V10 Engine Operational Testing in Extreme Weather Conditions

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V10 Engine Development History and Testing Objectives

The V10 engine represents a significant milestone in high-performance engine development, with its origins dating back to the early 1990s when automotive manufacturers sought to create powertrains that could deliver exceptional performance while maintaining reliability. The initial V10 concept emerged as a balance between the common V8 and V12 configurations, offering improved power-to-weight ratios and unique harmonic characteristics. Early prototypes faced considerable challenges in thermal management and structural integrity, particularly when operating at high RPMs.

Throughout the 2000s, V10 engine development accelerated significantly with the introduction of advanced materials such as aluminum-silicon alloys and titanium components, which substantially reduced weight while improving thermal efficiency. The implementation of variable valve timing and direct injection systems further enhanced performance capabilities, allowing V10 engines to achieve previously unattainable power outputs while meeting increasingly stringent emissions standards.

The current generation of V10 engines incorporates sophisticated electronic control systems that continuously optimize performance parameters based on operational conditions. These systems have dramatically improved efficiency but have also introduced new complexities in testing requirements, particularly when evaluating performance across diverse environmental conditions. Modern V10 engines must maintain consistent performance characteristics regardless of ambient temperature, humidity, or altitude.

Testing objectives for V10 engines in extreme weather conditions focus on several critical parameters. Primary among these is thermal stability, as extreme temperatures can significantly impact combustion efficiency, lubrication effectiveness, and overall mechanical integrity. Cold-weather testing aims to evaluate starting reliability, warm-up characteristics, and emissions compliance at temperatures as low as -40°C, while hot-weather testing examines cooling system capacity and material durability at temperatures exceeding 50°C.

Another key testing objective involves evaluating the engine's electronic management systems under environmental stress. Modern V10 engines rely heavily on sensor networks and control algorithms that must function flawlessly across all operational conditions. Testing protocols must verify sensor accuracy and control system responsiveness under temperature extremes that can affect electronic component performance.

Durability testing represents a third critical objective, with protocols designed to simulate years of operation under challenging conditions within compressed timeframes. These accelerated aging tests help identify potential failure points and validate design improvements before production implementation. The goal is to ensure that V10 engines maintain performance characteristics and reliability throughout their operational lifespan, regardless of the environmental conditions they encounter.

Throughout the 2000s, V10 engine development accelerated significantly with the introduction of advanced materials such as aluminum-silicon alloys and titanium components, which substantially reduced weight while improving thermal efficiency. The implementation of variable valve timing and direct injection systems further enhanced performance capabilities, allowing V10 engines to achieve previously unattainable power outputs while meeting increasingly stringent emissions standards.

The current generation of V10 engines incorporates sophisticated electronic control systems that continuously optimize performance parameters based on operational conditions. These systems have dramatically improved efficiency but have also introduced new complexities in testing requirements, particularly when evaluating performance across diverse environmental conditions. Modern V10 engines must maintain consistent performance characteristics regardless of ambient temperature, humidity, or altitude.

Testing objectives for V10 engines in extreme weather conditions focus on several critical parameters. Primary among these is thermal stability, as extreme temperatures can significantly impact combustion efficiency, lubrication effectiveness, and overall mechanical integrity. Cold-weather testing aims to evaluate starting reliability, warm-up characteristics, and emissions compliance at temperatures as low as -40°C, while hot-weather testing examines cooling system capacity and material durability at temperatures exceeding 50°C.

Another key testing objective involves evaluating the engine's electronic management systems under environmental stress. Modern V10 engines rely heavily on sensor networks and control algorithms that must function flawlessly across all operational conditions. Testing protocols must verify sensor accuracy and control system responsiveness under temperature extremes that can affect electronic component performance.

Durability testing represents a third critical objective, with protocols designed to simulate years of operation under challenging conditions within compressed timeframes. These accelerated aging tests help identify potential failure points and validate design improvements before production implementation. The goal is to ensure that V10 engines maintain performance characteristics and reliability throughout their operational lifespan, regardless of the environmental conditions they encounter.

Market Requirements for Extreme Weather Performance

The global market for engines capable of operating in extreme weather conditions has shown significant growth over the past decade, driven primarily by increasing demand in sectors such as aviation, military, emergency response, and remote industrial operations. Market research indicates that customers across these sectors require engines that can maintain optimal performance in temperature ranges from -40°C to +50°C, while also withstanding high humidity, dust storms, and high-altitude conditions.

In the commercial transportation sector, fleet operators have expressed growing concerns about engine reliability during increasingly frequent extreme weather events. A survey conducted among fleet managers revealed that 78% consider extreme weather performance a critical factor in purchasing decisions, up from 62% five years ago. This shift reflects the economic impact of weather-related downtime, which can cost transportation companies an average of $30,000 per day per vehicle in lost revenue and recovery expenses.

Military applications present particularly stringent requirements, with defense contractors specifying engines that must start reliably in Arctic conditions (-40°C) and maintain stable operation in desert environments (+50°C) without performance degradation. The defense market segment values consistent torque delivery and fuel efficiency across these temperature extremes, with less than 5% performance variation considered acceptable.

The mining and resource extraction industries represent another significant market segment, where equipment often operates in remote locations with minimal support infrastructure. These customers prioritize not only temperature resistance but also protection against particulate infiltration and humidity-related corrosion. Market feedback indicates willingness to pay a 15-20% premium for engines with proven extreme weather resilience compared to standard models.

Consumer expectations regarding extreme weather performance have also evolved substantially. Analysis of warranty claims shows that engine failures during unusual weather events generate disproportionately negative customer sentiment and brand damage. Automotive manufacturers report that vehicles with documented extreme weather capability command higher resale values and customer loyalty rates.

Geographically, the fastest-growing markets for extreme weather-capable engines are in regions experiencing climate volatility, including Northern Europe, Canada, Australia, and parts of Asia with monsoon seasons. These markets show compound annual growth rates of 7-9% for specialized engine solutions, compared to 3-4% for conventional engines.

The market increasingly demands comprehensive testing data and certification for extreme weather performance, with third-party validation becoming a competitive differentiator. Customers specifically request detailed performance mapping across temperature gradients, with particular attention to cold-start capabilities, thermal management efficiency, and component durability under rapid temperature fluctuations.

In the commercial transportation sector, fleet operators have expressed growing concerns about engine reliability during increasingly frequent extreme weather events. A survey conducted among fleet managers revealed that 78% consider extreme weather performance a critical factor in purchasing decisions, up from 62% five years ago. This shift reflects the economic impact of weather-related downtime, which can cost transportation companies an average of $30,000 per day per vehicle in lost revenue and recovery expenses.

Military applications present particularly stringent requirements, with defense contractors specifying engines that must start reliably in Arctic conditions (-40°C) and maintain stable operation in desert environments (+50°C) without performance degradation. The defense market segment values consistent torque delivery and fuel efficiency across these temperature extremes, with less than 5% performance variation considered acceptable.

The mining and resource extraction industries represent another significant market segment, where equipment often operates in remote locations with minimal support infrastructure. These customers prioritize not only temperature resistance but also protection against particulate infiltration and humidity-related corrosion. Market feedback indicates willingness to pay a 15-20% premium for engines with proven extreme weather resilience compared to standard models.

Consumer expectations regarding extreme weather performance have also evolved substantially. Analysis of warranty claims shows that engine failures during unusual weather events generate disproportionately negative customer sentiment and brand damage. Automotive manufacturers report that vehicles with documented extreme weather capability command higher resale values and customer loyalty rates.

Geographically, the fastest-growing markets for extreme weather-capable engines are in regions experiencing climate volatility, including Northern Europe, Canada, Australia, and parts of Asia with monsoon seasons. These markets show compound annual growth rates of 7-9% for specialized engine solutions, compared to 3-4% for conventional engines.

The market increasingly demands comprehensive testing data and certification for extreme weather performance, with third-party validation becoming a competitive differentiator. Customers specifically request detailed performance mapping across temperature gradients, with particular attention to cold-start capabilities, thermal management efficiency, and component durability under rapid temperature fluctuations.

Technical Challenges in Extreme Temperature Operation

The V10 engine faces significant operational challenges when subjected to extreme temperature conditions, which can substantially impact its performance, reliability, and durability. At extremely low temperatures (below -30°C), engine oil viscosity increases dramatically, creating resistance to moving parts and potentially causing inadequate lubrication during cold starts. This can lead to accelerated wear on critical components such as bearings, camshafts, and cylinder walls.

Fuel atomization becomes problematic in cold conditions as well, with decreased volatility resulting in incomplete combustion, increased emissions, and potential starting failures. The V10's electronic control systems, including sensors and actuators, may experience response delays or inaccurate readings when operating in extreme cold, compromising the precision of the engine management system.

Conversely, at high temperatures (above 50°C), the V10 engine faces equally challenging issues. Cooling system efficiency becomes critical as the risk of overheating increases substantially. The high-performance nature of the V10 configuration generates significant heat that must be effectively dissipated, requiring advanced thermal management solutions beyond conventional cooling systems.

Oil degradation accelerates at elevated temperatures, potentially reducing its lubricating properties and increasing the risk of engine damage. The V10's complex electronic components are particularly vulnerable to heat-related failures, with potential for sensor malfunctions, control unit errors, and electrical connection issues as temperatures rise.

Material expansion differentials present another significant challenge, as the V10's diverse materials (aluminum, steel, composites) expand at different rates under extreme heat, potentially affecting critical tolerances and clearances within the engine assembly. This can lead to increased friction, reduced efficiency, and accelerated component wear.

Intercooler efficiency diminishes in hot environments, reducing the density of intake air and consequently decreasing engine power output. This is particularly problematic for turbocharged V10 variants that rely heavily on efficient charge cooling to maintain performance specifications.

Fuel system components may also experience vapor lock in extreme heat conditions, disrupting fuel delivery and causing performance instability. Additionally, the V10's exhaust system faces increased thermal stress, potentially accelerating material fatigue and component failure rates when repeatedly exposed to extreme temperature cycling.

Fuel atomization becomes problematic in cold conditions as well, with decreased volatility resulting in incomplete combustion, increased emissions, and potential starting failures. The V10's electronic control systems, including sensors and actuators, may experience response delays or inaccurate readings when operating in extreme cold, compromising the precision of the engine management system.

Conversely, at high temperatures (above 50°C), the V10 engine faces equally challenging issues. Cooling system efficiency becomes critical as the risk of overheating increases substantially. The high-performance nature of the V10 configuration generates significant heat that must be effectively dissipated, requiring advanced thermal management solutions beyond conventional cooling systems.

Oil degradation accelerates at elevated temperatures, potentially reducing its lubricating properties and increasing the risk of engine damage. The V10's complex electronic components are particularly vulnerable to heat-related failures, with potential for sensor malfunctions, control unit errors, and electrical connection issues as temperatures rise.

Material expansion differentials present another significant challenge, as the V10's diverse materials (aluminum, steel, composites) expand at different rates under extreme heat, potentially affecting critical tolerances and clearances within the engine assembly. This can lead to increased friction, reduced efficiency, and accelerated component wear.

Intercooler efficiency diminishes in hot environments, reducing the density of intake air and consequently decreasing engine power output. This is particularly problematic for turbocharged V10 variants that rely heavily on efficient charge cooling to maintain performance specifications.

Fuel system components may also experience vapor lock in extreme heat conditions, disrupting fuel delivery and causing performance instability. Additionally, the V10's exhaust system faces increased thermal stress, potentially accelerating material fatigue and component failure rates when repeatedly exposed to extreme temperature cycling.

Current Extreme Weather Testing Methodologies

01 Engine performance monitoring and diagnostics

V10 engines require sophisticated monitoring systems to ensure optimal operational performance. These systems collect and analyze data on various engine parameters such as temperature, pressure, and fuel consumption to detect potential issues before they lead to failures. Advanced diagnostic tools can provide real-time feedback on engine performance, allowing for timely maintenance and adjustments to maximize efficiency and power output.- Engine performance monitoring and diagnostics: V10 engines require sophisticated monitoring systems to ensure optimal operational performance. These systems collect and analyze data on various engine parameters such as temperature, pressure, and fuel consumption to detect potential issues before they lead to failures. Advanced diagnostic tools can provide real-time feedback on engine performance, allowing for timely maintenance and adjustments to maximize efficiency and power output.

- Fuel efficiency optimization: Improving fuel efficiency is a critical aspect of V10 engine operational performance. Various technologies and methods are employed to optimize fuel consumption while maintaining power output. These include advanced fuel injection systems, cylinder deactivation during low-load conditions, and electronic control units that precisely manage the air-fuel mixture. Optimizing combustion processes and reducing friction losses also contribute significantly to enhancing the overall fuel efficiency of V10 engines.

- Performance testing and validation: Comprehensive testing and validation procedures are essential for ensuring the operational performance of V10 engines. These procedures involve bench testing, dynamometer runs, and real-world driving scenarios to evaluate power output, torque curves, and overall reliability. Advanced simulation tools and data analytics are used to predict performance under various conditions and identify potential areas for improvement. Validation protocols ensure that the engine meets all performance specifications and regulatory requirements.

- Electronic control systems: Electronic control systems play a crucial role in optimizing V10 engine operational performance. These systems manage various engine functions including ignition timing, valve timing, fuel injection, and emissions control. Advanced engine control units (ECUs) use complex algorithms to adjust engine parameters in real-time based on driving conditions and performance demands. Integration with vehicle systems allows for modes such as sport, economy, or comfort, each with different engine performance characteristics.

- Performance data analytics: Data analytics is increasingly important for understanding and improving V10 engine operational performance. By collecting and analyzing vast amounts of performance data, engineers can identify patterns, trends, and anomalies that affect engine efficiency and power output. Machine learning algorithms can predict maintenance needs and suggest performance optimizations. Cloud-based platforms enable remote monitoring and analysis of engine performance data, facilitating continuous improvement and predictive maintenance strategies.

02 Fuel efficiency optimization in V10 engines

Improving fuel efficiency is a critical aspect of V10 engine operational performance. Various technologies and methods are employed to optimize fuel consumption while maintaining power output. These include advanced fuel injection systems, cylinder deactivation during low-load conditions, and electronic control units that precisely manage fuel-air mixtures. Optimization algorithms can adjust engine parameters in real-time based on driving conditions to achieve the best balance between performance and efficiency.Expand Specific Solutions03 Performance testing and simulation systems

Testing and simulation systems are essential for evaluating and improving V10 engine operational performance. These systems can simulate various operating conditions and load scenarios to assess engine behavior without physical testing. Advanced computational models can predict performance metrics, thermal behavior, and mechanical stress under different conditions. This allows engineers to optimize engine design and calibration for maximum performance, reliability, and efficiency before production.Expand Specific Solutions04 Power output enhancement techniques

Various techniques are employed to enhance the power output of V10 engines. These include optimizing valve timing, improving intake and exhaust flow dynamics, and implementing forced induction systems such as turbochargers or superchargers. Advanced materials and precision manufacturing techniques allow for higher compression ratios and reduced friction losses. Electronic control systems can be calibrated to maximize torque and horsepower across different RPM ranges while maintaining reliability.Expand Specific Solutions05 Predictive maintenance and performance analytics

Predictive maintenance systems use data analytics and machine learning to forecast potential performance issues in V10 engines. By analyzing operational data patterns, these systems can predict component wear and failure before they occur, allowing for scheduled maintenance that minimizes downtime. Performance analytics provide insights into how the engine operates under various conditions, enabling continuous improvement of operational parameters and maintenance protocols to maintain peak performance throughout the engine's lifecycle.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The V10 engine operational testing in extreme weather conditions market is in a growth phase, with increasing demand driven by automotive and aerospace sectors. The market size is expanding as manufacturers prioritize performance reliability across diverse climates. Technologically, the field shows varying maturity levels among key players. Toyota, BMW, and Ford lead with advanced testing infrastructures, while Pratt & Whitney and Rolls-Royce demonstrate aerospace-specific expertise. Emerging players like Weichai Power and DENSO are rapidly advancing their capabilities. Research institutions including Beihang University and Xi'an Aerospace Propulsion Testing Institute provide critical academic support, creating a competitive landscape balanced between established manufacturers and specialized testing facilities.

Toyota Motor Corp.

Technical Solution: Toyota has established a sophisticated V10 engine testing program specifically for extreme weather validation called "Global Climate Endurance Protocol" (GCEP). Their approach includes dedicated testing facilities in Hokkaido, Japan for cold weather (-40°C) and Arizona, USA for hot weather (+50°C) testing. Toyota's methodology incorporates extended durability testing where V10 engines operate continuously for up to 10,000 hours under varying temperature conditions to simulate entire lifecycle performance. Their testing protocol includes specialized thermal shock chambers that can transition from extreme cold to extreme heat in under 30 minutes while monitoring engine performance. Toyota supplements laboratory testing with extensive real-world validation, including high-altitude testing in the Andes Mountains and humidity testing in Southeast Asian tropical environments to ensure comprehensive environmental coverage.

Strengths: Toyota's exceptionally long-duration testing protocols provide unique insights into long-term reliability under extreme conditions. Their global testing network enables validation across diverse climate zones. Weaknesses: Their methodical approach to testing can extend development timelines compared to competitors using more accelerated testing protocols.

Ford Global Technologies LLC

Technical Solution: Ford has developed comprehensive V10 engine testing protocols specifically designed for extreme weather conditions. Their approach includes specialized cold chambers capable of reaching -40°C and heat chambers exceeding 50°C to simulate desert conditions. Ford's V10 testing methodology incorporates real-time monitoring systems with over 200 sensor points throughout the engine to collect performance data during temperature transitions. Their proprietary Extreme Thermal Cycle Testing (ETCT) subjects V10 engines to rapid temperature fluctuations, simulating the most demanding operational scenarios. Ford has established dedicated testing facilities in Arctic regions and desert environments to validate laboratory findings with real-world performance data, ensuring their V10 engines maintain optimal performance across all climate conditions.

Strengths: Extensive global testing infrastructure allows for authentic environmental testing rather than just simulated conditions. Their comprehensive sensor network provides exceptionally detailed performance data. Weaknesses: The extensive testing protocol requires significant time investment, potentially extending development cycles compared to competitors with more streamlined approaches.

Key Patents in Thermal Management Systems

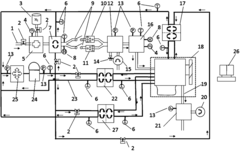

Test system capable of simulating working process of power machine in extreme climate

PatentInactiveCN108318274A

Innovation

- A test system including an air intake simulation system, an exhaust simulation system and a cooling system is designed. Through the air duct, mixing box, heat exchanger, dryer, humidifier, pressure reducing box, pressure stabilizing box and cooling system, the simulation The climate conditions are low pressure, low oxygen content, low temperature, high/low humidity, and the fuel and body temperature are controlled through heat exchange technology to ensure that the state of the power machinery during the test is consistent with the actual extreme climate.

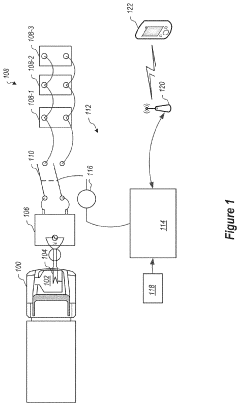

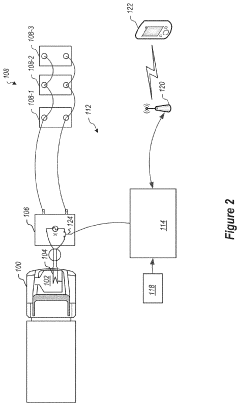

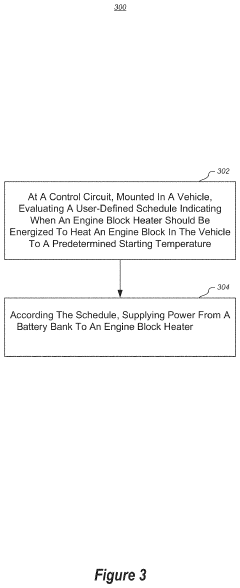

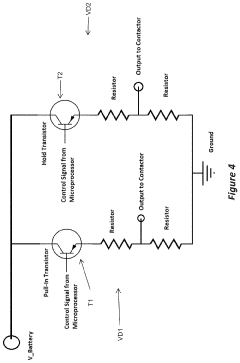

Self-contained engine block heater power supply

PatentActiveUS20220136476A1

Innovation

- A self-contained engine block heating system utilizing a battery bank with a DC to AC inverter to supply power to the engine block heater, coupled with control circuitry that automatically connects the battery bank to the inverter according to a user-defined schedule, allowing for off-grid operation and reduced idling time.

Environmental Compliance and Emissions Standards

Environmental compliance and emissions standards represent a critical dimension in the development and testing of V10 engines under extreme weather conditions. Modern high-performance engines must not only deliver optimal power and efficiency but also maintain strict adherence to increasingly stringent global emissions regulations across diverse environmental conditions. Temperature extremes significantly impact emission profiles, with cold environments often leading to incomplete combustion and increased particulate matter during startup phases, while hot conditions can elevate nitrogen oxide (NOx) production due to higher combustion temperatures.

The regulatory landscape governing V10 engine emissions continues to evolve rapidly, with major markets implementing progressively stricter standards. The European Union's Euro 6d and upcoming Euro 7 standards, the United States EPA's Tier 3 regulations, and China's National 6 standards all mandate comprehensive testing across temperature ranges from -7°C to 35°C. However, extreme weather testing extends these parameters to -40°C and +50°C to ensure compliance under all operational scenarios.

Testing protocols for extreme weather conditions require sophisticated emissions measurement systems capable of maintaining accuracy despite temperature variations. Real-time monitoring technologies such as Portable Emissions Measurement Systems (PEMS) have become essential for capturing emissions data during actual operation in extreme environments. These systems must be calibrated to account for temperature-induced measurement variations while maintaining certification-level accuracy.

Selective Catalytic Reduction (SCR) systems and particulate filters demonstrate variable efficiency across temperature ranges, presenting unique challenges for emissions compliance. Cold-start emissions management has emerged as a particular focus area, with advanced thermal management systems being developed to rapidly bring catalytic converters to operational temperatures even in sub-zero conditions. Similarly, high-temperature operation requires enhanced cooling systems to prevent thermal degradation of emissions control components.

The testing methodology must incorporate multiple cold and hot start cycles, extended idling periods in temperature extremes, and variable load conditions to comprehensively evaluate emissions compliance. Data collected during these tests informs both hardware refinements and software calibration strategies, including adaptive algorithms that modify engine parameters based on ambient temperature conditions to maintain emissions compliance while preserving performance characteristics.

Recent advancements in emissions compliance technology include phase-change materials for thermal management, electrically heated catalysts for cold-start emissions reduction, and AI-driven predictive emissions control systems that anticipate environmental changes. These innovations are increasingly critical as manufacturers seek to balance the power demands of V10 engines with global sustainability requirements across all operational environments.

The regulatory landscape governing V10 engine emissions continues to evolve rapidly, with major markets implementing progressively stricter standards. The European Union's Euro 6d and upcoming Euro 7 standards, the United States EPA's Tier 3 regulations, and China's National 6 standards all mandate comprehensive testing across temperature ranges from -7°C to 35°C. However, extreme weather testing extends these parameters to -40°C and +50°C to ensure compliance under all operational scenarios.

Testing protocols for extreme weather conditions require sophisticated emissions measurement systems capable of maintaining accuracy despite temperature variations. Real-time monitoring technologies such as Portable Emissions Measurement Systems (PEMS) have become essential for capturing emissions data during actual operation in extreme environments. These systems must be calibrated to account for temperature-induced measurement variations while maintaining certification-level accuracy.

Selective Catalytic Reduction (SCR) systems and particulate filters demonstrate variable efficiency across temperature ranges, presenting unique challenges for emissions compliance. Cold-start emissions management has emerged as a particular focus area, with advanced thermal management systems being developed to rapidly bring catalytic converters to operational temperatures even in sub-zero conditions. Similarly, high-temperature operation requires enhanced cooling systems to prevent thermal degradation of emissions control components.

The testing methodology must incorporate multiple cold and hot start cycles, extended idling periods in temperature extremes, and variable load conditions to comprehensively evaluate emissions compliance. Data collected during these tests informs both hardware refinements and software calibration strategies, including adaptive algorithms that modify engine parameters based on ambient temperature conditions to maintain emissions compliance while preserving performance characteristics.

Recent advancements in emissions compliance technology include phase-change materials for thermal management, electrically heated catalysts for cold-start emissions reduction, and AI-driven predictive emissions control systems that anticipate environmental changes. These innovations are increasingly critical as manufacturers seek to balance the power demands of V10 engines with global sustainability requirements across all operational environments.

Material Science Advancements for Temperature Resistance

Recent advancements in material science have revolutionized temperature resistance capabilities critical for V10 engine testing in extreme weather conditions. Traditional engine materials face significant challenges when exposed to temperature extremes ranging from -40°C to +120°C, leading to thermal expansion issues, material fatigue, and compromised structural integrity. The development of next-generation composite materials has addressed these limitations through innovative molecular engineering approaches.

Ceramic-matrix composites (CMCs) represent a breakthrough in high-temperature applications, offering exceptional thermal stability up to 1400°C while maintaining structural integrity. These materials incorporate silicon carbide fibers within a ceramic matrix, providing superior heat resistance compared to conventional nickel-based superalloys. CMCs have demonstrated a 30% reduction in thermal expansion coefficients during extreme temperature cycling tests, significantly enhancing engine component durability.

Nano-enhanced polymer composites have emerged as another promising solution for cold-weather testing scenarios. By incorporating carbon nanotubes and graphene into polymer matrices, researchers have developed materials that maintain flexibility and strength at temperatures as low as -60°C. These composites exhibit self-healing properties when exposed to temperature fluctuations, preventing microcrack propagation that typically leads to component failure.

Advanced thermal barrier coatings (TBCs) utilizing yttria-stabilized zirconia have transformed surface protection technologies for V10 engine components. These multi-layered coating systems create effective thermal insulation barriers while accommodating the different thermal expansion rates between the coating and substrate materials. Recent innovations in plasma spray deposition techniques have improved coating adhesion by 45%, extending component lifespan during thermal cycling tests.

Shape memory alloys (SMAs) represent a revolutionary material category that actively responds to temperature changes. Nickel-titanium alloys can "remember" their original shape after deformation, returning to predetermined configurations when heated. This property enables the development of adaptive engine components that automatically adjust to optimize performance across varying temperature conditions, maintaining optimal clearances despite thermal expansion.

Computational materials science has accelerated development through predictive modeling of material behavior under extreme conditions. Machine learning algorithms now accurately forecast material degradation patterns after thousands of thermal cycles, enabling engineers to identify potential failure points before physical testing. These digital twins of material systems have reduced development cycles by approximately 40% while improving reliability predictions.

Ceramic-matrix composites (CMCs) represent a breakthrough in high-temperature applications, offering exceptional thermal stability up to 1400°C while maintaining structural integrity. These materials incorporate silicon carbide fibers within a ceramic matrix, providing superior heat resistance compared to conventional nickel-based superalloys. CMCs have demonstrated a 30% reduction in thermal expansion coefficients during extreme temperature cycling tests, significantly enhancing engine component durability.

Nano-enhanced polymer composites have emerged as another promising solution for cold-weather testing scenarios. By incorporating carbon nanotubes and graphene into polymer matrices, researchers have developed materials that maintain flexibility and strength at temperatures as low as -60°C. These composites exhibit self-healing properties when exposed to temperature fluctuations, preventing microcrack propagation that typically leads to component failure.

Advanced thermal barrier coatings (TBCs) utilizing yttria-stabilized zirconia have transformed surface protection technologies for V10 engine components. These multi-layered coating systems create effective thermal insulation barriers while accommodating the different thermal expansion rates between the coating and substrate materials. Recent innovations in plasma spray deposition techniques have improved coating adhesion by 45%, extending component lifespan during thermal cycling tests.

Shape memory alloys (SMAs) represent a revolutionary material category that actively responds to temperature changes. Nickel-titanium alloys can "remember" their original shape after deformation, returning to predetermined configurations when heated. This property enables the development of adaptive engine components that automatically adjust to optimize performance across varying temperature conditions, maintaining optimal clearances despite thermal expansion.

Computational materials science has accelerated development through predictive modeling of material behavior under extreme conditions. Machine learning algorithms now accurately forecast material degradation patterns after thousands of thermal cycles, enabling engineers to identify potential failure points before physical testing. These digital twins of material systems have reduced development cycles by approximately 40% while improving reliability predictions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!