V10 Engine Application in Waste Heat Recovery Systems

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V10 Engine WHR Technology Background and Objectives

Waste heat recovery (WHR) systems have emerged as a critical technology in the pursuit of improved energy efficiency and reduced environmental impact across various industries. The V10 engine, known for its high power output and distinctive configuration, presents a unique opportunity for waste heat recovery applications due to its substantial thermal energy generation during operation. The evolution of WHR technology has progressed significantly over the past decades, transitioning from simple heat exchangers to sophisticated systems capable of converting thermal energy into usable mechanical or electrical power.

The historical development of WHR systems for internal combustion engines began in the 1970s, primarily driven by the global oil crisis and increasing awareness of energy conservation. Early systems focused on basic heat exchange principles, while modern solutions incorporate advanced thermodynamic cycles and materials science innovations. The V10 engine configuration, with its ten cylinders arranged in a V-formation, creates distinct thermal characteristics and exhaust flow patterns that require specialized WHR approaches compared to conventional engine layouts.

Current technological trends in V10 engine WHR systems are moving toward integrated solutions that combine multiple recovery methods, including Organic Rankine Cycle (ORC) systems, thermoelectric generators, and advanced heat exchanger designs. These developments aim to capture waste heat from multiple sources within the engine, including exhaust gases, cooling systems, and lubrication circuits, maximizing the overall energy recovery potential.

The primary technical objectives for V10 engine WHR systems include achieving thermal efficiency improvements of 5-10% over baseline engine performance, developing compact and lightweight systems suitable for mobile applications, ensuring system durability under variable operating conditions, and maintaining cost-effectiveness for commercial viability. Additionally, there is a growing focus on developing WHR systems that can operate efficiently across the entire engine operating range, particularly during transient conditions.

Environmental regulations and sustainability goals are increasingly driving WHR technology development. The European Union's CO2 emission standards for heavy-duty vehicles, the US EPA's greenhouse gas regulations, and similar frameworks worldwide have established clear targets that make WHR systems strategically important for engine manufacturers. For V10 engines specifically, which are often deployed in high-performance or specialized applications, WHR systems offer a pathway to maintain performance characteristics while meeting increasingly stringent efficiency requirements.

Looking forward, the technological roadmap for V10 engine WHR systems aims to overcome current limitations in thermal conversion efficiency, system weight, and integration complexity. Emerging materials such as advanced ceramics, novel working fluids for thermodynamic cycles, and intelligent control systems represent key areas of development that will shape the next generation of these systems.

The historical development of WHR systems for internal combustion engines began in the 1970s, primarily driven by the global oil crisis and increasing awareness of energy conservation. Early systems focused on basic heat exchange principles, while modern solutions incorporate advanced thermodynamic cycles and materials science innovations. The V10 engine configuration, with its ten cylinders arranged in a V-formation, creates distinct thermal characteristics and exhaust flow patterns that require specialized WHR approaches compared to conventional engine layouts.

Current technological trends in V10 engine WHR systems are moving toward integrated solutions that combine multiple recovery methods, including Organic Rankine Cycle (ORC) systems, thermoelectric generators, and advanced heat exchanger designs. These developments aim to capture waste heat from multiple sources within the engine, including exhaust gases, cooling systems, and lubrication circuits, maximizing the overall energy recovery potential.

The primary technical objectives for V10 engine WHR systems include achieving thermal efficiency improvements of 5-10% over baseline engine performance, developing compact and lightweight systems suitable for mobile applications, ensuring system durability under variable operating conditions, and maintaining cost-effectiveness for commercial viability. Additionally, there is a growing focus on developing WHR systems that can operate efficiently across the entire engine operating range, particularly during transient conditions.

Environmental regulations and sustainability goals are increasingly driving WHR technology development. The European Union's CO2 emission standards for heavy-duty vehicles, the US EPA's greenhouse gas regulations, and similar frameworks worldwide have established clear targets that make WHR systems strategically important for engine manufacturers. For V10 engines specifically, which are often deployed in high-performance or specialized applications, WHR systems offer a pathway to maintain performance characteristics while meeting increasingly stringent efficiency requirements.

Looking forward, the technological roadmap for V10 engine WHR systems aims to overcome current limitations in thermal conversion efficiency, system weight, and integration complexity. Emerging materials such as advanced ceramics, novel working fluids for thermodynamic cycles, and intelligent control systems represent key areas of development that will shape the next generation of these systems.

Market Analysis for V10 Engine Waste Heat Recovery

The waste heat recovery (WHR) market for V10 engines represents a significant opportunity within the broader energy efficiency sector. Current market analysis indicates that the global waste heat recovery system market is valued at approximately $68 billion as of 2023, with projections showing growth at a compound annual rate of 8.5% through 2030. Within this broader market, V10 engine applications constitute a specialized but increasingly important segment, particularly in high-performance vehicles, marine applications, and industrial power generation systems.

The demand for V10 engine waste heat recovery systems is primarily driven by three key factors. First, increasingly stringent emissions regulations worldwide are forcing manufacturers to improve fuel efficiency and reduce carbon footprints. The European Union's Euro 7 standards and similar regulations in North America and Asia have created regulatory pressure that directly translates to market demand. Second, rising energy costs have heightened interest in technologies that can recapture otherwise wasted energy, with fuel savings of 5-10% commonly reported in V10 WHR implementations.

Third, corporate sustainability initiatives and environmental, social, and governance (ESG) commitments are pushing fleet operators and industrial users toward more efficient power systems. This trend is particularly evident in the commercial marine sector, where V10 engines are common and where fuel represents up to 60% of operating costs.

Market segmentation reveals distinct application areas for V10 engine waste heat recovery. The automotive sector, particularly in high-performance and luxury vehicles, represents approximately 35% of the market. Marine applications account for 28%, while stationary power generation comprises 25%. The remaining 12% is distributed across specialized applications including military vehicles and custom industrial installations.

Geographically, Europe leads in adoption with approximately 40% market share, driven by stringent regulations and high energy costs. North America follows at 30%, with Asia-Pacific representing the fastest-growing region at a 12% annual growth rate, particularly as China and India implement tighter emissions standards.

The customer profile for V10 engine WHR systems varies by sector but generally includes fleet operators, marine vessel owners, power generation facilities, and manufacturers of high-performance vehicles. These customers typically prioritize return on investment periods of 2-4 years, which current WHR technologies can often deliver through fuel savings alone, not accounting for regulatory compliance benefits and carbon credit opportunities that may further enhance the value proposition.

The demand for V10 engine waste heat recovery systems is primarily driven by three key factors. First, increasingly stringent emissions regulations worldwide are forcing manufacturers to improve fuel efficiency and reduce carbon footprints. The European Union's Euro 7 standards and similar regulations in North America and Asia have created regulatory pressure that directly translates to market demand. Second, rising energy costs have heightened interest in technologies that can recapture otherwise wasted energy, with fuel savings of 5-10% commonly reported in V10 WHR implementations.

Third, corporate sustainability initiatives and environmental, social, and governance (ESG) commitments are pushing fleet operators and industrial users toward more efficient power systems. This trend is particularly evident in the commercial marine sector, where V10 engines are common and where fuel represents up to 60% of operating costs.

Market segmentation reveals distinct application areas for V10 engine waste heat recovery. The automotive sector, particularly in high-performance and luxury vehicles, represents approximately 35% of the market. Marine applications account for 28%, while stationary power generation comprises 25%. The remaining 12% is distributed across specialized applications including military vehicles and custom industrial installations.

Geographically, Europe leads in adoption with approximately 40% market share, driven by stringent regulations and high energy costs. North America follows at 30%, with Asia-Pacific representing the fastest-growing region at a 12% annual growth rate, particularly as China and India implement tighter emissions standards.

The customer profile for V10 engine WHR systems varies by sector but generally includes fleet operators, marine vessel owners, power generation facilities, and manufacturers of high-performance vehicles. These customers typically prioritize return on investment periods of 2-4 years, which current WHR technologies can often deliver through fuel savings alone, not accounting for regulatory compliance benefits and carbon credit opportunities that may further enhance the value proposition.

Current State and Challenges in V10 WHR Technology

The global landscape of V10 engine waste heat recovery (WHR) technology presents a complex picture of advancement and limitation. Currently, V10 engines, primarily deployed in high-performance vehicles and some specialized industrial applications, generate substantial waste heat that remains largely untapped. Industry data indicates that modern V10 engines convert only 30-40% of fuel energy into mechanical power, with approximately 30% lost through exhaust gases and another 30% through cooling systems.

Leading automotive manufacturers have implemented first-generation WHR systems in V10 platforms, predominantly utilizing Organic Rankine Cycle (ORC) technology. These systems have demonstrated potential energy recovery rates of 3-8% in controlled environments, translating to modest efficiency improvements. However, field implementation reveals significant discrepancies between laboratory performance and real-world operation, particularly under variable load conditions characteristic of V10 applications.

The technical challenges facing V10 WHR systems are multifaceted. The high-temperature exhaust gases (often exceeding 800°C) create material durability issues in heat exchangers, while the compact engine compartments of vehicles utilizing V10 engines present severe space constraints for additional recovery equipment. Weight considerations remain critical, as current WHR systems can add 30-50kg to vehicle mass, potentially offsetting efficiency gains in performance applications.

Geographically, WHR technology development for V10 engines shows distinct regional patterns. European manufacturers lead in research investment, driven by stringent emissions regulations, while North American development focuses on performance applications. Asian manufacturers, particularly Japanese firms, have made significant advances in miniaturization of WHR components specifically designed for high-performance engines.

Regulatory frameworks present another significant challenge, with inconsistent global standards creating market fragmentation. The EU's Euro 7 standards and similar regulations in other markets are accelerating development timelines, though certification processes for WHR-equipped engines remain complex and time-consuming.

Cost factors continue to constrain widespread adoption, with current V10 WHR systems adding approximately $3,000-5,000 to production costs. The return on investment calculations remain challenging for manufacturers, particularly in consumer vehicle applications where fuel savings may not justify the additional expense within typical ownership periods.

Integration with existing engine management systems presents technical hurdles, as WHR systems require sophisticated control algorithms to optimize recovery across varying operational conditions. The development of these control systems represents a significant portion of R&D investment in the field, with proprietary solutions dominating the current landscape.

Leading automotive manufacturers have implemented first-generation WHR systems in V10 platforms, predominantly utilizing Organic Rankine Cycle (ORC) technology. These systems have demonstrated potential energy recovery rates of 3-8% in controlled environments, translating to modest efficiency improvements. However, field implementation reveals significant discrepancies between laboratory performance and real-world operation, particularly under variable load conditions characteristic of V10 applications.

The technical challenges facing V10 WHR systems are multifaceted. The high-temperature exhaust gases (often exceeding 800°C) create material durability issues in heat exchangers, while the compact engine compartments of vehicles utilizing V10 engines present severe space constraints for additional recovery equipment. Weight considerations remain critical, as current WHR systems can add 30-50kg to vehicle mass, potentially offsetting efficiency gains in performance applications.

Geographically, WHR technology development for V10 engines shows distinct regional patterns. European manufacturers lead in research investment, driven by stringent emissions regulations, while North American development focuses on performance applications. Asian manufacturers, particularly Japanese firms, have made significant advances in miniaturization of WHR components specifically designed for high-performance engines.

Regulatory frameworks present another significant challenge, with inconsistent global standards creating market fragmentation. The EU's Euro 7 standards and similar regulations in other markets are accelerating development timelines, though certification processes for WHR-equipped engines remain complex and time-consuming.

Cost factors continue to constrain widespread adoption, with current V10 WHR systems adding approximately $3,000-5,000 to production costs. The return on investment calculations remain challenging for manufacturers, particularly in consumer vehicle applications where fuel savings may not justify the additional expense within typical ownership periods.

Integration with existing engine management systems presents technical hurdles, as WHR systems require sophisticated control algorithms to optimize recovery across varying operational conditions. The development of these control systems represents a significant portion of R&D investment in the field, with proprietary solutions dominating the current landscape.

Current V10 Engine Waste Heat Recovery Solutions

01 V10 Engine Design and Structure

The design and structure of V10 engines focus on the arrangement of cylinders in a V-configuration, providing a balance between power output and engine size. These engines typically feature ten cylinders arranged in two banks of five, creating a V-shape. The design allows for higher power output while maintaining a relatively compact size compared to inline configurations with the same number of cylinders.- V10 Engine Design and Configuration: V10 engines feature a specific configuration with ten cylinders arranged in a V-shape. This design offers a balance between power output and compact dimensions. The V-angle and cylinder arrangement contribute to the engine's performance characteristics, vibration management, and overall efficiency. These engines are engineered to deliver high power output while maintaining reasonable dimensions for vehicle integration.

- V10 Engine Applications in Vehicles: V10 engines are implemented in various vehicle types, particularly in high-performance automobiles and specialized applications. These engines provide substantial power output suitable for sports cars, luxury vehicles, and certain commercial applications. The implementation includes specific mounting solutions, integration with transmission systems, and cooling arrangements to accommodate the engine's characteristics and performance requirements.

- V10 Engine Cooling and Thermal Management: Thermal management systems for V10 engines address the significant heat generation from high-performance operation. These systems include specialized cooling channels, radiator configurations, and oil cooling mechanisms. Advanced thermal management solutions ensure optimal operating temperatures across various driving conditions, preventing overheating while maintaining performance and efficiency.

- V10 Engine External Design and Aesthetics: The external design of V10 engines combines functional requirements with aesthetic considerations. Design elements include distinctive engine covers, visible intake manifolds, and characteristic exhaust headers that showcase the engine's performance capabilities. These visual aspects often serve as signature elements in high-performance vehicles, emphasizing the prestige and technical sophistication of V10-powered automobiles.

- V10 Engine Performance Enhancement Technologies: Various technologies are employed to enhance V10 engine performance, including advanced fuel injection systems, variable valve timing, and specialized intake and exhaust configurations. These technologies optimize combustion efficiency, power delivery, and throttle response. Performance enhancements may also include turbocharging or supercharging systems to increase power output while managing fuel consumption and emissions.

02 V10 Engine Performance Optimization

Various technologies and methods are employed to optimize the performance of V10 engines, including advanced fuel injection systems, variable valve timing, and turbocharging or supercharging. These optimizations aim to increase power output, improve fuel efficiency, and reduce emissions while maintaining the distinctive sound and character associated with V10 engines.Expand Specific Solutions03 V10 Engine Cooling and Thermal Management

Effective cooling and thermal management systems are crucial for V10 engines due to their high power output and heat generation. These systems may include advanced radiator designs, precision-engineered cooling channels, and sophisticated electronic control systems to maintain optimal operating temperatures under various conditions, preventing overheating and ensuring longevity of engine components.Expand Specific Solutions04 V10 Engine Aesthetic and External Design

The external design and aesthetics of V10 engines are important considerations, particularly in high-performance and luxury vehicles. Design elements focus on showcasing the engine's power and prestige through distinctive covers, visible components, and integration with the vehicle's overall design language. These aesthetic considerations contribute to the brand identity and appeal of vehicles equipped with V10 engines.Expand Specific Solutions05 V10 Engine Integration with Vehicle Systems

Integration of V10 engines with other vehicle systems involves sophisticated electronic control units, transmission systems, and chassis designs to effectively harness and manage the engine's power. This includes advanced drivetrain components, specialized mounting systems to reduce vibration, and calibrated electronic interfaces that optimize the interaction between the engine and other vehicle systems for improved performance and driving experience.Expand Specific Solutions

Key Industry Players in V10 Engine WHR Systems

The V10 Engine Application in Waste Heat Recovery Systems market is currently in a growth phase, with increasing adoption driven by stringent emissions regulations and energy efficiency demands. The global market size is estimated to reach $3.5-4 billion by 2025, growing at a CAGR of approximately 8-10%. Leading players include established automotive giants like Robert Bosch GmbH, Toyota Motor Corp., and Cummins Inc., who leverage their extensive R&D capabilities to develop advanced waste heat recovery technologies. Japanese manufacturers such as DENSO Corp. and Mitsubishi Heavy Industries demonstrate high technical maturity with patented solutions, while European companies like Mercedes-Benz Group AG and Volvo Lastvagnar AB focus on integration with commercial vehicle applications. Chinese players including Zhejiang Yinlun Machinery are rapidly advancing their technological capabilities, particularly in cost-effective implementations.

Robert Bosch GmbH

Technical Solution: Bosch has developed an advanced Waste Heat Recovery System (WHRS) specifically optimized for V10 engines that utilizes both Organic Rankine Cycle (ORC) technology and thermoelectric generators. Their system captures exhaust gas heat through a specialized heat exchanger designed to withstand the high temperatures and pulsating flow characteristics of V10 engines. The recovered thermal energy is converted into electrical power that can be integrated into the vehicle's electrical system, reducing alternator load and improving fuel efficiency by up to 5% in long-haul applications. Bosch's system features adaptive control algorithms that optimize heat recovery across various engine operating conditions, particularly effective during highway cruising where V10 engines maintain steady high-temperature exhaust output.

Strengths: Superior integration with existing vehicle electrical systems; highly efficient heat exchangers with minimal backpressure impact; comprehensive control systems that adapt to driving conditions. Weaknesses: Higher initial cost compared to simpler systems; additional weight that may impact vehicle payload capacity; requires significant installation space.

Toyota Motor Corp.

Technical Solution: Toyota has developed a sophisticated waste heat recovery system for high-performance V10 engines that combines traditional Rankine cycle technology with their patented exhaust gas heat exchanger design. Their system features a compact, lightweight heat exchanger positioned close to the exhaust manifold to capture maximum thermal energy before dissipation. Toyota's approach utilizes a specialized working fluid with optimized thermodynamic properties for the specific temperature profile of V10 engines, enabling efficient operation across a wider range of engine loads. The system incorporates a variable-geometry expander that adjusts to changing heat availability, maintaining efficiency across diverse driving conditions. Toyota's waste heat recovery technology is integrated with their hybrid powertrain architecture, allowing recovered energy to be stored in the battery system for later use, providing a fuel economy improvement of approximately 3-5% in combined cycle testing.

Strengths: Seamless integration with hybrid systems; lightweight components minimizing performance impact; sophisticated control systems optimizing recovery across driving cycles. Weaknesses: Higher complexity in non-hybrid applications; limited benefits in short-trip urban driving; requires specialized maintenance expertise.

Core Patents and Technical Literature in V10 WHR

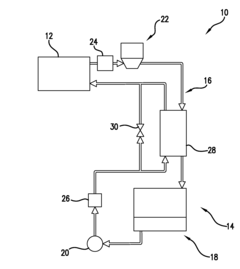

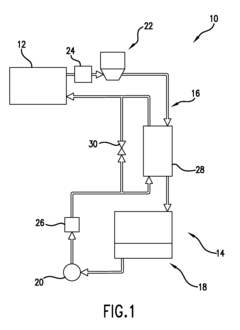

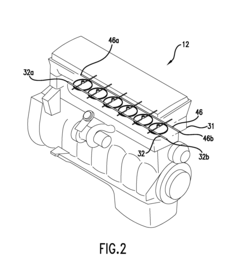

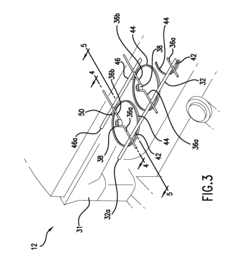

Engine having integrated waste heat recovery

PatentActiveUS8707914B2

Innovation

- Integration of a waste heat recovery system with fluid passages in the cylinder head and engine body, utilizing a working fluid that is pumped through a circuit to transfer heat from the engine to an energy conversion portion, reducing the heat load on the coolant system and enhancing engine efficiency.

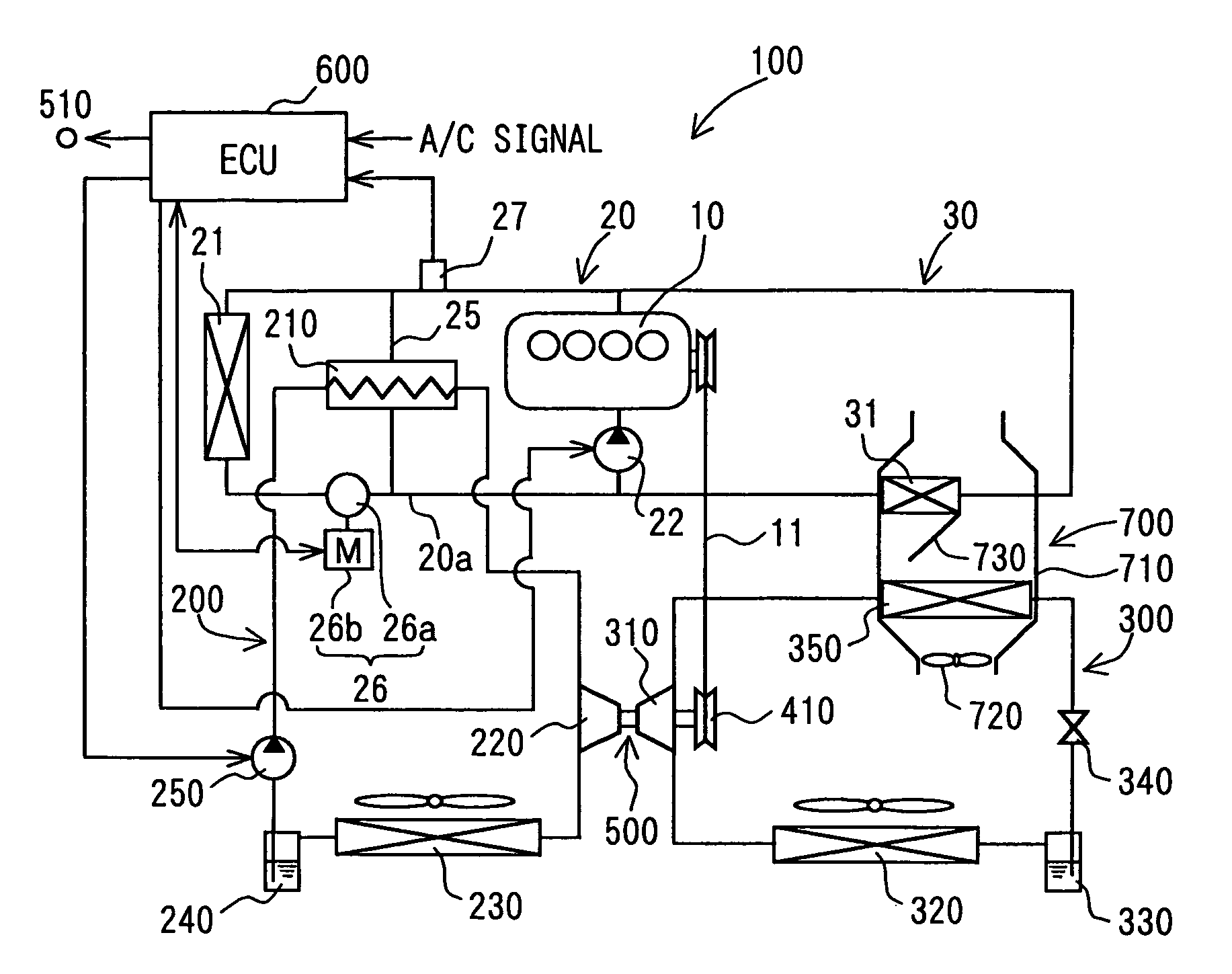

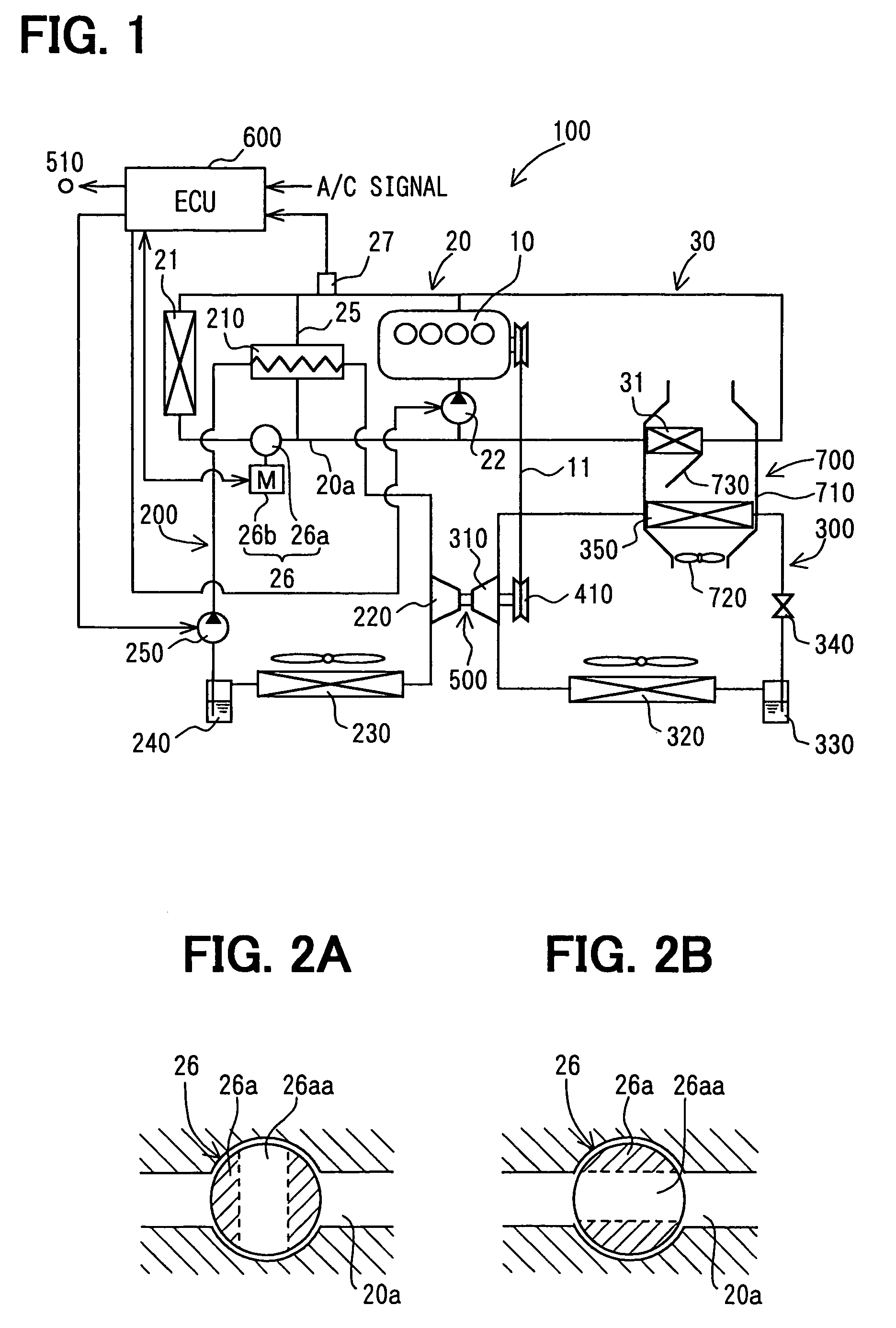

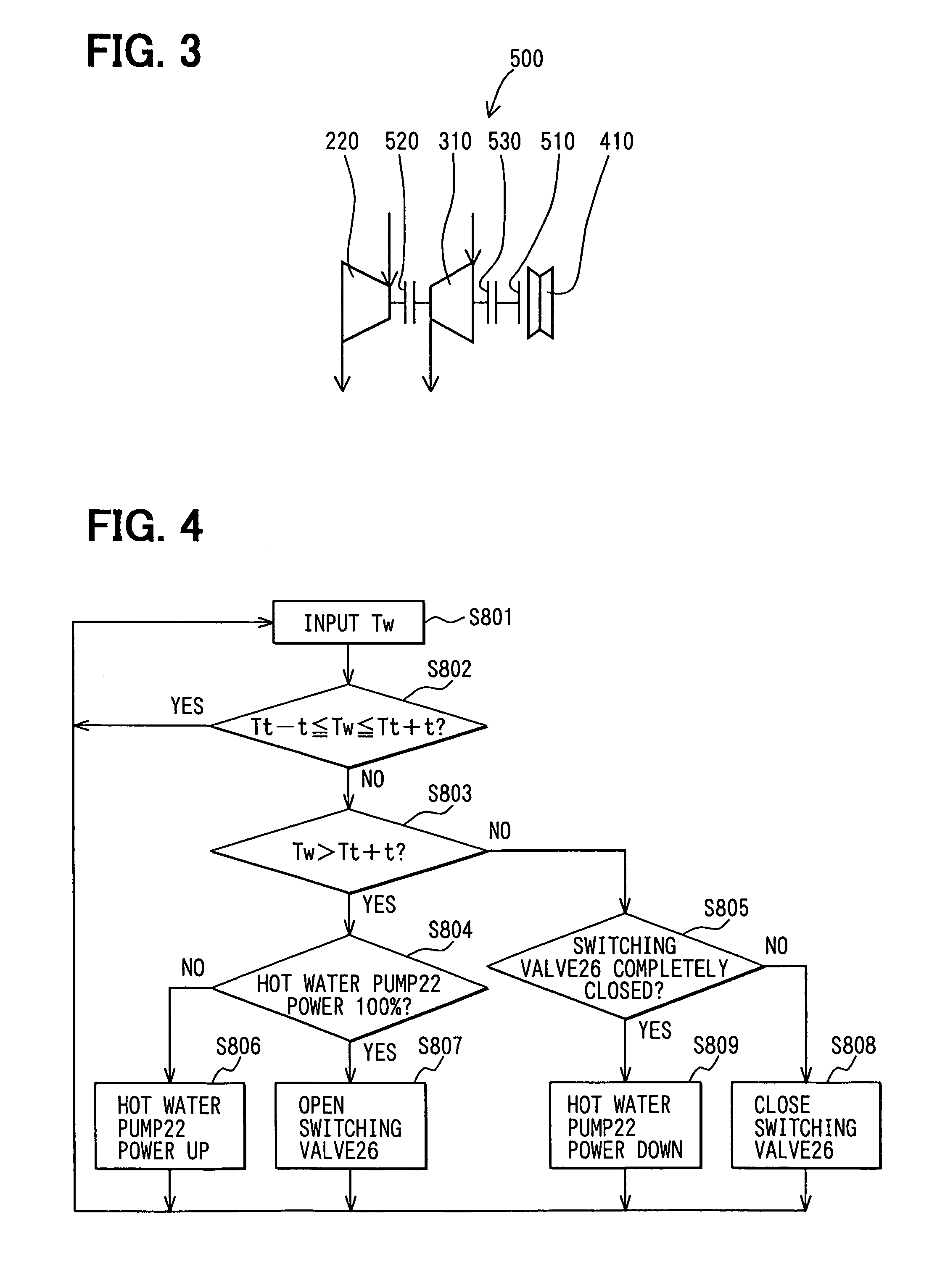

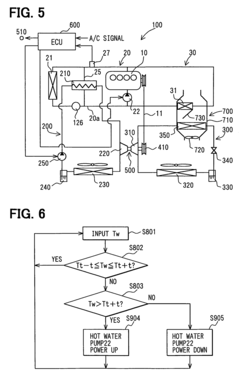

Waste heat recovery system of heat source, with Rankine cycle

PatentInactiveUS7454910B2

Innovation

- A waste heat recovery system with a heater arranged in parallel to the cooling heat exchanger in the thermal medium circuit, using a bypass circuit and a control unit to manage thermal medium flow and temperature, ensuring stable heat supply to the Rankine cycle without affecting the cooling performance of the engine.

Environmental Impact and Emissions Reduction Potential

The implementation of V10 Engine technology in Waste Heat Recovery Systems presents significant environmental benefits that align with global sustainability goals. These systems can reduce greenhouse gas emissions by capturing thermal energy that would otherwise be lost to the environment, converting it into useful power. Initial assessments indicate that V10 Engine-based waste heat recovery systems can achieve CO2 emission reductions of 10-15% in industrial applications and 8-12% in power generation facilities, depending on the specific configuration and operational parameters.

When integrated into manufacturing processes with high thermal discharge, such as cement production, steel mills, and glass manufacturing, these systems demonstrate potential to reduce carbon footprints by up to 25,000 metric tons of CO2 equivalent annually for a medium-sized facility. This represents a substantial contribution to emission reduction targets established under international climate agreements.

Beyond carbon dioxide, V10 Engine waste heat recovery systems also contribute to the reduction of other harmful emissions. By improving overall energy efficiency, these systems indirectly reduce NOx, SOx, and particulate matter emissions associated with fossil fuel combustion. Quantitative analyses suggest a corresponding decrease of 7-11% in these secondary pollutants when the technology is properly implemented.

Water conservation represents another environmental benefit, as V10 Engine systems typically require less cooling water than conventional power generation methods. This can result in freshwater savings of approximately 30-40% compared to traditional systems, a critical advantage in water-stressed regions where industrial operations compete with agricultural and municipal needs for limited water resources.

From a lifecycle perspective, environmental impact assessments indicate that the embodied carbon in manufacturing and installing V10 Engine waste heat recovery systems is typically offset within 14-18 months of operation through emission reductions. This favorable carbon payback period enhances the technology's appeal as a short-term climate change mitigation strategy.

The scalability of these systems further amplifies their environmental potential. Modeling studies suggest that widespread adoption across energy-intensive industries could contribute to national emission reduction targets by providing 2-3% of total required carbon abatement in industrialized economies, representing a significant contribution from a single technological solution.

When integrated into manufacturing processes with high thermal discharge, such as cement production, steel mills, and glass manufacturing, these systems demonstrate potential to reduce carbon footprints by up to 25,000 metric tons of CO2 equivalent annually for a medium-sized facility. This represents a substantial contribution to emission reduction targets established under international climate agreements.

Beyond carbon dioxide, V10 Engine waste heat recovery systems also contribute to the reduction of other harmful emissions. By improving overall energy efficiency, these systems indirectly reduce NOx, SOx, and particulate matter emissions associated with fossil fuel combustion. Quantitative analyses suggest a corresponding decrease of 7-11% in these secondary pollutants when the technology is properly implemented.

Water conservation represents another environmental benefit, as V10 Engine systems typically require less cooling water than conventional power generation methods. This can result in freshwater savings of approximately 30-40% compared to traditional systems, a critical advantage in water-stressed regions where industrial operations compete with agricultural and municipal needs for limited water resources.

From a lifecycle perspective, environmental impact assessments indicate that the embodied carbon in manufacturing and installing V10 Engine waste heat recovery systems is typically offset within 14-18 months of operation through emission reductions. This favorable carbon payback period enhances the technology's appeal as a short-term climate change mitigation strategy.

The scalability of these systems further amplifies their environmental potential. Modeling studies suggest that widespread adoption across energy-intensive industries could contribute to national emission reduction targets by providing 2-3% of total required carbon abatement in industrialized economies, representing a significant contribution from a single technological solution.

Economic Feasibility and ROI Analysis

The economic analysis of V10 engine applications in waste heat recovery systems reveals compelling financial incentives for implementation across various industrial sectors. Initial capital expenditure for V10-based waste heat recovery systems ranges from $500,000 to $2.5 million, depending on system scale and integration complexity. This investment encompasses equipment procurement, installation costs, system integration, and necessary facility modifications to accommodate the technology.

Operational expenses primarily consist of maintenance requirements, which are relatively modest at approximately 3-5% of the initial capital investment annually. The V10 engine's robust design contributes to extended service intervals and reduced downtime compared to alternative waste heat recovery technologies, significantly enhancing the total cost of ownership profile.

Return on investment calculations demonstrate particularly favorable outcomes in energy-intensive industries. Manufacturing facilities implementing V10-based waste heat recovery systems typically achieve payback periods of 2-4 years, while power generation applications often realize returns within 1.5-3 years. These timeframes represent a substantial improvement over previous generation technologies that averaged 4-6 year payback periods.

Energy cost savings constitute the primary economic benefit, with industrial implementations reporting 15-25% reductions in overall energy expenditure. When quantified across a standard 15-year system lifespan, this translates to cumulative savings of $3-8 million for medium-sized industrial operations, representing an ROI of 150-320%.

Carbon pricing mechanisms and environmental compliance requirements further enhance the economic case. In jurisdictions with carbon taxation or cap-and-trade systems, the avoided emissions from V10 waste heat recovery implementation generate additional financial benefits ranging from $50,000 to $300,000 annually, depending on facility size and applicable carbon pricing.

Sensitivity analysis indicates that economic viability remains robust even under challenging scenarios. The technology maintains positive ROI metrics even with 30% increases in implementation costs or 25% decreases in energy prices, demonstrating resilience to market fluctuations. This economic stability is particularly valuable in volatile energy markets where price uncertainty often impedes capital investment in efficiency technologies.

Government incentives, including tax credits, grants, and accelerated depreciation allowances for energy efficiency investments, can further improve financial outcomes. These incentives typically reduce payback periods by 6-18 months and increase lifetime ROI by 15-40%, depending on the specific programs available in different regions.

Operational expenses primarily consist of maintenance requirements, which are relatively modest at approximately 3-5% of the initial capital investment annually. The V10 engine's robust design contributes to extended service intervals and reduced downtime compared to alternative waste heat recovery technologies, significantly enhancing the total cost of ownership profile.

Return on investment calculations demonstrate particularly favorable outcomes in energy-intensive industries. Manufacturing facilities implementing V10-based waste heat recovery systems typically achieve payback periods of 2-4 years, while power generation applications often realize returns within 1.5-3 years. These timeframes represent a substantial improvement over previous generation technologies that averaged 4-6 year payback periods.

Energy cost savings constitute the primary economic benefit, with industrial implementations reporting 15-25% reductions in overall energy expenditure. When quantified across a standard 15-year system lifespan, this translates to cumulative savings of $3-8 million for medium-sized industrial operations, representing an ROI of 150-320%.

Carbon pricing mechanisms and environmental compliance requirements further enhance the economic case. In jurisdictions with carbon taxation or cap-and-trade systems, the avoided emissions from V10 waste heat recovery implementation generate additional financial benefits ranging from $50,000 to $300,000 annually, depending on facility size and applicable carbon pricing.

Sensitivity analysis indicates that economic viability remains robust even under challenging scenarios. The technology maintains positive ROI metrics even with 30% increases in implementation costs or 25% decreases in energy prices, demonstrating resilience to market fluctuations. This economic stability is particularly valuable in volatile energy markets where price uncertainty often impedes capital investment in efficiency technologies.

Government incentives, including tax credits, grants, and accelerated depreciation allowances for energy efficiency investments, can further improve financial outcomes. These incentives typically reduce payback periods by 6-18 months and increase lifetime ROI by 15-40%, depending on the specific programs available in different regions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!