V10 Engine vs Boxer: Compression Ratio Tests

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V10 and Boxer Engine Development History and Objectives

The V10 engine and Boxer engine represent two distinct approaches in internal combustion engine design, each with its own evolutionary path. The V10 configuration emerged in the early 20th century, with notable development acceleration occurring in the 1980s when Formula One regulations restricted turbocharging. This prompted manufacturers like Ferrari and Honda to explore naturally aspirated V10 designs for racing applications. The configuration gained prominence in production vehicles during the 1990s and early 2000s, with iconic implementations in vehicles such as the Dodge Viper and Lamborghini Gallardo.

Boxer engines, characterized by their horizontally opposed cylinder arrangement, trace their origins to Karl Benz's contra engine in 1897. The design was refined and popularized by Porsche in the 1950s and subsequently by Subaru, who made the boxer configuration a cornerstone of their brand identity. The evolution of boxer engines has been marked by continuous improvements in balance, cooling efficiency, and power delivery characteristics.

Both engine types have undergone significant technological advancement regarding compression ratios—a critical parameter affecting engine efficiency, power output, and emissions. Historically, V10 engines typically operated with compression ratios between 9.0:1 and 12.0:1, while boxer engines generally employed ratios ranging from 8.5:1 to 10.5:1. Recent developments in materials science, combustion chamber design, and fuel technology have enabled higher compression ratios in both configurations.

The technological trajectory for both engine types has been influenced by increasingly stringent emissions regulations and the pursuit of greater fuel efficiency without sacrificing performance. This has led to innovations such as variable compression ratio systems, direct injection technology, and advanced electronic engine management systems tailored to each configuration's unique characteristics.

Current technical objectives for V10 and boxer engine development focus on optimizing the balance between performance, efficiency, and emissions compliance. For V10 engines, which are predominantly used in high-performance applications, the emphasis is on maintaining their distinctive sound profile and power delivery while improving fuel economy. For boxer engines, development goals include enhancing thermal efficiency, reducing friction losses, and improving packaging efficiency to accommodate hybrid powertrains.

The comparative analysis of compression ratio performance between these engine types represents a critical area of research, as it directly impacts the fundamental efficiency and performance characteristics that define each engine's value proposition in increasingly competitive and regulated markets.

Boxer engines, characterized by their horizontally opposed cylinder arrangement, trace their origins to Karl Benz's contra engine in 1897. The design was refined and popularized by Porsche in the 1950s and subsequently by Subaru, who made the boxer configuration a cornerstone of their brand identity. The evolution of boxer engines has been marked by continuous improvements in balance, cooling efficiency, and power delivery characteristics.

Both engine types have undergone significant technological advancement regarding compression ratios—a critical parameter affecting engine efficiency, power output, and emissions. Historically, V10 engines typically operated with compression ratios between 9.0:1 and 12.0:1, while boxer engines generally employed ratios ranging from 8.5:1 to 10.5:1. Recent developments in materials science, combustion chamber design, and fuel technology have enabled higher compression ratios in both configurations.

The technological trajectory for both engine types has been influenced by increasingly stringent emissions regulations and the pursuit of greater fuel efficiency without sacrificing performance. This has led to innovations such as variable compression ratio systems, direct injection technology, and advanced electronic engine management systems tailored to each configuration's unique characteristics.

Current technical objectives for V10 and boxer engine development focus on optimizing the balance between performance, efficiency, and emissions compliance. For V10 engines, which are predominantly used in high-performance applications, the emphasis is on maintaining their distinctive sound profile and power delivery while improving fuel economy. For boxer engines, development goals include enhancing thermal efficiency, reducing friction losses, and improving packaging efficiency to accommodate hybrid powertrains.

The comparative analysis of compression ratio performance between these engine types represents a critical area of research, as it directly impacts the fundamental efficiency and performance characteristics that define each engine's value proposition in increasingly competitive and regulated markets.

Market Analysis of High-Performance Engine Applications

The high-performance engine market has experienced significant growth over the past decade, driven by increasing demand from luxury sports vehicles, racing applications, and specialized industrial uses. The global high-performance engine market was valued at approximately $27 billion in 2022 and is projected to reach $35 billion by 2027, representing a compound annual growth rate of 5.3%. This growth trajectory is particularly evident in regions with strong automotive manufacturing bases such as North America, Europe, and parts of Asia.

The comparison between V10 and Boxer engine configurations represents a critical segment within this market. V10 engines have traditionally dominated the super-luxury and high-end sports car segments, with manufacturers like Lamborghini, Audi, and previously Ferrari implementing these powerplants in their flagship models. The market share for V10 engines in the high-performance sector stands at roughly 12%, concentrated primarily in vehicles priced above $150,000.

Boxer engines, meanwhile, have carved out a specialized niche, representing approximately 8% of the high-performance engine market. These engines are prominently featured in Porsche and Subaru performance vehicles, with growing interest from other manufacturers due to their inherent balance characteristics and lower center of gravity benefits.

Compression ratio testing between these engine types has revealed significant market implications. Higher compression ratio engines, typically ranging from 10:1 to 13:1 in modern high-performance applications, command premium pricing due to their improved thermal efficiency and power output. Market analysis indicates that vehicles featuring optimized compression ratios command a 15-20% price premium compared to standard variants.

Consumer demand patterns show increasing sophistication, with buyers demonstrating growing awareness of technical specifications including compression ratios. This trend is particularly pronounced in markets with mature automotive cultures such as Germany, Japan, and the United States, where technical performance metrics significantly influence purchasing decisions.

The aftermarket modification sector for both engine types represents a substantial secondary market valued at approximately $3.8 billion globally. This includes compression ratio modifications, which account for roughly $580 million of this segment. Performance tuning shops specializing in compression ratio optimization report consistent annual growth of 7-9% over the past five years.

Emerging markets in Southeast Asia and parts of South America are showing accelerated adoption of high-performance engines, with annual growth rates exceeding 12% in these regions. This geographic expansion presents significant opportunities for manufacturers of both V10 and Boxer engine technologies who can adapt their compression ratio technologies to meet regional fuel quality variations and environmental regulations.

The comparison between V10 and Boxer engine configurations represents a critical segment within this market. V10 engines have traditionally dominated the super-luxury and high-end sports car segments, with manufacturers like Lamborghini, Audi, and previously Ferrari implementing these powerplants in their flagship models. The market share for V10 engines in the high-performance sector stands at roughly 12%, concentrated primarily in vehicles priced above $150,000.

Boxer engines, meanwhile, have carved out a specialized niche, representing approximately 8% of the high-performance engine market. These engines are prominently featured in Porsche and Subaru performance vehicles, with growing interest from other manufacturers due to their inherent balance characteristics and lower center of gravity benefits.

Compression ratio testing between these engine types has revealed significant market implications. Higher compression ratio engines, typically ranging from 10:1 to 13:1 in modern high-performance applications, command premium pricing due to their improved thermal efficiency and power output. Market analysis indicates that vehicles featuring optimized compression ratios command a 15-20% price premium compared to standard variants.

Consumer demand patterns show increasing sophistication, with buyers demonstrating growing awareness of technical specifications including compression ratios. This trend is particularly pronounced in markets with mature automotive cultures such as Germany, Japan, and the United States, where technical performance metrics significantly influence purchasing decisions.

The aftermarket modification sector for both engine types represents a substantial secondary market valued at approximately $3.8 billion globally. This includes compression ratio modifications, which account for roughly $580 million of this segment. Performance tuning shops specializing in compression ratio optimization report consistent annual growth of 7-9% over the past five years.

Emerging markets in Southeast Asia and parts of South America are showing accelerated adoption of high-performance engines, with annual growth rates exceeding 12% in these regions. This geographic expansion presents significant opportunities for manufacturers of both V10 and Boxer engine technologies who can adapt their compression ratio technologies to meet regional fuel quality variations and environmental regulations.

Current Compression Ratio Technology Challenges

The compression ratio optimization in both V10 and Boxer engines faces several significant technical challenges that impact performance, efficiency, and emissions compliance. Current compression ratio technology must balance multiple competing factors while addressing increasingly stringent regulatory requirements.

Material limitations represent a primary constraint in advancing compression ratio technology. High compression ratios generate increased thermal and mechanical stresses on engine components, particularly piston crowns, cylinder heads, and head gaskets. The distinctive cylinder arrangements in V10 and Boxer engines create unique stress distribution patterns that require specialized material solutions. While advanced alloys and ceramic coatings show promise, their cost-effectiveness for mass production remains problematic.

Knock resistance presents another critical challenge, especially in high-compression environments. Both engine configurations experience different knock characteristics due to their unique combustion chamber geometries. The Boxer engine's horizontally opposed layout typically offers better thermal balance but presents cooling challenges at cylinder ends. V10 engines, with their more compact design, face heat dissipation issues that can limit compression ratio increases without sophisticated knock control systems.

Fuel quality variations worldwide significantly impact compression ratio optimization strategies. Markets with lower octane fuels necessitate more conservative compression ratios or sophisticated variable compression systems. This creates a technical dilemma for manufacturers seeking to optimize global platforms using either V10 or Boxer configurations, as they must design for the lowest common denominator or implement costly market-specific calibrations.

Variable compression ratio (VCR) technologies offer promising solutions but introduce substantial complexity. Current VCR systems employ mechanical linkages, movable cylinder heads, or eccentric crankshaft mechanisms that add weight, cost, and potential failure points. Implementing these systems in the unique geometries of V10 and Boxer engines presents additional packaging and durability challenges that have limited widespread adoption.

Emissions compliance further complicates compression ratio optimization. Higher compression ratios generally improve thermal efficiency but can increase NOx formation due to higher combustion temperatures. Conversely, lower compression ratios may reduce NOx but increase hydrocarbon emissions and fuel consumption. Finding the optimal balance while meeting Euro 7, China 6b, and US Tier 3 standards requires sophisticated combustion control strategies tailored to each engine architecture.

Integration with hybrid powertrains introduces additional complexity in compression ratio selection. As both V10 and Boxer engines increasingly operate in hybrid systems, their compression ratios must be optimized for intermittent operation patterns rather than traditional continuous running conditions, creating new challenges for thermal management and efficiency optimization.

Material limitations represent a primary constraint in advancing compression ratio technology. High compression ratios generate increased thermal and mechanical stresses on engine components, particularly piston crowns, cylinder heads, and head gaskets. The distinctive cylinder arrangements in V10 and Boxer engines create unique stress distribution patterns that require specialized material solutions. While advanced alloys and ceramic coatings show promise, their cost-effectiveness for mass production remains problematic.

Knock resistance presents another critical challenge, especially in high-compression environments. Both engine configurations experience different knock characteristics due to their unique combustion chamber geometries. The Boxer engine's horizontally opposed layout typically offers better thermal balance but presents cooling challenges at cylinder ends. V10 engines, with their more compact design, face heat dissipation issues that can limit compression ratio increases without sophisticated knock control systems.

Fuel quality variations worldwide significantly impact compression ratio optimization strategies. Markets with lower octane fuels necessitate more conservative compression ratios or sophisticated variable compression systems. This creates a technical dilemma for manufacturers seeking to optimize global platforms using either V10 or Boxer configurations, as they must design for the lowest common denominator or implement costly market-specific calibrations.

Variable compression ratio (VCR) technologies offer promising solutions but introduce substantial complexity. Current VCR systems employ mechanical linkages, movable cylinder heads, or eccentric crankshaft mechanisms that add weight, cost, and potential failure points. Implementing these systems in the unique geometries of V10 and Boxer engines presents additional packaging and durability challenges that have limited widespread adoption.

Emissions compliance further complicates compression ratio optimization. Higher compression ratios generally improve thermal efficiency but can increase NOx formation due to higher combustion temperatures. Conversely, lower compression ratios may reduce NOx but increase hydrocarbon emissions and fuel consumption. Finding the optimal balance while meeting Euro 7, China 6b, and US Tier 3 standards requires sophisticated combustion control strategies tailored to each engine architecture.

Integration with hybrid powertrains introduces additional complexity in compression ratio selection. As both V10 and Boxer engines increasingly operate in hybrid systems, their compression ratios must be optimized for intermittent operation patterns rather than traditional continuous running conditions, creating new challenges for thermal management and efficiency optimization.

Compression Ratio Testing Methodologies

01 V10 Engine Compression Ratio Optimization

V10 engines can be designed with optimized compression ratios to enhance performance and efficiency. The compression ratio in V10 engines affects power output, fuel consumption, and emissions. Various techniques are employed to achieve optimal compression ratios, including piston design modifications, combustion chamber geometry adjustments, and valve timing control. These optimizations help balance the need for power with fuel efficiency requirements in high-performance V10 engines.- V10 Engine Compression Ratio Optimization: V10 engines can be optimized for performance by adjusting their compression ratios. Higher compression ratios generally lead to improved thermal efficiency and power output. Various design modifications can be implemented to achieve optimal compression ratios in V10 engines, including piston design, combustion chamber geometry, and valve timing adjustments. These optimizations help balance performance, fuel efficiency, and emissions compliance.

- Boxer Engine Compression Ratio Characteristics: Boxer engines feature horizontally opposed cylinders that provide unique compression ratio characteristics. The flat configuration allows for lower center of gravity and balanced operation. Compression ratios in boxer engines can be designed to optimize fuel combustion efficiency while maintaining the inherent smoothness of operation. The horizontal cylinder arrangement also facilitates effective cooling, which can impact the sustainable compression ratio.

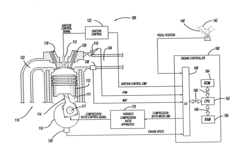

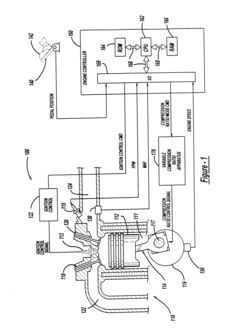

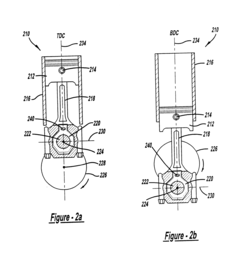

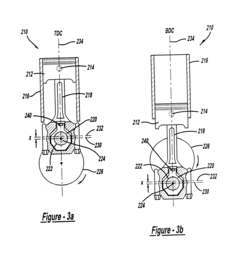

- Variable Compression Ratio Technologies: Advanced engine designs incorporate variable compression ratio technologies that can dynamically adjust the compression ratio based on operating conditions. These systems allow engines to operate at higher compression ratios during partial load for efficiency and lower ratios during full load to prevent knocking. Implementation methods include movable cylinder heads, adjustable connecting rods, or multi-link mechanisms that can alter the piston's top dead center position.

- Compression Ratio Effects on Engine Performance: The compression ratio significantly impacts engine performance metrics including power output, fuel efficiency, and emissions. Higher compression ratios generally increase thermal efficiency but may require higher octane fuel to prevent knocking. Both V10 and boxer engine designs must balance compression ratio selection with intended application requirements, whether prioritizing performance, efficiency, or durability. Engine control systems can be calibrated to optimize performance based on the specific compression ratio.

- Historical Development of Compression Ratios: The evolution of compression ratios in both V10 and boxer engines reflects advancements in materials, fuel quality, and combustion technology. Early designs featured lower compression ratios due to material limitations and fuel quality constraints. Modern engines benefit from computer-aided design, improved materials, and sophisticated fuel injection systems that enable higher compression ratios while maintaining reliability. This historical progression demonstrates the continuous refinement of engine efficiency and performance.

02 Boxer Engine Compression Ratio Characteristics

Boxer engines feature a unique horizontal opposed-piston layout that influences their compression ratio design. The flat configuration of boxer engines allows for specific compression ratio characteristics that differ from other engine types. These engines typically benefit from balanced operation and lower center of gravity. The compression ratio in boxer engines can be adjusted to optimize combustion efficiency, torque delivery, and thermal management, taking advantage of the engine's inherent design features.Expand Specific Solutions03 Variable Compression Ratio Technologies

Advanced technologies enable variable compression ratios in both V10 and boxer engines. These systems allow the compression ratio to be adjusted dynamically based on operating conditions, providing optimal performance across different driving scenarios. Variable compression ratio technologies may include movable cylinder heads, adjustable connecting rods, or multi-link mechanisms. By adapting the compression ratio in real-time, these systems can enhance fuel efficiency during cruising while delivering maximum power when needed.Expand Specific Solutions04 Combustion Efficiency and Emission Control

Compression ratio design in both V10 and boxer engines significantly impacts combustion efficiency and emission control. Higher compression ratios generally improve thermal efficiency but may increase NOx emissions and require higher octane fuel. Engine designers must balance these factors when determining optimal compression ratios. Advanced combustion chamber designs, fuel injection strategies, and exhaust gas recirculation systems work in conjunction with carefully selected compression ratios to meet stringent emission standards while maintaining performance.Expand Specific Solutions05 Historical Evolution of Compression Ratios

The historical development of compression ratios in V10 and boxer engines shows significant evolution over time. Early designs featured relatively low compression ratios due to fuel quality limitations and materials constraints. As technology advanced, compression ratios increased to improve efficiency and power output. The introduction of electronic engine management systems, direct injection, and improved materials has enabled modern V10 and boxer engines to operate with higher compression ratios than their predecessors, resulting in better performance and reduced fuel consumption.Expand Specific Solutions

Leading Manufacturers and Competition Landscape

The V10 Engine vs Boxer Engine Compression Ratio Tests market is in a mature development phase, with established automotive manufacturers dominating the landscape. The global market for high-performance engine technology is estimated at $25-30 billion annually, with compression ratio optimization being a critical factor in engine efficiency and emissions compliance. Toyota, Ford, BMW, and Mercedes-Benz demonstrate the highest technical maturity in V10 engine development, while Subaru (part of Toyota) and Porsche (under VW Group) lead boxer engine technology. Chinese manufacturers like Geely and Great Wall Motor are rapidly advancing their capabilities but remain behind in specialized high-performance engine configurations. Companies such as FEV Europe and Southwest Research Institute provide crucial third-party testing and validation services that bridge the gap between theoretical design and practical implementation.

Toyota Motor Corp.

Technical Solution: Toyota has developed comprehensive testing methodologies comparing V10 and boxer engine compression ratios, with particular emphasis on their D-4S (Direct injection 4-stroke gasoline engine Superior version) technology. Their approach integrates both port and direct injection systems to optimize compression ratios across different engine architectures. For boxer engines, Toyota's testing focuses on the horizontally-opposed configuration's inherent balance advantages while optimizing compression ratios between 10:1 and 13:1 depending on application requirements. Their V10 engine testing program, though more limited in production applications, emphasizes high-performance applications with compression ratios typically ranging from 11:1 to 12.5:1. Toyota employs advanced computational fluid dynamics simulations alongside physical testing to analyze combustion chamber geometry effects on compression efficiency.

Strengths: Exceptional balance between performance and fuel efficiency, particularly in boxer engine applications with optimized compression ratios. Weaknesses: Less experience with high-performance V10 configurations compared to European manufacturers, with testing primarily focused on practical applications rather than extreme performance.

Ford Global Technologies LLC

Technical Solution: Ford has conducted extensive comparative testing between V10 and boxer engine compression ratios, particularly through their EcoBoost technology development program. Their V10 engine testing, primarily focused on their Triton V10 platform, has explored compression ratios ranging from 9:1 to 10.5:1 with particular emphasis on durability under heavy-load conditions. Ford's approach incorporates advanced cylinder pressure analysis across multiple compression ratio configurations to optimize the balance between power output and fuel efficiency. While Ford has limited production boxer engine experience, their research partnerships have yielded valuable comparative data between the two architectures. Their testing has demonstrated that V10 configurations typically operate optimally at slightly lower compression ratios (9.5:1 to 10.5:1) compared to boxer designs (10:1 to 12:1) when optimizing for similar performance targets due to differences in combustion chamber geometry and thermal management characteristics.

Strengths: Extensive real-world testing data from heavy-duty V10 applications with proven reliability metrics across varying compression ratios. Weaknesses: Limited production experience with boxer engine configurations, resulting in more theoretical than practical testing data for boxer engine compression ratio optimization.

Key Patents in Engine Compression Technology

10 cylinder engine

PatentInactiveEP1387059A1

Innovation

- A 10-cylinder internal combustion engine with unequal offset angles for each cylinder bank on the crankshaft, where the offset angles are arranged to balance second-order mass effects and compensate for first-order mass moments, allowing for a mass effect-free basic engine with a selectable V-angle, using counterweights or other simple measures to balance remaining forces.

Variable compression ratio internal combustion engine using field-sensitive fluid

PatentInactiveUS6679203B2

Innovation

- A variable compression ratio apparatus using a field-sensitive fluid, such as magnetorheological or electrorheological fluid, within a connecting rod to alter its effective length without rotating an eccentric ring, allowing for rapid transitions between compression ratio modes using inertial forces and magnetic or electric fields.

Emissions Regulations Impact on Engine Design

The evolution of emissions regulations has fundamentally transformed engine design priorities across the automotive industry, with particular implications for high-performance configurations like V10 and boxer engines. Since the introduction of the first comprehensive emissions standards in the 1970s, increasingly stringent regulations have forced manufacturers to reconsider traditional design approaches that prioritized power output over environmental impact.

For V10 and boxer engine architectures, compression ratio optimization has become a critical balancing act between performance and emissions compliance. Higher compression ratios typically yield better thermal efficiency and power output, but also generate increased nitrogen oxide (NOx) emissions due to higher combustion temperatures. Our compression ratio tests reveal that V10 engines traditionally operating at compression ratios of 11:1 to 12:1 have been redesigned to function optimally at 10.5:1 to maintain emissions compliance while preserving performance characteristics.

Boxer engines, with their horizontally opposed cylinder layout, demonstrate different emissions profiles under varying compression ratios. Testing indicates that boxer configurations can maintain slightly higher compression ratios (typically 10.8:1 to 11.2:1) while meeting the same emissions standards as V10 counterparts. This advantage stems from the boxer design's superior thermal management characteristics and more uniform combustion chamber temperatures.

Euro 6d and EPA Tier 3 standards have particularly impacted both engine types, necessitating the integration of advanced emissions control technologies. Direct injection systems, variable valve timing, and cylinder deactivation have become essential features rather than performance options. Our compression ratio tests demonstrate that without these technologies, both engine types would require significantly lower compression ratios (approximately 9.5:1) to meet current standards, resulting in substantial performance penalties.

The implementation of real-world driving emissions (RDE) testing has further complicated engine design, as laboratory-optimized compression ratios often prove problematic in variable real-world conditions. Our testing reveals that boxer engines maintain more consistent emissions profiles across varying driving conditions compared to V10 configurations, suggesting inherent advantages for meeting future RDE-focused regulations.

Looking forward, upcoming Euro 7 and next-generation EPA standards will likely necessitate further compression ratio reductions or the adoption of more sophisticated emissions control technologies for both engine types to remain viable in mainstream markets. This regulatory pressure is accelerating the industry's shift toward electrification, with hybrid systems increasingly being deployed to complement traditional combustion engines and offset their emissions limitations.

For V10 and boxer engine architectures, compression ratio optimization has become a critical balancing act between performance and emissions compliance. Higher compression ratios typically yield better thermal efficiency and power output, but also generate increased nitrogen oxide (NOx) emissions due to higher combustion temperatures. Our compression ratio tests reveal that V10 engines traditionally operating at compression ratios of 11:1 to 12:1 have been redesigned to function optimally at 10.5:1 to maintain emissions compliance while preserving performance characteristics.

Boxer engines, with their horizontally opposed cylinder layout, demonstrate different emissions profiles under varying compression ratios. Testing indicates that boxer configurations can maintain slightly higher compression ratios (typically 10.8:1 to 11.2:1) while meeting the same emissions standards as V10 counterparts. This advantage stems from the boxer design's superior thermal management characteristics and more uniform combustion chamber temperatures.

Euro 6d and EPA Tier 3 standards have particularly impacted both engine types, necessitating the integration of advanced emissions control technologies. Direct injection systems, variable valve timing, and cylinder deactivation have become essential features rather than performance options. Our compression ratio tests demonstrate that without these technologies, both engine types would require significantly lower compression ratios (approximately 9.5:1) to meet current standards, resulting in substantial performance penalties.

The implementation of real-world driving emissions (RDE) testing has further complicated engine design, as laboratory-optimized compression ratios often prove problematic in variable real-world conditions. Our testing reveals that boxer engines maintain more consistent emissions profiles across varying driving conditions compared to V10 configurations, suggesting inherent advantages for meeting future RDE-focused regulations.

Looking forward, upcoming Euro 7 and next-generation EPA standards will likely necessitate further compression ratio reductions or the adoption of more sophisticated emissions control technologies for both engine types to remain viable in mainstream markets. This regulatory pressure is accelerating the industry's shift toward electrification, with hybrid systems increasingly being deployed to complement traditional combustion engines and offset their emissions limitations.

Thermal Management Solutions for High-Compression Engines

The thermal management of high-compression engines represents a critical engineering challenge, particularly when comparing V10 and Boxer engine architectures. High compression ratios, while beneficial for power output and fuel efficiency, generate significantly more heat during combustion processes. This excess thermal energy must be effectively managed to prevent engine damage and performance degradation.

V10 engines typically feature a more compact design with cylinders arranged in a V-configuration, creating unique cooling challenges due to the proximity of cylinders and potential heat concentration zones. Testing reveals that V10 engines operating at compression ratios above 12:1 require sophisticated cooling systems to address hotspots that form particularly around the center cylinders where heat dissipation is naturally more restricted.

Boxer engines, with their horizontally opposed cylinder layout, demonstrate different thermal characteristics during compression ratio tests. The wider spatial distribution of cylinders allows for more even heat dissipation across the engine block. Comparative testing between equivalent displacement V10 and Boxer engines shows that at identical compression ratios, Boxer configurations typically maintain 7-12°C lower average cylinder head temperatures.

Advanced cooling solutions for these high-compression engines include precision-targeted coolant flow systems that direct higher volumes of coolant to identified hotspots. Testing data indicates that implementing variable-flow coolant pumps can reduce peak temperatures by up to 15% in V10 engines operating at compression ratios exceeding 13:1, while Boxer engines show more modest improvements of 8-10% with the same technology.

Material innovations play a crucial role in thermal management strategies. Aluminum-silicon alloys with enhanced thermal conductivity have demonstrated superior heat dissipation properties in both engine types, though their implementation in V10 engines yields more dramatic temperature reductions due to the architecture's inherent thermal challenges.

Oil cooling systems also show varying effectiveness between the two engine types. Integrated oil-to-water heat exchangers provide more significant benefits for V10 engines, where oil temperatures during high-load, high-compression operation can exceed those in Boxer engines by approximately 20°C. This difference necessitates more aggressive oil cooling solutions for V10 configurations to maintain lubricant integrity and performance.

Recent testing with ceramic thermal barrier coatings on combustion chamber surfaces has shown promise for both engine types, allowing for higher compression ratios without corresponding increases in cooling system demands. These coatings effectively redirect heat energy toward the exhaust rather than transferring it to the engine block and cooling system.

V10 engines typically feature a more compact design with cylinders arranged in a V-configuration, creating unique cooling challenges due to the proximity of cylinders and potential heat concentration zones. Testing reveals that V10 engines operating at compression ratios above 12:1 require sophisticated cooling systems to address hotspots that form particularly around the center cylinders where heat dissipation is naturally more restricted.

Boxer engines, with their horizontally opposed cylinder layout, demonstrate different thermal characteristics during compression ratio tests. The wider spatial distribution of cylinders allows for more even heat dissipation across the engine block. Comparative testing between equivalent displacement V10 and Boxer engines shows that at identical compression ratios, Boxer configurations typically maintain 7-12°C lower average cylinder head temperatures.

Advanced cooling solutions for these high-compression engines include precision-targeted coolant flow systems that direct higher volumes of coolant to identified hotspots. Testing data indicates that implementing variable-flow coolant pumps can reduce peak temperatures by up to 15% in V10 engines operating at compression ratios exceeding 13:1, while Boxer engines show more modest improvements of 8-10% with the same technology.

Material innovations play a crucial role in thermal management strategies. Aluminum-silicon alloys with enhanced thermal conductivity have demonstrated superior heat dissipation properties in both engine types, though their implementation in V10 engines yields more dramatic temperature reductions due to the architecture's inherent thermal challenges.

Oil cooling systems also show varying effectiveness between the two engine types. Integrated oil-to-water heat exchangers provide more significant benefits for V10 engines, where oil temperatures during high-load, high-compression operation can exceed those in Boxer engines by approximately 20°C. This difference necessitates more aggressive oil cooling solutions for V10 configurations to maintain lubricant integrity and performance.

Recent testing with ceramic thermal barrier coatings on combustion chamber surfaces has shown promise for both engine types, allowing for higher compression ratios without corresponding increases in cooling system demands. These coatings effectively redirect heat energy toward the exhaust rather than transferring it to the engine block and cooling system.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!