Turbo-lag minimization strategies for L92 engines

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

L92 Engine Turbo-lag Background and Objectives

The L92 engine, a high-performance V8 powerplant developed by General Motors, has been a cornerstone in the automotive industry since its introduction in 2006. Known for its impressive power output and efficiency, the L92 has found applications in various GM vehicles, including the Chevrolet Silverado, GMC Sierra, and Cadillac Escalade. However, like many turbocharged engines, the L92 faces challenges related to turbo lag, which can significantly impact vehicle performance and driver experience.

Turbo lag, the delay between throttle input and the engine's response due to the time required for the turbocharger to spool up, has been a persistent issue in turbocharged engines. This phenomenon is particularly noticeable in large displacement engines like the L92, where the balance between power delivery and responsiveness is crucial. As automotive technology advances, minimizing turbo lag has become a key objective for engineers and manufacturers seeking to enhance the overall performance and drivability of turbocharged vehicles.

The evolution of turbocharging technology has seen significant progress over the years, with various strategies employed to mitigate turbo lag. From mechanical solutions such as variable geometry turbochargers to electronic interventions like anti-lag systems, the industry has continuously innovated to address this challenge. In the context of the L92 engine, the focus on turbo lag minimization aligns with broader trends in the automotive sector, including the push for improved fuel efficiency without compromising performance.

The objectives of turbo lag minimization in L92 engines are multifaceted. Primarily, engineers aim to reduce the response time between throttle input and power delivery, enhancing the engine's responsiveness across various operating conditions. This improvement not only contributes to a more engaging driving experience but also has implications for vehicle safety, particularly in situations requiring rapid acceleration.

Furthermore, optimizing turbo response in L92 engines seeks to broaden the power band, ensuring consistent performance across a wider range of engine speeds. This objective is particularly relevant for vehicles that may encounter diverse driving conditions, from city traffic to highway cruising and off-road adventures. By minimizing turbo lag, engineers strive to create a more versatile and adaptable powertrain that can meet the demands of various driving scenarios.

Another critical goal in addressing turbo lag in L92 engines is to maintain or improve fuel efficiency. As environmental regulations become increasingly stringent, the ability to deliver high performance with optimal fuel consumption is paramount. Strategies for turbo lag minimization must, therefore, be developed with a keen eye on their impact on overall engine efficiency and emissions.

Turbo lag, the delay between throttle input and the engine's response due to the time required for the turbocharger to spool up, has been a persistent issue in turbocharged engines. This phenomenon is particularly noticeable in large displacement engines like the L92, where the balance between power delivery and responsiveness is crucial. As automotive technology advances, minimizing turbo lag has become a key objective for engineers and manufacturers seeking to enhance the overall performance and drivability of turbocharged vehicles.

The evolution of turbocharging technology has seen significant progress over the years, with various strategies employed to mitigate turbo lag. From mechanical solutions such as variable geometry turbochargers to electronic interventions like anti-lag systems, the industry has continuously innovated to address this challenge. In the context of the L92 engine, the focus on turbo lag minimization aligns with broader trends in the automotive sector, including the push for improved fuel efficiency without compromising performance.

The objectives of turbo lag minimization in L92 engines are multifaceted. Primarily, engineers aim to reduce the response time between throttle input and power delivery, enhancing the engine's responsiveness across various operating conditions. This improvement not only contributes to a more engaging driving experience but also has implications for vehicle safety, particularly in situations requiring rapid acceleration.

Furthermore, optimizing turbo response in L92 engines seeks to broaden the power band, ensuring consistent performance across a wider range of engine speeds. This objective is particularly relevant for vehicles that may encounter diverse driving conditions, from city traffic to highway cruising and off-road adventures. By minimizing turbo lag, engineers strive to create a more versatile and adaptable powertrain that can meet the demands of various driving scenarios.

Another critical goal in addressing turbo lag in L92 engines is to maintain or improve fuel efficiency. As environmental regulations become increasingly stringent, the ability to deliver high performance with optimal fuel consumption is paramount. Strategies for turbo lag minimization must, therefore, be developed with a keen eye on their impact on overall engine efficiency and emissions.

Market Demand for Responsive Turbocharged Engines

The market demand for responsive turbocharged engines, particularly those with minimized turbo-lag, has been steadily increasing in recent years. This trend is driven by several factors, including stricter emissions regulations, the push for improved fuel efficiency, and consumer expectations for enhanced driving performance.

In the automotive industry, turbocharged engines have become increasingly popular due to their ability to deliver higher power output from smaller displacement engines. However, the issue of turbo-lag has been a persistent challenge, affecting vehicle responsiveness and overall driving experience. As a result, there is a growing demand for engines that can provide the benefits of turbocharging without the drawbacks of delayed throttle response.

The L92 engine, known for its performance capabilities, has been a focus of interest in this context. Consumers and automotive manufacturers alike are seeking solutions that can minimize turbo-lag in these engines, aiming to combine the power advantages of turbocharging with the immediate responsiveness of naturally aspirated engines.

Market research indicates that vehicle buyers, especially in the performance and luxury segments, place a high value on engine responsiveness. This demand extends beyond traditional sports car markets and into mainstream vehicle categories, where consumers expect smooth and immediate power delivery across various driving conditions.

Furthermore, the commercial vehicle sector has shown increasing interest in responsive turbocharged engines. Fleet operators and logistics companies are looking for solutions that can provide both fuel efficiency and responsive performance, particularly in urban delivery scenarios where frequent stops and starts are common.

The automotive aftermarket has also recognized this demand, with a growing number of products and services aimed at reducing turbo-lag in existing turbocharged engines, including the L92. This indicates a significant market opportunity for both OEM manufacturers and aftermarket suppliers who can effectively address the turbo-lag issue.

As environmental concerns continue to shape automotive regulations, the demand for efficient yet responsive engines is expected to grow further. Manufacturers that can successfully implement turbo-lag minimization strategies in their engines, particularly in popular platforms like the L92, are likely to gain a competitive edge in the market.

In the automotive industry, turbocharged engines have become increasingly popular due to their ability to deliver higher power output from smaller displacement engines. However, the issue of turbo-lag has been a persistent challenge, affecting vehicle responsiveness and overall driving experience. As a result, there is a growing demand for engines that can provide the benefits of turbocharging without the drawbacks of delayed throttle response.

The L92 engine, known for its performance capabilities, has been a focus of interest in this context. Consumers and automotive manufacturers alike are seeking solutions that can minimize turbo-lag in these engines, aiming to combine the power advantages of turbocharging with the immediate responsiveness of naturally aspirated engines.

Market research indicates that vehicle buyers, especially in the performance and luxury segments, place a high value on engine responsiveness. This demand extends beyond traditional sports car markets and into mainstream vehicle categories, where consumers expect smooth and immediate power delivery across various driving conditions.

Furthermore, the commercial vehicle sector has shown increasing interest in responsive turbocharged engines. Fleet operators and logistics companies are looking for solutions that can provide both fuel efficiency and responsive performance, particularly in urban delivery scenarios where frequent stops and starts are common.

The automotive aftermarket has also recognized this demand, with a growing number of products and services aimed at reducing turbo-lag in existing turbocharged engines, including the L92. This indicates a significant market opportunity for both OEM manufacturers and aftermarket suppliers who can effectively address the turbo-lag issue.

As environmental concerns continue to shape automotive regulations, the demand for efficient yet responsive engines is expected to grow further. Manufacturers that can successfully implement turbo-lag minimization strategies in their engines, particularly in popular platforms like the L92, are likely to gain a competitive edge in the market.

Current Turbo-lag Challenges in L92 Engines

Turbo-lag remains a significant challenge in L92 engines, impacting their overall performance and efficiency. This phenomenon occurs due to the inherent delay between the driver's demand for acceleration and the turbocharger's response, resulting in a momentary lack of power delivery.

One of the primary factors contributing to turbo-lag in L92 engines is the inertia of the turbocharger's rotating components. The turbine and compressor wheels, along with the connecting shaft, possess considerable mass, which requires time to overcome and reach optimal rotational speeds. This inertia-induced delay is particularly noticeable during sudden throttle inputs or rapid changes in engine load.

Another challenge stems from the exhaust gas flow dynamics. At low engine speeds or during sudden acceleration, the exhaust gas volume and velocity may be insufficient to quickly spool up the turbocharger. This results in a lag between the increased fuel injection and the corresponding boost in intake air pressure, leading to suboptimal combustion and delayed power delivery.

The L92 engine's specific design characteristics also play a role in turbo-lag manifestation. The engine's displacement, compression ratio, and valve timing all influence the exhaust gas energy available to drive the turbocharger. Balancing these parameters to minimize lag while maintaining overall engine efficiency presents a complex engineering challenge.

Thermal management is another critical aspect affecting turbo-lag in L92 engines. The turbocharger's performance is highly dependent on operating temperatures, and rapid temperature fluctuations during transient conditions can impact its responsiveness. Ensuring optimal thermal conditions for the turbocharger while managing overall engine heat dissipation adds another layer of complexity to the turbo-lag minimization efforts.

Furthermore, the electronic control systems governing the engine and turbocharger operation face challenges in predicting and compensating for turbo-lag. Developing algorithms that can accurately anticipate driver inputs, engine load changes, and environmental conditions to preemptively adjust turbocharger operation is an ongoing area of research and development.

The integration of advanced materials in turbocharger construction, such as lightweight alloys or ceramic components, presents both opportunities and challenges. While these materials can potentially reduce inertia and improve thermal efficiency, they often come with increased costs and manufacturing complexities, making their widespread adoption in L92 engines challenging.

Addressing these turbo-lag challenges in L92 engines requires a multifaceted approach, combining mechanical design optimizations, advanced control strategies, and innovative materials. The ongoing pursuit of solutions to these challenges drives continuous innovation in engine technology and turbocharger design.

One of the primary factors contributing to turbo-lag in L92 engines is the inertia of the turbocharger's rotating components. The turbine and compressor wheels, along with the connecting shaft, possess considerable mass, which requires time to overcome and reach optimal rotational speeds. This inertia-induced delay is particularly noticeable during sudden throttle inputs or rapid changes in engine load.

Another challenge stems from the exhaust gas flow dynamics. At low engine speeds or during sudden acceleration, the exhaust gas volume and velocity may be insufficient to quickly spool up the turbocharger. This results in a lag between the increased fuel injection and the corresponding boost in intake air pressure, leading to suboptimal combustion and delayed power delivery.

The L92 engine's specific design characteristics also play a role in turbo-lag manifestation. The engine's displacement, compression ratio, and valve timing all influence the exhaust gas energy available to drive the turbocharger. Balancing these parameters to minimize lag while maintaining overall engine efficiency presents a complex engineering challenge.

Thermal management is another critical aspect affecting turbo-lag in L92 engines. The turbocharger's performance is highly dependent on operating temperatures, and rapid temperature fluctuations during transient conditions can impact its responsiveness. Ensuring optimal thermal conditions for the turbocharger while managing overall engine heat dissipation adds another layer of complexity to the turbo-lag minimization efforts.

Furthermore, the electronic control systems governing the engine and turbocharger operation face challenges in predicting and compensating for turbo-lag. Developing algorithms that can accurately anticipate driver inputs, engine load changes, and environmental conditions to preemptively adjust turbocharger operation is an ongoing area of research and development.

The integration of advanced materials in turbocharger construction, such as lightweight alloys or ceramic components, presents both opportunities and challenges. While these materials can potentially reduce inertia and improve thermal efficiency, they often come with increased costs and manufacturing complexities, making their widespread adoption in L92 engines challenging.

Addressing these turbo-lag challenges in L92 engines requires a multifaceted approach, combining mechanical design optimizations, advanced control strategies, and innovative materials. The ongoing pursuit of solutions to these challenges drives continuous innovation in engine technology and turbocharger design.

Existing Turbo-lag Reduction Techniques

01 Turbocharger design optimization

Improving turbocharger design to reduce turbo lag in L92 engines. This includes optimizing the size, shape, and materials of the turbine and compressor wheels, as well as enhancing the overall efficiency of the turbocharger system.- Turbocharger design optimization: Improving turbocharger design to reduce turbo lag in L92 engines. This includes optimizing the size and geometry of the turbine and compressor wheels, as well as enhancing the overall efficiency of the turbocharger system. These improvements aim to decrease the time required for the turbocharger to spool up and deliver boost pressure.

- Variable geometry turbochargers: Implementing variable geometry turbochargers (VGT) in L92 engines to mitigate turbo lag. VGTs allow for adjustable turbine geometry, which can optimize exhaust flow across different engine speeds and loads. This technology helps maintain boost pressure at lower engine speeds, reducing the effects of turbo lag.

- Electric assist systems: Integrating electric assist systems with turbochargers to combat turbo lag in L92 engines. These systems use an electric motor to quickly spool up the turbocharger, providing immediate boost pressure before the exhaust gases can drive the turbine. This approach significantly reduces the delay in power delivery associated with turbo lag.

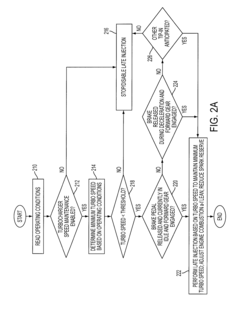

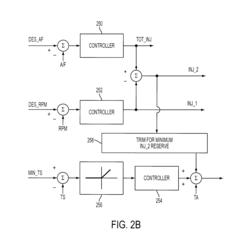

- Advanced engine control strategies: Developing sophisticated engine control strategies to minimize turbo lag in L92 engines. This involves optimizing fuel injection timing, valve timing, and ignition timing to improve exhaust gas flow and turbocharger response. Advanced algorithms and sensors can be used to predict and compensate for turbo lag under various driving conditions.

- Twin-turbo or sequential turbocharging: Employing twin-turbo or sequential turbocharging systems in L92 engines to reduce turbo lag. These configurations use multiple turbochargers of different sizes or in different arrangements to provide better boost response across a wider range of engine speeds. Smaller turbochargers can be used for low-end response, while larger ones handle high-end power delivery.

02 Variable geometry turbochargers

Implementing variable geometry turbochargers in L92 engines to mitigate turbo lag. These systems can adjust the flow of exhaust gases to the turbine wheel, allowing for better performance across a wider range of engine speeds.Expand Specific Solutions03 Electric assist systems

Integrating electric assist systems with the turbocharger to reduce lag. These systems use an electric motor to spin up the turbocharger quickly, providing boost pressure before the exhaust gases can do so naturally.Expand Specific Solutions04 Advanced engine control strategies

Developing sophisticated engine control strategies to minimize turbo lag. This includes optimizing fuel injection timing, valve timing, and boost pressure control to improve engine response and reduce lag.Expand Specific Solutions05 Twin-turbo or sequential turbocharging

Employing twin-turbo or sequential turbocharging systems in L92 engines. These setups use multiple turbochargers of different sizes to provide better boost across a wider range of engine speeds, effectively reducing turbo lag.Expand Specific Solutions

Key Players in Turbocharger Industry

The turbo-lag minimization strategies for L92 engines market is in a mature stage, with established players competing to refine existing technologies. The global automotive turbocharger market size is projected to reach $24.23 billion by 2027, growing at a CAGR of 5.3%. Major companies like Ford, ZF Friedrichshafen, GM, Continental, and Schaeffler are at the forefront of innovation in this space. These firms are investing heavily in R&D to develop advanced solutions such as electric turbochargers and variable geometry turbochargers to address turbo-lag issues. The technology is relatively mature, with ongoing incremental improvements rather than disruptive breakthroughs. Collaboration between OEMs and suppliers is common to accelerate development and implementation of new turbocharging technologies.

GM Global Technology Operations LLC

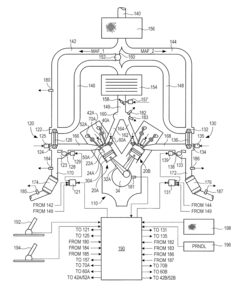

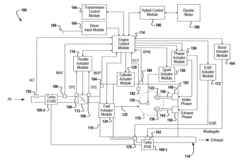

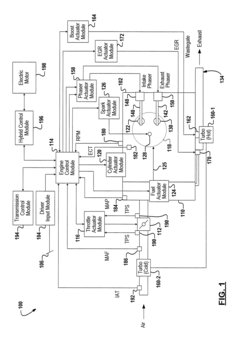

Technical Solution: GM has developed a multi-pronged approach to minimize turbo lag in L92 engines. Their strategy includes the use of twin-scroll turbochargers, which separate exhaust pulses from different cylinders to maintain exhaust gas velocity and reduce lag[2]. GM has also implemented an innovative electrically-assisted turbocharger system, which uses a small electric motor to quickly spool up the turbo at low engine speeds[4]. Additionally, GM's solution incorporates advanced engine control modules that optimize fuel injection timing and valve actuation to maintain optimal exhaust gas flow to the turbine[6]. The company has also experimented with a unique "pre-spooling" technique that maintains turbocharger speed during off-throttle conditions[8].

Strengths: Comprehensive approach combining mechanical and electrical solutions, advanced control systems. Weaknesses: Potential for increased manufacturing costs, complexity in system integration.

Continental Automotive GmbH

Technical Solution: Continental has developed an innovative e-turbo system aimed at minimizing turbo lag in L92 and similar engines. Their solution incorporates a high-speed electric motor integrated directly into the turbocharger shaft, capable of spinning up to 200,000 RPM[2]. This allows for near-instantaneous boost pressure generation, even at low engine speeds. Continental's system also features advanced bearing technology to handle the high rotational speeds and a sophisticated power electronics unit for precise control[4]. The e-turbo is designed to work in conjunction with a 48V electrical system, enabling energy recuperation during deceleration and braking[6]. Continental has also implemented predictive control algorithms that anticipate boost demand based on driving conditions and driver behavior, further reducing perceived turbo lag[8].

Strengths: Ultra-high-speed electric assist, energy recuperation capability, predictive control algorithms. Weaknesses: Requires integration with 48V electrical system, potential for increased system complexity and cost.

Innovative Turbo-lag Minimization Patents

Engine idle speed and turbocharger speed control

PatentActiveUS20140188370A1

Innovation

- A method involving dual fuel injections during a cylinder cycle, where the first injection generates lean combustion and the second injection occurs post-combustion to maintain turbocharger speed, adjusting based on engine speed and turbocharger speed, to manage torque and speed disturbances while maintaining a stoichiometric air-fuel ratio.

Method and system for reducing turbo lag in an engine

PatentInactiveUS20110257867A1

Innovation

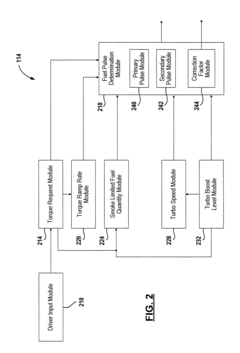

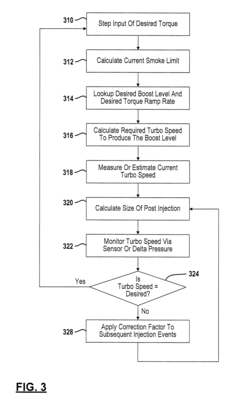

- A system and method that generate a secondary fuel pulse to increase the pressure or temperature of exhaust gases driving the turbocharger turbine, determining primary and secondary fuel injection pulsewidths based on driver-requested torque and desired boost levels to reduce turbo lag.

Emissions Regulations Impact on Turbocharger Design

Emissions regulations have significantly influenced turbocharger design in recent years, particularly for L92 engines. These regulations have become increasingly stringent, driving manufacturers to develop innovative solutions for reducing turbo-lag while maintaining compliance with emission standards.

The primary focus of emissions regulations has been on reducing nitrogen oxides (NOx), particulate matter (PM), and carbon dioxide (CO2) emissions. These regulations have led to the development of more efficient turbocharger designs that can operate effectively across a wider range of engine speeds and loads.

One of the key impacts of emissions regulations on turbocharger design has been the push towards smaller, more responsive turbos. This trend has led to the development of variable geometry turbochargers (VGTs) and twin-scroll turbochargers, which can provide better low-end torque and reduced turbo-lag while still meeting emissions requirements.

Emissions regulations have also driven the integration of advanced materials in turbocharger design. High-temperature resistant alloys and ceramic components are now commonly used to improve durability and efficiency, allowing turbochargers to operate at higher temperatures and pressures without compromising performance or emissions.

The need for precise control of air-fuel ratios to meet emissions standards has led to the development of more sophisticated electronic control systems for turbochargers. These systems can adjust boost pressure and wastegate operation in real-time, optimizing engine performance while minimizing emissions across various operating conditions.

Another significant impact has been the increased adoption of electric assist technologies in turbocharger design. Electric compressors and hybrid turbochargers have emerged as solutions to reduce turbo-lag and improve low-end response while maintaining compliance with emissions regulations.

Emissions regulations have also pushed manufacturers to focus on reducing parasitic losses in turbocharger systems. This has resulted in the development of low-friction bearings, aerodynamically optimized compressor and turbine wheels, and more efficient intercooling systems.

The integration of turbochargers with other emissions control technologies, such as exhaust gas recirculation (EGR) and selective catalytic reduction (SCR) systems, has become increasingly important. This integration allows for a more holistic approach to emissions reduction, balancing the performance benefits of turbocharging with the need to meet stringent emissions standards.

In conclusion, emissions regulations have been a driving force in turbocharger design innovation, particularly for L92 engines. These regulations have led to the development of more efficient, responsive, and environmentally friendly turbocharging solutions, shaping the future of engine technology and performance.

The primary focus of emissions regulations has been on reducing nitrogen oxides (NOx), particulate matter (PM), and carbon dioxide (CO2) emissions. These regulations have led to the development of more efficient turbocharger designs that can operate effectively across a wider range of engine speeds and loads.

One of the key impacts of emissions regulations on turbocharger design has been the push towards smaller, more responsive turbos. This trend has led to the development of variable geometry turbochargers (VGTs) and twin-scroll turbochargers, which can provide better low-end torque and reduced turbo-lag while still meeting emissions requirements.

Emissions regulations have also driven the integration of advanced materials in turbocharger design. High-temperature resistant alloys and ceramic components are now commonly used to improve durability and efficiency, allowing turbochargers to operate at higher temperatures and pressures without compromising performance or emissions.

The need for precise control of air-fuel ratios to meet emissions standards has led to the development of more sophisticated electronic control systems for turbochargers. These systems can adjust boost pressure and wastegate operation in real-time, optimizing engine performance while minimizing emissions across various operating conditions.

Another significant impact has been the increased adoption of electric assist technologies in turbocharger design. Electric compressors and hybrid turbochargers have emerged as solutions to reduce turbo-lag and improve low-end response while maintaining compliance with emissions regulations.

Emissions regulations have also pushed manufacturers to focus on reducing parasitic losses in turbocharger systems. This has resulted in the development of low-friction bearings, aerodynamically optimized compressor and turbine wheels, and more efficient intercooling systems.

The integration of turbochargers with other emissions control technologies, such as exhaust gas recirculation (EGR) and selective catalytic reduction (SCR) systems, has become increasingly important. This integration allows for a more holistic approach to emissions reduction, balancing the performance benefits of turbocharging with the need to meet stringent emissions standards.

In conclusion, emissions regulations have been a driving force in turbocharger design innovation, particularly for L92 engines. These regulations have led to the development of more efficient, responsive, and environmentally friendly turbocharging solutions, shaping the future of engine technology and performance.

Cost-Benefit Analysis of Turbo-lag Reduction Strategies

The cost-benefit analysis of turbo-lag reduction strategies for L92 engines reveals a complex interplay between performance improvements and associated expenses. Implementing advanced technologies to minimize turbo-lag often requires significant upfront investments in research, development, and manufacturing processes. However, these investments can yield substantial long-term benefits in terms of enhanced engine performance, fuel efficiency, and customer satisfaction.

One of the primary cost considerations is the integration of sophisticated electronic control systems. These systems, while initially expensive, offer precise management of boost pressure and fuel injection timing, resulting in improved throttle response and reduced turbo-lag. The cost of sensors, actuators, and ECU upgrades must be weighed against the performance gains and potential fuel savings over the engine's lifetime.

Variable geometry turbochargers (VGTs) represent another significant investment area. Although more costly than traditional fixed-geometry turbochargers, VGTs provide superior low-end torque and faster spooling, effectively reducing turbo-lag across a broader range of engine speeds. The increased complexity of VGTs may lead to higher maintenance costs, but this is often offset by improved overall engine efficiency and longevity.

Electric-assisted turbochargers, incorporating a small electric motor to spin up the turbine quickly, offer promising turbo-lag reduction benefits. While the initial cost and complexity of integrating these systems are high, they can provide near-instantaneous boost response, significantly enhancing drivability and performance. The potential fuel economy improvements from this technology may justify the investment, especially in markets with stringent emissions regulations.

From a manufacturing perspective, lightweight materials and advanced machining techniques for turbocharger components can reduce inertia and improve responsiveness. Although these materials and processes may increase production costs, they contribute to overall weight reduction and improved engine dynamics, potentially leading to better vehicle performance and fuel efficiency.

The benefits of turbo-lag reduction extend beyond mere performance metrics. Enhanced drivability and responsiveness can significantly impact customer perception and brand reputation, potentially leading to increased market share and customer loyalty. This intangible benefit, while difficult to quantify, can have a substantial impact on long-term profitability and competitive positioning in the automotive market.

In conclusion, while the implementation of turbo-lag reduction strategies for L92 engines involves considerable upfront costs, the long-term benefits in performance, efficiency, and market positioning often justify the investment. A careful balance must be struck between technological advancement and cost-effectiveness to ensure optimal returns on investment in this critical area of engine development.

One of the primary cost considerations is the integration of sophisticated electronic control systems. These systems, while initially expensive, offer precise management of boost pressure and fuel injection timing, resulting in improved throttle response and reduced turbo-lag. The cost of sensors, actuators, and ECU upgrades must be weighed against the performance gains and potential fuel savings over the engine's lifetime.

Variable geometry turbochargers (VGTs) represent another significant investment area. Although more costly than traditional fixed-geometry turbochargers, VGTs provide superior low-end torque and faster spooling, effectively reducing turbo-lag across a broader range of engine speeds. The increased complexity of VGTs may lead to higher maintenance costs, but this is often offset by improved overall engine efficiency and longevity.

Electric-assisted turbochargers, incorporating a small electric motor to spin up the turbine quickly, offer promising turbo-lag reduction benefits. While the initial cost and complexity of integrating these systems are high, they can provide near-instantaneous boost response, significantly enhancing drivability and performance. The potential fuel economy improvements from this technology may justify the investment, especially in markets with stringent emissions regulations.

From a manufacturing perspective, lightweight materials and advanced machining techniques for turbocharger components can reduce inertia and improve responsiveness. Although these materials and processes may increase production costs, they contribute to overall weight reduction and improved engine dynamics, potentially leading to better vehicle performance and fuel efficiency.

The benefits of turbo-lag reduction extend beyond mere performance metrics. Enhanced drivability and responsiveness can significantly impact customer perception and brand reputation, potentially leading to increased market share and customer loyalty. This intangible benefit, while difficult to quantify, can have a substantial impact on long-term profitability and competitive positioning in the automotive market.

In conclusion, while the implementation of turbo-lag reduction strategies for L92 engines involves considerable upfront costs, the long-term benefits in performance, efficiency, and market positioning often justify the investment. A careful balance must be struck between technological advancement and cost-effectiveness to ensure optimal returns on investment in this critical area of engine development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!