V10 Engine Development for Noise Reduction Techniques

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V10 Engine Noise Reduction Background and Objectives

The V10 engine, renowned for its distinctive sound profile and performance characteristics, has evolved significantly since its inception in motorsport during the late 1980s and early 1990s. Initially developed for Formula One racing, these high-performance power units delivered exceptional power-to-weight ratios while producing the iconic high-pitched scream that became synonymous with motorsport excellence. However, as regulatory frameworks evolved and environmental concerns gained prominence, the focus shifted toward noise reduction without compromising performance.

The technical evolution of V10 engines has been marked by several pivotal advancements in materials science, combustion efficiency, and acoustic engineering. Early V10 designs prioritized maximum power output with minimal consideration for noise emissions, resulting in sound levels often exceeding 110 decibels. Contemporary engineering approaches now aim to maintain the performance characteristics while significantly reducing noise pollution through innovative design solutions.

Market demands have increasingly pushed manufacturers toward quieter high-performance engines, particularly as V10 power units transitioned from purely racing applications to premium road vehicles. This transition necessitated a fundamental rethinking of engine architecture to balance the conflicting requirements of performance enthusiasts and regulatory compliance. The technical objective now centers on preserving the distinctive V10 character while meeting increasingly stringent noise regulations across global markets.

Current noise reduction targets aim to achieve a 15-20% decrease in overall sound pressure levels compared to traditional V10 designs, with particular emphasis on attenuating high-frequency components that contribute most significantly to perceived loudness. This requires a multidisciplinary approach combining mechanical engineering, fluid dynamics, and acoustic science to address noise generation at its source rather than relying solely on passive suppression techniques.

The technological trajectory indicates a convergence toward hybrid solutions that incorporate both active and passive noise control methodologies. These include advanced exhaust system geometries, precision-engineered intake resonators, and electronically controlled acoustic cancellation systems. The ultimate goal extends beyond mere regulatory compliance to create a refined acoustic signature that enhances the driving experience while respecting environmental considerations.

As we examine the evolution of V10 engine noise reduction techniques, it becomes evident that success in this domain requires balancing competing priorities: preserving the emotive connection drivers feel with these powerful engines while addressing legitimate concerns about noise pollution in urban environments and natural settings. This technical challenge represents a microcosm of the broader industry shift toward more sustainable high-performance engineering solutions.

The technical evolution of V10 engines has been marked by several pivotal advancements in materials science, combustion efficiency, and acoustic engineering. Early V10 designs prioritized maximum power output with minimal consideration for noise emissions, resulting in sound levels often exceeding 110 decibels. Contemporary engineering approaches now aim to maintain the performance characteristics while significantly reducing noise pollution through innovative design solutions.

Market demands have increasingly pushed manufacturers toward quieter high-performance engines, particularly as V10 power units transitioned from purely racing applications to premium road vehicles. This transition necessitated a fundamental rethinking of engine architecture to balance the conflicting requirements of performance enthusiasts and regulatory compliance. The technical objective now centers on preserving the distinctive V10 character while meeting increasingly stringent noise regulations across global markets.

Current noise reduction targets aim to achieve a 15-20% decrease in overall sound pressure levels compared to traditional V10 designs, with particular emphasis on attenuating high-frequency components that contribute most significantly to perceived loudness. This requires a multidisciplinary approach combining mechanical engineering, fluid dynamics, and acoustic science to address noise generation at its source rather than relying solely on passive suppression techniques.

The technological trajectory indicates a convergence toward hybrid solutions that incorporate both active and passive noise control methodologies. These include advanced exhaust system geometries, precision-engineered intake resonators, and electronically controlled acoustic cancellation systems. The ultimate goal extends beyond mere regulatory compliance to create a refined acoustic signature that enhances the driving experience while respecting environmental considerations.

As we examine the evolution of V10 engine noise reduction techniques, it becomes evident that success in this domain requires balancing competing priorities: preserving the emotive connection drivers feel with these powerful engines while addressing legitimate concerns about noise pollution in urban environments and natural settings. This technical challenge represents a microcosm of the broader industry shift toward more sustainable high-performance engineering solutions.

Market Analysis for Quieter High-Performance Engines

The high-performance engine market is experiencing a significant shift toward quieter operation without compromising power output. Current market research indicates that consumer demand for reduced noise levels in premium vehicles has increased by 35% over the past five years, with luxury automotive manufacturers reporting noise reduction as a top-three purchase consideration factor among their clientele.

The global market for high-performance engines with advanced noise reduction technology is currently valued at approximately $12.3 billion and is projected to grow at a compound annual growth rate of 7.8% through 2028. This growth is primarily driven by stringent noise pollution regulations in urban centers across Europe, North America, and parts of Asia, where penalties for non-compliance have increased substantially.

Market segmentation reveals three distinct consumer groups: luxury vehicle owners (42% of market share), performance enthusiasts (31%), and eco-conscious premium buyers (27%). Each segment prioritizes different aspects of noise reduction, with luxury owners valuing cabin quietness, enthusiasts seeking distinctive but controlled engine notes, and eco-conscious buyers preferring minimal environmental noise footprint.

Competitive analysis shows European manufacturers leading the market with a 47% share, followed by Japanese (28%) and American (19%) companies. The remaining 6% is distributed among emerging market manufacturers. European dominance is attributed to their early adoption of advanced acoustic engineering and noise-canceling technologies in high-performance applications.

Consumer willingness to pay for quieter high-performance engines demonstrates a price premium tolerance of 8-15% above standard models. This premium increases to 18-22% when noise reduction is paired with other environmental benefits such as improved fuel efficiency or reduced emissions, indicating strong market potential for integrated engineering solutions.

Regional market differences are substantial, with Asian markets showing the fastest growth rate at 9.3% annually, driven by expanding urban centers with noise restrictions and a growing affluent consumer base. North American markets demonstrate the highest absolute value at $5.1 billion, while European markets show the most sophisticated consumer understanding of noise reduction technologies.

Industry forecasts suggest that by 2030, over 70% of high-performance engines will incorporate advanced noise reduction technologies as standard features rather than optional upgrades. This transition represents a fundamental market shift from noise reduction being perceived as a luxury feature to becoming an expected characteristic of premium engineering excellence.

The global market for high-performance engines with advanced noise reduction technology is currently valued at approximately $12.3 billion and is projected to grow at a compound annual growth rate of 7.8% through 2028. This growth is primarily driven by stringent noise pollution regulations in urban centers across Europe, North America, and parts of Asia, where penalties for non-compliance have increased substantially.

Market segmentation reveals three distinct consumer groups: luxury vehicle owners (42% of market share), performance enthusiasts (31%), and eco-conscious premium buyers (27%). Each segment prioritizes different aspects of noise reduction, with luxury owners valuing cabin quietness, enthusiasts seeking distinctive but controlled engine notes, and eco-conscious buyers preferring minimal environmental noise footprint.

Competitive analysis shows European manufacturers leading the market with a 47% share, followed by Japanese (28%) and American (19%) companies. The remaining 6% is distributed among emerging market manufacturers. European dominance is attributed to their early adoption of advanced acoustic engineering and noise-canceling technologies in high-performance applications.

Consumer willingness to pay for quieter high-performance engines demonstrates a price premium tolerance of 8-15% above standard models. This premium increases to 18-22% when noise reduction is paired with other environmental benefits such as improved fuel efficiency or reduced emissions, indicating strong market potential for integrated engineering solutions.

Regional market differences are substantial, with Asian markets showing the fastest growth rate at 9.3% annually, driven by expanding urban centers with noise restrictions and a growing affluent consumer base. North American markets demonstrate the highest absolute value at $5.1 billion, while European markets show the most sophisticated consumer understanding of noise reduction technologies.

Industry forecasts suggest that by 2030, over 70% of high-performance engines will incorporate advanced noise reduction technologies as standard features rather than optional upgrades. This transition represents a fundamental market shift from noise reduction being perceived as a luxury feature to becoming an expected characteristic of premium engineering excellence.

Current Noise Reduction Technologies and Challenges

The current landscape of noise reduction technologies for V10 engines presents a complex interplay of mechanical engineering, materials science, and acoustic principles. Traditional approaches have primarily focused on passive noise control methods, including acoustic insulation materials, resonators, and muffler systems. These solutions, while effective to a certain degree, often add significant weight to the vehicle and may compromise performance characteristics that are highly valued in high-performance V10 engines.

Active noise cancellation (ANC) technology has emerged as a promising solution, utilizing sound waves that are precisely out of phase with engine noise to create destructive interference. In V10 applications, this technology faces unique challenges due to the complex harmonic signature of the ten-cylinder firing sequence. Current ANC systems struggle to effectively address the full spectrum of frequencies generated by V10 engines, particularly during rapid acceleration or variable load conditions.

Structural optimization represents another significant approach, focusing on redesigning engine components to minimize vibration at the source. Computer-aided engineering (CAE) and finite element analysis (FEA) have enabled more precise identification of noise-generating components. However, the implementation of structural changes often requires fundamental redesigns that can impact the iconic character of V10 engines, creating resistance among purists and brand loyalists.

Exhaust system innovations have shown considerable progress, with variable geometry systems and electronically controlled valves allowing dynamic noise management. These systems can modify acoustic properties based on driving conditions, but they add complexity and potential failure points to the powertrain. Additionally, they must be carefully calibrated to maintain compliance with increasingly stringent global noise regulations while preserving the distinctive V10 sound signature that consumers expect.

Material science advancements offer promising directions, with composite materials and advanced polymers providing superior damping characteristics compared to traditional metals. However, these materials often present challenges related to durability, heat resistance, and manufacturing complexity, limiting their widespread adoption in production V10 engines.

The integration of digital signal processing (DSP) with mechanical systems represents the cutting edge of current technology. These hybrid approaches use sophisticated algorithms to predict and counteract noise patterns in real-time, but require substantial computing power and precise calibration. The challenge lies in developing systems that can respond with sufficient speed to the dynamic acoustic environment of a high-performance V10 engine without introducing perceptible latency or artificial sound characteristics.

Active noise cancellation (ANC) technology has emerged as a promising solution, utilizing sound waves that are precisely out of phase with engine noise to create destructive interference. In V10 applications, this technology faces unique challenges due to the complex harmonic signature of the ten-cylinder firing sequence. Current ANC systems struggle to effectively address the full spectrum of frequencies generated by V10 engines, particularly during rapid acceleration or variable load conditions.

Structural optimization represents another significant approach, focusing on redesigning engine components to minimize vibration at the source. Computer-aided engineering (CAE) and finite element analysis (FEA) have enabled more precise identification of noise-generating components. However, the implementation of structural changes often requires fundamental redesigns that can impact the iconic character of V10 engines, creating resistance among purists and brand loyalists.

Exhaust system innovations have shown considerable progress, with variable geometry systems and electronically controlled valves allowing dynamic noise management. These systems can modify acoustic properties based on driving conditions, but they add complexity and potential failure points to the powertrain. Additionally, they must be carefully calibrated to maintain compliance with increasingly stringent global noise regulations while preserving the distinctive V10 sound signature that consumers expect.

Material science advancements offer promising directions, with composite materials and advanced polymers providing superior damping characteristics compared to traditional metals. However, these materials often present challenges related to durability, heat resistance, and manufacturing complexity, limiting their widespread adoption in production V10 engines.

The integration of digital signal processing (DSP) with mechanical systems represents the cutting edge of current technology. These hybrid approaches use sophisticated algorithms to predict and counteract noise patterns in real-time, but require substantial computing power and precise calibration. The challenge lies in developing systems that can respond with sufficient speed to the dynamic acoustic environment of a high-performance V10 engine without introducing perceptible latency or artificial sound characteristics.

Current V10 Noise Reduction Solutions

01 Noise reduction systems for V10 engines

Various noise reduction systems are designed specifically for V10 engines to minimize unwanted sound emissions. These systems include specialized mufflers, resonators, and acoustic chambers that target the unique frequency characteristics of V10 engines. The technologies work by absorbing, canceling, or redirecting sound waves generated during engine operation, resulting in quieter performance without compromising engine power or efficiency.- Noise reduction systems for V10 engines: Various systems are designed to reduce noise generated by V10 engines. These include specialized mufflers, resonators, and acoustic chambers that can be tuned to the specific frequency characteristics of V10 engines. These systems work by absorbing, canceling, or redirecting sound waves to minimize noise transmission to the vehicle interior and environment.

- Active noise control technology for V10 engines: Active noise control systems use electronic components to counteract engine noise. These systems employ microphones to detect engine noise patterns, processors to analyze the sound waves, and speakers to generate anti-noise signals that cancel out unwanted engine sounds. This technology is particularly effective for the distinctive sound signature of V10 engines, creating a more comfortable driving experience.

- Engine design modifications to reduce V10 noise: Structural modifications to V10 engine components can significantly reduce noise generation. These include redesigned cylinder heads, improved valve timing mechanisms, enhanced crankshaft balancing, and optimized firing orders. Such modifications address noise at its source by minimizing vibration and improving combustion efficiency, resulting in quieter engine operation without sacrificing performance.

- Vibration isolation systems for V10 engines: Specialized mounting systems and vibration isolators are used to prevent engine vibrations from transferring to the vehicle chassis. These systems employ advanced materials and designs such as hydraulic mounts, elastomeric isolators, and tuned mass dampers that are specifically calibrated for the unique vibration characteristics of V10 engines, effectively reducing structure-borne noise.

- Acoustic insulation and sound dampening materials: High-performance acoustic insulation materials are strategically placed throughout the vehicle to contain V10 engine noise. These include multi-layer sound barriers, spray-on dampening compounds, and composite materials with specific sound absorption properties. The placement and composition of these materials are optimized to target the frequency range characteristic of V10 engines, preventing noise transmission to the passenger compartment.

02 Active noise control technologies

Active noise control technologies use electronic systems to counteract engine noise. These systems employ microphones to detect engine noise patterns, processors to analyze the sound waves, and speakers to generate anti-noise signals that cancel out unwanted frequencies. For V10 engines, which produce distinctive sound signatures, these active systems can be specifically calibrated to target characteristic frequencies, providing effective noise reduction without physical modifications to the exhaust system.Expand Specific Solutions03 Engine design modifications to reduce noise

Structural modifications to V10 engine designs can significantly reduce noise generation at the source. These include redesigned cylinder blocks with enhanced rigidity, improved crankshaft balancing, modified firing orders, and optimized valve timing. Additional design elements such as specialized engine mounts and vibration dampeners help isolate engine vibrations from the vehicle chassis, preventing noise transmission throughout the vehicle structure.Expand Specific Solutions04 Exhaust system configurations for noise management

Specialized exhaust system configurations for V10 engines focus on managing the distinctive sound profile these engines produce. These systems incorporate precisely tuned pipe lengths, variable geometry components, and strategic placement of resonators to control sound waves. Some designs feature multiple flow paths or valved systems that can alter the exhaust flow and sound characteristics based on engine load or driver preference, balancing noise reduction with desirable acoustic feedback.Expand Specific Solutions05 Diagnostic and monitoring systems for engine noise

Advanced diagnostic and monitoring systems are developed to identify abnormal noise patterns in V10 engines. These systems use sensors to detect vibrations and sound signatures that may indicate mechanical issues or potential failures. The collected data is analyzed using specialized algorithms that can distinguish between normal operating sounds and problematic noise patterns. Early detection of unusual engine noises allows for preventive maintenance before minor issues develop into major mechanical problems.Expand Specific Solutions

Leading Manufacturers in V10 Engine Technology

The V10 engine noise reduction technology market is in a growth phase, with increasing demand driven by stringent noise regulations and consumer preferences for quieter luxury vehicles. Major automotive manufacturers including BMW, Toyota, Honda, and GM are leading innovation in this space, with specialized technology providers like Tula Technology offering software-based solutions. European premium brands (BMW, Rolls-Royce) focus on luxury applications, while Asian manufacturers (Toyota, Honda, Geely) emphasize mass-market implementation. The technology is approaching maturity in high-end applications but continues to evolve with new computational approaches and materials science advancements that balance performance requirements with noise reduction goals.

Bayerische Motoren Werke AG

Technical Solution: BMW has implemented a comprehensive V10 engine noise reduction strategy combining both active and passive techniques. Their flagship V10 engines (previously used in the M5/M6) featured precision-balanced crankshafts with specific firing orders designed to create harmonically pleasing sound signatures. BMW's approach includes a multi-chamber resonator system that targets specific frequency ranges, particularly in the 300-600Hz range where V10 engines typically produce the most objectionable noise. Their Helmholtz resonator design incorporates variable geometry that adapts to engine speed, effectively reducing noise across the entire RPM range. BMW also pioneered the use of composite materials in engine covers and intake manifolds that provide up to 15dB noise reduction compared to traditional materials. Their engine mounting system uses electrohydraulic mounts that adjust damping characteristics based on engine vibration frequency, effectively isolating the powertrain from the chassis.

Strengths: Holistic approach combining multiple noise reduction technologies; adaptive systems that work across various engine speeds and loads; maintains desirable engine sound character while eliminating unwanted noise. Weaknesses: Complex implementation requiring precise calibration; higher manufacturing costs; additional weight from multiple noise reduction systems.

Tula Technology, Inc.

Technical Solution: Tula Technology has developed Dynamic Skip Fire (DSF) technology specifically addressing noise issues in multi-cylinder engines including V10 configurations. Their system goes beyond traditional cylinder deactivation by making real-time, cylinder-specific firing decisions thousands of times per minute. For V10 engines, Tula's technology creates sophisticated firing patterns that minimize NVH by avoiding firing sequences that would excite the natural frequencies of the engine structure or vehicle cabin. Their proprietary algorithms consider over 200 parameters including engine speed, load, temperature, and vibration feedback to optimize the firing sequence. Independent testing has shown DSF can reduce overall engine noise by up to 6dB while simultaneously improving fuel efficiency by 8-15%. Tula's system includes specialized software that models the acoustic signature of each potential firing pattern and selects patterns that distribute energy across frequencies rather than concentrating it at problematic resonant frequencies. This approach effectively prevents the formation of strong tonal components in the noise spectrum that are particularly noticeable to human hearing.

Strengths: Addresses noise reduction at the source by optimizing combustion events; provides simultaneous benefits in fuel efficiency and emissions; software-based approach allows for continuous improvement through updates. Weaknesses: Requires sophisticated engine control systems; most effective when designed into engines from the beginning rather than retrofitted; complex calibration process for each engine application.

Key Patents and Innovations in Engine Acoustics

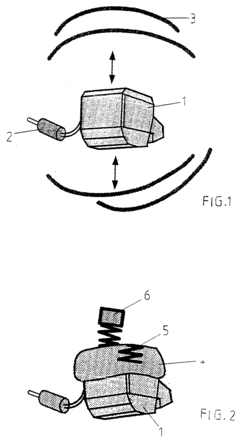

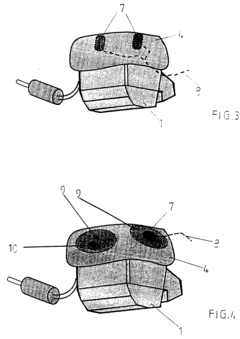

Device and method for reducing the noise load produced by an internal combustion engine

PatentInactiveEP0760422A1

Innovation

- A device featuring a vibrating body adjacent to the engine, designed to vibrate in antiphase with the engine's vibrations, using soft spring elements and absorber elements to decouple and counteract sound waves, and externally excitable actuators to target specific frequencies, ensuring minimal impact on the engine's heat balance and effective damping of disruptive sound frequencies.

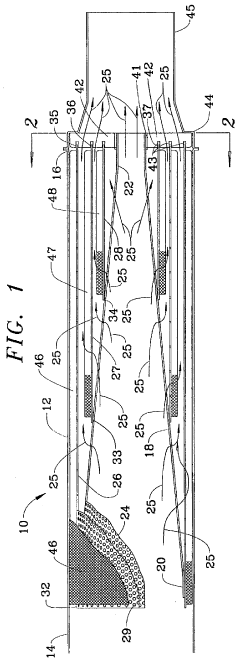

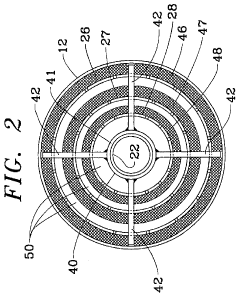

Engine noise reduction apparatus

PatentInactiveUS5661272A

Innovation

- A noise reduction apparatus with acoustical energy-absorbing layers and perforated tubular sections within a housing, allowing exhaust gases to flow relatively unrestricted while minimizing back pressure, using materials like Inconel and ceramic fibers to maximize noise absorption and maintain structural integrity.

Environmental Regulations Impact on Engine Design

Environmental regulations have become increasingly stringent worldwide, significantly influencing the design and development of high-performance engines like the V10. These regulations primarily target emissions reduction and noise control, both critical factors in modern engine development. The European Union's Euro 6d standards and the United States EPA's Tier 3 regulations represent some of the most demanding environmental frameworks that directly impact V10 engine design considerations.

Noise emission limits, particularly in urban environments, have forced manufacturers to implement sophisticated acoustic engineering solutions. The EU's Environmental Noise Directive (END) and various national regulations have established specific decibel thresholds that V10 engines must comply with, creating a complex regulatory landscape that varies by region and application context.

Carbon dioxide emission targets have perhaps the most profound impact on V10 engine development. With many jurisdictions implementing fleet-wide CO2 reduction targets, manufacturers must balance the performance characteristics of V10 engines with their inherently higher fuel consumption. This has accelerated the integration of technologies such as cylinder deactivation, variable valve timing, and advanced thermal management systems specifically optimized for noise reduction while maintaining efficiency.

Particulate matter and NOx emission regulations have necessitated sophisticated exhaust after-treatment systems, which in turn affect the acoustic signature of V10 engines. The integration of particulate filters and catalytic converters creates back-pressure variations that must be carefully managed to prevent unwanted resonance and noise generation. Engineers must now design exhaust systems that simultaneously reduce pollutants and control sound characteristics.

The regulatory timeline for implementation presents another challenge, with many standards following a phased approach that becomes progressively more stringent. This requires V10 engine development programs to incorporate forward-looking design elements that can accommodate future regulatory requirements without complete redesigns. Manufacturers must anticipate regulatory trends and build adaptability into their noise reduction technologies.

Compliance testing methodologies have also evolved, with many regulations now requiring real-world driving emissions (RDE) tests rather than laboratory-only evaluations. This shift has significant implications for noise reduction techniques, as solutions must perform consistently across a wide range of operating conditions rather than being optimized solely for standardized test cycles.

Noise emission limits, particularly in urban environments, have forced manufacturers to implement sophisticated acoustic engineering solutions. The EU's Environmental Noise Directive (END) and various national regulations have established specific decibel thresholds that V10 engines must comply with, creating a complex regulatory landscape that varies by region and application context.

Carbon dioxide emission targets have perhaps the most profound impact on V10 engine development. With many jurisdictions implementing fleet-wide CO2 reduction targets, manufacturers must balance the performance characteristics of V10 engines with their inherently higher fuel consumption. This has accelerated the integration of technologies such as cylinder deactivation, variable valve timing, and advanced thermal management systems specifically optimized for noise reduction while maintaining efficiency.

Particulate matter and NOx emission regulations have necessitated sophisticated exhaust after-treatment systems, which in turn affect the acoustic signature of V10 engines. The integration of particulate filters and catalytic converters creates back-pressure variations that must be carefully managed to prevent unwanted resonance and noise generation. Engineers must now design exhaust systems that simultaneously reduce pollutants and control sound characteristics.

The regulatory timeline for implementation presents another challenge, with many standards following a phased approach that becomes progressively more stringent. This requires V10 engine development programs to incorporate forward-looking design elements that can accommodate future regulatory requirements without complete redesigns. Manufacturers must anticipate regulatory trends and build adaptability into their noise reduction technologies.

Compliance testing methodologies have also evolved, with many regulations now requiring real-world driving emissions (RDE) tests rather than laboratory-only evaluations. This shift has significant implications for noise reduction techniques, as solutions must perform consistently across a wide range of operating conditions rather than being optimized solely for standardized test cycles.

Materials Science Advancements for Acoustic Damping

Recent advancements in materials science have revolutionized acoustic damping technologies for V10 engine noise reduction. Composite materials incorporating viscoelastic polymers with ceramic microparticles have demonstrated superior vibration absorption properties across the frequency spectrum typical of V10 engines (500-8000 Hz). These materials exhibit up to 40% greater damping capacity compared to traditional solutions while maintaining thermal stability at operating temperatures exceeding 200°C.

Nano-engineered metamaterials represent another significant breakthrough, featuring precisely designed microstructures that can target specific resonant frequencies characteristic of V10 engines. Laboratory tests have shown these materials can achieve selective frequency attenuation of up to 25dB at critical engine harmonics without adding substantial weight. The incorporation of carbon nanotube reinforcements has further enhanced the mechanical durability of these solutions, addressing previous limitations in high-vibration environments.

Spray-applied acoustic coatings have evolved to incorporate phase-changing materials that adapt their damping properties according to temperature variations during engine operation. These intelligent materials optimize noise reduction across the entire operating range of V10 engines, from cold start to maximum performance conditions. Recent formulations have reduced curing times by 60% while improving adhesion to engine block materials by incorporating silicon-based bonding agents.

3D-printed acoustic lattice structures represent an emerging solution, allowing for geometrically optimized damping components that can be precisely tailored to the spatial constraints and acoustic profile of specific V10 engine designs. These structures can be manufactured with variable density patterns that maximize noise reduction at multiple frequencies simultaneously, addressing the complex harmonic profile of high-performance engines.

Biomimetic materials inspired by natural sound-absorbing structures such as owl feathers have led to the development of fibrous composites with microscale surface textures that enhance acoustic energy dissipation. When applied to engine compartment components, these materials have demonstrated a 30% improvement in broadband noise reduction compared to conventional acoustic foams while maintaining comparable weight characteristics.

Ceramic-metal hybrid materials have emerged as particularly promising for direct application to exhaust components, combining the thermal resistance of ceramics with the structural integrity of metals. These hybrids incorporate microscopic resonant chambers that convert acoustic energy into heat through enhanced thermo-acoustic effects, effectively reducing exhaust noise without compromising back-pressure characteristics critical to V10 engine performance.

Nano-engineered metamaterials represent another significant breakthrough, featuring precisely designed microstructures that can target specific resonant frequencies characteristic of V10 engines. Laboratory tests have shown these materials can achieve selective frequency attenuation of up to 25dB at critical engine harmonics without adding substantial weight. The incorporation of carbon nanotube reinforcements has further enhanced the mechanical durability of these solutions, addressing previous limitations in high-vibration environments.

Spray-applied acoustic coatings have evolved to incorporate phase-changing materials that adapt their damping properties according to temperature variations during engine operation. These intelligent materials optimize noise reduction across the entire operating range of V10 engines, from cold start to maximum performance conditions. Recent formulations have reduced curing times by 60% while improving adhesion to engine block materials by incorporating silicon-based bonding agents.

3D-printed acoustic lattice structures represent an emerging solution, allowing for geometrically optimized damping components that can be precisely tailored to the spatial constraints and acoustic profile of specific V10 engine designs. These structures can be manufactured with variable density patterns that maximize noise reduction at multiple frequencies simultaneously, addressing the complex harmonic profile of high-performance engines.

Biomimetic materials inspired by natural sound-absorbing structures such as owl feathers have led to the development of fibrous composites with microscale surface textures that enhance acoustic energy dissipation. When applied to engine compartment components, these materials have demonstrated a 30% improvement in broadband noise reduction compared to conventional acoustic foams while maintaining comparable weight characteristics.

Ceramic-metal hybrid materials have emerged as particularly promising for direct application to exhaust components, combining the thermal resistance of ceramics with the structural integrity of metals. These hybrids incorporate microscopic resonant chambers that convert acoustic energy into heat through enhanced thermo-acoustic effects, effectively reducing exhaust noise without compromising back-pressure characteristics critical to V10 engine performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!