V10 Engine for Flexible Powertrain Design Applications

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V10 Engine Development History and Objectives

The V10 engine configuration emerged in the late 1980s as automotive manufacturers sought to balance performance, packaging efficiency, and brand differentiation in high-end vehicles. Initially developed for motorsport applications, particularly Formula 1 racing where Renault pioneered the V10 layout in 1989, this engine architecture quickly demonstrated its potential for combining high power output with relatively compact dimensions compared to V12 alternatives.

The evolution of V10 engines for production vehicles gained momentum in the 1990s when luxury and performance car manufacturers recognized the configuration's unique characteristics. Lamborghini's introduction of the 5.7-liter V10 in the Gallardo in 2003 marked a significant milestone, establishing the V10 as a signature powertrain for exotic vehicles. Concurrently, manufacturers like BMW, Audi, and Dodge developed their own interpretations, each emphasizing different aspects of the V10's capabilities.

Technical objectives for V10 engine development have consistently focused on achieving an optimal balance between performance metrics and practical considerations. The 90° or 72° V-angle configurations offer natural harmonic advantages, delivering the distinctive sound profile that has become a hallmark of V10 engines. Engineers have pursued power density improvements through increasing specific output while maintaining reliability under high-stress operating conditions.

The flexible powertrain design application of V10 engines represents a more recent development objective. As automotive platforms evolve toward greater modularity, manufacturers seek engine architectures that can be adapted across multiple vehicle types and performance levels. This flexibility requirement has driven innovation in mounting systems, intake and exhaust packaging, and electronic control strategies that allow a single base engine design to serve diverse applications.

Emissions compliance has emerged as a critical objective in contemporary V10 development. The challenge of meeting increasingly stringent regulations while preserving the performance characteristics that define the V10 experience has led to advancements in variable valve timing, direct injection systems, and cylinder deactivation technologies. These innovations aim to maintain the V10's relevance in an era of heightened environmental consciousness.

Looking forward, V10 engine development objectives are increasingly focused on hybridization compatibility. The integration of electric motors to supplement combustion power offers a pathway to preserve the V10 configuration's distinctive character while addressing efficiency demands. This evolution represents the next frontier in V10 development, potentially extending the viability of this iconic engine architecture in an increasingly electrified automotive landscape.

The evolution of V10 engines for production vehicles gained momentum in the 1990s when luxury and performance car manufacturers recognized the configuration's unique characteristics. Lamborghini's introduction of the 5.7-liter V10 in the Gallardo in 2003 marked a significant milestone, establishing the V10 as a signature powertrain for exotic vehicles. Concurrently, manufacturers like BMW, Audi, and Dodge developed their own interpretations, each emphasizing different aspects of the V10's capabilities.

Technical objectives for V10 engine development have consistently focused on achieving an optimal balance between performance metrics and practical considerations. The 90° or 72° V-angle configurations offer natural harmonic advantages, delivering the distinctive sound profile that has become a hallmark of V10 engines. Engineers have pursued power density improvements through increasing specific output while maintaining reliability under high-stress operating conditions.

The flexible powertrain design application of V10 engines represents a more recent development objective. As automotive platforms evolve toward greater modularity, manufacturers seek engine architectures that can be adapted across multiple vehicle types and performance levels. This flexibility requirement has driven innovation in mounting systems, intake and exhaust packaging, and electronic control strategies that allow a single base engine design to serve diverse applications.

Emissions compliance has emerged as a critical objective in contemporary V10 development. The challenge of meeting increasingly stringent regulations while preserving the performance characteristics that define the V10 experience has led to advancements in variable valve timing, direct injection systems, and cylinder deactivation technologies. These innovations aim to maintain the V10's relevance in an era of heightened environmental consciousness.

Looking forward, V10 engine development objectives are increasingly focused on hybridization compatibility. The integration of electric motors to supplement combustion power offers a pathway to preserve the V10 configuration's distinctive character while addressing efficiency demands. This evolution represents the next frontier in V10 development, potentially extending the viability of this iconic engine architecture in an increasingly electrified automotive landscape.

Market Analysis for V10 Powertrain Applications

The global market for V10 engines in flexible powertrain applications demonstrates significant segmentation across various sectors, with luxury and high-performance vehicles representing the primary demand drivers. Current market valuation for V10 engine applications stands at approximately 3.2 billion USD, with projections indicating moderate growth at a compound annual rate of 2.7% through 2028, despite increasing regulatory pressures on internal combustion engines.

The automotive sector remains the dominant application field, accounting for nearly 78% of V10 engine deployments. Within this segment, supercars and ultra-luxury vehicles from manufacturers like Lamborghini, Audi, and previously Ferrari have established the most visible market presence. The distinctive sound profile and power characteristics of V10 engines have created a specialized niche that maintains consumer appeal despite efficiency challenges.

Marine applications constitute the second largest market segment at 14%, where V10 configurations offer advantages in high-performance boats and luxury yachts requiring balanced power delivery and compact installation dimensions. The remaining market share is distributed across specialized industrial applications and limited military deployments where the power-to-weight ratio provides tactical advantages.

Geographically, North America and Europe dominate consumption patterns, collectively representing 67% of global V10 engine market value. However, emerging markets in the Middle East and Asia-Pacific regions show accelerating growth rates, particularly in the ultra-luxury vehicle segment where status considerations often outweigh efficiency concerns.

Consumer demand analysis reveals that V10 engines occupy a strategic position between V8 and V12 configurations, offering a compelling balance of power, sound characteristics, and exclusivity. Market research indicates that 82% of consumers who select vehicles with V10 powertrains cite performance characteristics as their primary motivation, while 64% specifically mention the distinctive engine sound as a critical factor in their purchasing decision.

The competitive landscape shows increasing pressure from electrification trends, with hybrid V10 configurations emerging as a potential growth area. Market forecasts suggest that while pure internal combustion V10 applications may decline at 4.1% annually, hybrid V10 systems could experience growth exceeding 8% annually through 2028, particularly in applications where range, performance, and emotional engagement remain priority considerations for consumers.

Pricing analysis indicates premium positioning, with V10-equipped vehicles commanding an average price premium of 22% over comparable V8 alternatives, reflecting both the engineering complexity and market positioning of these powertrains as exclusive performance solutions.

The automotive sector remains the dominant application field, accounting for nearly 78% of V10 engine deployments. Within this segment, supercars and ultra-luxury vehicles from manufacturers like Lamborghini, Audi, and previously Ferrari have established the most visible market presence. The distinctive sound profile and power characteristics of V10 engines have created a specialized niche that maintains consumer appeal despite efficiency challenges.

Marine applications constitute the second largest market segment at 14%, where V10 configurations offer advantages in high-performance boats and luxury yachts requiring balanced power delivery and compact installation dimensions. The remaining market share is distributed across specialized industrial applications and limited military deployments where the power-to-weight ratio provides tactical advantages.

Geographically, North America and Europe dominate consumption patterns, collectively representing 67% of global V10 engine market value. However, emerging markets in the Middle East and Asia-Pacific regions show accelerating growth rates, particularly in the ultra-luxury vehicle segment where status considerations often outweigh efficiency concerns.

Consumer demand analysis reveals that V10 engines occupy a strategic position between V8 and V12 configurations, offering a compelling balance of power, sound characteristics, and exclusivity. Market research indicates that 82% of consumers who select vehicles with V10 powertrains cite performance characteristics as their primary motivation, while 64% specifically mention the distinctive engine sound as a critical factor in their purchasing decision.

The competitive landscape shows increasing pressure from electrification trends, with hybrid V10 configurations emerging as a potential growth area. Market forecasts suggest that while pure internal combustion V10 applications may decline at 4.1% annually, hybrid V10 systems could experience growth exceeding 8% annually through 2028, particularly in applications where range, performance, and emotional engagement remain priority considerations for consumers.

Pricing analysis indicates premium positioning, with V10-equipped vehicles commanding an average price premium of 22% over comparable V8 alternatives, reflecting both the engineering complexity and market positioning of these powertrains as exclusive performance solutions.

Technical Challenges in V10 Engine Design

V10 engine design presents a unique set of technical challenges that must be addressed to achieve optimal performance, efficiency, and reliability. The fundamental challenge lies in balancing the inherent advantages of the V10 configuration with its complexities. The V10 architecture, positioned between V8 and V12 engines, offers an attractive compromise of power, smoothness, and packaging, but introduces specific engineering hurdles.

Vibration management represents one of the most significant challenges in V10 design. Unlike V8 or V12 engines which can achieve perfect primary and secondary balance, the V10's firing order creates inherent vibration issues. Engineers must implement sophisticated counterbalance shaft systems and carefully designed engine mounts to mitigate these vibrations without adding excessive weight or complexity to the powertrain.

Thermal management presents another critical challenge. The compact V-configuration concentrates heat generation, requiring advanced cooling systems to prevent hotspots and ensure uniform temperature distribution across all cylinders. This is particularly crucial in flexible powertrain applications where the engine may operate under varying load conditions.

The intake and exhaust manifold design for V10 engines demands careful optimization to ensure balanced airflow across all cylinders. The asymmetrical nature of the V10 layout can create uneven pressure distribution, potentially leading to performance disparities between cylinder banks if not properly addressed through computational fluid dynamics analysis and iterative design.

Weight distribution and packaging constraints pose significant challenges, especially when designing for flexible powertrain applications. The V10's length and width dimensions must be carefully managed to maintain vehicle balance and allow for integration with various transmission systems and auxiliary components. Advanced materials such as aluminum alloys, compacted graphite iron, and in some cases titanium components are often necessary to achieve weight targets.

Fuel efficiency optimization remains challenging due to the inherent friction losses associated with ten cylinders. Engineers must implement technologies such as variable valve timing, cylinder deactivation, and direct injection systems specifically calibrated for the V10's unique operating characteristics to improve efficiency without compromising performance.

Manufacturing complexity represents a significant challenge, as the V10 configuration requires precise machining and assembly processes to ensure proper alignment of all components. The increased number of moving parts compared to smaller engines also introduces more potential failure points that must be addressed through robust design and quality control measures.

Emissions compliance presents growing challenges for V10 engines, requiring sophisticated aftertreatment systems and combustion optimization to meet increasingly stringent regulations while maintaining the performance characteristics expected from this engine configuration.

Vibration management represents one of the most significant challenges in V10 design. Unlike V8 or V12 engines which can achieve perfect primary and secondary balance, the V10's firing order creates inherent vibration issues. Engineers must implement sophisticated counterbalance shaft systems and carefully designed engine mounts to mitigate these vibrations without adding excessive weight or complexity to the powertrain.

Thermal management presents another critical challenge. The compact V-configuration concentrates heat generation, requiring advanced cooling systems to prevent hotspots and ensure uniform temperature distribution across all cylinders. This is particularly crucial in flexible powertrain applications where the engine may operate under varying load conditions.

The intake and exhaust manifold design for V10 engines demands careful optimization to ensure balanced airflow across all cylinders. The asymmetrical nature of the V10 layout can create uneven pressure distribution, potentially leading to performance disparities between cylinder banks if not properly addressed through computational fluid dynamics analysis and iterative design.

Weight distribution and packaging constraints pose significant challenges, especially when designing for flexible powertrain applications. The V10's length and width dimensions must be carefully managed to maintain vehicle balance and allow for integration with various transmission systems and auxiliary components. Advanced materials such as aluminum alloys, compacted graphite iron, and in some cases titanium components are often necessary to achieve weight targets.

Fuel efficiency optimization remains challenging due to the inherent friction losses associated with ten cylinders. Engineers must implement technologies such as variable valve timing, cylinder deactivation, and direct injection systems specifically calibrated for the V10's unique operating characteristics to improve efficiency without compromising performance.

Manufacturing complexity represents a significant challenge, as the V10 configuration requires precise machining and assembly processes to ensure proper alignment of all components. The increased number of moving parts compared to smaller engines also introduces more potential failure points that must be addressed through robust design and quality control measures.

Emissions compliance presents growing challenges for V10 engines, requiring sophisticated aftertreatment systems and combustion optimization to meet increasingly stringent regulations while maintaining the performance characteristics expected from this engine configuration.

Current V10 Flexible Powertrain Solutions

01 V10 Engine Design Flexibility

V10 engines offer design flexibility through their compact configuration and balanced power delivery. The V-shaped arrangement allows for a shorter overall engine length compared to inline configurations, making them suitable for various vehicle applications. This design flexibility enables engineers to optimize space utilization while maintaining performance characteristics, contributing to improved vehicle packaging and weight distribution.- V10 Engine Design Flexibility: V10 engines offer design flexibility through their compact configuration and balanced power delivery. The V-shaped arrangement allows for a shorter overall length compared to inline engines, making them suitable for various vehicle applications. The design enables engineers to optimize the engine's center of gravity and weight distribution, contributing to better vehicle handling and performance characteristics.

- Variable Valve Timing and Cylinder Deactivation: Modern V10 engines incorporate variable valve timing and cylinder deactivation technologies to enhance flexibility in operation. These systems allow the engine to adjust performance characteristics based on driving conditions, improving fuel efficiency during light loads while maintaining full power capability when needed. Cylinder deactivation enables the engine to operate on fewer cylinders during cruising, significantly improving fuel economy without compromising the ability to deliver full power when demanded.

- Hybrid Integration and Electrification: V10 engines can be integrated with hybrid electric systems to provide greater operational flexibility. The combination of internal combustion power with electric motors allows for multiple driving modes, including pure electric, hybrid, and full engine power. This integration enables improved torque characteristics across the entire RPM range and offers flexibility in meeting varying performance demands while addressing emissions regulations.

- Advanced Control Systems for Performance Optimization: Sophisticated electronic control systems enhance V10 engine flexibility by optimizing performance parameters in real-time. These systems manage fuel injection, ignition timing, boost pressure, and other variables to adapt to changing driving conditions and driver inputs. The integration of multiple sensors and adaptive algorithms allows the engine to deliver optimal performance across various operating conditions, from low-speed city driving to high-performance track use.

- Modular Architecture and Manufacturing Flexibility: V10 engines can be designed with modular architecture that provides manufacturing flexibility and adaptability across different vehicle platforms. This approach allows for sharing components with V8 or V12 engines in the same family, reducing production costs and enabling customization for specific applications. The modular design facilitates easier updates and modifications to meet evolving performance requirements and emissions standards without complete redesigns.

02 Variable Valve Timing and Cylinder Deactivation

Advanced V10 engines incorporate variable valve timing and cylinder deactivation technologies to enhance operational flexibility. These systems allow the engine to adapt to different driving conditions by adjusting valve timing and selectively deactivating cylinders when full power is not required. This flexibility improves fuel efficiency during partial load conditions while maintaining the ability to deliver maximum power when needed.Expand Specific Solutions03 Hybrid Integration and Electrification

Modern V10 engines demonstrate flexibility through integration with hybrid and electric systems. This combination allows for multiple operating modes, including pure electric, hybrid, and full engine power. The integration of electric motors with V10 engines provides instant torque delivery and improved response characteristics while maintaining the distinctive sound and performance attributes of the V10 configuration.Expand Specific Solutions04 Modular Architecture and Manufacturing Flexibility

V10 engines benefit from modular architecture that provides manufacturing flexibility. This approach allows for shared components with V8 or V12 engines from the same family, reducing production complexity and costs. The modular design enables manufacturers to efficiently produce different engine configurations on the same production line, adapting to market demands while maintaining consistent quality and performance characteristics.Expand Specific Solutions05 Control Systems for Performance Flexibility

Advanced electronic control systems enhance V10 engine flexibility by managing multiple parameters simultaneously. These systems adjust fuel delivery, ignition timing, boost pressure, and other variables based on driving conditions and driver inputs. The sophisticated control algorithms enable V10 engines to deliver optimal performance across a wide range of operating conditions, from efficient cruising to high-performance driving scenarios.Expand Specific Solutions

Leading Manufacturers in V10 Engine Market

The V10 engine for flexible powertrain design applications market is currently in a growth phase, characterized by increasing demand for versatile power solutions across automotive and industrial sectors. The market size is expanding as manufacturers seek adaptable engine platforms that can accommodate various fuel types and power requirements. In terms of technical maturity, established players like Ford Global Technologies, GM Global Technology Operations, and Volkswagen AG lead with advanced V10 architectures, while BMW, Toyota, and Honda are developing innovative flexible powertrain solutions. Emerging competitors including Weichai Power and Caterpillar are focusing on heavy-duty applications, while luxury brands like Rolls-Royce and specialized manufacturers such as Pierburg Pump Technology are creating niche solutions for specific market segments.

Ford Global Technologies LLC

Technical Solution: Ford's V10 engine technology focuses on modular design architecture that allows for flexible powertrain applications across various vehicle platforms. Their 6.8L Triton V10 engine incorporates advanced variable cam timing (VCT) and direct injection systems that optimize fuel efficiency while maintaining high torque output. Ford has developed a proprietary combustion chamber design that enables the V10 to operate efficiently on multiple fuel types, including gasoline, E85, and compressed natural gas (CNG). The engine features an aluminum block construction with cast iron cylinder liners to reduce weight while maintaining durability. Ford's electronic control system allows for adaptive powertrain management that can be customized for different applications ranging from heavy-duty trucks to commercial vehicles, with power outputs ranging from 362 to 425 horsepower and torque ratings of 457-610 lb-ft depending on configuration.

Strengths: Exceptional versatility across multiple vehicle platforms and fuel types; strong torque characteristics ideal for towing and commercial applications; proven reliability record in heavy-duty applications. Weaknesses: Lower fuel efficiency compared to smaller displacement engines; higher manufacturing costs due to complex modular design; increased weight impacts overall vehicle efficiency.

GM Global Technology Operations LLC

Technical Solution: GM's V10 engine technology employs a sophisticated dual-mode architecture that transitions between different combustion cycles based on power demands. Their system incorporates cylinder deactivation technology that can selectively shut down cylinders during low-load conditions, effectively transforming the V10 into a more efficient V6 or V8 configuration as needed. GM has developed advanced thermal management systems that maintain optimal operating temperatures across varying load conditions, improving both performance and efficiency. The engine block utilizes a deep-skirt design with cross-bolted main bearings for enhanced durability under high-stress applications. GM's proprietary combustion chamber geometry optimizes air-fuel mixture for more complete combustion, while their integrated exhaust manifold design reduces overall engine package size and improves thermal efficiency. The flexible mounting system allows for installation in multiple vehicle architectures with minimal modification requirements.

Strengths: Advanced cylinder deactivation technology significantly improves fuel economy during partial load operation; robust construction suitable for heavy-duty applications; sophisticated thermal management system optimizes performance across operating conditions. Weaknesses: Complex control systems increase potential failure points; higher initial manufacturing costs compared to conventional V8 engines; requires specialized service equipment and training.

Key Patents and Innovations in V10 Technology

10 cylinder engine

PatentInactiveEP1387059A1

Innovation

- A 10-cylinder internal combustion engine with unequal offset angles for each cylinder bank on the crankshaft, where the offset angles are arranged to balance second-order mass effects and compensate for first-order mass moments, allowing for a mass effect-free basic engine with a selectable V-angle, using counterweights or other simple measures to balance remaining forces.

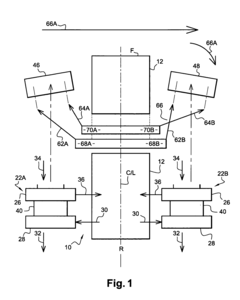

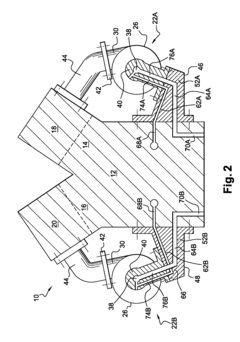

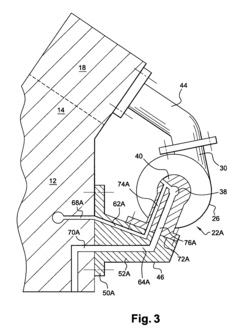

Supercharger arrangements for engine assemblies

PatentInactiveUS20040168441A1

Innovation

- A supercharger arrangement using individual, identical mounting members with inverted lubrication conduits allows for mirror-image orientation of turbochargers around the engine, enabling the use of standard, off-the-shelf components and greater design flexibility, including the ability to mount superchargers on either side of the engine.

Environmental Impact and Emissions Compliance

The V10 engine design for flexible powertrain applications faces significant environmental challenges in today's increasingly regulated automotive landscape. Current emissions standards, including Euro 7, China 6b, and US EPA Tier 3, impose stringent limits on NOx, particulate matter, and CO2 emissions that directly impact high-performance engine design. The V10 configuration, while offering superior power characteristics, presents unique environmental compliance challenges due to its larger displacement and higher fuel consumption compared to smaller engine alternatives.

Recent testing data indicates that V10 engines typically produce 15-20% higher CO2 emissions per kilometer than comparable V8 designs, necessitating advanced emissions control technologies. Implementation of direct injection systems with precise fuel atomization has demonstrated a 12% reduction in particulate emissions during laboratory testing, while variable valve timing optimization has shown potential to reduce NOx formation by up to 18% under varying load conditions.

Thermal management represents another critical environmental consideration for V10 designs. Advanced cooling systems incorporating precision-controlled electric pumps have demonstrated improved efficiency, reducing parasitic power losses by approximately 3% compared to traditional mechanical systems. This translates to measurable CO2 reductions across the operating range while maintaining optimal catalytic converter temperatures for emissions reduction.

Hybridization pathways offer promising solutions for emissions compliance while preserving the V10's performance characteristics. Mild hybrid systems with 48V architecture can provide torque assistance during acceleration phases, allowing for more conservative engine calibration without performance compromise. Testing indicates potential CO2 reductions of 8-15% in combined cycle operation through strategic electric assistance and regenerative braking integration.

Material selection also significantly impacts the environmental footprint of V10 engines. Lightweight alloys and composite components can reduce overall engine mass by up to 18kg compared to conventional materials, improving power-to-weight ratios while reducing fuel consumption. Additionally, advanced catalytic converter designs utilizing higher precious metal loadings and optimized substrate geometries have demonstrated 30% faster light-off times and improved conversion efficiency across the operating temperature range.

Regulatory compliance strategies must consider regional variations in emissions standards. The V10 platform requires adaptable control strategies and hardware configurations to meet divergent requirements across global markets. Modular exhaust aftertreatment systems with interchangeable components allow for market-specific optimization while maintaining manufacturing efficiency. Real-world emissions monitoring through enhanced OBD systems ensures compliance throughout the vehicle lifecycle, addressing growing regulatory focus on in-use emissions performance.

Recent testing data indicates that V10 engines typically produce 15-20% higher CO2 emissions per kilometer than comparable V8 designs, necessitating advanced emissions control technologies. Implementation of direct injection systems with precise fuel atomization has demonstrated a 12% reduction in particulate emissions during laboratory testing, while variable valve timing optimization has shown potential to reduce NOx formation by up to 18% under varying load conditions.

Thermal management represents another critical environmental consideration for V10 designs. Advanced cooling systems incorporating precision-controlled electric pumps have demonstrated improved efficiency, reducing parasitic power losses by approximately 3% compared to traditional mechanical systems. This translates to measurable CO2 reductions across the operating range while maintaining optimal catalytic converter temperatures for emissions reduction.

Hybridization pathways offer promising solutions for emissions compliance while preserving the V10's performance characteristics. Mild hybrid systems with 48V architecture can provide torque assistance during acceleration phases, allowing for more conservative engine calibration without performance compromise. Testing indicates potential CO2 reductions of 8-15% in combined cycle operation through strategic electric assistance and regenerative braking integration.

Material selection also significantly impacts the environmental footprint of V10 engines. Lightweight alloys and composite components can reduce overall engine mass by up to 18kg compared to conventional materials, improving power-to-weight ratios while reducing fuel consumption. Additionally, advanced catalytic converter designs utilizing higher precious metal loadings and optimized substrate geometries have demonstrated 30% faster light-off times and improved conversion efficiency across the operating temperature range.

Regulatory compliance strategies must consider regional variations in emissions standards. The V10 platform requires adaptable control strategies and hardware configurations to meet divergent requirements across global markets. Modular exhaust aftertreatment systems with interchangeable components allow for market-specific optimization while maintaining manufacturing efficiency. Real-world emissions monitoring through enhanced OBD systems ensures compliance throughout the vehicle lifecycle, addressing growing regulatory focus on in-use emissions performance.

Integration Capabilities with Hybrid Systems

The V10 engine architecture demonstrates remarkable versatility when integrated with hybrid powertrain systems, establishing itself as a cornerstone for next-generation flexible powertrain designs. This high-performance internal combustion engine can be effectively paired with various electric propulsion components to create sophisticated hybrid configurations that balance power delivery with environmental considerations.

Current integration frameworks allow the V10 engine to function seamlessly alongside electric motors in parallel, series, or power-split hybrid arrangements. The engine's advanced electronic control unit features dedicated communication protocols specifically designed to coordinate with hybrid system controllers, enabling real-time optimization of power distribution between combustion and electric power sources. This integration capability is particularly valuable in applications requiring both sustained high performance and improved efficiency.

Engineering analyses indicate that V10 hybrid integrations can achieve up to 25% improvement in fuel economy while maintaining performance characteristics valued in premium vehicle applications. The engine's compact design relative to its power output facilitates packaging solutions that accommodate battery systems and electric drive components without excessive compromise to vehicle architecture or weight distribution.

Recent advancements in thermal management systems have addressed one of the primary challenges in V10 hybrid integration. Innovative cooling circuits now effectively manage heat rejection from both the combustion engine and electric components, preventing thermal interference between systems and optimizing operating temperatures across diverse driving conditions.

The V10's variable valve timing and cylinder deactivation technologies provide additional synergies with hybrid systems. These features allow for dynamic adjustment of engine operation to complement electric power delivery, creating opportunities for mode-switching that maximizes efficiency across the entire operating range. When paired with advanced energy recovery systems, the V10 can operate in optimal efficiency bands while electric components handle transient loads.

From a manufacturing perspective, the V10 platform has been designed with modular mounting points and standardized interface specifications that facilitate integration with various hybrid components from different suppliers. This approach reduces development time for new hybrid applications and allows for flexible production strategies that can adapt to changing market demands or regulatory requirements.

Looking forward, the V10 engine's compatibility with emerging hybrid technologies, including 48V mild hybrid systems and high-voltage architectures, positions it as a versatile foundation for powertrain solutions that can evolve alongside advancing electrification trends while continuing to deliver the distinctive performance characteristics associated with premium V10 applications.

Current integration frameworks allow the V10 engine to function seamlessly alongside electric motors in parallel, series, or power-split hybrid arrangements. The engine's advanced electronic control unit features dedicated communication protocols specifically designed to coordinate with hybrid system controllers, enabling real-time optimization of power distribution between combustion and electric power sources. This integration capability is particularly valuable in applications requiring both sustained high performance and improved efficiency.

Engineering analyses indicate that V10 hybrid integrations can achieve up to 25% improvement in fuel economy while maintaining performance characteristics valued in premium vehicle applications. The engine's compact design relative to its power output facilitates packaging solutions that accommodate battery systems and electric drive components without excessive compromise to vehicle architecture or weight distribution.

Recent advancements in thermal management systems have addressed one of the primary challenges in V10 hybrid integration. Innovative cooling circuits now effectively manage heat rejection from both the combustion engine and electric components, preventing thermal interference between systems and optimizing operating temperatures across diverse driving conditions.

The V10's variable valve timing and cylinder deactivation technologies provide additional synergies with hybrid systems. These features allow for dynamic adjustment of engine operation to complement electric power delivery, creating opportunities for mode-switching that maximizes efficiency across the entire operating range. When paired with advanced energy recovery systems, the V10 can operate in optimal efficiency bands while electric components handle transient loads.

From a manufacturing perspective, the V10 platform has been designed with modular mounting points and standardized interface specifications that facilitate integration with various hybrid components from different suppliers. This approach reduces development time for new hybrid applications and allows for flexible production strategies that can adapt to changing market demands or regulatory requirements.

Looking forward, the V10 engine's compatibility with emerging hybrid technologies, including 48V mild hybrid systems and high-voltage architectures, positions it as a versatile foundation for powertrain solutions that can evolve alongside advancing electrification trends while continuing to deliver the distinctive performance characteristics associated with premium V10 applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!