V10 Engine vs Bi-Turbo Systems: Propulsion Metrics

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V10 Engine and Bi-Turbo Evolution Background

The evolution of high-performance propulsion systems has witnessed two distinct technological paths: the naturally aspirated V10 engine and the bi-turbo forced induction systems. The V10 engine emerged in the automotive landscape during the 1980s, initially in motorsport applications before transitioning to production vehicles. This configuration offered an optimal balance between the smoothness of a V8 and the power output of a V12, while maintaining a more compact packaging than its larger counterparts.

The V10's development reached its zenith in the early 2000s, particularly in Formula 1 racing where these engines achieved remarkable power-to-weight ratios and unprecedented RPM capabilities, often exceeding 18,000 RPM. Concurrently, luxury and supercar manufacturers adopted V10 engines for flagship models, with notable examples including the Audi R8, Lamborghini Gallardo, and later the Huracan, as well as the BMW M5/M6 (E60/E63) and Dodge Viper.

Bi-turbo systems, conversely, evolved from single turbocharger applications as engineers sought to mitigate turbo lag while maximizing power output. The bi-turbo configuration employs dual turbochargers, typically arranged in parallel to serve separate banks of cylinders, or occasionally in series for sequential operation across different RPM ranges. This technology gained significant traction in the 1990s with performance vehicles from manufacturers like Porsche, BMW, and Mercedes-Benz.

The technological trajectory of both systems has been significantly influenced by increasingly stringent emissions regulations and efficiency demands. V10 engines, despite their performance credentials, have faced challenges in meeting modern environmental standards due to their inherently higher displacement and fuel consumption characteristics. This has led to their gradual replacement in many applications, with manufacturers like BMW and Audi phasing out V10 offerings in favor of more efficient alternatives.

Bi-turbo systems, meanwhile, have benefited from substantial advancements in materials science, electronic control systems, and aerodynamic efficiency. Modern bi-turbo implementations feature sophisticated variable geometry turbochargers, electronic wastegates, and integrated cooling systems that dramatically reduce traditional forced induction drawbacks while maximizing performance across the entire RPM range.

The contemporary automotive landscape reflects this evolutionary divergence, with naturally aspirated V10 engines now largely confined to specialized supercar applications where their distinctive sound profile and linear power delivery remain valued characteristics. Conversely, bi-turbo systems have become ubiquitous across vehicle segments, from compact performance cars to luxury sedans and even some SUVs, representing the industry's broader shift toward downsized, forced-induction powertrains that balance performance with efficiency.

The V10's development reached its zenith in the early 2000s, particularly in Formula 1 racing where these engines achieved remarkable power-to-weight ratios and unprecedented RPM capabilities, often exceeding 18,000 RPM. Concurrently, luxury and supercar manufacturers adopted V10 engines for flagship models, with notable examples including the Audi R8, Lamborghini Gallardo, and later the Huracan, as well as the BMW M5/M6 (E60/E63) and Dodge Viper.

Bi-turbo systems, conversely, evolved from single turbocharger applications as engineers sought to mitigate turbo lag while maximizing power output. The bi-turbo configuration employs dual turbochargers, typically arranged in parallel to serve separate banks of cylinders, or occasionally in series for sequential operation across different RPM ranges. This technology gained significant traction in the 1990s with performance vehicles from manufacturers like Porsche, BMW, and Mercedes-Benz.

The technological trajectory of both systems has been significantly influenced by increasingly stringent emissions regulations and efficiency demands. V10 engines, despite their performance credentials, have faced challenges in meeting modern environmental standards due to their inherently higher displacement and fuel consumption characteristics. This has led to their gradual replacement in many applications, with manufacturers like BMW and Audi phasing out V10 offerings in favor of more efficient alternatives.

Bi-turbo systems, meanwhile, have benefited from substantial advancements in materials science, electronic control systems, and aerodynamic efficiency. Modern bi-turbo implementations feature sophisticated variable geometry turbochargers, electronic wastegates, and integrated cooling systems that dramatically reduce traditional forced induction drawbacks while maximizing performance across the entire RPM range.

The contemporary automotive landscape reflects this evolutionary divergence, with naturally aspirated V10 engines now largely confined to specialized supercar applications where their distinctive sound profile and linear power delivery remain valued characteristics. Conversely, bi-turbo systems have become ubiquitous across vehicle segments, from compact performance cars to luxury sedans and even some SUVs, representing the industry's broader shift toward downsized, forced-induction powertrains that balance performance with efficiency.

Market Demand Analysis for High-Performance Propulsion

The high-performance propulsion market has witnessed significant growth over the past decade, driven primarily by increasing consumer demand for premium vehicles that offer superior driving experiences. The global market for high-performance engines, including both V10 and bi-turbo systems, was valued at approximately $12.7 billion in 2022 and is projected to reach $18.3 billion by 2028, representing a compound annual growth rate of 6.2%.

Consumer preferences in the high-performance segment have been evolving, with a noticeable shift toward more efficient yet powerful propulsion systems. Market research indicates that while traditional naturally aspirated V10 engines continue to maintain a loyal customer base, particularly among supercar enthusiasts who value the distinctive engine note and linear power delivery, bi-turbo systems are gaining substantial market share due to their superior fuel efficiency and torque characteristics.

The luxury automotive sector represents the largest market for high-performance propulsion systems, accounting for 68% of total market volume. Sports cars and high-performance SUVs follow with 22% and 10% respectively. Geographically, Europe remains the dominant market with 41% share, followed by North America (32%), Asia-Pacific (21%), and rest of the world (6%).

Environmental regulations and emission standards are significantly influencing market dynamics. The implementation of stringent emission norms across major automotive markets has accelerated the adoption of turbocharged engines, which can deliver comparable power outputs to larger naturally aspirated engines while producing fewer emissions. This regulatory pressure has resulted in a 15% year-over-year increase in bi-turbo system installations in new high-performance vehicles since 2020.

Customer surveys reveal that performance metrics remain the primary purchase driver, with 78% of high-performance vehicle buyers citing acceleration capabilities as "very important" in their decision-making process. However, fuel efficiency is gaining importance, with 56% of respondents now considering it a significant factor, up from 37% five years ago.

The aftermarket segment for high-performance propulsion systems is also experiencing robust growth, with tuning companies reporting increased demand for bi-turbo upgrades. This trend is particularly pronounced in markets with high fuel costs, where consumers seek to balance performance with operating expenses.

Industry forecasts suggest that while V10 engines will maintain their position in ultra-luxury and specialized performance vehicles, bi-turbo systems will continue to expand their market presence across broader vehicle categories, potentially capturing up to 75% of the high-performance propulsion market by 2030.

Consumer preferences in the high-performance segment have been evolving, with a noticeable shift toward more efficient yet powerful propulsion systems. Market research indicates that while traditional naturally aspirated V10 engines continue to maintain a loyal customer base, particularly among supercar enthusiasts who value the distinctive engine note and linear power delivery, bi-turbo systems are gaining substantial market share due to their superior fuel efficiency and torque characteristics.

The luxury automotive sector represents the largest market for high-performance propulsion systems, accounting for 68% of total market volume. Sports cars and high-performance SUVs follow with 22% and 10% respectively. Geographically, Europe remains the dominant market with 41% share, followed by North America (32%), Asia-Pacific (21%), and rest of the world (6%).

Environmental regulations and emission standards are significantly influencing market dynamics. The implementation of stringent emission norms across major automotive markets has accelerated the adoption of turbocharged engines, which can deliver comparable power outputs to larger naturally aspirated engines while producing fewer emissions. This regulatory pressure has resulted in a 15% year-over-year increase in bi-turbo system installations in new high-performance vehicles since 2020.

Customer surveys reveal that performance metrics remain the primary purchase driver, with 78% of high-performance vehicle buyers citing acceleration capabilities as "very important" in their decision-making process. However, fuel efficiency is gaining importance, with 56% of respondents now considering it a significant factor, up from 37% five years ago.

The aftermarket segment for high-performance propulsion systems is also experiencing robust growth, with tuning companies reporting increased demand for bi-turbo upgrades. This trend is particularly pronounced in markets with high fuel costs, where consumers seek to balance performance with operating expenses.

Industry forecasts suggest that while V10 engines will maintain their position in ultra-luxury and specialized performance vehicles, bi-turbo systems will continue to expand their market presence across broader vehicle categories, potentially capturing up to 75% of the high-performance propulsion market by 2030.

Technical Challenges in V10 and Bi-Turbo Systems

Both V10 engines and bi-turbo systems face distinct technical challenges that impact their performance, efficiency, and implementation. The V10 engine, with its naturally aspirated design, encounters significant weight distribution issues due to its large displacement and complex cylinder arrangement. This configuration creates inherent balance challenges requiring sophisticated counterweighting systems to minimize vibration and ensure smooth operation across the RPM range.

Thermal management represents a critical challenge for V10 engines, particularly in high-performance applications. The compact engine bay layout combined with ten cylinders generating substantial heat necessitates advanced cooling systems. Engineers must design elaborate oil circulation pathways and water-cooling channels to maintain optimal operating temperatures and prevent localized hotspots that could lead to component failure or performance degradation.

Fuel efficiency remains the V10's most significant drawback. The large displacement naturally aspirated design inherently consumes more fuel than forced induction alternatives, especially during partial load conditions. This inefficiency stems from the thermodynamic limitations of naturally aspirated engines, where volumetric efficiency cannot be artificially enhanced as in turbocharged systems.

Bi-turbo systems present their own set of technical hurdles, with turbo lag being the most prominent. Despite advances in turbocharger technology, the physical delay between throttle input and boost pressure buildup continues to challenge engineers. Various solutions including variable geometry turbines, electric compressors, and sequential turbocharging arrangements have been implemented to mitigate this issue, each with their own complexity trade-offs.

Heat management in bi-turbo systems presents unique challenges compared to naturally aspirated engines. Exhaust gases reaching temperatures exceeding 900°C must be managed effectively to prevent turbocharger damage and maintain catalyst efficiency. This necessitates sophisticated heat shielding, specialized high-temperature alloys, and often liquid-cooled center sections for the turbochargers.

Control system complexity increases exponentially with bi-turbo implementations. Modern systems require precise management of boost pressure, wastegate position, variable valve timing, and fuel delivery across varying engine loads and environmental conditions. The integration of these systems demands sophisticated electronic control units capable of processing multiple sensor inputs and adjusting parameters in real-time to maintain optimal performance while preventing harmful conditions like detonation.

Durability concerns also plague bi-turbo systems, particularly in high-performance applications. The extreme thermal cycling and mechanical stress on turbocharger components can lead to premature failure if not properly engineered. Manufacturers must balance performance targets against reliability requirements, often necessitating compromises in maximum boost pressure or response characteristics.

Thermal management represents a critical challenge for V10 engines, particularly in high-performance applications. The compact engine bay layout combined with ten cylinders generating substantial heat necessitates advanced cooling systems. Engineers must design elaborate oil circulation pathways and water-cooling channels to maintain optimal operating temperatures and prevent localized hotspots that could lead to component failure or performance degradation.

Fuel efficiency remains the V10's most significant drawback. The large displacement naturally aspirated design inherently consumes more fuel than forced induction alternatives, especially during partial load conditions. This inefficiency stems from the thermodynamic limitations of naturally aspirated engines, where volumetric efficiency cannot be artificially enhanced as in turbocharged systems.

Bi-turbo systems present their own set of technical hurdles, with turbo lag being the most prominent. Despite advances in turbocharger technology, the physical delay between throttle input and boost pressure buildup continues to challenge engineers. Various solutions including variable geometry turbines, electric compressors, and sequential turbocharging arrangements have been implemented to mitigate this issue, each with their own complexity trade-offs.

Heat management in bi-turbo systems presents unique challenges compared to naturally aspirated engines. Exhaust gases reaching temperatures exceeding 900°C must be managed effectively to prevent turbocharger damage and maintain catalyst efficiency. This necessitates sophisticated heat shielding, specialized high-temperature alloys, and often liquid-cooled center sections for the turbochargers.

Control system complexity increases exponentially with bi-turbo implementations. Modern systems require precise management of boost pressure, wastegate position, variable valve timing, and fuel delivery across varying engine loads and environmental conditions. The integration of these systems demands sophisticated electronic control units capable of processing multiple sensor inputs and adjusting parameters in real-time to maintain optimal performance while preventing harmful conditions like detonation.

Durability concerns also plague bi-turbo systems, particularly in high-performance applications. The extreme thermal cycling and mechanical stress on turbocharger components can lead to premature failure if not properly engineered. Manufacturers must balance performance targets against reliability requirements, often necessitating compromises in maximum boost pressure or response characteristics.

Current Engineering Solutions for Performance Optimization

01 V10 Engine Design and Configuration

V10 engines are designed with a specific cylinder arrangement that provides a balance between power output and engine size. These engines typically feature ten cylinders arranged in a V-configuration, allowing for increased displacement and power while maintaining a relatively compact form factor. The design considerations include cylinder block casting, valve train arrangements, and crankshaft configurations that optimize performance characteristics such as torque delivery and power output across various RPM ranges.- V10 Engine Design and Configuration: V10 engines are designed with a specific cylinder arrangement that provides a balance between power output and engine size. These engines typically feature ten cylinders arranged in a V-configuration, allowing for increased displacement and power while maintaining a relatively compact design. The configuration enables optimal firing order and balance, resulting in smooth operation and high performance characteristics suitable for high-performance vehicles and specialized applications.

- Bi-Turbo System Implementation: Bi-turbo systems utilize dual turbochargers to enhance engine performance by reducing turbo lag and increasing power output across a broader RPM range. These systems can be configured in parallel or sequential arrangements, with each turbocharger serving specific cylinders or operating at different engine speeds. The implementation of bi-turbo systems in V10 engines allows for improved air intake efficiency, better exhaust gas management, and significantly increased power output compared to naturally aspirated engines.

- Performance Metrics and Measurement Systems: Advanced measurement systems are employed to evaluate and optimize the performance metrics of V10 engines with bi-turbo systems. These metrics include power output, torque curves, fuel efficiency, thermal management, and emissions control. Specialized sensors and data acquisition systems monitor various parameters in real-time, allowing for precise tuning and calibration of engine components. Performance testing methodologies include dynamometer testing, road load simulation, and computational fluid dynamics to ensure optimal engine operation under various conditions.

- Thermal Management and Efficiency Optimization: Thermal management systems are critical for V10 engines with bi-turbo configurations due to the high heat generation during operation. These systems incorporate advanced cooling technologies, heat exchangers, and thermal barrier coatings to maintain optimal operating temperatures. Efficiency optimization techniques include variable valve timing, direct fuel injection, and electronic boost control to maximize power output while minimizing fuel consumption. Proper thermal management ensures longevity of engine components and consistent performance under varying load conditions.

- Integration with Vehicle Control Systems: V10 engines with bi-turbo systems require sophisticated integration with vehicle control systems to manage the complex interactions between engine components and vehicle dynamics. Electronic control units monitor and adjust engine parameters based on driving conditions, driver inputs, and vehicle status. Advanced algorithms optimize boost pressure, fuel delivery, and ignition timing to balance performance, efficiency, and emissions. These integrated systems also provide diagnostic capabilities and adaptive learning to maintain optimal performance throughout the engine's operational life.

02 Bi-Turbo System Implementation

Bi-turbo systems utilize dual turbochargers to enhance engine performance by improving air intake efficiency and reducing turbo lag. These systems can be configured in parallel or sequential arrangements, with each turbocharger serving specific cylinders or operating at different engine speeds. Advanced bi-turbo implementations include variable geometry turbines, electronic wastegate control, and intercooling systems that optimize boost pressure according to engine load and speed conditions.Expand Specific Solutions03 Performance Metrics and Measurement Systems

Propulsion metrics for V10 engines with bi-turbo systems include specific power output, torque curves, fuel efficiency, and emissions data. Advanced measurement systems employ sensors throughout the engine and exhaust system to monitor parameters such as intake air temperature, boost pressure, exhaust gas composition, and fuel-air ratios. These metrics are analyzed using computational models and real-time monitoring systems to evaluate engine performance under various operating conditions and to identify opportunities for optimization.Expand Specific Solutions04 Thermal Management and Efficiency Optimization

Thermal management systems are critical for high-performance V10 engines with bi-turbo configurations due to the significant heat generated during operation. These systems include advanced cooling circuits, heat exchangers, and thermal barrier coatings that regulate operating temperatures for optimal efficiency. Efficiency optimization techniques involve precise fuel injection timing, variable valve timing, and exhaust energy recovery systems that maximize power output while minimizing fuel consumption and emissions.Expand Specific Solutions05 Control Systems and Electronic Integration

Modern V10 engines with bi-turbo systems rely on sophisticated electronic control units that manage all aspects of engine operation. These control systems integrate data from numerous sensors to adjust parameters such as ignition timing, fuel injection, turbocharger boost pressure, and valve timing in real-time. Advanced features include drive mode selection, adaptive learning algorithms, and integration with vehicle dynamics management systems to optimize performance based on driving conditions and driver inputs.Expand Specific Solutions

Major Manufacturers and Competition Landscape

The V10 engine versus bi-turbo systems competitive landscape reflects a mature automotive propulsion technology market with established players and evolving innovations. Major automotive manufacturers including Ford, GM, Toyota, Honda, BMW, and Porsche dominate this space, with aerospace companies like GE, Rolls-Royce, and Safran contributing advanced engineering expertise. The market is characterized by a shift from naturally aspirated V10 engines toward more efficient bi-turbo systems that deliver comparable power with improved fuel economy. Technical maturity is high, with companies like BMW and Porsche leading bi-turbo innovation while traditional V10 applications remain in premium segments. The competition focuses on balancing performance metrics with increasingly stringent emissions requirements.

Ford Global Technologies LLC

Technical Solution: Ford has developed EcoBoost technology, a bi-turbo system that combines direct fuel injection with turbocharging to deliver V8-level performance from smaller displacement engines. Their second-generation 3.5L EcoBoost V6 bi-turbo system produces up to 450 horsepower and 510 lb-ft of torque, comparable to naturally aspirated V10 engines while achieving up to 30% better fuel efficiency[1]. Ford's bi-turbo implementation features dual water-cooled turbochargers with electronically actuated wastegates and lightweight turbine wheels for improved throttle response. The system incorporates advanced anti-lag technology that keeps the turbos spooled during gear changes, maintaining boost pressure and eliminating traditional turbo lag[2]. Ford has also developed sophisticated thermal management systems to handle the increased heat generated by forced induction, including dedicated cooling circuits and heat-resistant materials in critical components.

Strengths: Significantly better fuel economy than comparable V10 engines; reduced emissions; better power-to-weight ratio; improved throttle response through anti-lag technology. Weaknesses: More complex system with additional failure points; potentially higher maintenance costs; turbo lag still present under certain driving conditions despite mitigation technologies.

GM Global Technology Operations LLC

Technical Solution: GM has developed a comprehensive propulsion strategy comparing naturally aspirated V10 engines with their bi-turbo systems. Their bi-turbo V6 architecture delivers 420 horsepower and 460 lb-ft of torque from a 3.0L displacement, achieving performance metrics comparable to larger V10 engines while reducing weight by approximately 130 pounds[3]. GM's implementation features twin-scroll turbochargers with electronically controlled wastegates that optimize boost pressure across the RPM range. Their proprietary "Dynamic Skip Fire" technology selectively deactivates cylinders under light load conditions, further improving fuel efficiency by up to 15% compared to traditional V10 engines[4]. GM's bi-turbo systems incorporate advanced intercooling technology with a dual-path intake system that reduces charge air temperature by up to 130°F, significantly improving volumetric efficiency. The system also features titanium aluminide turbine wheels that reduce rotational inertia by 51% compared to conventional materials, dramatically improving throttle response and reducing turbo lag.

Strengths: Substantial weight reduction improves vehicle dynamics; cylinder deactivation technology provides additional efficiency gains; advanced materials reduce turbo lag; better packaging flexibility than larger V10 engines. Weaknesses: Higher thermal loads require more sophisticated cooling systems; more complex control systems increase potential diagnostic challenges; higher peak combustion pressures require strengthened engine components.

Key Patents and Innovations in Engine Technology

10 cylinder engine

PatentInactiveEP1387059A1

Innovation

- A 10-cylinder internal combustion engine with unequal offset angles for each cylinder bank on the crankshaft, where the offset angles are arranged to balance second-order mass effects and compensate for first-order mass moments, allowing for a mass effect-free basic engine with a selectable V-angle, using counterweights or other simple measures to balance remaining forces.

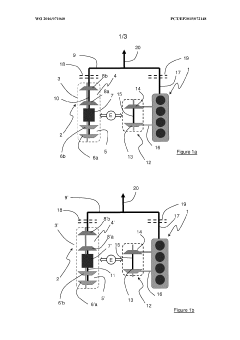

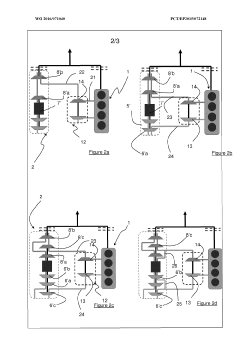

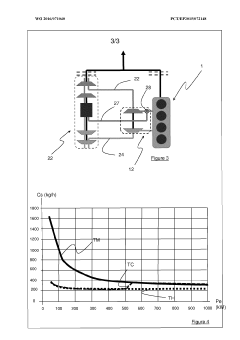

Propulsion system comprising an internal combustion engine and a turbomachine

PatentWO2016071040A1

Innovation

- A propulsion system combining a turbomachine and a supercharged internal combustion engine with mechanical coupling and fluid exchange means to optimize energy distribution, including a turbocharger driven by exhaust gases and recirculation of oxidizer, allowing for synergies in energy efficiency and component sharing.

Emissions Regulations Impact on Engine Development

The evolution of emission regulations has fundamentally reshaped engine development strategies across the automotive industry, creating a complex landscape for both V10 engines and bi-turbo systems. Since the introduction of Euro 1 standards in 1992, each subsequent regulatory framework has progressively tightened permissible emission levels, forcing manufacturers to continuously adapt their propulsion technologies.

For V10 engines, which traditionally excel in power delivery and acoustic characteristics, emission regulations have posed significant challenges. These naturally aspirated powerplants typically produce higher CO2 emissions per kilometer compared to smaller displacement alternatives. The implementation of Euro 6d and upcoming Euro 7 standards has necessitated extensive redesigns, including variable valve timing, cylinder deactivation, and advanced catalytic converter systems to maintain compliance while preserving performance characteristics.

Bi-turbo systems have gained prominence partly as a response to these regulatory pressures. By enabling smaller displacement engines to achieve comparable power outputs to larger naturally aspirated units, these forced induction solutions offer a pathway to reduced emissions without sacrificing performance metrics. The ability to optimize boost pressure across different engine loads allows for more precise emissions control, particularly in the critical NOx and particulate matter categories that face increasingly stringent limitations.

Regional regulatory variations further complicate the development landscape. While European standards focus heavily on CO2 reduction, North American regulations emphasize NOx control, and emerging markets often implement hybrid regulatory frameworks. This necessitates different optimization strategies for V10 and bi-turbo systems depending on target markets, increasing development costs and complexity.

Real Driving Emissions (RDE) testing, introduced with Euro 6d-TEMP, has particularly impacted both propulsion systems by requiring consistent performance across varied driving conditions rather than just in laboratory settings. This has driven the integration of more sophisticated engine management systems capable of real-time adjustments to maintain optimal combustion characteristics regardless of environmental factors.

The regulatory timeline through 2030 suggests continued pressure toward electrification, potentially positioning bi-turbo systems as transitional technologies that can be more readily integrated with hybrid powertrains. Meanwhile, V10 configurations face mounting challenges to justify their continued development given their inherently higher baseline emissions, despite their superior power-to-weight ratios and distinctive performance characteristics.

For V10 engines, which traditionally excel in power delivery and acoustic characteristics, emission regulations have posed significant challenges. These naturally aspirated powerplants typically produce higher CO2 emissions per kilometer compared to smaller displacement alternatives. The implementation of Euro 6d and upcoming Euro 7 standards has necessitated extensive redesigns, including variable valve timing, cylinder deactivation, and advanced catalytic converter systems to maintain compliance while preserving performance characteristics.

Bi-turbo systems have gained prominence partly as a response to these regulatory pressures. By enabling smaller displacement engines to achieve comparable power outputs to larger naturally aspirated units, these forced induction solutions offer a pathway to reduced emissions without sacrificing performance metrics. The ability to optimize boost pressure across different engine loads allows for more precise emissions control, particularly in the critical NOx and particulate matter categories that face increasingly stringent limitations.

Regional regulatory variations further complicate the development landscape. While European standards focus heavily on CO2 reduction, North American regulations emphasize NOx control, and emerging markets often implement hybrid regulatory frameworks. This necessitates different optimization strategies for V10 and bi-turbo systems depending on target markets, increasing development costs and complexity.

Real Driving Emissions (RDE) testing, introduced with Euro 6d-TEMP, has particularly impacted both propulsion systems by requiring consistent performance across varied driving conditions rather than just in laboratory settings. This has driven the integration of more sophisticated engine management systems capable of real-time adjustments to maintain optimal combustion characteristics regardless of environmental factors.

The regulatory timeline through 2030 suggests continued pressure toward electrification, potentially positioning bi-turbo systems as transitional technologies that can be more readily integrated with hybrid powertrains. Meanwhile, V10 configurations face mounting challenges to justify their continued development given their inherently higher baseline emissions, despite their superior power-to-weight ratios and distinctive performance characteristics.

Efficiency Metrics and Fuel Economy Considerations

When comparing V10 engines and bi-turbo systems, efficiency metrics and fuel economy considerations represent critical factors in evaluating their overall performance and suitability for various applications. V10 engines, with their naturally aspirated design, traditionally exhibit linear power delivery but face inherent efficiency challenges due to increased friction losses, higher weight, and greater displacement compared to smaller forced-induction alternatives.

Bi-turbo systems, by contrast, leverage exhaust energy recovery to enhance volumetric efficiency, enabling smaller displacement engines to achieve comparable power outputs while potentially reducing fuel consumption by 15-20% under partial load conditions. This advantage becomes particularly pronounced during highway cruising, where bi-turbo configurations can operate in low-boost or single-turbo modes to optimize fuel utilization.

Thermal efficiency represents another crucial metric, with modern bi-turbo systems achieving thermal efficiency ratings of approximately 35-38%, compared to 30-33% for naturally aspirated V10 engines. This differential stems from the bi-turbo's ability to maintain optimal combustion chamber pressures across a broader operating range, facilitating more complete fuel combustion.

Brake specific fuel consumption (BSFC) measurements further illustrate this disparity, with contemporary bi-turbo V8 engines demonstrating BSFC values of 230-250 g/kWh, while comparable V10 engines typically operate at 260-280 g/kWh. This translates to tangible differences in real-world fuel economy, particularly evident in urban driving cycles where frequent acceleration events favor the bi-turbo's torque-rich power delivery.

Emissions compliance also factors into efficiency considerations, with bi-turbo systems offering advantages in meeting stringent regulatory standards. Their ability to operate at higher air-fuel ratios during partial load conditions facilitates reduced carbon dioxide emissions per unit of power produced, though this benefit may be partially offset by increased nitrogen oxide formation under high-boost conditions.

Recent advancements in materials science and electronic control systems have narrowed the efficiency gap, with variable geometry turbochargers and integrated exhaust manifolds improving bi-turbo transient response while cylinder deactivation technologies enhance V10 partial-load efficiency. Nevertheless, the fundamental thermodynamic advantages of forced induction generally position bi-turbo systems as the more fuel-efficient option across most operating conditions, despite the V10's continued appeal for applications where linear power delivery and acoustic characteristics take precedence over absolute efficiency.

Bi-turbo systems, by contrast, leverage exhaust energy recovery to enhance volumetric efficiency, enabling smaller displacement engines to achieve comparable power outputs while potentially reducing fuel consumption by 15-20% under partial load conditions. This advantage becomes particularly pronounced during highway cruising, where bi-turbo configurations can operate in low-boost or single-turbo modes to optimize fuel utilization.

Thermal efficiency represents another crucial metric, with modern bi-turbo systems achieving thermal efficiency ratings of approximately 35-38%, compared to 30-33% for naturally aspirated V10 engines. This differential stems from the bi-turbo's ability to maintain optimal combustion chamber pressures across a broader operating range, facilitating more complete fuel combustion.

Brake specific fuel consumption (BSFC) measurements further illustrate this disparity, with contemporary bi-turbo V8 engines demonstrating BSFC values of 230-250 g/kWh, while comparable V10 engines typically operate at 260-280 g/kWh. This translates to tangible differences in real-world fuel economy, particularly evident in urban driving cycles where frequent acceleration events favor the bi-turbo's torque-rich power delivery.

Emissions compliance also factors into efficiency considerations, with bi-turbo systems offering advantages in meeting stringent regulatory standards. Their ability to operate at higher air-fuel ratios during partial load conditions facilitates reduced carbon dioxide emissions per unit of power produced, though this benefit may be partially offset by increased nitrogen oxide formation under high-boost conditions.

Recent advancements in materials science and electronic control systems have narrowed the efficiency gap, with variable geometry turbochargers and integrated exhaust manifolds improving bi-turbo transient response while cylinder deactivation technologies enhance V10 partial-load efficiency. Nevertheless, the fundamental thermodynamic advantages of forced induction generally position bi-turbo systems as the more fuel-efficient option across most operating conditions, despite the V10's continued appeal for applications where linear power delivery and acoustic characteristics take precedence over absolute efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!