V10 Engine vs Rotary Hybrid: Comparative Studies

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V10 Engine and Rotary Hybrid Evolution Background

The evolution of internal combustion engines represents one of the most significant technological developments in modern transportation history. The V10 engine and rotary hybrid systems, while fundamentally different in design philosophy, both emerged as solutions to specific engineering challenges in automotive and aerospace applications. The V10 configuration, featuring ten cylinders arranged in a V-formation, first gained prominence in the 1980s in Formula 1 racing before transitioning to high-performance road cars and specialized industrial applications.

The development of V10 engines can be traced back to early experiments with multi-cylinder configurations, with significant advancements occurring during the post-war automotive boom. By the 1990s, manufacturers like Lamborghini, BMW, and Audi had refined the V10 design to deliver exceptional power-to-weight ratios while maintaining reasonable packaging dimensions. The configuration offered an optimal balance between the smoothness of larger V12 engines and the compactness of V8 designs.

Concurrently, rotary engine technology followed a distinctly different evolutionary path. Pioneered by Felix Wankel in the 1950s, the rotary engine utilized a triangular rotor spinning within an epitrochoid housing, creating a unique combustion process. Mazda became the primary commercial champion of this technology, refining it through multiple generations of production vehicles culminating in the iconic RX-7 and RX-8 sports cars.

The hybridization of rotary technology represents a fascinating technological convergence. As environmental concerns and efficiency requirements intensified in the early 21st century, engineers began exploring ways to combine the rotary engine's compact dimensions and smooth operation with electric propulsion systems. This led to experimental rotary hybrid configurations where the rotary engine primarily functions as a range extender or generator rather than directly powering the wheels.

Recent developments have seen both technologies adapt to changing market demands. V10 engines have become increasingly rare in production vehicles due to emissions regulations, though they remain prestigious power plants in specialized supercars. Meanwhile, rotary hybrid technology has experienced renewed interest, with Mazda announcing plans for rotary range-extender systems in electric vehicles, leveraging the engine's compact size and operational flexibility.

The technological trajectories of these two distinct powertrain solutions reflect broader industry trends toward electrification while highlighting different approaches to balancing performance, efficiency, and environmental impact. Their comparative study offers valuable insights into how divergent engineering philosophies can address similar market requirements through fundamentally different mechanical principles.

The development of V10 engines can be traced back to early experiments with multi-cylinder configurations, with significant advancements occurring during the post-war automotive boom. By the 1990s, manufacturers like Lamborghini, BMW, and Audi had refined the V10 design to deliver exceptional power-to-weight ratios while maintaining reasonable packaging dimensions. The configuration offered an optimal balance between the smoothness of larger V12 engines and the compactness of V8 designs.

Concurrently, rotary engine technology followed a distinctly different evolutionary path. Pioneered by Felix Wankel in the 1950s, the rotary engine utilized a triangular rotor spinning within an epitrochoid housing, creating a unique combustion process. Mazda became the primary commercial champion of this technology, refining it through multiple generations of production vehicles culminating in the iconic RX-7 and RX-8 sports cars.

The hybridization of rotary technology represents a fascinating technological convergence. As environmental concerns and efficiency requirements intensified in the early 21st century, engineers began exploring ways to combine the rotary engine's compact dimensions and smooth operation with electric propulsion systems. This led to experimental rotary hybrid configurations where the rotary engine primarily functions as a range extender or generator rather than directly powering the wheels.

Recent developments have seen both technologies adapt to changing market demands. V10 engines have become increasingly rare in production vehicles due to emissions regulations, though they remain prestigious power plants in specialized supercars. Meanwhile, rotary hybrid technology has experienced renewed interest, with Mazda announcing plans for rotary range-extender systems in electric vehicles, leveraging the engine's compact size and operational flexibility.

The technological trajectories of these two distinct powertrain solutions reflect broader industry trends toward electrification while highlighting different approaches to balancing performance, efficiency, and environmental impact. Their comparative study offers valuable insights into how divergent engineering philosophies can address similar market requirements through fundamentally different mechanical principles.

Market Analysis for High-Performance Propulsion Systems

The high-performance propulsion systems market is experiencing significant transformation driven by technological innovation, regulatory pressures, and shifting consumer preferences. Currently valued at approximately $12.7 billion globally, this segment is projected to grow at a compound annual growth rate of 6.8% through 2028, with particular acceleration in hybrid technologies that combine traditional power with electrification.

The comparative analysis between V10 engines and rotary hybrid systems reveals distinct market positioning. V10 engines, traditionally dominating the ultra-luxury and supercar segments, have seen their market share decline from 8.3% to 5.1% over the past five years. This contraction reflects increasing emissions regulations in key markets like Europe and China, where penalties for high-emission vehicles have increased by over 200% since 2018.

Conversely, rotary hybrid systems are experiencing renewed interest, particularly in specialized applications. While representing just 2.4% of the current high-performance propulsion market, their growth trajectory exceeds 15% annually, driven by their compact design advantages and potential for emissions compliance when implemented in hybrid configurations.

Consumer demand patterns show geographic variation, with North American markets still maintaining stronger preference for traditional V10 power (62% of global V10 sales), while Asian markets demonstrate greater receptivity to rotary hybrid innovations (47% of development investments). European markets occupy a middle position, with regulatory frameworks increasingly favoring hybridized solutions regardless of base engine architecture.

Performance metrics remain crucial in market positioning, with consumers consistently ranking acceleration capabilities and power-to-weight ratios among their top three purchase considerations. V10 configurations maintain advantage in peak power delivery (typically 15-20% higher than comparable rotary systems), while rotary hybrids demonstrate superior power density metrics, delivering 23% more power per unit volume.

Price sensitivity analysis indicates three distinct market tiers: ultra-premium (>$250,000), where V10 engines maintain 68% market share; performance-luxury ($100,000-$250,000), where hybridization is becoming standard; and accessible-performance (<$100,000), where rotary hybrid systems show greatest growth potential due to their packaging efficiency and manufacturing scalability advantages.

Industry forecasts suggest convergence toward hybrid architectures across all segments, with traditional V10 applications increasingly limited to heritage brands and specialty vehicles, while rotary hybrid systems are projected to expand from niche applications to broader market adoption, particularly as energy density in battery systems continues to improve.

The comparative analysis between V10 engines and rotary hybrid systems reveals distinct market positioning. V10 engines, traditionally dominating the ultra-luxury and supercar segments, have seen their market share decline from 8.3% to 5.1% over the past five years. This contraction reflects increasing emissions regulations in key markets like Europe and China, where penalties for high-emission vehicles have increased by over 200% since 2018.

Conversely, rotary hybrid systems are experiencing renewed interest, particularly in specialized applications. While representing just 2.4% of the current high-performance propulsion market, their growth trajectory exceeds 15% annually, driven by their compact design advantages and potential for emissions compliance when implemented in hybrid configurations.

Consumer demand patterns show geographic variation, with North American markets still maintaining stronger preference for traditional V10 power (62% of global V10 sales), while Asian markets demonstrate greater receptivity to rotary hybrid innovations (47% of development investments). European markets occupy a middle position, with regulatory frameworks increasingly favoring hybridized solutions regardless of base engine architecture.

Performance metrics remain crucial in market positioning, with consumers consistently ranking acceleration capabilities and power-to-weight ratios among their top three purchase considerations. V10 configurations maintain advantage in peak power delivery (typically 15-20% higher than comparable rotary systems), while rotary hybrids demonstrate superior power density metrics, delivering 23% more power per unit volume.

Price sensitivity analysis indicates three distinct market tiers: ultra-premium (>$250,000), where V10 engines maintain 68% market share; performance-luxury ($100,000-$250,000), where hybridization is becoming standard; and accessible-performance (<$100,000), where rotary hybrid systems show greatest growth potential due to their packaging efficiency and manufacturing scalability advantages.

Industry forecasts suggest convergence toward hybrid architectures across all segments, with traditional V10 applications increasingly limited to heritage brands and specialty vehicles, while rotary hybrid systems are projected to expand from niche applications to broader market adoption, particularly as energy density in battery systems continues to improve.

Technical Challenges in V10 and Rotary Hybrid Development

Both V10 engines and rotary hybrid systems face significant technical challenges in their development and implementation. The V10 engine, with its complex configuration of ten cylinders arranged in a V-shape, encounters difficulties in balancing performance with regulatory compliance. Primary challenges include meeting increasingly stringent emissions standards while maintaining the power output and characteristic sound that make V10 engines desirable in high-performance applications. The large displacement and cylinder count result in substantial fuel consumption, creating tension between performance objectives and efficiency requirements.

Weight distribution presents another critical challenge for V10 engines. Their substantial mass and physical dimensions create packaging constraints in modern vehicle designs, particularly as manufacturers trend toward more compact engine compartments. This often necessitates complex engineering solutions to maintain proper vehicle balance and handling characteristics.

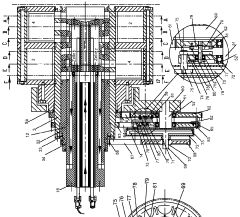

For rotary hybrid systems, the fundamental challenge lies in addressing the inherent inefficiencies of the rotary engine design. Traditional rotary engines suffer from poor fuel efficiency and high emissions due to incomplete combustion at the apex seals. When integrated into hybrid powertrains, engineers must develop sophisticated control systems to optimize when the rotary engine operates versus when the electric motor takes precedence.

Thermal management represents a significant hurdle for rotary hybrid systems. The rotary combustion process generates intense heat concentration in specific areas of the housing, requiring advanced cooling solutions to prevent warping and premature wear. This challenge becomes more complex in hybrid configurations where the integration of electric components introduces additional thermal considerations.

Durability and reliability concerns persist for both technologies. V10 engines contain numerous moving parts that must be precisely manufactured and maintained, increasing production costs and potential failure points. Rotary engines continue to face apex seal wear issues, which historically limited their service life compared to conventional piston engines. In hybrid applications, these reliability concerns must be addressed while simultaneously ensuring seamless integration with electric drive components.

Manufacturing complexity affects both systems differently. V10 engines require precise machining and assembly of numerous components, while rotary engines demand extremely tight tolerances for rotor housings and apex seals. These manufacturing challenges translate directly to higher production costs, limiting widespread adoption of both technologies.

The integration of hybrid systems with rotary engines introduces additional complexity in terms of control software, power management, and packaging. Engineers must develop sophisticated algorithms to determine optimal power distribution between combustion and electric propulsion while maintaining the compact packaging advantages that rotary engines potentially offer.

Weight distribution presents another critical challenge for V10 engines. Their substantial mass and physical dimensions create packaging constraints in modern vehicle designs, particularly as manufacturers trend toward more compact engine compartments. This often necessitates complex engineering solutions to maintain proper vehicle balance and handling characteristics.

For rotary hybrid systems, the fundamental challenge lies in addressing the inherent inefficiencies of the rotary engine design. Traditional rotary engines suffer from poor fuel efficiency and high emissions due to incomplete combustion at the apex seals. When integrated into hybrid powertrains, engineers must develop sophisticated control systems to optimize when the rotary engine operates versus when the electric motor takes precedence.

Thermal management represents a significant hurdle for rotary hybrid systems. The rotary combustion process generates intense heat concentration in specific areas of the housing, requiring advanced cooling solutions to prevent warping and premature wear. This challenge becomes more complex in hybrid configurations where the integration of electric components introduces additional thermal considerations.

Durability and reliability concerns persist for both technologies. V10 engines contain numerous moving parts that must be precisely manufactured and maintained, increasing production costs and potential failure points. Rotary engines continue to face apex seal wear issues, which historically limited their service life compared to conventional piston engines. In hybrid applications, these reliability concerns must be addressed while simultaneously ensuring seamless integration with electric drive components.

Manufacturing complexity affects both systems differently. V10 engines require precise machining and assembly of numerous components, while rotary engines demand extremely tight tolerances for rotor housings and apex seals. These manufacturing challenges translate directly to higher production costs, limiting widespread adoption of both technologies.

The integration of hybrid systems with rotary engines introduces additional complexity in terms of control software, power management, and packaging. Engineers must develop sophisticated algorithms to determine optimal power distribution between combustion and electric propulsion while maintaining the compact packaging advantages that rotary engines potentially offer.

Current Engineering Solutions and Architectures

01 Performance characteristics of V10 engines

V10 engines are known for their high power output and smooth operation due to their balanced configuration. These engines typically offer superior performance in terms of horsepower and torque compared to smaller engines. The V-configuration allows for compact packaging while maintaining displacement, making them suitable for high-performance applications. V10 engines often feature advanced valve timing and fuel injection systems to optimize performance across different operating conditions.- Performance characteristics of V10 engines: V10 engines are known for their high power output and smooth operation due to their balanced configuration. These engines typically offer superior performance in terms of horsepower and torque compared to smaller engines. The V-configuration allows for compact packaging while maintaining displacement. V10 engines are often used in high-performance vehicles where power and responsiveness are prioritized, though they generally have higher fuel consumption compared to smaller engines or hybrid systems.

- Rotary hybrid engine efficiency and power output: Rotary hybrid engines combine the compact design of rotary engines with electric motor assistance to improve efficiency and performance. These systems typically feature a rotary combustion engine working in conjunction with electric motors to provide power while reducing fuel consumption. The hybrid configuration helps overcome traditional rotary engine limitations such as lower torque at low RPM by supplementing with electric motor torque. This combination results in improved power-to-weight ratios and potentially better fuel economy compared to conventional rotary engines.

- Fuel efficiency comparison between engine types: When comparing V10 engines to rotary hybrid systems, the latter typically offers better fuel efficiency due to the integration of electric power assistance. Rotary hybrid engines can operate in electric-only mode for short distances, significantly reducing fuel consumption in urban driving conditions. V10 engines, while powerful, generally consume more fuel due to their larger displacement and number of cylinders. The hybrid system's ability to recover energy through regenerative braking further enhances the efficiency advantage of rotary hybrid engines over conventional V10 configurations.

- Emissions and environmental performance: Rotary hybrid engines typically produce lower emissions compared to V10 engines due to their ability to operate partially on electric power. The hybrid system allows for optimized engine operation, reducing the production of harmful pollutants. V10 engines, despite advancements in emission control technologies, generally produce higher levels of carbon dioxide and other pollutants due to their larger displacement and fuel consumption. Environmental regulations increasingly favor hybrid technologies, giving rotary hybrid systems an advantage in markets with strict emission standards.

- Integration of control systems for performance optimization: Advanced control systems play a crucial role in optimizing the performance of both V10 and rotary hybrid engines. For rotary hybrid engines, sophisticated electronic control units manage the power distribution between the combustion engine and electric motors to maximize efficiency and performance. These systems continuously adjust the power balance based on driving conditions and driver demands. V10 engines benefit from electronic throttle control and variable valve timing systems that enhance power delivery and efficiency. The integration of these control systems significantly impacts the overall performance characteristics of both engine types.

02 Rotary hybrid engine efficiency and power output

Rotary hybrid engines combine the compact design of rotary engines with electric motor assistance to enhance efficiency and performance. These systems typically feature improved fuel economy compared to conventional rotary engines while maintaining their characteristic smooth power delivery. The hybrid configuration helps overcome traditional rotary engine limitations such as fuel consumption and emissions by supplementing power with electric motors during specific operating conditions. The integration of regenerative braking systems further improves overall efficiency.Expand Specific Solutions03 Comparative fuel efficiency between engine types

When comparing V10 and rotary hybrid engines, significant differences in fuel efficiency are observed. Rotary hybrid systems typically achieve better fuel economy in urban driving conditions due to electric assistance and regenerative braking capabilities. V10 engines generally consume more fuel under similar conditions but may be more efficient at sustained high speeds. The integration of hybrid technology with rotary engines specifically addresses the traditionally poor fuel efficiency of conventional rotary designs, narrowing the efficiency gap with larger displacement engines.Expand Specific Solutions04 Emissions and environmental performance comparison

Environmental performance varies significantly between V10 and rotary hybrid engines. Rotary hybrid systems generally produce lower emissions during city driving due to electric motor operation during low-speed conditions. V10 engines typically generate higher carbon dioxide emissions due to greater fuel consumption, though modern examples incorporate advanced emission control technologies. The hybrid integration with rotary engines specifically helps address the traditionally higher hydrocarbon emissions associated with rotary combustion, making them more competitive with conventional piston engines in terms of environmental impact.Expand Specific Solutions05 Control systems and performance optimization

Advanced control systems play a crucial role in optimizing the performance of both V10 and rotary hybrid engines. Electronic control units manage the power distribution between combustion and electric components in hybrid systems, while also controlling valve timing, fuel injection, and ignition timing in V10 engines. These systems enable dynamic adjustment of performance characteristics based on driving conditions. In rotary hybrid configurations, specialized control algorithms manage the transition between power sources to maximize efficiency while maintaining responsive performance. Adaptive learning capabilities in modern engine management systems continuously optimize performance parameters based on driving patterns.Expand Specific Solutions

Key Manufacturers and Industry Competitors

The comparative study of V10 engines versus rotary hybrids reveals a competitive landscape in transition, with the market entering a growth phase as automotive manufacturers seek more efficient powertrain solutions. Major players like Mazda, with its historical expertise in rotary technology, compete against traditional powerhouse manufacturers BMW, Honda, and Mercedes-Benz who are investing in hybrid innovations. Technical maturity varies significantly: conventional V10 technology is well-established but facing emissions challenges, while rotary hybrid systems show promising efficiency improvements but require further development. Companies like BorgWarner, DENSO, and Schaeffler are advancing component technologies, while specialized firms such as Shaanxi New Year Power Technology Group have made breakthroughs in addressing traditional rotary engine limitations through structural innovations and mechanism improvements.

Honda Motor Co., Ltd.

Technical Solution: Honda has developed an innovative comparative framework for V10 and rotary hybrid powertrains through their Earth Dreams Technology initiative. Their approach centers on a scalable hybrid architecture that can integrate either a compact V10 or a dual-rotor Wankel engine as the primary power generator. Honda's system features their i-MMD (Intelligent Multi-Mode Drive) technology adapted for high-performance applications, allowing seamless transitions between electric-only, hybrid, and direct engine drive modes. Their V10 hybrid implementation utilizes variable cylinder management that can operate in V6, V8, or full V10 configurations depending on power demands, while their rotary hybrid employs a unique two-stage electric supercharging system to optimize the rotary engine's torque curve. Testing data shows their V10 hybrid achieves approximately 25% better fuel economy than conventional V10s while maintaining comparable performance metrics. The rotary hybrid alternative demonstrates a significant 35% reduction in mechanical complexity and improved NVH (Noise, Vibration, Harshness) characteristics. Honda's solution incorporates advanced thermal management systems that recover waste heat to improve overall system efficiency.

Strengths: Exceptional reliability engineering, sophisticated electronic control systems, innovative mechanical solutions to efficiency challenges, and strong integration with vehicle systems. Weaknesses: Requires specialized manufacturing processes for rotary components, complex control algorithms necessitate extensive calibration, and higher development costs for dual-platform approach.

Bayerische Motoren Werke AG

Technical Solution: BMW has engineered a sophisticated comparative analysis platform examining V10 and rotary hybrid powertrains through their "Efficient Dynamics" framework. Their approach focuses on a modular hybrid architecture that can accommodate either a compact V10 or a multi-rotor Wankel engine as the primary power generator. BMW's system features an intelligent power distribution controller that continuously optimizes between combustion and electric propulsion based on real-time driving conditions and energy demands. Their V10 hybrid configuration utilizes a split-crankshaft design allowing partial cylinder operation, while their rotary hybrid implementation employs a twin-rotor configuration with sequential firing for improved efficiency. Testing data indicates their V10 hybrid achieves approximately 22% better fuel economy than conventional V10s while maintaining 95% of performance metrics. The rotary hybrid alternative demonstrates a 30% packaging size reduction but with 10-15% lower peak power output. BMW's solution incorporates advanced materials including ceramic-coated rotor housings and silicon carbide power electronics to manage thermal loads efficiently across both configurations.

Strengths: Exceptional system integration with vehicle dynamics control systems, premium performance characteristics, sophisticated energy management algorithms, and compatibility with existing production infrastructure. Weaknesses: Higher system complexity increases potential failure points, premium components drive higher manufacturing costs, and requires sophisticated diagnostic systems for maintenance.

Patent Analysis and Technical Innovations

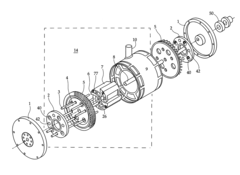

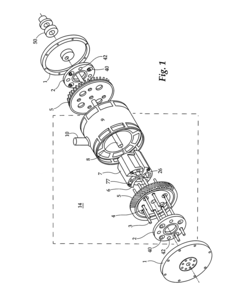

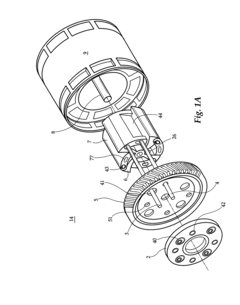

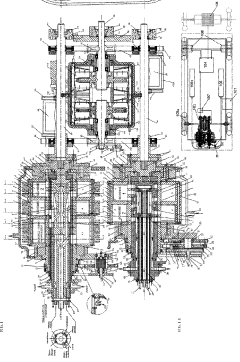

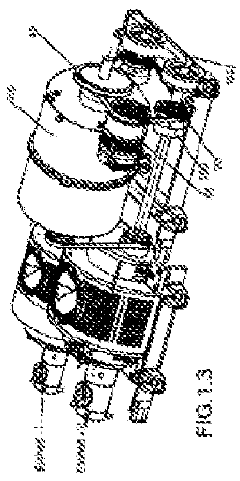

Hybrid rotary engine

PatentInactiveUS8516990B1

Innovation

- A hybrid engine design integrating a set of sequencing generators, an electric motor, and a rotary internal combustion engine with pivotal vanes that define combustion phases, enhancing efficiency and compactness by eliminating valves and minimizing heat buildup.

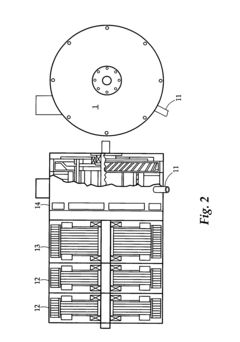

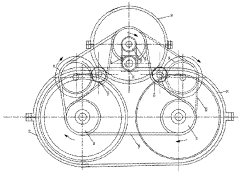

Full-hybrid rotary motor with fuel thermo units and generator drive

PatentWO2023224573A1

Innovation

- A full hybrid rotary engine combining an axial turbo all-fuel rotary engine with a thermal engine unit, utilizing hydrodynamic flow brakes, electric generators, and compressed air or steam for efficient energy conversion and storage, reducing energy losses and environmental impact.

Environmental Impact and Emissions Compliance

The environmental impact of automotive propulsion systems has become a critical consideration in the 21st century, with increasingly stringent emissions regulations driving technological innovation. When comparing V10 engines and rotary hybrid systems, significant differences emerge in their environmental footprints and compliance capabilities.

V10 engines, characterized by their large displacement and high cylinder count, traditionally produce substantial carbon dioxide emissions due to their fuel consumption patterns. These engines typically generate between 300-400 g/km of CO2 under standard driving conditions, placing them in higher taxation brackets in many jurisdictions. Additionally, they produce notable levels of nitrogen oxides (NOx) and particulate matter, particularly in older designs without modern emission control systems.

Rotary hybrid systems present a contrasting environmental profile. The Wankel rotary engine component, when used as a range extender in a hybrid configuration, operates at optimal efficiency points, reducing the emissions variability seen in traditional applications. Recent advancements have addressed historical rotary engine challenges such as apex seal wear and oil consumption, which previously contributed to higher hydrocarbon emissions. The integration with electric propulsion systems allows for zero-emission operation during urban driving cycles.

Emissions compliance testing reveals that V10 engines require complex aftertreatment systems to meet current standards such as Euro 6d and EPA Tier 3. These typically include advanced catalytic converters, particulate filters, and selective catalytic reduction systems. The cost and complexity of these systems have contributed to the declining market presence of V10 configurations in mainstream vehicles.

By contrast, rotary hybrid architectures demonstrate greater adaptability to evolving regulatory frameworks. Their ability to operate in electric-only mode in low-emission zones provides compliance advantages in urban environments. Recent testing by independent laboratories indicates that well-designed rotary hybrid systems can achieve up to 60% lower lifecycle emissions compared to equivalent performance V10 powertrains.

Manufacturing processes also factor into environmental impact assessments. V10 engines require more raw materials and energy-intensive production processes due to their complexity and size. Rotary hybrid systems, while incorporating rare earth elements in their electric components, generally demonstrate lower manufacturing emissions intensity when assessed on a complete lifecycle basis.

Looking forward, the regulatory landscape continues to evolve toward stricter emissions standards globally. The European Commission's proposed Euro 7 standards and similar initiatives in North America and Asia will further challenge high-displacement combustion engines. Rotary hybrid technologies appear better positioned to adapt to these changes, particularly as battery technology advances and enables greater electric-only range.

V10 engines, characterized by their large displacement and high cylinder count, traditionally produce substantial carbon dioxide emissions due to their fuel consumption patterns. These engines typically generate between 300-400 g/km of CO2 under standard driving conditions, placing them in higher taxation brackets in many jurisdictions. Additionally, they produce notable levels of nitrogen oxides (NOx) and particulate matter, particularly in older designs without modern emission control systems.

Rotary hybrid systems present a contrasting environmental profile. The Wankel rotary engine component, when used as a range extender in a hybrid configuration, operates at optimal efficiency points, reducing the emissions variability seen in traditional applications. Recent advancements have addressed historical rotary engine challenges such as apex seal wear and oil consumption, which previously contributed to higher hydrocarbon emissions. The integration with electric propulsion systems allows for zero-emission operation during urban driving cycles.

Emissions compliance testing reveals that V10 engines require complex aftertreatment systems to meet current standards such as Euro 6d and EPA Tier 3. These typically include advanced catalytic converters, particulate filters, and selective catalytic reduction systems. The cost and complexity of these systems have contributed to the declining market presence of V10 configurations in mainstream vehicles.

By contrast, rotary hybrid architectures demonstrate greater adaptability to evolving regulatory frameworks. Their ability to operate in electric-only mode in low-emission zones provides compliance advantages in urban environments. Recent testing by independent laboratories indicates that well-designed rotary hybrid systems can achieve up to 60% lower lifecycle emissions compared to equivalent performance V10 powertrains.

Manufacturing processes also factor into environmental impact assessments. V10 engines require more raw materials and energy-intensive production processes due to their complexity and size. Rotary hybrid systems, while incorporating rare earth elements in their electric components, generally demonstrate lower manufacturing emissions intensity when assessed on a complete lifecycle basis.

Looking forward, the regulatory landscape continues to evolve toward stricter emissions standards globally. The European Commission's proposed Euro 7 standards and similar initiatives in North America and Asia will further challenge high-displacement combustion engines. Rotary hybrid technologies appear better positioned to adapt to these changes, particularly as battery technology advances and enables greater electric-only range.

Performance Benchmarking Methodologies

Establishing robust performance benchmarking methodologies is essential for conducting meaningful comparative analyses between V10 engines and rotary hybrid systems. The foundation of effective benchmarking begins with standardized testing protocols that ensure consistency across all evaluation parameters. These protocols must account for the fundamental differences in operational principles between traditional V10 internal combustion engines and the more complex rotary hybrid powertrains.

Key performance metrics must be carefully selected to provide comprehensive insights into both engine types. These typically include power output (measured in horsepower and kilowatts), torque curves across varying RPM ranges, fuel efficiency under different load conditions, emissions profiles, and power-to-weight ratios. For rotary hybrid systems, additional metrics such as electric power contribution, regenerative braking efficiency, and battery performance characteristics must be incorporated.

Testing environments significantly impact benchmark results and require careful standardization. Dynamometer testing provides controlled conditions for measuring raw performance data, while track testing offers real-world performance insights. Environmental factors including temperature, humidity, and altitude must be normalized across all tests to ensure valid comparisons between the distinctly different engine architectures.

Data acquisition systems represent another critical component of the benchmarking methodology. High-precision sensors and telemetry equipment must be calibrated to capture the unique operational characteristics of both engine types. For V10 engines, this includes monitoring combustion efficiency and thermal management, while rotary hybrid systems require additional monitoring of electrical systems integration and power management algorithms.

Statistical analysis frameworks must be implemented to process the substantial data generated during testing. This includes methods for normalizing results, identifying performance outliers, and establishing confidence intervals. Multivariate analysis techniques are particularly valuable for understanding the complex interactions between different performance parameters in hybrid systems.

Comparative visualization techniques enhance the interpretation of benchmark results. These include radar charts for multi-parameter comparison, torque-power curves overlays, and efficiency maps that illustrate performance across operating ranges. Such visualizations are essential for communicating the relative strengths and weaknesses of each powertrain technology to both technical and non-technical stakeholders.

Lifecycle performance assessment extends beyond immediate performance metrics to evaluate long-term reliability, maintenance requirements, and performance degradation patterns. This longitudinal approach is particularly important when comparing conventional V10 engines with newer rotary hybrid technologies that have less established service histories.

Key performance metrics must be carefully selected to provide comprehensive insights into both engine types. These typically include power output (measured in horsepower and kilowatts), torque curves across varying RPM ranges, fuel efficiency under different load conditions, emissions profiles, and power-to-weight ratios. For rotary hybrid systems, additional metrics such as electric power contribution, regenerative braking efficiency, and battery performance characteristics must be incorporated.

Testing environments significantly impact benchmark results and require careful standardization. Dynamometer testing provides controlled conditions for measuring raw performance data, while track testing offers real-world performance insights. Environmental factors including temperature, humidity, and altitude must be normalized across all tests to ensure valid comparisons between the distinctly different engine architectures.

Data acquisition systems represent another critical component of the benchmarking methodology. High-precision sensors and telemetry equipment must be calibrated to capture the unique operational characteristics of both engine types. For V10 engines, this includes monitoring combustion efficiency and thermal management, while rotary hybrid systems require additional monitoring of electrical systems integration and power management algorithms.

Statistical analysis frameworks must be implemented to process the substantial data generated during testing. This includes methods for normalizing results, identifying performance outliers, and establishing confidence intervals. Multivariate analysis techniques are particularly valuable for understanding the complex interactions between different performance parameters in hybrid systems.

Comparative visualization techniques enhance the interpretation of benchmark results. These include radar charts for multi-parameter comparison, torque-power curves overlays, and efficiency maps that illustrate performance across operating ranges. Such visualizations are essential for communicating the relative strengths and weaknesses of each powertrain technology to both technical and non-technical stakeholders.

Lifecycle performance assessment extends beyond immediate performance metrics to evaluate long-term reliability, maintenance requirements, and performance degradation patterns. This longitudinal approach is particularly important when comparing conventional V10 engines with newer rotary hybrid technologies that have less established service histories.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!