), packaging (Graphic Packaging International LLC), and energy (TotalEnergies OneTech SAS), indicating the broad potential of PLA in sustainable solutions across industries.

Arctic Biomaterials Oy

Technical Solution: Arctic Biomaterials Oy has developed a proprietary technology for producing PLA (Polylactic Acid) composites reinforced with mineral fibers. Their approach focuses on enhancing the mechanical and thermal properties of PLA while maintaining its biodegradability. The company's technology involves a unique compounding process that ensures uniform dispersion of mineral fibers within the PLA matrix, resulting in a material with improved strength, stiffness, and heat resistance compared to standard PLA.

Strengths: Enhanced mechanical properties, improved heat resistance, maintains biodegradability. Weaknesses: Potentially higher production costs, limited scalability compared to traditional PLA manufacturing.

Floreon Technology Ltd.

Technical Solution: Floreon Technology Ltd. has developed an innovative additive technology for PLA that significantly enhances its performance characteristics. Their proprietary blend of additives, when combined with standard PLA, creates a material with improved impact resistance, durability, and processability. Floreon's technology allows for the production of PLA-based products with properties comparable to traditional petroleum-based plastics, while maintaining the biodegradability and compostability of PLA. This advancement enables the use of PLA in a wider range of applications, particularly in packaging and consumer goods sectors.

Strengths: Improved material properties, wider application range, maintains biodegradability. Weaknesses: Potential increase in material costs, may require modifications to existing PLA processing equipment.

PLA Core Innovations

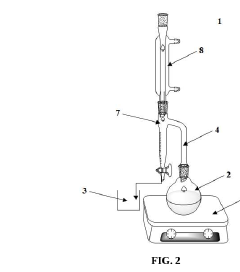

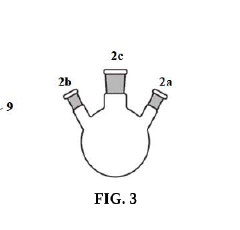

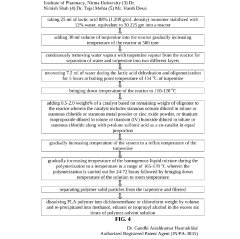

Synthesis of biopolymer polylactic acid using azeotropic polycondensation method

PatentPendingIN202421030473A

Innovation

- Azeotropic dehydrative polycondensation using turpentine, a FDA-approved green bio-solvent, is employed to synthesize PLA, allowing for solvent recovery and recycling, reducing environmental impact and operational costs.

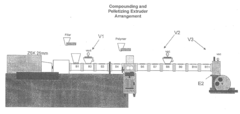

Sustainable compositions, related methods, and members formed therefrom

PatentInactiveUS20160108243A1

Innovation

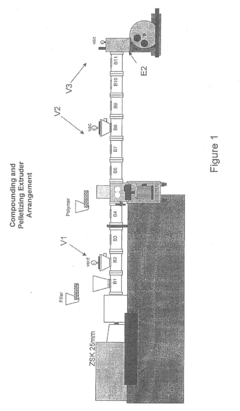

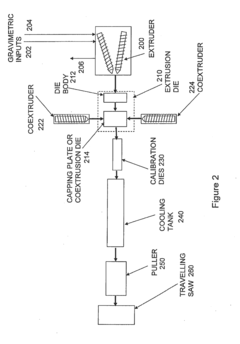

- A method of compounding and extruding PLA with wood fiber, using additives and controlled temperature profiles to enhance crystallization, resulting in improved heat distortion temperature and hydrolysis resistance, along with coextruding a capping material to improve mechanical properties and durability.

Environmental Impact of PLA

The environmental impact of PLA (Polylactic Acid) is a crucial aspect to consider in its strategic importance for sustainable development. PLA, derived from renewable resources such as corn starch or sugarcane, offers a promising alternative to traditional petroleum-based plastics.

One of the primary environmental benefits of PLA is its biodegradability. Under proper conditions, PLA can decompose into water, carbon dioxide, and biomass within a few months to several years, significantly reducing the long-term environmental burden compared to conventional plastics that persist for centuries.

PLA production also contributes to lower greenhouse gas emissions compared to petroleum-based plastics. Studies have shown that the production of PLA can result in up to 80% fewer carbon dioxide emissions than traditional plastic manufacturing processes. This reduction in carbon footprint aligns with global efforts to mitigate climate change and transition towards a low-carbon economy.

Furthermore, PLA's renewable sourcing helps conserve fossil fuel resources. By utilizing plant-based materials, PLA production reduces dependence on non-renewable petroleum, contributing to the preservation of finite resources and promoting a more sustainable material economy.

However, it is essential to consider the potential environmental trade-offs associated with PLA production. The cultivation of crops for PLA feedstock may lead to increased land use, potentially competing with food production or contributing to deforestation if not managed sustainably. Additionally, the use of fertilizers and pesticides in crop cultivation can have negative impacts on soil and water quality.

The end-of-life management of PLA products also presents both opportunities and challenges. While PLA is compostable under industrial conditions, it requires specific infrastructure and processes for proper decomposition. Improper disposal or mixing with conventional plastic waste streams can complicate recycling efforts and potentially lead to contamination of recycled materials.

To maximize the environmental benefits of PLA, it is crucial to implement comprehensive life cycle assessments and develop efficient recycling and composting systems. Continued research and development efforts should focus on improving PLA's properties, enhancing its biodegradability in various environments, and optimizing production processes to further reduce environmental impacts.

One of the primary environmental benefits of PLA is its biodegradability. Under proper conditions, PLA can decompose into water, carbon dioxide, and biomass within a few months to several years, significantly reducing the long-term environmental burden compared to conventional plastics that persist for centuries.

PLA production also contributes to lower greenhouse gas emissions compared to petroleum-based plastics. Studies have shown that the production of PLA can result in up to 80% fewer carbon dioxide emissions than traditional plastic manufacturing processes. This reduction in carbon footprint aligns with global efforts to mitigate climate change and transition towards a low-carbon economy.

Furthermore, PLA's renewable sourcing helps conserve fossil fuel resources. By utilizing plant-based materials, PLA production reduces dependence on non-renewable petroleum, contributing to the preservation of finite resources and promoting a more sustainable material economy.

However, it is essential to consider the potential environmental trade-offs associated with PLA production. The cultivation of crops for PLA feedstock may lead to increased land use, potentially competing with food production or contributing to deforestation if not managed sustainably. Additionally, the use of fertilizers and pesticides in crop cultivation can have negative impacts on soil and water quality.

The end-of-life management of PLA products also presents both opportunities and challenges. While PLA is compostable under industrial conditions, it requires specific infrastructure and processes for proper decomposition. Improper disposal or mixing with conventional plastic waste streams can complicate recycling efforts and potentially lead to contamination of recycled materials.

To maximize the environmental benefits of PLA, it is crucial to implement comprehensive life cycle assessments and develop efficient recycling and composting systems. Continued research and development efforts should focus on improving PLA's properties, enhancing its biodegradability in various environments, and optimizing production processes to further reduce environmental impacts.

PLA Policy Landscape

The policy landscape surrounding Polylactic Acid (PLA) has evolved significantly in recent years, reflecting the growing emphasis on sustainable development and circular economy principles. Governments worldwide are increasingly recognizing the strategic importance of biodegradable plastics like PLA in addressing environmental challenges and reducing dependence on fossil-based materials.

At the international level, several policy frameworks have been established to promote the adoption of bio-based materials. The United Nations Sustainable Development Goals (SDGs), particularly SDG 12 on responsible consumption and production, have provided a global impetus for the development and use of sustainable materials like PLA. This has led to increased funding and support for research and development in the field of bioplastics.

In the European Union, the European Green Deal and the Circular Economy Action Plan have set ambitious targets for reducing plastic waste and promoting bio-based alternatives. These policies have created a favorable environment for PLA production and use, with incentives for manufacturers to invest in sustainable materials and technologies. The EU's Single-Use Plastics Directive, which aims to reduce the impact of certain plastic products on the environment, has further boosted the demand for biodegradable alternatives like PLA.

In the United States, policies vary at the state and federal levels. Some states, such as California, have implemented comprehensive plastic reduction strategies that indirectly benefit PLA and other bioplastics. The USDA BioPreferred Program promotes the purchase and use of bio-based products, including those made from PLA, in federal agencies and their contractors.

Asian countries, particularly China and Japan, have also introduced policies to support the development of the bioplastics industry. China's ban on certain types of plastic waste imports has accelerated domestic efforts to develop sustainable alternatives, including PLA. Japan's Biomass Industrialization Strategy has set targets for increasing the production and use of bio-based materials, creating opportunities for PLA manufacturers.

However, the policy landscape for PLA is not without challenges. The lack of standardized end-of-life management systems for biodegradable plastics in many regions poses a significant hurdle. Additionally, conflicting regulations regarding the classification and disposal of bioplastics across different jurisdictions create confusion for manufacturers and consumers alike.

As the strategic importance of PLA in sustainable development becomes increasingly apparent, policymakers are working to address these challenges. Efforts are underway to develop harmonized standards for biodegradability and compostability, as well as to improve waste management infrastructure to accommodate bioplastics. These policy developments are likely to shape the future trajectory of PLA adoption and its role in achieving global sustainability goals.

At the international level, several policy frameworks have been established to promote the adoption of bio-based materials. The United Nations Sustainable Development Goals (SDGs), particularly SDG 12 on responsible consumption and production, have provided a global impetus for the development and use of sustainable materials like PLA. This has led to increased funding and support for research and development in the field of bioplastics.

In the European Union, the European Green Deal and the Circular Economy Action Plan have set ambitious targets for reducing plastic waste and promoting bio-based alternatives. These policies have created a favorable environment for PLA production and use, with incentives for manufacturers to invest in sustainable materials and technologies. The EU's Single-Use Plastics Directive, which aims to reduce the impact of certain plastic products on the environment, has further boosted the demand for biodegradable alternatives like PLA.

In the United States, policies vary at the state and federal levels. Some states, such as California, have implemented comprehensive plastic reduction strategies that indirectly benefit PLA and other bioplastics. The USDA BioPreferred Program promotes the purchase and use of bio-based products, including those made from PLA, in federal agencies and their contractors.

Asian countries, particularly China and Japan, have also introduced policies to support the development of the bioplastics industry. China's ban on certain types of plastic waste imports has accelerated domestic efforts to develop sustainable alternatives, including PLA. Japan's Biomass Industrialization Strategy has set targets for increasing the production and use of bio-based materials, creating opportunities for PLA manufacturers.

However, the policy landscape for PLA is not without challenges. The lack of standardized end-of-life management systems for biodegradable plastics in many regions poses a significant hurdle. Additionally, conflicting regulations regarding the classification and disposal of bioplastics across different jurisdictions create confusion for manufacturers and consumers alike.

As the strategic importance of PLA in sustainable development becomes increasingly apparent, policymakers are working to address these challenges. Efforts are underway to develop harmonized standards for biodegradability and compostability, as well as to improve waste management infrastructure to accommodate bioplastics. These policy developments are likely to shape the future trajectory of PLA adoption and its role in achieving global sustainability goals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!