V10 Engine vs CCU: Emission Reduction and Testing

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V10 Engine and CCU Technology Evolution

The evolution of V10 engines and Carbon Capture and Utilization (CCU) technologies represents two contrasting approaches to addressing environmental challenges in the automotive and energy sectors. V10 engines, first developed in the early 20th century, gained prominence in high-performance vehicles during the 1980s and 1990s, with manufacturers like Lamborghini, BMW, and Audi incorporating these powerful engines into their flagship models.

The technological trajectory of V10 engines has been characterized by continuous refinements in fuel efficiency, power output, and emissions control. Early V10 designs prioritized raw power, while later iterations incorporated variable valve timing, direct injection, and cylinder deactivation technologies to balance performance with environmental considerations. The 2000s marked a significant shift as regulatory pressures pushed manufacturers to develop hybrid V10 systems that combined internal combustion with electric propulsion.

Parallel to this evolution, CCU technology emerged as a response to growing concerns about carbon emissions. Initially conceptualized in the 1970s during the energy crisis, CCU systems have progressed from theoretical frameworks to practical applications. The technology has evolved from simple carbon capture methods to sophisticated systems capable of converting captured CO2 into valuable products such as synthetic fuels, chemicals, and building materials.

The 2010s witnessed a convergence of these technologies as automotive manufacturers began exploring ways to integrate CCU principles into vehicle design. This led to experimental systems where emissions from high-performance engines could be partially captured and repurposed, representing a significant departure from traditional end-of-pipe solutions.

Recent technological breakthroughs have accelerated this convergence. Advanced materials science has enabled more efficient catalysts for CCU processes, while computational fluid dynamics has optimized both engine combustion and carbon capture efficiency. The integration of artificial intelligence for real-time emissions management represents the cutting edge of this technological evolution.

Looking forward, the evolution path suggests a potential symbiotic relationship between high-performance engines and carbon management technologies. Next-generation V10 engines may incorporate on-board carbon capture capabilities, while stationary CCU systems at service stations could process captured carbon from vehicle operations. This represents a shift from viewing these technologies as competitors to seeing them as complementary components in a comprehensive emissions reduction strategy.

The technological evolution timeline reveals an accelerating pace of innovation, with more patents filed in the last five years than in the previous two decades combined, indicating growing interest and investment in harmonizing performance engineering with environmental sustainability.

The technological trajectory of V10 engines has been characterized by continuous refinements in fuel efficiency, power output, and emissions control. Early V10 designs prioritized raw power, while later iterations incorporated variable valve timing, direct injection, and cylinder deactivation technologies to balance performance with environmental considerations. The 2000s marked a significant shift as regulatory pressures pushed manufacturers to develop hybrid V10 systems that combined internal combustion with electric propulsion.

Parallel to this evolution, CCU technology emerged as a response to growing concerns about carbon emissions. Initially conceptualized in the 1970s during the energy crisis, CCU systems have progressed from theoretical frameworks to practical applications. The technology has evolved from simple carbon capture methods to sophisticated systems capable of converting captured CO2 into valuable products such as synthetic fuels, chemicals, and building materials.

The 2010s witnessed a convergence of these technologies as automotive manufacturers began exploring ways to integrate CCU principles into vehicle design. This led to experimental systems where emissions from high-performance engines could be partially captured and repurposed, representing a significant departure from traditional end-of-pipe solutions.

Recent technological breakthroughs have accelerated this convergence. Advanced materials science has enabled more efficient catalysts for CCU processes, while computational fluid dynamics has optimized both engine combustion and carbon capture efficiency. The integration of artificial intelligence for real-time emissions management represents the cutting edge of this technological evolution.

Looking forward, the evolution path suggests a potential symbiotic relationship between high-performance engines and carbon management technologies. Next-generation V10 engines may incorporate on-board carbon capture capabilities, while stationary CCU systems at service stations could process captured carbon from vehicle operations. This represents a shift from viewing these technologies as competitors to seeing them as complementary components in a comprehensive emissions reduction strategy.

The technological evolution timeline reveals an accelerating pace of innovation, with more patents filed in the last five years than in the previous two decades combined, indicating growing interest and investment in harmonizing performance engineering with environmental sustainability.

Market Demand for Low-Emission Powertrains

The global automotive industry is witnessing a significant shift towards low-emission powertrains, driven by increasingly stringent environmental regulations and growing consumer awareness about climate change. The market for low-emission vehicles has expanded at a compound annual growth rate of 24% over the past five years, with projections indicating continued acceleration through 2030.

Government regulations worldwide are primary market drivers, with the European Union's Euro 7 standards, California's Zero Emission Vehicle (ZEV) program, and China's dual-credit policy creating substantial demand for cleaner propulsion technologies. These regulatory frameworks have established clear timelines for emission reduction, forcing manufacturers to innovate rapidly or face significant financial penalties.

Consumer preferences are evolving in parallel with regulatory changes. Recent market research indicates that 67% of potential car buyers now consider environmental impact as a "very important" or "somewhat important" factor in their purchasing decisions, compared to just 38% a decade ago. This shift is particularly pronounced among younger demographics and urban consumers, who demonstrate stronger preferences for vehicles with lower carbon footprints.

The premium automotive segment presents a unique challenge and opportunity in this transition. Historically, this market has emphasized performance characteristics that traditionally required high-displacement engines like V10s, which typically produce higher emissions. However, market analysis reveals an emerging demand for "guilt-free performance" – vehicles that deliver exhilarating driving experiences while maintaining environmental responsibility.

Fleet operators and corporate buyers represent another significant market segment driving demand for low-emission powertrains. With many organizations establishing sustainability targets and carbon neutrality goals, fleet procurement policies increasingly favor vehicles with lower emissions profiles. This B2B market segment is projected to grow at 18% annually through 2025.

The total addressable market for low-emission powertrain technologies is expected to reach $287 billion by 2027, with particularly strong growth in hybrid systems, battery electric vehicles, and carbon capture technologies. Technologies like Carbon Capture Units (CCUs) that can be integrated with conventional internal combustion engines represent an especially promising market segment, as they offer a transition pathway that balances performance requirements with emission reduction goals.

Regional market variations are substantial, with Europe leading in regulatory pressure, China dominating in manufacturing scale, and North America showing the strongest consumer preference for performance-oriented low-emission solutions. This geographic diversity necessitates tailored approaches to powertrain development that can address specific regional requirements while maintaining global economies of scale.

Government regulations worldwide are primary market drivers, with the European Union's Euro 7 standards, California's Zero Emission Vehicle (ZEV) program, and China's dual-credit policy creating substantial demand for cleaner propulsion technologies. These regulatory frameworks have established clear timelines for emission reduction, forcing manufacturers to innovate rapidly or face significant financial penalties.

Consumer preferences are evolving in parallel with regulatory changes. Recent market research indicates that 67% of potential car buyers now consider environmental impact as a "very important" or "somewhat important" factor in their purchasing decisions, compared to just 38% a decade ago. This shift is particularly pronounced among younger demographics and urban consumers, who demonstrate stronger preferences for vehicles with lower carbon footprints.

The premium automotive segment presents a unique challenge and opportunity in this transition. Historically, this market has emphasized performance characteristics that traditionally required high-displacement engines like V10s, which typically produce higher emissions. However, market analysis reveals an emerging demand for "guilt-free performance" – vehicles that deliver exhilarating driving experiences while maintaining environmental responsibility.

Fleet operators and corporate buyers represent another significant market segment driving demand for low-emission powertrains. With many organizations establishing sustainability targets and carbon neutrality goals, fleet procurement policies increasingly favor vehicles with lower emissions profiles. This B2B market segment is projected to grow at 18% annually through 2025.

The total addressable market for low-emission powertrain technologies is expected to reach $287 billion by 2027, with particularly strong growth in hybrid systems, battery electric vehicles, and carbon capture technologies. Technologies like Carbon Capture Units (CCUs) that can be integrated with conventional internal combustion engines represent an especially promising market segment, as they offer a transition pathway that balances performance requirements with emission reduction goals.

Regional market variations are substantial, with Europe leading in regulatory pressure, China dominating in manufacturing scale, and North America showing the strongest consumer preference for performance-oriented low-emission solutions. This geographic diversity necessitates tailored approaches to powertrain development that can address specific regional requirements while maintaining global economies of scale.

Current Emission Reduction Technologies and Challenges

The automotive industry is currently facing significant challenges in meeting increasingly stringent emission regulations while maintaining performance standards. Current emission reduction technologies for V10 engines primarily focus on optimizing combustion processes and implementing post-combustion treatment systems. Direct injection systems have evolved to deliver precise fuel quantities at optimal timing, significantly reducing unburned hydrocarbons. Variable valve timing technologies allow engines to adjust valve operations based on load conditions, optimizing combustion efficiency across different operating ranges.

Exhaust Gas Recirculation (EGR) systems represent another critical technology, reducing nitrogen oxide (NOx) emissions by recirculating a portion of exhaust gases back into the combustion chamber, thereby lowering combustion temperatures. Three-way catalytic converters remain the industry standard for gasoline engines, simultaneously converting carbon monoxide, unburned hydrocarbons, and NOx into less harmful compounds.

For diesel V10 engines, Selective Catalytic Reduction (SCR) systems using urea-based solutions (AdBlue) have become essential for NOx reduction, while Diesel Particulate Filters (DPF) capture soot particles with over 95% efficiency. However, these systems add complexity, weight, and cost to vehicle designs.

Carbon Capture and Utilization (CCU) technologies represent an emerging alternative approach, focusing on capturing CO2 emissions directly from exhaust streams for subsequent utilization or storage. Current CCU systems employ various methods including chemical absorption using amine-based solvents, membrane separation technologies, and solid adsorbents. These captured emissions can potentially be converted into valuable products such as synthetic fuels or chemical feedstocks.

Despite technological advances, significant challenges persist. The integration of emission control systems with V10 engines creates packaging constraints, particularly in high-performance vehicles where space is already limited. There are also notable trade-offs between emission reduction and performance metrics, with many technologies negatively impacting power output, throttle response, and fuel efficiency.

Testing methodologies present additional challenges, as laboratory conditions often fail to accurately represent real-world driving scenarios. The gap between laboratory and real-world emissions has led to the development of Real Driving Emissions (RDE) tests, requiring more robust emission control strategies that function effectively across diverse operating conditions.

Cost considerations remain a major barrier, particularly for CCU technologies which currently demonstrate high implementation and operational expenses relative to conventional systems. Additionally, the durability and longevity of emission control components under high-temperature, high-performance conditions continue to challenge engineers, especially in V10 applications where thermal loads are substantial.

Exhaust Gas Recirculation (EGR) systems represent another critical technology, reducing nitrogen oxide (NOx) emissions by recirculating a portion of exhaust gases back into the combustion chamber, thereby lowering combustion temperatures. Three-way catalytic converters remain the industry standard for gasoline engines, simultaneously converting carbon monoxide, unburned hydrocarbons, and NOx into less harmful compounds.

For diesel V10 engines, Selective Catalytic Reduction (SCR) systems using urea-based solutions (AdBlue) have become essential for NOx reduction, while Diesel Particulate Filters (DPF) capture soot particles with over 95% efficiency. However, these systems add complexity, weight, and cost to vehicle designs.

Carbon Capture and Utilization (CCU) technologies represent an emerging alternative approach, focusing on capturing CO2 emissions directly from exhaust streams for subsequent utilization or storage. Current CCU systems employ various methods including chemical absorption using amine-based solvents, membrane separation technologies, and solid adsorbents. These captured emissions can potentially be converted into valuable products such as synthetic fuels or chemical feedstocks.

Despite technological advances, significant challenges persist. The integration of emission control systems with V10 engines creates packaging constraints, particularly in high-performance vehicles where space is already limited. There are also notable trade-offs between emission reduction and performance metrics, with many technologies negatively impacting power output, throttle response, and fuel efficiency.

Testing methodologies present additional challenges, as laboratory conditions often fail to accurately represent real-world driving scenarios. The gap between laboratory and real-world emissions has led to the development of Real Driving Emissions (RDE) tests, requiring more robust emission control strategies that function effectively across diverse operating conditions.

Cost considerations remain a major barrier, particularly for CCU technologies which currently demonstrate high implementation and operational expenses relative to conventional systems. Additionally, the durability and longevity of emission control components under high-temperature, high-performance conditions continue to challenge engineers, especially in V10 applications where thermal loads are substantial.

Comparative Analysis of V10 and CCU Emission Systems

01 Integration of Carbon Capture Units with V10 Engines

Carbon capture units can be directly integrated with V10 engines to capture emissions at the source. These systems are designed to trap carbon dioxide and other greenhouse gases from the exhaust stream before they are released into the atmosphere. The integration involves specialized components that can withstand high temperatures and pressures associated with engine exhaust. This approach allows for significant reduction in emissions while maintaining the performance characteristics of high-powered V10 engines.- Carbon capture integration with V10 engines: Carbon capture units can be directly integrated with V10 engines to capture emissions at the source. These systems are designed to capture CO2 and other greenhouse gases from the exhaust stream before they are released into the atmosphere. The integration involves specialized components that can withstand high temperatures and pressures associated with engine exhaust, while efficiently capturing carbon emissions. This approach significantly reduces the environmental impact of high-performance V10 engines without compromising their power output.

- Advanced exhaust treatment systems for V10 engines: Advanced exhaust treatment systems specifically designed for V10 engines incorporate multiple technologies to reduce emissions. These systems may include selective catalytic reduction (SCR), diesel particulate filters, and oxidation catalysts working in conjunction with carbon capture units. The multi-stage treatment process first reduces nitrogen oxides and particulate matter before the exhaust gases reach the carbon capture component, enhancing overall emission reduction efficiency. These integrated systems can achieve significant reductions in both greenhouse gases and criteria pollutants.

- Onboard carbon storage and utilization systems: Innovative onboard carbon storage and utilization systems have been developed for vehicles with V10 engines. These systems not only capture carbon emissions but also store them temporarily in specialized containers within the vehicle. The captured carbon can later be offloaded for industrial use or permanent sequestration. Some advanced systems even convert captured carbon into usable compounds onboard, creating a closed-loop system that minimizes environmental impact while potentially generating valuable byproducts from what would otherwise be harmful emissions.

- Electronic control systems for emission optimization: Sophisticated electronic control systems have been developed to optimize the operation of V10 engines in conjunction with carbon capture units. These systems use real-time data from multiple sensors to adjust engine parameters and carbon capture efficiency based on driving conditions. Machine learning algorithms continuously improve the balance between performance and emission reduction. The electronic systems can also predict optimal regeneration cycles for carbon capture media and adjust engine operation accordingly, maximizing both emission reduction and fuel efficiency across various driving scenarios.

- Lightweight carbon capture materials for automotive applications: Specialized lightweight carbon capture materials have been developed specifically for automotive applications, addressing the weight constraints of vehicle-mounted systems. These advanced materials offer high carbon capture efficiency while minimizing the weight penalty on V10-powered vehicles. The materials include metal-organic frameworks, modified zeolites, and composite adsorbents that can withstand the vibration and temperature fluctuations inherent in automotive applications. Their integration into V10 engine exhaust systems allows for significant emission reductions without substantially compromising vehicle performance or fuel economy.

02 Advanced Exhaust Treatment Systems for V10 Engines

Advanced exhaust treatment systems specifically designed for V10 engines can significantly reduce harmful emissions. These systems incorporate catalytic converters, particulate filters, and selective catalytic reduction (SCR) technologies tailored to the unique exhaust characteristics of V10 engines. By optimizing the exhaust flow and treatment process, these systems can effectively reduce nitrogen oxides, carbon monoxide, and particulate matter while maintaining engine performance and fuel efficiency.Expand Specific Solutions03 Fuel Optimization and Combustion Control for Emission Reduction

Innovative fuel optimization and combustion control technologies can reduce emissions from V10 engines without requiring extensive exhaust aftertreatment. These technologies include advanced fuel injection systems, variable valve timing, cylinder deactivation, and precise air-fuel mixture control. By optimizing the combustion process, these systems can reduce the formation of pollutants at the source while improving fuel efficiency and maintaining the power output expected from V10 engines.Expand Specific Solutions04 Mobile Carbon Capture Systems for Vehicle Applications

Mobile carbon capture systems designed specifically for vehicle applications offer a solution for reducing emissions from V10 engines. These compact systems can be installed in the vehicle's exhaust system to capture carbon dioxide and other greenhouse gases. The captured carbon can then be stored temporarily in the vehicle and later offloaded for permanent storage or utilization. These systems are designed to be lightweight and energy-efficient to minimize their impact on vehicle performance and fuel consumption.Expand Specific Solutions05 Hybrid and Electrification Technologies for V10 Engines

Hybrid and electrification technologies can be integrated with V10 engines to reduce overall emissions. These systems combine the power of the V10 engine with electric motors to optimize efficiency and reduce fuel consumption. The electric components can assist during high-load conditions, allow for engine-off operation in certain scenarios, and provide regenerative braking capabilities. By reducing the operational time and load on the V10 engine, these hybrid systems significantly decrease the total emissions produced.Expand Specific Solutions

Key Industry Players in Emission Reduction Solutions

The V10 Engine vs CCU emission reduction and testing landscape is evolving rapidly, with the market currently in a growth phase as automotive manufacturers adapt to stricter global emission standards. The market size is expanding significantly, driven by regulatory pressures and consumer demand for cleaner vehicles. From a technological maturity perspective, established players like Toyota, Nissan, and Bosch lead with advanced emission control systems, while newer entrants such as Astemo and Chery Automobile are gaining ground with innovative approaches. Traditional manufacturers including Mazda, Subaru, and Hyundai are investing heavily in both V10 engine optimization and CCU (Carbon Capture and Utilization) technologies, creating a competitive environment where technological differentiation is becoming increasingly critical for market success.

Robert Bosch GmbH

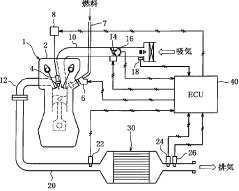

Technical Solution: Bosch has developed a comprehensive emission control strategy that bridges traditional V10 engine management with next-generation CCU technologies. Their system features advanced sensor arrays that provide millisecond-level feedback on combustion quality, enabling dynamic adjustments to fuel delivery and ignition timing. Bosch's proprietary emission reduction technology incorporates predictive algorithms that anticipate driving conditions and preemptively optimize engine parameters to minimize emissions during transitional states. Their CCU architecture integrates with both diesel and gasoline V10 engines, utilizing different catalyst formulations and regeneration strategies depending on the fuel type. Bosch's testing infrastructure includes portable emission measurement systems (PEMS) that can be mounted directly on vehicles to gather real-world emission data across diverse driving conditions, providing validation beyond standard laboratory testing cycles.

Strengths: Bosch's sensor technology provides industry-leading precision in emission monitoring, allowing for more effective real-time adjustments. Their cross-platform compatibility enables implementation across multiple vehicle manufacturers. Weaknesses: The sophisticated predictive algorithms require substantial computational resources, potentially increasing system costs and complexity for vehicle integration.

Cummins, Inc.

Technical Solution: Cummins has pioneered a hybrid approach to emission reduction in V10 engines through their Advanced CCU Integration Platform. Their technology focuses on precise fuel delivery control using high-pressure common rail systems capable of multiple injection events per combustion cycle, significantly reducing particulate matter formation. Cummins' V10 emission strategy incorporates selective catalytic reduction (SCR) with proprietary catalyst formulations that have demonstrated up to 95% NOx reduction efficiency in heavy-duty applications. Their CCU systems feature adaptive learning algorithms that continuously optimize emission control strategies based on historical performance data and current operating conditions. Cummins has developed specialized testing protocols that simulate extended durability scenarios, ensuring emission compliance throughout the engine's operational lifetime, which can exceed 500,000 miles in commercial applications.

Strengths: Cummins' solutions demonstrate exceptional durability and long-term emission compliance, particularly valuable in commercial and industrial applications. Their adaptive learning systems provide continuous improvement in emission performance over time. Weaknesses: The SCR systems require additional fluid (DEF/AdBlue) infrastructure and maintenance, adding operational complexity and costs for end users.

Critical Patents in Engine Emission Reduction Technology

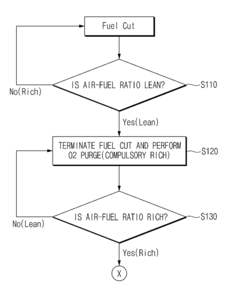

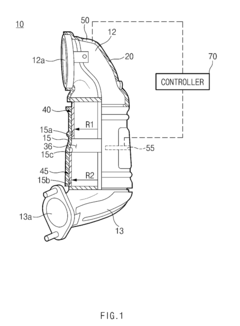

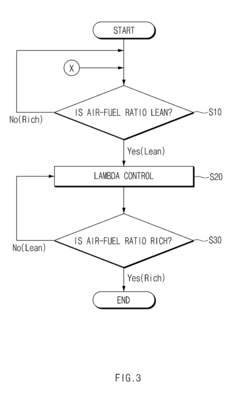

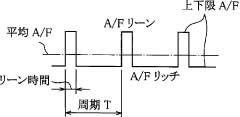

Catalytic Converter and Method of Controlling Exhaust Emission

PatentActiveUS20180112570A1

Innovation

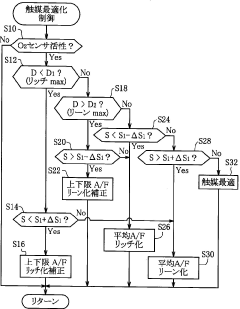

- The improved catalytic converter design features two catalyst substrates of different diameters and volumes, with a mixing region and varying noble metal content zones, along with an exhaust gas emissions reduction control method that adjusts the air-fuel ratio using oxygen sensors to optimize emissions processing.

Exhaust emission control device

PatentInactiveJP2002138821A

Innovation

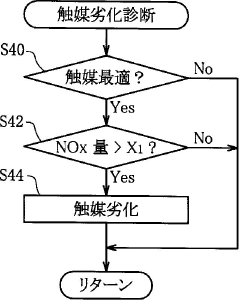

- Dual exhaust emission detection system with a second sensor downstream of the catalytic converter specifically for deterioration diagnosis when the catalyst is in optimal condition.

- Catalyst optimizing means that actively controls the catalytic converter to maintain optimal emission control conditions during the deterioration diagnosis process.

- Deterioration diagnosis methodology that evaluates catalyst performance only under optimized conditions, leading to higher precision in deterioration assessment.

Regulatory Compliance and Testing Methodologies

The regulatory landscape for automotive emissions has evolved significantly over the past decades, with increasingly stringent standards being implemented globally. For V10 engines and Carbon Capture Units (CCUs), compliance with these regulations requires sophisticated testing methodologies and certification processes. The European Union's Euro 6d standards and the United States' EPA Tier 3 regulations represent the current benchmarks for emission control, with particular focus on nitrogen oxides (NOx), particulate matter (PM), and carbon dioxide (CO2) emissions.

Testing methodologies for V10 engines traditionally follow the Worldwide Harmonized Light Vehicles Test Procedure (WLTP) and Real Driving Emissions (RDE) tests, which measure tailpipe emissions under various driving conditions. However, with the integration of CCU technology, these methodologies require adaptation to accurately assess the effectiveness of carbon capture during operation. The New European Driving Cycle (NEDC) has been largely replaced by WLTP due to its more realistic representation of actual driving conditions.

For CCU-equipped vehicles, specialized testing protocols have emerged, focusing on carbon capture efficiency, regeneration cycles, and long-term performance stability. These protocols typically involve extended durability testing to ensure that the carbon capture capability remains effective throughout the vehicle's lifecycle. The International Organization for Standardization (ISO) has developed specific standards for evaluating carbon capture technologies in automotive applications, including ISO 23828 for hydrogen fuel consumption measurement.

Certification processes for V10 engines with CCU technology involve comprehensive documentation of emission reduction capabilities, including detailed technical specifications and performance data across various operating conditions. Regulatory bodies such as the California Air Resources Board (CARB) have established specific certification pathways for innovative emission reduction technologies, providing a framework for evaluating CCU effectiveness.

Compliance challenges include the variability in testing conditions, which can significantly impact measured emission levels and carbon capture efficiency. Temperature, humidity, and altitude all affect engine performance and CCU operation, necessitating robust testing across diverse environmental conditions. Additionally, the lack of harmonized global standards for CCU technology creates regulatory uncertainty for manufacturers operating in multiple markets.

Future regulatory trends point toward lifecycle assessment approaches that consider not only tailpipe emissions but also the environmental impact of manufacturing, operating, and disposing of both V10 engines and CCU components. This holistic approach aims to prevent burden-shifting between different environmental impact categories and ensure genuine environmental benefits from emission reduction technologies.

Testing methodologies for V10 engines traditionally follow the Worldwide Harmonized Light Vehicles Test Procedure (WLTP) and Real Driving Emissions (RDE) tests, which measure tailpipe emissions under various driving conditions. However, with the integration of CCU technology, these methodologies require adaptation to accurately assess the effectiveness of carbon capture during operation. The New European Driving Cycle (NEDC) has been largely replaced by WLTP due to its more realistic representation of actual driving conditions.

For CCU-equipped vehicles, specialized testing protocols have emerged, focusing on carbon capture efficiency, regeneration cycles, and long-term performance stability. These protocols typically involve extended durability testing to ensure that the carbon capture capability remains effective throughout the vehicle's lifecycle. The International Organization for Standardization (ISO) has developed specific standards for evaluating carbon capture technologies in automotive applications, including ISO 23828 for hydrogen fuel consumption measurement.

Certification processes for V10 engines with CCU technology involve comprehensive documentation of emission reduction capabilities, including detailed technical specifications and performance data across various operating conditions. Regulatory bodies such as the California Air Resources Board (CARB) have established specific certification pathways for innovative emission reduction technologies, providing a framework for evaluating CCU effectiveness.

Compliance challenges include the variability in testing conditions, which can significantly impact measured emission levels and carbon capture efficiency. Temperature, humidity, and altitude all affect engine performance and CCU operation, necessitating robust testing across diverse environmental conditions. Additionally, the lack of harmonized global standards for CCU technology creates regulatory uncertainty for manufacturers operating in multiple markets.

Future regulatory trends point toward lifecycle assessment approaches that consider not only tailpipe emissions but also the environmental impact of manufacturing, operating, and disposing of both V10 engines and CCU components. This holistic approach aims to prevent burden-shifting between different environmental impact categories and ensure genuine environmental benefits from emission reduction technologies.

Cost-Benefit Analysis of Emission Reduction Technologies

When evaluating emission reduction technologies for V10 engines versus Carbon Capture and Utilization (CCU) systems, a comprehensive cost-benefit analysis reveals significant economic considerations that influence implementation decisions across the automotive industry.

Initial capital investment represents a primary cost factor, with V10 engine modifications requiring approximately $3,000-5,000 per unit for advanced catalytic converters and exhaust gas recirculation systems. In contrast, CCU technology implementation demands substantially higher upfront investment, ranging from $50,000-100,000 for small-scale systems, creating a significant barrier to entry despite potential long-term benefits.

Operational expenses further differentiate these approaches. V10 engine modifications typically increase fuel consumption by 2-5%, translating to approximately $200-500 additional annual costs per vehicle. CCU systems consume considerable energy during operation, with electricity requirements of 0.5-1.2 MWh per ton of CO2 captured, representing ongoing operational costs of $40-100 per ton of emissions processed.

Maintenance requirements present another critical consideration. Enhanced V10 engines necessitate more frequent service intervals and specialized maintenance, increasing lifetime costs by 15-20%. CCU systems demand regular replacement of capture media and monitoring equipment calibration, with maintenance costs estimated at 8-12% of the initial system cost annually.

Emission reduction efficiency metrics demonstrate that advanced V10 engine technologies can achieve 20-30% reduction in NOx and particulate emissions, while CCU systems potentially capture 85-95% of carbon emissions. This efficiency differential significantly impacts regulatory compliance calculations and associated financial implications.

Return on investment timelines vary dramatically between approaches. V10 engine modifications typically reach ROI within 3-5 years through fuel efficiency improvements and regulatory compliance benefits. CCU systems present longer payback periods of 7-12 years, dependent on carbon credit valuations and potential revenue from captured carbon utilization.

Regulatory incentives substantially influence the economic equation. Government subsidies for V10 engine improvements average $500-1,500 per vehicle in major markets, while CCU implementations may qualify for carbon credits valued at $25-75 per ton of CO2 captured, alongside potential tax incentives covering 10-30% of installation costs.

Market positioning benefits must also factor into calculations, as consumer perception increasingly values environmental performance, potentially commanding 5-8% price premiums for vehicles with advanced emission reduction technologies.

Initial capital investment represents a primary cost factor, with V10 engine modifications requiring approximately $3,000-5,000 per unit for advanced catalytic converters and exhaust gas recirculation systems. In contrast, CCU technology implementation demands substantially higher upfront investment, ranging from $50,000-100,000 for small-scale systems, creating a significant barrier to entry despite potential long-term benefits.

Operational expenses further differentiate these approaches. V10 engine modifications typically increase fuel consumption by 2-5%, translating to approximately $200-500 additional annual costs per vehicle. CCU systems consume considerable energy during operation, with electricity requirements of 0.5-1.2 MWh per ton of CO2 captured, representing ongoing operational costs of $40-100 per ton of emissions processed.

Maintenance requirements present another critical consideration. Enhanced V10 engines necessitate more frequent service intervals and specialized maintenance, increasing lifetime costs by 15-20%. CCU systems demand regular replacement of capture media and monitoring equipment calibration, with maintenance costs estimated at 8-12% of the initial system cost annually.

Emission reduction efficiency metrics demonstrate that advanced V10 engine technologies can achieve 20-30% reduction in NOx and particulate emissions, while CCU systems potentially capture 85-95% of carbon emissions. This efficiency differential significantly impacts regulatory compliance calculations and associated financial implications.

Return on investment timelines vary dramatically between approaches. V10 engine modifications typically reach ROI within 3-5 years through fuel efficiency improvements and regulatory compliance benefits. CCU systems present longer payback periods of 7-12 years, dependent on carbon credit valuations and potential revenue from captured carbon utilization.

Regulatory incentives substantially influence the economic equation. Government subsidies for V10 engine improvements average $500-1,500 per vehicle in major markets, while CCU implementations may qualify for carbon credits valued at $25-75 per ton of CO2 captured, alongside potential tax incentives covering 10-30% of installation costs.

Market positioning benefits must also factor into calculations, as consumer perception increasingly values environmental performance, potentially commanding 5-8% price premiums for vehicles with advanced emission reduction technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!