Transforming Modern Industries with Innovations in Cellulose Acetate

Cellulose Acetate Evolution and Innovation Goals

Cellulose acetate has a rich history dating back to its discovery in the late 19th century. Initially developed as a substitute for celluloid, it quickly found applications in various industries due to its unique properties. The evolution of cellulose acetate has been marked by continuous improvements in production processes and the expansion of its applications.

In the early 20th century, cellulose acetate gained prominence in the textile industry, particularly in the production of artificial silk. This breakthrough led to the development of acetate fibers, which offered advantages such as softness, luster, and ease of dyeing. As manufacturing techniques advanced, cellulose acetate found its way into the film industry, becoming a popular base for photographic films and motion picture films.

The mid-20th century saw cellulose acetate expanding into new territories, including the production of eyeglass frames, tool handles, and various consumer goods. Its versatility and moldability made it an attractive material for designers and manufacturers alike. The plastics revolution further propelled the use of cellulose acetate in diverse applications, from packaging materials to automotive components.

Recent decades have witnessed a renewed interest in cellulose acetate due to growing environmental concerns. As a biodegradable and renewable material, it aligns well with the principles of sustainability and circular economy. This has led to increased research and development efforts to enhance its properties and explore novel applications.

Looking ahead, the innovation goals for cellulose acetate are multifaceted. One primary objective is to improve its mechanical properties, making it more durable and suitable for high-performance applications. Researchers are exploring ways to enhance its heat resistance, impact strength, and overall stability without compromising its biodegradability.

Another key goal is to expand the range of cellulose acetate-based composites. By combining it with other materials, scientists aim to create hybrid materials that offer superior performance characteristics while maintaining environmental benefits. This includes developing cellulose acetate-based nanocomposites with enhanced barrier properties for packaging applications.

Sustainability remains a central focus, with efforts directed towards optimizing production processes to reduce energy consumption and minimize waste. Researchers are also investigating ways to improve the biodegradability of cellulose acetate products, ensuring faster decomposition in various environmental conditions.

In the medical field, there is growing interest in utilizing cellulose acetate for drug delivery systems and tissue engineering scaffolds. The biocompatibility of the material makes it an attractive candidate for these applications, with ongoing research aimed at tailoring its properties for specific medical uses.

Market Demand Analysis for Cellulose Acetate Products

The global market for cellulose acetate products has been experiencing steady growth, driven by increasing demand across various industries. The versatility and eco-friendly nature of cellulose acetate have positioned it as a preferred material in multiple applications, particularly in the textile, packaging, and consumer goods sectors.

In the textile industry, cellulose acetate fibers are gaining popularity due to their softness, breathability, and moisture-wicking properties. The growing awareness of sustainable fashion has led to a surge in demand for cellulose acetate-based fabrics, as they offer a more environmentally friendly alternative to synthetic fibers. This trend is expected to continue, with the market for cellulose acetate textiles projected to expand significantly in the coming years.

The packaging industry represents another key growth area for cellulose acetate products. With increasing concerns about plastic pollution, many companies are turning to biodegradable and compostable packaging solutions. Cellulose acetate films and sheets are being widely adopted for food packaging, pharmaceutical blister packs, and other consumer goods packaging applications. The demand for these sustainable packaging materials is anticipated to rise sharply as more countries implement stricter regulations on single-use plastics.

In the consumer goods sector, cellulose acetate is finding applications in various products, including eyewear frames, personal care items, and household goods. The material's durability, flexibility, and aesthetic appeal make it an attractive choice for manufacturers looking to reduce their environmental footprint without compromising on product quality.

The automotive industry is also emerging as a potential growth market for cellulose acetate products. As automakers strive to reduce vehicle weight and improve fuel efficiency, cellulose acetate composites are being explored as alternatives to traditional materials in interior components and trim.

Geographically, Asia-Pacific is expected to be the fastest-growing market for cellulose acetate products, driven by rapid industrialization, increasing disposable incomes, and growing environmental awareness in countries like China and India. North America and Europe are also significant markets, with a strong focus on sustainable materials in various industries.

Despite the positive outlook, the cellulose acetate market faces challenges such as competition from other bio-based materials and the need for continuous innovation to improve performance and reduce production costs. However, ongoing research and development efforts are addressing these challenges, focusing on enhancing the material's properties and expanding its applications.

Current State and Challenges in Cellulose Acetate Technology

Cellulose acetate technology has made significant strides in recent years, revolutionizing various industries with its versatile applications. Currently, the global market for cellulose acetate is experiencing steady growth, driven by increasing demand in textiles, cigarette filters, and packaging materials. The technology has evolved to offer improved properties, such as enhanced biodegradability and thermal stability, making it an attractive alternative to traditional plastics in many sectors.

Despite these advancements, the cellulose acetate industry faces several challenges. One of the primary concerns is the environmental impact of acetate production, particularly the use of acetic anhydride and other chemicals in the manufacturing process. Efforts are underway to develop more sustainable production methods, including the exploration of bio-based alternatives for acetylation agents.

Another significant challenge is the limited availability of high-quality cellulose sources. As the demand for cellulose acetate grows, there is increasing pressure on raw material supplies, leading to potential price fluctuations and supply chain disruptions. This has prompted research into alternative cellulose sources, such as agricultural waste and non-wood plant fibers.

The industry is also grappling with the need for improved performance characteristics to expand cellulose acetate's applications. While current formulations offer good optical clarity and moldability, there is a push to enhance properties like heat resistance, mechanical strength, and barrier properties to compete with other materials in high-performance applications.

Recycling and end-of-life management of cellulose acetate products present another hurdle. Although the material is biodegradable under certain conditions, the rate of decomposition can be slow, and proper disposal infrastructure is not widely available. Developing efficient recycling technologies and improving the material's compostability are key areas of focus for researchers and industry stakeholders.

Geographically, the cellulose acetate technology landscape is diverse, with significant production capabilities in North America, Europe, and Asia. China has emerged as a major player in recent years, investing heavily in production capacity and research. However, concerns about intellectual property protection and technology transfer continue to shape the global competitive landscape.

In conclusion, while cellulose acetate technology has made remarkable progress, it still faces substantial challenges in sustainability, raw material sourcing, performance enhancement, and end-of-life management. Addressing these issues will be crucial for the continued growth and adoption of cellulose acetate across various industries, paving the way for more sustainable and innovative applications in the future.

Existing Cellulose Acetate Manufacturing Processes

01 Cellulose acetate production methods

Various methods for producing cellulose acetate are described, including improvements in acetylation processes, solvent systems, and reaction conditions. These methods aim to enhance the efficiency and quality of cellulose acetate production, potentially leading to better material properties for diverse applications.- Production methods for cellulose acetate: Various methods for producing cellulose acetate are described, including improvements in acetylation processes, solvent systems, and reaction conditions. These methods aim to enhance the efficiency and quality of cellulose acetate production, potentially leading to better material properties for diverse applications.

- Cellulose acetate fibers and films: Innovations in the production and processing of cellulose acetate fibers and films are presented. These advancements focus on improving the physical properties, durability, and functionality of cellulose acetate-based materials for use in textiles, packaging, and other industrial applications.

- Cellulose acetate composites and blends: Development of cellulose acetate composites and blends with other materials to enhance performance characteristics. These innovations aim to create materials with improved mechanical properties, biodegradability, or specific functionalities for various applications in industries such as packaging, construction, and consumer goods.

- Modification and functionalization of cellulose acetate: Techniques for modifying and functionalizing cellulose acetate to impart new properties or enhance existing ones. These methods include chemical modifications, surface treatments, and the incorporation of additives to create cellulose acetate derivatives with tailored characteristics for specific applications.

- Applications of cellulose acetate in various industries: Exploration of novel applications for cellulose acetate in diverse industries, including but not limited to pharmaceuticals, electronics, and environmental remediation. These innovations leverage the unique properties of cellulose acetate to develop new products or improve existing ones in areas such as drug delivery systems, membrane technologies, and sustainable materials.

02 Cellulose acetate fiber applications

Cellulose acetate fibers are utilized in a wide range of applications, including textiles, filters, and composite materials. The unique properties of these fibers, such as biodegradability and versatility, make them suitable for various industrial and consumer products.Expand Specific Solutions03 Cellulose acetate film and membrane technology

Advancements in cellulose acetate film and membrane technology are presented, focusing on improved manufacturing techniques and novel applications. These developments enhance the performance of cellulose acetate in areas such as separation processes, packaging, and optical films.Expand Specific Solutions04 Modification and blending of cellulose acetate

Techniques for modifying cellulose acetate and blending it with other materials are explored to enhance its properties. These modifications can improve characteristics such as thermal stability, mechanical strength, and compatibility with other polymers, expanding the potential applications of cellulose acetate.Expand Specific Solutions05 Cellulose acetate in sustainable and biodegradable products

The use of cellulose acetate in environmentally friendly and biodegradable products is investigated. This includes research into improving the biodegradability of cellulose acetate materials and developing sustainable alternatives to traditional plastics in various industries.Expand Specific Solutions

Key Players in Cellulose Acetate Industry

The cellulose acetate industry is in a mature stage, with a global market size expected to reach $5.9 billion by 2027. The technology's maturity is evident in the diverse applications across various sectors, including textiles, packaging, and electronics. Key players like Daicel Corp., BASF Corp., and Eastman Chemical Co. are driving innovation in this field. Research institutions such as Beijing Forestry University and the Chinese Academy of Science Institute of Chemistry are contributing to advancements in cellulose acetate technology. The competitive landscape is characterized by a mix of established chemical companies and specialized manufacturers, with increasing focus on sustainable and bio-based alternatives to traditional cellulose acetate products.

Daicel Corp.

Eastman Chemical Co.

Core Innovations in Cellulose Acetate Production

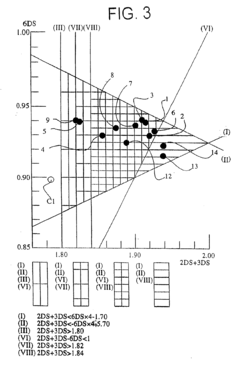

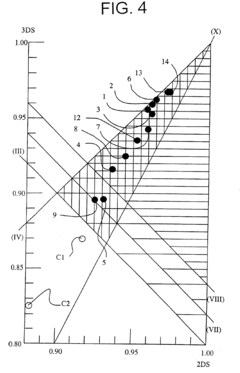

- Development of a molded composite material using cellulose acetate as a binder with natural cellulose fibers, achieving a degree of substitution (DS) of 1.2 to 2.7 and a mass ratio of 10:90 to 90:10, allowing for biodegradability and high Vicat temperatures without the need for external plasticizers, utilizing processing conditions such as moisture content, temperature, and pressure to enhance mechanical and thermal properties.

- A process involving ripening cellulose acetate in the presence of a catalyst, an acetyl donor, and water or alcohol, with controlled amounts of water and alcohol (0.1 to 10 mol % based on the acetyl donor, to adjust and control the intermolecular or intramolecular degree of acetyl substitution, improving solubility and physical characteristics.

Environmental Impact and Sustainability Considerations

Cellulose acetate, a versatile biopolymer derived from natural sources, has gained significant attention in recent years due to its potential to transform various industries while addressing environmental concerns. As industries worldwide strive to reduce their carbon footprint and adopt more sustainable practices, cellulose acetate emerges as a promising alternative to conventional petroleum-based materials.

One of the primary environmental benefits of cellulose acetate lies in its biodegradability. Unlike traditional plastics that persist in the environment for centuries, cellulose acetate can decompose naturally within a few months to a few years, depending on environmental conditions. This characteristic significantly reduces the long-term environmental impact associated with product disposal and helps mitigate the growing problem of plastic pollution in ecosystems.

Furthermore, the production of cellulose acetate from renewable resources, such as wood pulp or cotton linters, contributes to a more sustainable material lifecycle. By utilizing biomass feedstocks, the reliance on finite fossil fuel resources is diminished, leading to a reduction in greenhouse gas emissions and overall carbon footprint. This aligns with global efforts to transition towards a circular economy and reduce dependence on non-renewable resources.

The energy efficiency of cellulose acetate production processes has also improved significantly in recent years. Innovations in manufacturing techniques have led to reduced energy consumption and minimized waste generation during production. Additionally, advancements in recycling technologies have made it possible to recover and reuse cellulose acetate materials, further enhancing their sustainability profile.

However, it is essential to consider the potential environmental trade-offs associated with cellulose acetate production. The cultivation and harvesting of raw materials for cellulose acetate may have implications for land use, biodiversity, and water resources. Sustainable forestry practices and responsible sourcing of raw materials are crucial to mitigate these concerns and ensure the overall environmental benefits of cellulose acetate adoption.

Water consumption and chemical usage in cellulose acetate production processes also warrant attention from a sustainability perspective. Ongoing research and development efforts focus on optimizing these aspects to minimize environmental impact while maintaining product quality and performance. Innovations in water recycling systems and the development of eco-friendly chemical alternatives are promising avenues for further improving the sustainability of cellulose acetate production.

As industries continue to explore and implement cellulose acetate-based solutions, life cycle assessments and environmental impact studies play a crucial role in quantifying the overall sustainability benefits. These analyses help identify areas for improvement and guide decision-making processes in product development and manufacturing. By considering the entire lifecycle of cellulose acetate products, from raw material sourcing to end-of-life management, industries can maximize the environmental benefits and minimize potential negative impacts.

Regulatory Framework for Cellulose Acetate Applications

The regulatory framework for cellulose acetate applications plays a crucial role in shaping the industry's landscape and ensuring the safe and responsible use of this versatile material. As cellulose acetate continues to transform modern industries, regulatory bodies worldwide have established comprehensive guidelines and standards to govern its production, application, and disposal.

In the United States, the Food and Drug Administration (FDA) oversees the use of cellulose acetate in food packaging and medical devices. The agency has set specific requirements for the material's composition, manufacturing processes, and safety testing to ensure its suitability for these applications. Similarly, the Environmental Protection Agency (EPA) regulates the environmental impact of cellulose acetate production and disposal, particularly focusing on emissions control and waste management practices.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to cellulose acetate and its derivatives. This comprehensive framework requires manufacturers and importers to assess and manage the risks associated with these substances, promoting safer alternatives and sustainable practices throughout the supply chain.

In Asia, countries like Japan and South Korea have established their own regulatory frameworks for cellulose acetate applications. The Japanese Ministry of Health, Labour and Welfare has set standards for cellulose acetate used in food contact materials, while the Korean Food and Drug Administration regulates its use in pharmaceutical packaging and medical devices.

International organizations, such as the International Organization for Standardization (ISO), have developed global standards for cellulose acetate products. These standards address various aspects, including quality control, testing methods, and performance requirements, facilitating international trade and ensuring consistency across different markets.

As the applications of cellulose acetate continue to expand, regulatory bodies are adapting their frameworks to address emerging challenges. For instance, the growing use of cellulose acetate in biodegradable plastics has prompted the development of new standards and certification processes to verify environmental claims and ensure proper disposal methods.

The regulatory landscape also encompasses occupational health and safety considerations. Agencies like the Occupational Safety and Health Administration (OSHA) in the United States have established guidelines for worker protection in cellulose acetate manufacturing facilities, addressing issues such as exposure limits and personal protective equipment requirements.

As innovation in cellulose acetate applications accelerates, regulatory bodies are increasingly collaborating with industry stakeholders to develop forward-looking policies. These efforts aim to strike a balance between fostering innovation and ensuring public safety, environmental protection, and sustainable practices in the rapidly evolving cellulose acetate industry.