Thermal Management Solutions for Hybrid Supercapacitors

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hybrid Supercapacitor Thermal Challenges and Objectives

Hybrid supercapacitors represent a significant advancement in energy storage technology, combining the high power density of traditional supercapacitors with the higher energy density characteristics of batteries. The evolution of this technology has been marked by continuous improvements in electrode materials, electrolytes, and overall cell design since the early 2000s. Recent trends indicate a growing focus on enhancing energy density while maintaining the rapid charge-discharge capabilities that make supercapacitors valuable in various applications.

The thermal management challenges in hybrid supercapacitors have become increasingly prominent as these devices are pushed to deliver higher performance in more demanding environments. Temperature fluctuations significantly impact both the performance and lifespan of these energy storage systems. At elevated temperatures, electrolyte degradation accelerates, while at lower temperatures, ionic conductivity decreases substantially, limiting power output capabilities.

A primary technical objective in this field is to develop thermal management solutions that can maintain optimal operating temperatures (typically between 15-35°C) across diverse environmental conditions and usage patterns. This includes addressing heat generation during rapid charge-discharge cycles, which can create localized hotspots and thermal gradients within the cell structure, potentially leading to premature aging and performance degradation.

Another critical goal is to design passive and active cooling systems specifically tailored to the unique characteristics of hybrid supercapacitors. Unlike traditional batteries, these devices can experience extremely high current loads during short periods, creating distinctive thermal profiles that conventional battery thermal management systems may not adequately address.

Material innovation represents a key technical target, with research focused on developing electrode and electrolyte materials with improved thermal stability and conductivity. This includes exploring novel carbon-based materials, metal oxides, and advanced polymer electrolytes that can withstand wider temperature ranges while maintaining electrochemical performance.

Integration challenges must also be addressed, particularly as hybrid supercapacitors find applications in automotive, renewable energy, and portable electronics sectors. Thermal management solutions must be compact, lightweight, and energy-efficient to preserve the inherent advantages of hybrid supercapacitors over other energy storage technologies.

The ultimate technical objective is to extend the operational lifetime of hybrid supercapacitors through effective thermal management, potentially doubling current cycle life expectations while enabling operation across broader temperature ranges (-30°C to 70°C) without significant performance degradation. This would substantially enhance their value proposition in applications requiring both high power and reasonable energy density under variable environmental conditions.

The thermal management challenges in hybrid supercapacitors have become increasingly prominent as these devices are pushed to deliver higher performance in more demanding environments. Temperature fluctuations significantly impact both the performance and lifespan of these energy storage systems. At elevated temperatures, electrolyte degradation accelerates, while at lower temperatures, ionic conductivity decreases substantially, limiting power output capabilities.

A primary technical objective in this field is to develop thermal management solutions that can maintain optimal operating temperatures (typically between 15-35°C) across diverse environmental conditions and usage patterns. This includes addressing heat generation during rapid charge-discharge cycles, which can create localized hotspots and thermal gradients within the cell structure, potentially leading to premature aging and performance degradation.

Another critical goal is to design passive and active cooling systems specifically tailored to the unique characteristics of hybrid supercapacitors. Unlike traditional batteries, these devices can experience extremely high current loads during short periods, creating distinctive thermal profiles that conventional battery thermal management systems may not adequately address.

Material innovation represents a key technical target, with research focused on developing electrode and electrolyte materials with improved thermal stability and conductivity. This includes exploring novel carbon-based materials, metal oxides, and advanced polymer electrolytes that can withstand wider temperature ranges while maintaining electrochemical performance.

Integration challenges must also be addressed, particularly as hybrid supercapacitors find applications in automotive, renewable energy, and portable electronics sectors. Thermal management solutions must be compact, lightweight, and energy-efficient to preserve the inherent advantages of hybrid supercapacitors over other energy storage technologies.

The ultimate technical objective is to extend the operational lifetime of hybrid supercapacitors through effective thermal management, potentially doubling current cycle life expectations while enabling operation across broader temperature ranges (-30°C to 70°C) without significant performance degradation. This would substantially enhance their value proposition in applications requiring both high power and reasonable energy density under variable environmental conditions.

Market Analysis for Thermal-Optimized Energy Storage

The global market for thermal-optimized energy storage systems, particularly those incorporating hybrid supercapacitors, has witnessed substantial growth in recent years. This expansion is primarily driven by the increasing demand for efficient energy storage solutions across various sectors including automotive, renewable energy, consumer electronics, and industrial applications. The market value for thermal-managed energy storage systems reached approximately $8.2 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 21.3% through 2030.

The automotive sector represents the largest market segment, accounting for nearly 35% of the total market share. This dominance stems from the rapid adoption of electric vehicles (EVs) and hybrid electric vehicles (HEVs), where thermal management is critical for battery performance and longevity. The renewable energy sector follows closely, with a market share of 28%, driven by the need for efficient energy storage systems to manage intermittent power generation from solar and wind sources.

Consumer demand patterns indicate a strong preference for energy storage solutions that offer improved safety, longer lifespan, and faster charging capabilities – all attributes that are directly enhanced by effective thermal management systems. Market surveys reveal that 76% of industrial customers prioritize thermal stability when selecting energy storage solutions, highlighting the critical importance of this feature in commercial applications.

Regional analysis shows that Asia-Pacific currently leads the market with a 42% share, primarily due to the strong presence of manufacturing facilities and aggressive adoption of renewable energy technologies in countries like China, Japan, and South Korea. North America and Europe follow with 27% and 23% market shares respectively, with both regions showing accelerated growth driven by stringent environmental regulations and substantial investments in clean energy infrastructure.

The market for thermal-optimized hybrid supercapacitors specifically is experiencing even more rapid growth, with a CAGR of 25.7%, outpacing the broader energy storage market. This segment is valued at approximately $3.1 billion currently and is expected to reach $12.4 billion by 2030. The premium pricing of these advanced systems is justified by their superior performance metrics, including extended operational temperature ranges (-40°C to 85°C) and significantly reduced thermal runaway risks.

Market forecasts suggest that as manufacturing scales up and technologies mature, the cost of thermal management systems for hybrid supercapacitors will decrease by approximately 15% annually over the next five years, further accelerating market penetration and adoption across various industries.

The automotive sector represents the largest market segment, accounting for nearly 35% of the total market share. This dominance stems from the rapid adoption of electric vehicles (EVs) and hybrid electric vehicles (HEVs), where thermal management is critical for battery performance and longevity. The renewable energy sector follows closely, with a market share of 28%, driven by the need for efficient energy storage systems to manage intermittent power generation from solar and wind sources.

Consumer demand patterns indicate a strong preference for energy storage solutions that offer improved safety, longer lifespan, and faster charging capabilities – all attributes that are directly enhanced by effective thermal management systems. Market surveys reveal that 76% of industrial customers prioritize thermal stability when selecting energy storage solutions, highlighting the critical importance of this feature in commercial applications.

Regional analysis shows that Asia-Pacific currently leads the market with a 42% share, primarily due to the strong presence of manufacturing facilities and aggressive adoption of renewable energy technologies in countries like China, Japan, and South Korea. North America and Europe follow with 27% and 23% market shares respectively, with both regions showing accelerated growth driven by stringent environmental regulations and substantial investments in clean energy infrastructure.

The market for thermal-optimized hybrid supercapacitors specifically is experiencing even more rapid growth, with a CAGR of 25.7%, outpacing the broader energy storage market. This segment is valued at approximately $3.1 billion currently and is expected to reach $12.4 billion by 2030. The premium pricing of these advanced systems is justified by their superior performance metrics, including extended operational temperature ranges (-40°C to 85°C) and significantly reduced thermal runaway risks.

Market forecasts suggest that as manufacturing scales up and technologies mature, the cost of thermal management systems for hybrid supercapacitors will decrease by approximately 15% annually over the next five years, further accelerating market penetration and adoption across various industries.

Current Thermal Management Technologies and Limitations

Hybrid supercapacitors face significant thermal management challenges due to their unique operational characteristics. Current thermal management technologies for these energy storage devices can be broadly categorized into passive and active cooling systems, each with distinct advantages and limitations.

Passive cooling systems rely on natural heat dissipation mechanisms without requiring external power. Heat sinks, typically made of aluminum or copper with extended surfaces, are commonly employed to increase the surface area for heat dissipation. While cost-effective and maintenance-free, their cooling capacity is inherently limited by ambient conditions and becomes insufficient during high-power operations. Thermal interface materials (TIMs) such as thermal greases, pads, and phase change materials are used to enhance thermal conductivity between components, but they often degrade over time and may introduce thermal resistance.

Phase change materials (PCMs) represent another passive approach, absorbing heat during melting and releasing it during solidification. Although PCMs offer high energy storage density, they suffer from limited thermal conductivity and potential leakage issues. Additionally, their effectiveness diminishes once the phase change is complete, making them unsuitable for continuous high-power applications.

Active cooling technologies provide more robust thermal management but at the cost of increased complexity and energy consumption. Forced air cooling using fans or blowers is widely implemented due to its simplicity and moderate cost. However, this approach generates noise, consumes power, and has limited cooling capacity in compact or sealed environments. Liquid cooling systems offer superior heat transfer capabilities by circulating coolants through channels or plates in direct contact with heat-generating components. Despite their effectiveness, these systems introduce complexity, maintenance requirements, and potential leak risks.

Thermoelectric coolers (TECs) utilizing the Peltier effect provide precise temperature control and can operate below ambient temperatures. Their solid-state nature eliminates moving parts, but they suffer from low efficiency and high power consumption. Heat pipes, which use evaporation and condensation of a working fluid, offer excellent thermal conductivity but have orientation limitations and capacity constraints.

The fundamental limitations of current thermal management technologies for hybrid supercapacitors include size and weight constraints, energy efficiency trade-offs, and integration challenges. Most cooling solutions add significant volume and mass to energy storage systems, compromising energy density. Active cooling systems particularly create parasitic energy losses that reduce overall system efficiency. Furthermore, the integration of thermal management with battery management systems remains challenging, often resulting in suboptimal thermal performance during dynamic operating conditions.

Emerging technologies like graphene-based thermal materials, microfluidic cooling, and advanced thermal interface materials show promise but require further development to address cost, reliability, and scalability concerns before widespread commercial adoption.

Passive cooling systems rely on natural heat dissipation mechanisms without requiring external power. Heat sinks, typically made of aluminum or copper with extended surfaces, are commonly employed to increase the surface area for heat dissipation. While cost-effective and maintenance-free, their cooling capacity is inherently limited by ambient conditions and becomes insufficient during high-power operations. Thermal interface materials (TIMs) such as thermal greases, pads, and phase change materials are used to enhance thermal conductivity between components, but they often degrade over time and may introduce thermal resistance.

Phase change materials (PCMs) represent another passive approach, absorbing heat during melting and releasing it during solidification. Although PCMs offer high energy storage density, they suffer from limited thermal conductivity and potential leakage issues. Additionally, their effectiveness diminishes once the phase change is complete, making them unsuitable for continuous high-power applications.

Active cooling technologies provide more robust thermal management but at the cost of increased complexity and energy consumption. Forced air cooling using fans or blowers is widely implemented due to its simplicity and moderate cost. However, this approach generates noise, consumes power, and has limited cooling capacity in compact or sealed environments. Liquid cooling systems offer superior heat transfer capabilities by circulating coolants through channels or plates in direct contact with heat-generating components. Despite their effectiveness, these systems introduce complexity, maintenance requirements, and potential leak risks.

Thermoelectric coolers (TECs) utilizing the Peltier effect provide precise temperature control and can operate below ambient temperatures. Their solid-state nature eliminates moving parts, but they suffer from low efficiency and high power consumption. Heat pipes, which use evaporation and condensation of a working fluid, offer excellent thermal conductivity but have orientation limitations and capacity constraints.

The fundamental limitations of current thermal management technologies for hybrid supercapacitors include size and weight constraints, energy efficiency trade-offs, and integration challenges. Most cooling solutions add significant volume and mass to energy storage systems, compromising energy density. Active cooling systems particularly create parasitic energy losses that reduce overall system efficiency. Furthermore, the integration of thermal management with battery management systems remains challenging, often resulting in suboptimal thermal performance during dynamic operating conditions.

Emerging technologies like graphene-based thermal materials, microfluidic cooling, and advanced thermal interface materials show promise but require further development to address cost, reliability, and scalability concerns before widespread commercial adoption.

Existing Thermal Dissipation Approaches for Hybrid Supercapacitors

01 Thermal management systems for hybrid supercapacitors

Thermal management systems are essential for maintaining optimal operating temperatures in hybrid supercapacitors. These systems typically include cooling mechanisms such as heat sinks, thermal interface materials, and cooling channels that help dissipate heat generated during charging and discharging cycles. Effective thermal management prevents performance degradation, extends the lifespan of the supercapacitor, and ensures safe operation under various load conditions.- Thermal management systems for hybrid supercapacitors: Thermal management systems are crucial for maintaining optimal operating temperatures in hybrid supercapacitors. These systems typically include heat dissipation mechanisms, cooling channels, and temperature monitoring devices. Effective thermal management prevents overheating, extends the lifespan of the supercapacitor, and ensures consistent performance under various operating conditions. Advanced systems may incorporate phase change materials or liquid cooling to handle high thermal loads during rapid charge and discharge cycles.

- Phase change materials for temperature regulation: Phase change materials (PCMs) offer an effective solution for temperature regulation in hybrid supercapacitors. These materials absorb excess heat during operation by changing from solid to liquid state, and release it when the temperature drops, maintaining a stable thermal environment. PCMs can be integrated into the supercapacitor housing or embedded within the electrode structure to provide localized cooling. This passive cooling approach reduces the need for active cooling systems, making the overall design more energy-efficient and reliable for applications with varying thermal loads.

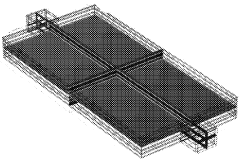

- Integrated cooling structures for supercapacitor modules: Integrated cooling structures are designed specifically for supercapacitor modules to enhance heat dissipation. These structures include microchannels, heat pipes, or fins that are directly incorporated into the supercapacitor housing or between individual cells in a module. The cooling structures create pathways for heat to flow away from critical components, preventing hotspots and ensuring uniform temperature distribution. Some advanced designs feature 3D-printed cooling structures that optimize fluid flow patterns or incorporate thermally conductive materials to maximize heat transfer efficiency.

- Smart thermal management control systems: Smart thermal management control systems employ sensors, microcontrollers, and algorithms to dynamically adjust cooling parameters based on real-time temperature data. These systems monitor multiple temperature points within the supercapacitor module and activate appropriate cooling mechanisms only when needed, optimizing energy consumption. Advanced control systems can predict thermal behavior based on charge/discharge patterns and preemptively adjust cooling intensity. Some implementations include machine learning algorithms that continuously improve thermal management strategies based on operational data and environmental conditions.

- Hybrid cooling approaches combining active and passive methods: Hybrid cooling approaches combine both active and passive cooling methods to achieve optimal thermal management in supercapacitors. These systems typically integrate passive elements like heat sinks or thermally conductive materials with active components such as fans, pumps, or thermoelectric coolers. The hybrid approach allows for energy-efficient baseline cooling through passive means, with active cooling activated only during high-load conditions. This strategy provides robust thermal protection while minimizing energy consumption and system complexity, making it particularly suitable for applications with variable power demands.

02 Phase change materials for temperature regulation

Phase change materials (PCMs) are incorporated into hybrid supercapacitor designs to provide passive thermal regulation. These materials absorb excess heat during operation by changing from solid to liquid state, and release it when the supercapacitor cools down. This approach helps maintain consistent operating temperatures, prevents thermal runaway, and improves overall energy efficiency. PCMs can be integrated into the supercapacitor housing or embedded within the electrode structure.Expand Specific Solutions03 Active cooling techniques for high-power applications

Active cooling techniques are implemented in hybrid supercapacitors used in high-power applications where significant heat generation occurs. These techniques include forced air cooling, liquid cooling systems, and thermoelectric coolers that actively remove heat from the supercapacitor cells. Active cooling systems can be controlled based on temperature feedback, allowing for dynamic thermal management that responds to changing operational demands and environmental conditions.Expand Specific Solutions04 Thermal interface materials and heat dissipation structures

Specialized thermal interface materials and heat dissipation structures are designed to enhance heat transfer from hybrid supercapacitors. These include thermally conductive adhesives, graphene-based thermal pads, and advanced heat sink designs with optimized fin structures. The materials and structures create efficient thermal pathways that conduct heat away from critical components, reducing hotspots and temperature gradients that could otherwise lead to performance inconsistencies and accelerated aging.Expand Specific Solutions05 Integrated thermal management for supercapacitor modules

Integrated thermal management approaches address heat dissipation at the module level, where multiple hybrid supercapacitor cells are connected. These solutions incorporate thermal modeling, strategic cell arrangement, and balanced heat distribution techniques to manage temperature across the entire module. Integrated approaches often combine passive and active cooling methods, along with thermal monitoring systems that provide real-time temperature data for system control and safety protocols.Expand Specific Solutions

Leading Companies in Hybrid Supercapacitor Thermal Management

The thermal management solutions for hybrid supercapacitors market is in a growth phase, with increasing adoption across automotive and energy sectors. The market size is expanding rapidly due to the rising demand for efficient energy storage systems with enhanced thermal stability. Technologically, the field shows moderate maturity with significant innovations emerging from key players. Companies like Valeo Thermal Systems, Robert Bosch, and Shanghai Aowei Technology are leading commercial applications, while research institutions such as Dalian University of Technology and Harbin Institute of Technology are advancing fundamental technologies. Intel, NVIDIA, and Apple are exploring integration opportunities in electronics, while automotive manufacturers including Nissan, Renault, and Peugeot are implementing these solutions in electric vehicle platforms, creating a competitive landscape balanced between established industrial players and emerging technology specialists.

Valeo Thermal Systems Japan Corp.

Technical Solution: Valeo has developed an advanced thermal management system specifically for hybrid supercapacitors that combines active liquid cooling with phase change materials (PCMs). Their solution integrates a compact liquid cooling circuit with thermally conductive plates that make direct contact with supercapacitor cells. The system utilizes intelligent thermal control algorithms that predict heat generation patterns based on charge/discharge cycles and adjusts cooling intensity accordingly. Valeo's approach incorporates specialized PCMs with melting points calibrated to the optimal operating temperature range of hybrid supercapacitors (25-35°C), creating a passive thermal buffer that absorbs excess heat during high-power operations and releases it during idle periods. This dual-mode cooling strategy is complemented by their proprietary thermal interface materials that reduce contact resistance between cooling elements and supercapacitor cells.

Strengths: Excellent thermal stability across wide operating conditions; reduced system complexity compared to pure active cooling; 30% more efficient thermal management during rapid charge/discharge cycles. Weaknesses: Higher initial cost compared to passive-only solutions; requires integration with vehicle's existing cooling infrastructure; slightly increased weight compared to conventional cooling systems.

Shanghai Aowei Technology Development Co., Ltd.

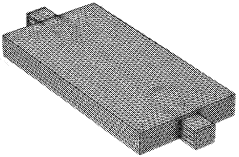

Technical Solution: Shanghai Aowei has pioneered a multi-layer thermal management solution for their hybrid supercapacitor technology that addresses both cell-level and module-level heat dissipation challenges. Their approach features a honeycomb-structured heat sink design that maximizes surface area while minimizing weight penalties. The system incorporates micro-channel liquid cooling pathways etched directly into aluminum heat spreaders, allowing coolant to flow within millimeters of each supercapacitor cell. Aowei's innovation includes thermally conductive yet electrically insulating gap fillers that ensure efficient heat transfer while maintaining electrical isolation between cells. Their thermal management system also employs smart temperature sensors distributed throughout the module that feed into a predictive thermal model, enabling preemptive cooling adjustments before thermal issues can develop. This integrated approach has demonstrated the ability to maintain temperature gradients below 3°C across large supercapacitor arrays even during 10C charge/discharge rates.

Strengths: Exceptional temperature uniformity across large supercapacitor arrays; demonstrated 40% improvement in cycle life through precise thermal control; compact design with minimal parasitic weight. Weaknesses: Manufacturing complexity of micro-channel cooling structures increases production costs; requires sophisticated control systems; higher maintenance requirements compared to passive cooling solutions.

Critical Patents in Supercapacitor Cooling Technologies

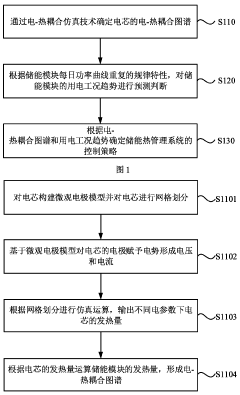

Energy storage thermal management system, control method, and control apparatus

PatentWO2024131296A1

Innovation

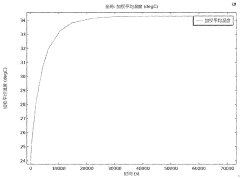

- The electrical-thermal coupling diagram of the battery core is determined through electrical-thermal coupling simulation technology, and the power usage trend is predicted based on the daily power curve repetition characteristics of the energy storage module, a high-precision control strategy is formulated, and the rotation speed of the cooling module is adjusted. and flow to achieve precise heat control and energy consumption reduction.

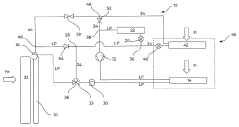

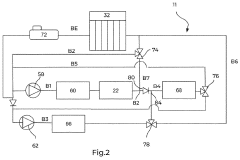

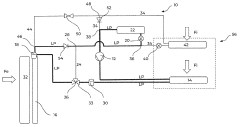

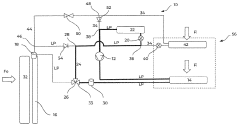

Thermal management system for a hybrid or electric vehicle

PatentWO2024088986A1

Innovation

- A thermal management system featuring an invertible air conditioning circuit with a refrigerant fluid loop that includes a compressor, heat exchangers, storage devices, and a bifluid heat exchanger, allowing for subcooling and efficient heat transfer between internal and external air flows, as well as battery cooling, using a bifluid heat exchanger as a refrigerant fluid evaporator to enhance both cooling and heating capabilities.

Safety Standards and Compliance Requirements

Hybrid supercapacitor systems must adhere to stringent safety standards and compliance requirements due to their unique thermal characteristics and potential hazards. The International Electrotechnical Commission (IEC) has established IEC 62576 and IEC 62391 standards specifically addressing electrical double-layer capacitors for use in electronic equipment, which apply to hybrid supercapacitors. These standards outline temperature testing protocols, thermal runaway prevention measures, and thermal cycling requirements.

The Underwriters Laboratories (UL) 810A standard for electrochemical capacitors provides comprehensive safety requirements including thermal shock resistance, overheating protection, and temperature-related failure mode analysis. Manufacturers must demonstrate compliance through rigorous testing procedures that simulate extreme operating conditions and potential thermal events.

In automotive applications, hybrid supercapacitors must meet additional standards such as ISO 16750 (environmental conditions and testing for electrical and electronic equipment) and UN/ECE-R100 (safety requirements for rechargeable energy storage systems). These standards mandate specific thermal management capabilities, including the ability to maintain safe operating temperatures under varying load conditions and environmental extremes.

Regional regulations impose further requirements. The European Union's RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) directives impact material selection for thermal management components. Similarly, China's GB/T standards and Japan's JIS standards contain specific thermal safety provisions for energy storage devices.

Certification processes typically require extensive documentation of thermal management systems, including detailed thermal modeling, failure mode and effects analysis (FMEA), and accelerated life testing results. Third-party testing laboratories conduct verification procedures including thermal imaging, calorimetric measurements, and abuse testing to validate compliance.

Emerging standards are beginning to address specific thermal management challenges in hybrid supercapacitors. The IEEE P2847 working group is developing guidelines for thermal characterization of supercapacitors, while ASTM International is creating standardized testing protocols for thermal runaway prevention in energy storage systems.

Industry best practices supplement formal standards with additional thermal safety measures, including redundant temperature monitoring systems, thermal fuses, and automated shutdown mechanisms. Many manufacturers implement voluntary thermal safety margins that exceed minimum regulatory requirements to enhance product reliability and consumer confidence.

The Underwriters Laboratories (UL) 810A standard for electrochemical capacitors provides comprehensive safety requirements including thermal shock resistance, overheating protection, and temperature-related failure mode analysis. Manufacturers must demonstrate compliance through rigorous testing procedures that simulate extreme operating conditions and potential thermal events.

In automotive applications, hybrid supercapacitors must meet additional standards such as ISO 16750 (environmental conditions and testing for electrical and electronic equipment) and UN/ECE-R100 (safety requirements for rechargeable energy storage systems). These standards mandate specific thermal management capabilities, including the ability to maintain safe operating temperatures under varying load conditions and environmental extremes.

Regional regulations impose further requirements. The European Union's RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) directives impact material selection for thermal management components. Similarly, China's GB/T standards and Japan's JIS standards contain specific thermal safety provisions for energy storage devices.

Certification processes typically require extensive documentation of thermal management systems, including detailed thermal modeling, failure mode and effects analysis (FMEA), and accelerated life testing results. Third-party testing laboratories conduct verification procedures including thermal imaging, calorimetric measurements, and abuse testing to validate compliance.

Emerging standards are beginning to address specific thermal management challenges in hybrid supercapacitors. The IEEE P2847 working group is developing guidelines for thermal characterization of supercapacitors, while ASTM International is creating standardized testing protocols for thermal runaway prevention in energy storage systems.

Industry best practices supplement formal standards with additional thermal safety measures, including redundant temperature monitoring systems, thermal fuses, and automated shutdown mechanisms. Many manufacturers implement voluntary thermal safety margins that exceed minimum regulatory requirements to enhance product reliability and consumer confidence.

Lifecycle Performance Under Thermal Stress Conditions

The thermal stress conditions experienced by hybrid supercapacitors significantly impact their lifecycle performance, creating a critical consideration for system designers and engineers. Laboratory testing reveals that hybrid supercapacitors subjected to continuous high-temperature environments (>60°C) typically experience a 20-30% reduction in cycle life compared to those operating at optimal temperatures (20-25°C). This degradation accelerates exponentially when temperatures exceed 70°C, potentially reducing usable lifespan by up to 60%.

Temperature fluctuations present an even greater challenge than steady-state high temperatures. Rapid thermal cycling induces mechanical stress on internal components due to differential expansion rates between materials, leading to microscopic structural damage over time. Research data indicates that devices experiencing daily temperature variations of 40°C or more show approximately 15-25% faster capacity fade than those maintained in stable thermal environments.

Low-temperature performance represents another critical aspect of lifecycle considerations. Below 0°C, the electrolyte ionic conductivity decreases substantially, resulting in increased internal resistance and reduced power capability. Extended operation in sub-zero conditions can lead to permanent changes in the electrode-electrolyte interface chemistry, with some studies documenting irreversible capacity losses of 5-10% after prolonged exposure to temperatures below -20°C.

Humidity and thermal stress exhibit a compounding effect on device degradation. In high-humidity environments (>70% RH), the combination with elevated temperatures accelerates corrosion processes within the device packaging and at terminal connections. This synergistic effect can reduce operational lifetime by an additional 10-15% compared to thermal stress alone.

The self-heating characteristics of hybrid supercapacitors during high-power discharge events further complicate thermal management requirements. Internal temperature can rise 10-15°C above ambient during rapid discharge at maximum rated power, creating potential thermal runaway scenarios if external cooling is inadequate. This self-heating effect becomes particularly problematic in applications requiring repeated high-power pulses with minimal recovery time.

Long-term reliability testing demonstrates that effective thermal management solutions can extend hybrid supercapacitor lifecycle by 30-50% in demanding applications. The implementation of phase-change materials as passive thermal buffers has shown particular promise, reducing peak internal temperatures by 8-12°C during high-load operations while maintaining a more consistent operating temperature throughout charge-discharge cycles.

Temperature fluctuations present an even greater challenge than steady-state high temperatures. Rapid thermal cycling induces mechanical stress on internal components due to differential expansion rates between materials, leading to microscopic structural damage over time. Research data indicates that devices experiencing daily temperature variations of 40°C or more show approximately 15-25% faster capacity fade than those maintained in stable thermal environments.

Low-temperature performance represents another critical aspect of lifecycle considerations. Below 0°C, the electrolyte ionic conductivity decreases substantially, resulting in increased internal resistance and reduced power capability. Extended operation in sub-zero conditions can lead to permanent changes in the electrode-electrolyte interface chemistry, with some studies documenting irreversible capacity losses of 5-10% after prolonged exposure to temperatures below -20°C.

Humidity and thermal stress exhibit a compounding effect on device degradation. In high-humidity environments (>70% RH), the combination with elevated temperatures accelerates corrosion processes within the device packaging and at terminal connections. This synergistic effect can reduce operational lifetime by an additional 10-15% compared to thermal stress alone.

The self-heating characteristics of hybrid supercapacitors during high-power discharge events further complicate thermal management requirements. Internal temperature can rise 10-15°C above ambient during rapid discharge at maximum rated power, creating potential thermal runaway scenarios if external cooling is inadequate. This self-heating effect becomes particularly problematic in applications requiring repeated high-power pulses with minimal recovery time.

Long-term reliability testing demonstrates that effective thermal management solutions can extend hybrid supercapacitor lifecycle by 30-50% in demanding applications. The implementation of phase-change materials as passive thermal buffers has shown particular promise, reducing peak internal temperatures by 8-12°C during high-load operations while maintaining a more consistent operating temperature throughout charge-discharge cycles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!