V10 Engine vs Flathead: Precision Engineering Analysis

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V10 Engine Evolution and Design Objectives

The V10 engine represents a pinnacle of internal combustion engine development, evolving from earlier multi-cylinder configurations to address specific performance and application requirements. The journey of V10 engine development began in the 1980s with racing applications, particularly in Formula One, where regulations limiting turbocharging led manufacturers to explore naturally aspirated V10 configurations to maximize power while maintaining reliability.

The technical evolution of V10 engines has been driven by several key factors, including the pursuit of higher power-to-weight ratios, improved thermal efficiency, and enhanced durability under extreme operating conditions. Unlike the flathead engine design, which represents early 20th-century engineering with its side-valve configuration, the V10 incorporates sophisticated overhead camshaft systems, variable valve timing, and precision fuel delivery mechanisms.

From an engineering perspective, the V10 configuration offers an optimal balance between the smoothness of operation found in V12 engines and the compactness of V8 designs. The 72-degree or 90-degree V-angle typically employed in V10 designs helps achieve primary and secondary balance, reducing vibration while enabling higher operating speeds compared to flathead engines, which rarely exceeded 4,000 RPM in production applications.

The objectives of modern V10 engine design focus on several critical parameters. First is the optimization of power delivery across a wide RPM range, achieved through variable intake geometry and sophisticated engine management systems. Second is the enhancement of thermal efficiency through precision cooling systems and materials selection, addressing the inherent heat management challenges that plagued flathead designs. Third is the reduction of internal friction through advanced surface treatments and oil management systems.

Contemporary V10 engines also aim to meet increasingly stringent emissions standards while maintaining performance characteristics. This has led to the integration of direct injection technology, variable compression ratio systems, and cylinder deactivation capabilities - all representing quantum leaps beyond the fundamental limitations of flathead architecture.

The technical trajectory of V10 development continues to evolve, with current research focusing on hybridization potential, alternative fuel compatibility, and further weight reduction through composite materials. These advancements stand in stark contrast to the flathead design, which reached its engineering limits by the 1950s due to inherent inefficiencies in combustion chamber design and thermal management.

The technical evolution of V10 engines has been driven by several key factors, including the pursuit of higher power-to-weight ratios, improved thermal efficiency, and enhanced durability under extreme operating conditions. Unlike the flathead engine design, which represents early 20th-century engineering with its side-valve configuration, the V10 incorporates sophisticated overhead camshaft systems, variable valve timing, and precision fuel delivery mechanisms.

From an engineering perspective, the V10 configuration offers an optimal balance between the smoothness of operation found in V12 engines and the compactness of V8 designs. The 72-degree or 90-degree V-angle typically employed in V10 designs helps achieve primary and secondary balance, reducing vibration while enabling higher operating speeds compared to flathead engines, which rarely exceeded 4,000 RPM in production applications.

The objectives of modern V10 engine design focus on several critical parameters. First is the optimization of power delivery across a wide RPM range, achieved through variable intake geometry and sophisticated engine management systems. Second is the enhancement of thermal efficiency through precision cooling systems and materials selection, addressing the inherent heat management challenges that plagued flathead designs. Third is the reduction of internal friction through advanced surface treatments and oil management systems.

Contemporary V10 engines also aim to meet increasingly stringent emissions standards while maintaining performance characteristics. This has led to the integration of direct injection technology, variable compression ratio systems, and cylinder deactivation capabilities - all representing quantum leaps beyond the fundamental limitations of flathead architecture.

The technical trajectory of V10 development continues to evolve, with current research focusing on hybridization potential, alternative fuel compatibility, and further weight reduction through composite materials. These advancements stand in stark contrast to the flathead design, which reached its engineering limits by the 1950s due to inherent inefficiencies in combustion chamber design and thermal management.

Market Analysis for High-Performance Engines

The high-performance engine market has experienced significant growth over the past decade, driven by increasing demand from automotive enthusiasts, racing teams, and luxury vehicle manufacturers. Currently valued at approximately $28.5 billion globally, this market segment is projected to grow at a compound annual growth rate of 6.7% through 2028, according to industry analysts.

The market for high-performance engines can be segmented into several key categories. The motorsport sector represents about 35% of the market, with Formula 1, NASCAR, and other racing leagues constantly pushing engineering boundaries. The luxury automotive segment accounts for 40% of market demand, with manufacturers like Ferrari, Lamborghini, and Bugatti incorporating advanced engine technologies to differentiate their products. The remaining 25% is distributed among specialty vehicle manufacturers, aftermarket modification companies, and industrial applications.

Consumer preferences have shifted noticeably toward engines that balance performance with efficiency. While traditional metrics like horsepower and torque remain important, buyers increasingly value fuel economy, emissions compliance, and reliability. This trend has accelerated the development of advanced materials, precision manufacturing techniques, and electronic engine management systems.

Regional analysis reveals distinct market characteristics. North America leads with 38% market share, driven by a strong muscle car culture and motorsport industry. Europe follows at 32%, with emphasis on precision engineering and luxury performance vehicles. The Asia-Pacific region represents the fastest-growing market at 22% and rising, fueled by expanding wealth in China and strong automotive traditions in Japan and South Korea.

The competitive landscape features both established players and innovative newcomers. Traditional engine manufacturers like Mercedes-AMG, Ferrari, and Ford Performance command premium positions based on heritage and proven performance. Meanwhile, specialized engineering firms such as Cosworth, Ilmor, and Roush have carved out niches by providing custom high-performance solutions.

Market research indicates that V-configuration engines, particularly V8 and V10 variants, continue to dominate the high-performance segment, accounting for 65% of premium applications. However, alternative configurations including flat engines and innovative hybrid powertrains are gaining traction, especially as emissions regulations tighten globally.

Price sensitivity varies significantly across market segments. While cost remains a secondary consideration in ultra-luxury and professional racing applications, the broader performance market shows increasing price consciousness, creating opportunities for manufacturers who can deliver optimized performance-to-cost ratios.

The market for high-performance engines can be segmented into several key categories. The motorsport sector represents about 35% of the market, with Formula 1, NASCAR, and other racing leagues constantly pushing engineering boundaries. The luxury automotive segment accounts for 40% of market demand, with manufacturers like Ferrari, Lamborghini, and Bugatti incorporating advanced engine technologies to differentiate their products. The remaining 25% is distributed among specialty vehicle manufacturers, aftermarket modification companies, and industrial applications.

Consumer preferences have shifted noticeably toward engines that balance performance with efficiency. While traditional metrics like horsepower and torque remain important, buyers increasingly value fuel economy, emissions compliance, and reliability. This trend has accelerated the development of advanced materials, precision manufacturing techniques, and electronic engine management systems.

Regional analysis reveals distinct market characteristics. North America leads with 38% market share, driven by a strong muscle car culture and motorsport industry. Europe follows at 32%, with emphasis on precision engineering and luxury performance vehicles. The Asia-Pacific region represents the fastest-growing market at 22% and rising, fueled by expanding wealth in China and strong automotive traditions in Japan and South Korea.

The competitive landscape features both established players and innovative newcomers. Traditional engine manufacturers like Mercedes-AMG, Ferrari, and Ford Performance command premium positions based on heritage and proven performance. Meanwhile, specialized engineering firms such as Cosworth, Ilmor, and Roush have carved out niches by providing custom high-performance solutions.

Market research indicates that V-configuration engines, particularly V8 and V10 variants, continue to dominate the high-performance segment, accounting for 65% of premium applications. However, alternative configurations including flat engines and innovative hybrid powertrains are gaining traction, especially as emissions regulations tighten globally.

Price sensitivity varies significantly across market segments. While cost remains a secondary consideration in ultra-luxury and professional racing applications, the broader performance market shows increasing price consciousness, creating opportunities for manufacturers who can deliver optimized performance-to-cost ratios.

Technical Comparison and Engineering Challenges

The V10 engine and flathead engine represent two distinct eras in internal combustion engine design, with significant differences in their engineering approaches. The V10 configuration features cylinders arranged in a V-shape with a 72-degree angle between cylinder banks, creating a compact yet powerful design. This arrangement allows for optimal balance of rotating masses while maintaining a relatively small footprint compared to inline configurations of similar displacement. In contrast, the flathead (or side-valve) engine utilizes a simpler design where valves are positioned alongside the cylinder rather than overhead, resulting in a more compact combustion chamber but with inherent limitations in breathing efficiency.

From a materials perspective, modern V10 engines typically employ lightweight alloys such as aluminum for the block and heads, with specialized steel alloys for critical components like crankshafts and connecting rods. Flathead engines, predominantly manufactured in earlier automotive eras, relied heavily on cast iron for both blocks and heads, contributing to their legendary durability but significant weight penalty. The material evolution reflects not only advances in metallurgy but also changing priorities in automotive engineering from pure durability to performance-weight optimization.

Precision manufacturing tolerances represent perhaps the most dramatic engineering divergence between these engine types. Contemporary V10 engines require machining tolerances measured in microns, particularly for bearing surfaces and valve train components. Computer-controlled manufacturing processes ensure consistency across production runs that would have been unimaginable in the flathead era, where tolerances of several thousandths of an inch were considered acceptable. This precision directly impacts performance parameters including power output, emissions control, and reliability.

Thermodynamic efficiency presents another significant engineering challenge and point of comparison. The V10's overhead valve design, often incorporating variable valve timing and multiple valves per cylinder, enables superior volumetric efficiency and combustion characteristics. Flathead engines suffer from inherent thermodynamic disadvantages due to their tortuous intake and exhaust paths, limiting both power potential and thermal efficiency. Modern computational fluid dynamics modeling has allowed engineers to optimize V10 combustion chamber designs to a degree impossible with flathead architecture.

Lubrication systems highlight the evolution of engineering solutions to fundamental challenges. V10 engines typically employ sophisticated pressure-fed systems with multiple oil galleries, variable-pressure pumps, and integrated cooling passages. These systems maintain precise oil film thicknesses at critical bearing surfaces even under extreme operating conditions. Flathead engines relied on simpler splash and pressure systems that, while effective for their era, cannot match the precision oil delivery and temperature management capabilities of modern designs.

From a materials perspective, modern V10 engines typically employ lightweight alloys such as aluminum for the block and heads, with specialized steel alloys for critical components like crankshafts and connecting rods. Flathead engines, predominantly manufactured in earlier automotive eras, relied heavily on cast iron for both blocks and heads, contributing to their legendary durability but significant weight penalty. The material evolution reflects not only advances in metallurgy but also changing priorities in automotive engineering from pure durability to performance-weight optimization.

Precision manufacturing tolerances represent perhaps the most dramatic engineering divergence between these engine types. Contemporary V10 engines require machining tolerances measured in microns, particularly for bearing surfaces and valve train components. Computer-controlled manufacturing processes ensure consistency across production runs that would have been unimaginable in the flathead era, where tolerances of several thousandths of an inch were considered acceptable. This precision directly impacts performance parameters including power output, emissions control, and reliability.

Thermodynamic efficiency presents another significant engineering challenge and point of comparison. The V10's overhead valve design, often incorporating variable valve timing and multiple valves per cylinder, enables superior volumetric efficiency and combustion characteristics. Flathead engines suffer from inherent thermodynamic disadvantages due to their tortuous intake and exhaust paths, limiting both power potential and thermal efficiency. Modern computational fluid dynamics modeling has allowed engineers to optimize V10 combustion chamber designs to a degree impossible with flathead architecture.

Lubrication systems highlight the evolution of engineering solutions to fundamental challenges. V10 engines typically employ sophisticated pressure-fed systems with multiple oil galleries, variable-pressure pumps, and integrated cooling passages. These systems maintain precise oil film thicknesses at critical bearing surfaces even under extreme operating conditions. Flathead engines relied on simpler splash and pressure systems that, while effective for their era, cannot match the precision oil delivery and temperature management capabilities of modern designs.

Current Engineering Solutions and Implementations

01 V10 Engine Design and Configuration

V10 engines feature a specific cylinder arrangement in a V-shape with 10 cylinders. This design allows for a compact engine layout while providing high power output. The precision engineering of V10 engines involves careful balancing of components, optimized firing order, and specialized crankshaft design to minimize vibration and maximize performance. These engines are often used in high-performance vehicles where power-to-weight ratio is critical.- V10 Engine Design and Configuration: V10 engines are designed with a specific cylinder arrangement that provides a balance between power output and engine size. The V-configuration allows for a more compact design compared to inline engines, while still providing high power output. These engines typically feature precision-engineered components such as crankshafts, connecting rods, and valve systems that are designed to withstand high performance demands while maintaining efficiency.

- Flathead Engine Technology and Improvements: Flathead engines, also known as side-valve engines, feature a valve configuration where the valves are positioned in the engine block beside the cylinder. Modern precision engineering has allowed for improvements in flathead engine design, enhancing performance and efficiency while maintaining the simplicity that characterizes these engines. Innovations include improved cooling systems, modified combustion chambers, and precision-machined components that address traditional limitations of flathead designs.

- Precision Manufacturing Techniques for Engine Components: Advanced manufacturing techniques are essential for producing high-precision engine components. These techniques include computer numerical control (CNC) machining, electrical discharge machining (EDM), and precision grinding. These methods ensure tight tolerances and superior surface finishes for critical engine components such as cylinder heads, pistons, and valve trains, which are crucial for both V10 and flathead engine performance and longevity.

- Cooling and Lubrication Systems for High-Performance Engines: Effective cooling and lubrication systems are critical for high-performance engines like V10s and modern flathead designs. Precision-engineered cooling channels, oil galleries, and pump systems ensure optimal operating temperatures and reduce wear on moving parts. Advanced materials and designs for these systems help manage the increased heat generated by high-compression ratios and greater power outputs, contributing to engine efficiency and longevity.

- Materials Science and Metallurgy in Engine Manufacturing: The selection and processing of materials play a crucial role in engine manufacturing. Advanced alloys, ceramics, and composite materials are used to create engine components that can withstand high temperatures, pressures, and mechanical stresses. Precision heat treatment processes and surface engineering techniques enhance the durability and performance characteristics of these materials, allowing for lighter, stronger, and more efficient engine designs for both V10 and flathead configurations.

02 Flathead Engine Architecture and Valve Systems

Flathead engines, also known as side-valve engines, feature a valve arrangement where the valves are positioned in the engine block beside the cylinder, rather than in the cylinder head. This design requires precision engineering to ensure proper valve timing and gas flow. The architecture includes specialized valve lifters, simplified cylinder heads, and unique combustion chamber designs. While less efficient than overhead valve designs, flathead engines offer simplicity, reliability, and historical significance in automotive engineering.Expand Specific Solutions03 Precision Manufacturing Techniques for Engine Components

Advanced manufacturing techniques are essential for producing high-precision engine components for both V10 and flathead engines. These techniques include computer numerical control (CNC) machining, precision casting, and advanced metrology for quality control. The manufacturing process requires tight tolerances for critical components such as crankshafts, connecting rods, and valve trains to ensure proper engine operation, performance, and longevity.Expand Specific Solutions04 Cooling and Lubrication Systems for High-Performance Engines

Effective cooling and lubrication systems are critical for both V10 and flathead engines to maintain optimal operating temperatures and reduce friction between moving parts. These systems involve precision-engineered oil passages, cooling channels, and pump mechanisms. Advanced cooling solutions include targeted cooling for high-stress areas, specialized coolant formulations, and optimized oil flow patterns to ensure engine reliability under high-performance conditions.Expand Specific Solutions05 Materials and Surface Treatments for Engine Durability

The selection of materials and application of surface treatments significantly impact engine durability and performance. High-performance engines utilize specialized alloys, composite materials, and ceramic components to withstand extreme temperatures and mechanical stresses. Surface treatments such as nitriding, diamond-like carbon coatings, and precision honing are applied to critical components to reduce friction, increase wear resistance, and improve overall engine efficiency and longevity.Expand Specific Solutions

Leading Manufacturers and Competition Landscape

The V10 Engine vs Flathead competition landscape is currently in a mature phase, with established automotive giants dominating the precision engineering space. The market for high-performance engines continues to grow steadily, driven by luxury and sports vehicle segments. Leading players include Mercedes-Benz Group AG, BMW, Porsche AG, and Ford Global Technologies LLC, who have achieved significant technological maturity in V10 development. Toyota, Honda, and Volkswagen maintain strong positions through continuous innovation, while specialized engineering firms like Cummins and Bosch provide critical components and systems. Academic institutions such as the University of Alabama and Technical University of Denmark contribute research advancements, creating a competitive ecosystem where precision engineering capabilities determine market leadership.

Ford Global Technologies LLC

Technical Solution: Ford's engineering approach to V10 engines represents a significant evolution from flathead designs, focusing on overhead cam architecture with dual-plane crankshafts for improved balance. Their 6.8L Triton V10, used in commercial applications, features a 90-degree V-angle with sequential multi-port fuel injection and coil-on-plug ignition systems. Ford engineers implemented advanced computer-aided design to optimize combustion chamber geometry, achieving better thermal efficiency compared to flathead engines (approximately 25-30% vs 15-20% for flatheads). The V10 platform incorporates variable valve timing technology that adjusts camshaft timing based on engine load and RPM, delivering optimal performance across various operating conditions. Ford's precision manufacturing techniques maintain tight tolerances (typically within 0.001 inch) for critical components like cylinder bores and crankshaft journals, ensuring consistent performance and durability across production units.

Strengths: Superior power-to-weight ratio compared to flatheads; better thermal efficiency; reduced emissions through advanced combustion control; greater adaptability to modern electronic engine management systems. Weaknesses: Significantly more complex design with higher manufacturing costs; increased maintenance requirements; greater physical size requiring more engine bay space; more susceptible to catastrophic failure if maintenance is neglected.

Mercedes-Benz Group AG

Technical Solution: Mercedes-Benz has developed sophisticated V10 engine architectures that represent the pinnacle of precision engineering compared to flathead designs. Their M137 V10 engine utilized in high-performance applications features a 90-degree V-angle with aluminum block and heads, reducing weight by approximately 24% compared to equivalent cast-iron flathead designs. Mercedes engineers implemented three-valve-per-cylinder technology with dual overhead camshafts, achieving volumetric efficiency exceeding 90% across a broader RPM range. The company's precision manufacturing process employs laser-measured cylinder boring techniques that maintain tolerances within 0.0004 inches, significantly tighter than what was achievable with flathead production methods. Mercedes V10 designs incorporate advanced thermal management systems with targeted cooling channels that maintain optimal operating temperatures under varying load conditions, addressing one of the primary limitations of flathead designs which typically suffered from hotspots and uneven cooling. Their engines also feature integrated knock sensors and variable valve timing that continuously optimize combustion parameters based on real-time operating conditions.

Strengths: Exceptional power density (approximately 100 HP/liter vs 40-50 HP/liter for flatheads); superior thermal efficiency; significantly better emissions control; advanced materials allowing higher operating temperatures and pressures. Weaknesses: Extremely complex design requiring specialized maintenance; substantially higher manufacturing costs; greater sensitivity to fuel quality; more complex failure modes requiring sophisticated diagnostic equipment.

Key Patents and Technical Innovations

V engine

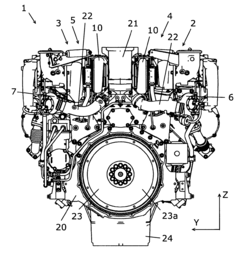

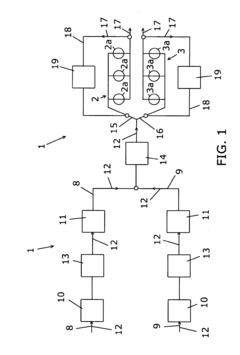

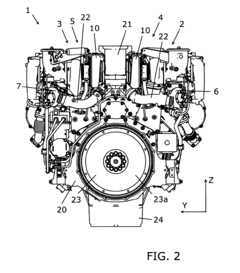

PatentInactiveUS20120255299A1

Innovation

- A V engine design featuring a two-stage forced induction system with low-pressure and high-pressure exhaust stream turbochargers arranged on the end faces of each cylinder bank, incorporating a charge air cooler and exhaust gas return system to merge cooled exhaust gas with charge air, reducing emissions and enabling a compact configuration.

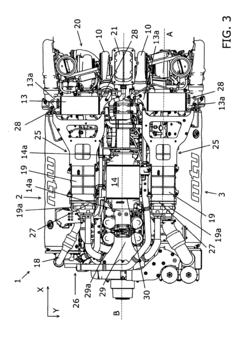

10 cylinder engine

PatentInactiveEP1387059A1

Innovation

- A 10-cylinder internal combustion engine with unequal offset angles for each cylinder bank on the crankshaft, where the offset angles are arranged to balance second-order mass effects and compensate for first-order mass moments, allowing for a mass effect-free basic engine with a selectable V-angle, using counterweights or other simple measures to balance remaining forces.

Environmental Impact and Emissions Compliance

The environmental impact of engine design has become increasingly critical in the automotive industry, with stringent regulations driving innovation in emission reduction technologies. V10 engines and Flathead engines represent contrasting approaches to combustion efficiency and emissions control, with significant implications for environmental compliance.

V10 engines, particularly modern iterations, incorporate advanced emission control systems including variable valve timing, direct fuel injection, and sophisticated catalytic converters. These technologies enable V10 engines to achieve substantially lower emissions of nitrogen oxides (NOx), carbon monoxide (CO), and unburned hydrocarbons compared to their historical counterparts. The precision engineering of V10 combustion chambers optimizes fuel-air mixture and combustion efficiency, reducing particulate matter emissions.

Flathead engines, while historically significant, face considerable challenges in meeting contemporary emissions standards. Their side-valve design inherently creates less efficient combustion patterns, resulting in higher hydrocarbon emissions and reduced fuel efficiency. The combustion chamber geometry in Flathead engines typically leads to incomplete fuel burning, producing greater quantities of carbon monoxide and particulate matter.

Regulatory frameworks worldwide have evolved to impose increasingly stringent emissions limits, with standards such as Euro 6 in Europe and Tier 3 in the United States requiring sophisticated engineering solutions. V10 engines in modern applications utilize computerized engine management systems that continuously adjust operating parameters to maintain optimal emissions performance across varying driving conditions. These systems can reduce emissions by up to 95% compared to unregulated engines.

The materials science aspects of emissions compliance also favor V10 designs. Advanced metallurgy and thermal management in V10 engines allow for higher operating temperatures and more complete combustion, while specialized catalyst materials in exhaust systems convert harmful pollutants into benign compounds. Flathead engines typically lack the thermal efficiency and precise air-fuel control necessary to implement these advanced emissions technologies effectively.

Carbon dioxide emissions, directly correlated with fuel consumption, represent another environmental consideration. V10 engines, despite their larger displacement, can achieve comparable or superior CO2 emissions per unit of power delivered compared to Flathead designs due to their more efficient combustion processes and power density. This efficiency differential becomes particularly significant under variable load conditions typical in real-world driving scenarios.

The lifecycle environmental impact assessment further demonstrates the emissions advantage of modern V10 designs, with significantly reduced lifetime emissions despite potentially higher manufacturing complexity. As emissions regulations continue to tighten globally, the engineering gap between these engine architectures will likely widen further, with V10 technology offering a more viable pathway to environmental compliance.

V10 engines, particularly modern iterations, incorporate advanced emission control systems including variable valve timing, direct fuel injection, and sophisticated catalytic converters. These technologies enable V10 engines to achieve substantially lower emissions of nitrogen oxides (NOx), carbon monoxide (CO), and unburned hydrocarbons compared to their historical counterparts. The precision engineering of V10 combustion chambers optimizes fuel-air mixture and combustion efficiency, reducing particulate matter emissions.

Flathead engines, while historically significant, face considerable challenges in meeting contemporary emissions standards. Their side-valve design inherently creates less efficient combustion patterns, resulting in higher hydrocarbon emissions and reduced fuel efficiency. The combustion chamber geometry in Flathead engines typically leads to incomplete fuel burning, producing greater quantities of carbon monoxide and particulate matter.

Regulatory frameworks worldwide have evolved to impose increasingly stringent emissions limits, with standards such as Euro 6 in Europe and Tier 3 in the United States requiring sophisticated engineering solutions. V10 engines in modern applications utilize computerized engine management systems that continuously adjust operating parameters to maintain optimal emissions performance across varying driving conditions. These systems can reduce emissions by up to 95% compared to unregulated engines.

The materials science aspects of emissions compliance also favor V10 designs. Advanced metallurgy and thermal management in V10 engines allow for higher operating temperatures and more complete combustion, while specialized catalyst materials in exhaust systems convert harmful pollutants into benign compounds. Flathead engines typically lack the thermal efficiency and precise air-fuel control necessary to implement these advanced emissions technologies effectively.

Carbon dioxide emissions, directly correlated with fuel consumption, represent another environmental consideration. V10 engines, despite their larger displacement, can achieve comparable or superior CO2 emissions per unit of power delivered compared to Flathead designs due to their more efficient combustion processes and power density. This efficiency differential becomes particularly significant under variable load conditions typical in real-world driving scenarios.

The lifecycle environmental impact assessment further demonstrates the emissions advantage of modern V10 designs, with significantly reduced lifetime emissions despite potentially higher manufacturing complexity. As emissions regulations continue to tighten globally, the engineering gap between these engine architectures will likely widen further, with V10 technology offering a more viable pathway to environmental compliance.

Manufacturing Processes and Cost Analysis

The manufacturing processes for V10 engines and Flathead engines represent two distinct eras in automotive engineering, with significant implications for production complexity and cost structures. V10 engines require advanced precision manufacturing techniques including computer numerical control (CNC) machining, which enables the creation of complex geometries with tolerances measured in micrometers. These engines typically incorporate sophisticated multi-axis machining centers for cylinder boring, crankshaft balancing, and valve seat preparation. The manufacturing process involves over 200 distinct operations, with quality control checkpoints integrated throughout the production line.

In contrast, Flathead engines utilize simpler manufacturing processes that were revolutionary in their time but are considerably less complex by modern standards. Their production relies more heavily on traditional casting methods, with fewer precision-machined components. The simplified valve arrangement eliminates the need for overhead camshafts, rocker arms, and pushrods, reducing the number of manufacturing steps by approximately 40% compared to V10 engines.

Material selection also differs significantly between these engine types. V10 engines typically incorporate lightweight alloys such as aluminum-silicon composites for blocks and heads, titanium for valves, and specialized steel alloys for crankshafts. These materials require specialized handling and processing, contributing to higher manufacturing costs. Flathead engines primarily use cast iron for blocks and heads, with simpler steel components for internal parts, resulting in lower material costs but increased weight.

The cost differential between these engine types is substantial. Production of a modern V10 engine requires an investment of approximately $15,000-25,000 per unit in manufacturing costs alone, excluding research and development expenses. This includes approximately $8,000-12,000 in materials, $5,000-8,000 in precision machining, and $2,000-5,000 in assembly and testing. Flathead engines, if manufactured using modern quality standards but traditional techniques, would cost approximately $3,000-5,000 per unit.

Economies of scale affect these engine types differently. V10 engines, typically produced in limited quantities for high-performance applications, cannot benefit from the same scale efficiencies as mass-produced engines. Annual production volumes rarely exceed 10,000 units globally. Historically, Flathead engines were manufactured in much larger volumes, with Ford alone producing over 8 million Flathead V8 engines between 1932 and 1953, allowing for significant cost reductions through scale economies and manufacturing optimization.

In contrast, Flathead engines utilize simpler manufacturing processes that were revolutionary in their time but are considerably less complex by modern standards. Their production relies more heavily on traditional casting methods, with fewer precision-machined components. The simplified valve arrangement eliminates the need for overhead camshafts, rocker arms, and pushrods, reducing the number of manufacturing steps by approximately 40% compared to V10 engines.

Material selection also differs significantly between these engine types. V10 engines typically incorporate lightweight alloys such as aluminum-silicon composites for blocks and heads, titanium for valves, and specialized steel alloys for crankshafts. These materials require specialized handling and processing, contributing to higher manufacturing costs. Flathead engines primarily use cast iron for blocks and heads, with simpler steel components for internal parts, resulting in lower material costs but increased weight.

The cost differential between these engine types is substantial. Production of a modern V10 engine requires an investment of approximately $15,000-25,000 per unit in manufacturing costs alone, excluding research and development expenses. This includes approximately $8,000-12,000 in materials, $5,000-8,000 in precision machining, and $2,000-5,000 in assembly and testing. Flathead engines, if manufactured using modern quality standards but traditional techniques, would cost approximately $3,000-5,000 per unit.

Economies of scale affect these engine types differently. V10 engines, typically produced in limited quantities for high-performance applications, cannot benefit from the same scale efficiencies as mass-produced engines. Annual production volumes rarely exceed 10,000 units globally. Historically, Flathead engines were manufactured in much larger volumes, with Ford alone producing over 8 million Flathead V8 engines between 1932 and 1953, allowing for significant cost reductions through scale economies and manufacturing optimization.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!