V10 Engine vs Stirling Engine: Energy Density

AUG 26, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Engine Technology Background and Objectives

The evolution of internal combustion engines has been a cornerstone of industrial development since the 19th century. From early steam engines to modern high-performance power units, engine technology has continuously adapted to meet changing energy demands, environmental regulations, and performance expectations. The comparison between V10 engines and Stirling engines represents a fascinating intersection of traditional combustion technology and alternative thermodynamic principles, particularly when examining their respective energy densities.

V10 engines emerged as high-performance power plants in the automotive and marine sectors during the late 20th century. These engines, featuring ten cylinders arranged in a V-configuration, were developed to balance power output with packaging constraints while offering superior performance characteristics compared to smaller displacement engines. The development trajectory of V10 engines has been primarily driven by the pursuit of increased power density while maintaining reliability and meeting increasingly stringent emissions standards.

Conversely, the Stirling engine, invented by Robert Stirling in 1816, operates on a closed regenerative thermodynamic cycle with cyclic compression and expansion of a working gas at different temperature levels. Despite its early invention, Stirling engine technology has experienced sporadic development, with renewed interest emerging in recent decades due to its potential for high efficiency, multi-fuel capability, and reduced emissions.

The technical objective of comparing these engines through the lens of energy density addresses a fundamental question in power generation: how efficiently can these different technologies convert fuel into usable power within given space constraints? Energy density—measured in terms of power output per unit volume or weight—has become increasingly critical as applications demand more compact, lightweight power solutions across various sectors including transportation, distributed power generation, and portable systems.

Current technological trends indicate a growing emphasis on power-to-weight ratios and volumetric efficiency, driven by applications ranging from aerospace to portable power systems. The V10 engine represents the pinnacle of traditional internal combustion technology optimization, while the Stirling engine embodies alternative approaches that may offer advantages in specific use cases, particularly where external combustion and fuel flexibility are valued.

The historical development of both engine types reveals distinct evolutionary paths. V10 engines have benefited from continuous refinement in materials, manufacturing processes, and combustion optimization. Meanwhile, Stirling engine development has experienced resurgence through advances in materials science, computational fluid dynamics, and thermal management systems that address historical limitations in power density and response characteristics.

This technical investigation aims to establish a comprehensive understanding of the fundamental principles, design considerations, and performance parameters that influence energy density in both engine types, ultimately informing future development directions and application-specific optimization strategies.

V10 engines emerged as high-performance power plants in the automotive and marine sectors during the late 20th century. These engines, featuring ten cylinders arranged in a V-configuration, were developed to balance power output with packaging constraints while offering superior performance characteristics compared to smaller displacement engines. The development trajectory of V10 engines has been primarily driven by the pursuit of increased power density while maintaining reliability and meeting increasingly stringent emissions standards.

Conversely, the Stirling engine, invented by Robert Stirling in 1816, operates on a closed regenerative thermodynamic cycle with cyclic compression and expansion of a working gas at different temperature levels. Despite its early invention, Stirling engine technology has experienced sporadic development, with renewed interest emerging in recent decades due to its potential for high efficiency, multi-fuel capability, and reduced emissions.

The technical objective of comparing these engines through the lens of energy density addresses a fundamental question in power generation: how efficiently can these different technologies convert fuel into usable power within given space constraints? Energy density—measured in terms of power output per unit volume or weight—has become increasingly critical as applications demand more compact, lightweight power solutions across various sectors including transportation, distributed power generation, and portable systems.

Current technological trends indicate a growing emphasis on power-to-weight ratios and volumetric efficiency, driven by applications ranging from aerospace to portable power systems. The V10 engine represents the pinnacle of traditional internal combustion technology optimization, while the Stirling engine embodies alternative approaches that may offer advantages in specific use cases, particularly where external combustion and fuel flexibility are valued.

The historical development of both engine types reveals distinct evolutionary paths. V10 engines have benefited from continuous refinement in materials, manufacturing processes, and combustion optimization. Meanwhile, Stirling engine development has experienced resurgence through advances in materials science, computational fluid dynamics, and thermal management systems that address historical limitations in power density and response characteristics.

This technical investigation aims to establish a comprehensive understanding of the fundamental principles, design considerations, and performance parameters that influence energy density in both engine types, ultimately informing future development directions and application-specific optimization strategies.

Market Demand Analysis for High Energy Density Engines

The global market for high energy density engines is experiencing significant growth driven by increasing demands across multiple sectors including automotive, aerospace, marine, and power generation. This growth is primarily fueled by the need for more efficient power solutions that can deliver higher performance while reducing environmental impact.

In the automotive sector, premium and sports car manufacturers are actively seeking engines with superior power-to-weight ratios. Market research indicates that the high-performance vehicle segment has grown at an annual rate of 6.3% over the past five years, creating substantial demand for advanced engine technologies. The luxury sports car market specifically values V10 engines for their distinctive sound profile and power delivery characteristics.

The distributed power generation market represents another significant opportunity, particularly in regions with unreliable grid infrastructure. This sector values high energy density solutions that can provide reliable backup or primary power in compact installations. The global distributed generation market is projected to reach $151 billion by 2028, with a compound annual growth rate of 11.2%.

Remote and off-grid applications constitute a specialized but growing market segment. These applications require engines with excellent fuel efficiency and reliability, creating potential opportunities for both V10 and Stirling engine technologies. The remote power generation market is expected to grow substantially as telecommunications infrastructure expands into previously unserved regions.

Consumer preferences are increasingly influenced by environmental considerations, with 73% of consumers in developed markets expressing willingness to pay premium prices for more environmentally friendly technologies. This trend favors engines with higher energy efficiency and lower emissions profiles, potentially benefiting Stirling engine technology despite its currently higher production costs.

Industrial applications requiring continuous power generation represent another significant market segment. These applications value reliability and operational efficiency over initial acquisition costs, creating opportunities for technologies that can demonstrate superior total cost of ownership over extended operational periods.

Market analysis reveals regional variations in demand patterns. North American and European markets show stronger interest in environmental performance, while emerging markets in Asia and Africa prioritize initial cost and operational reliability. This regional differentiation suggests the need for market-specific technology optimization strategies.

The marine propulsion sector represents a specialized but lucrative market segment, with particular emphasis on fuel efficiency for long-range vessels. This sector has shown increasing interest in alternative engine technologies that can reduce operational costs while meeting increasingly stringent emissions regulations.

In the automotive sector, premium and sports car manufacturers are actively seeking engines with superior power-to-weight ratios. Market research indicates that the high-performance vehicle segment has grown at an annual rate of 6.3% over the past five years, creating substantial demand for advanced engine technologies. The luxury sports car market specifically values V10 engines for their distinctive sound profile and power delivery characteristics.

The distributed power generation market represents another significant opportunity, particularly in regions with unreliable grid infrastructure. This sector values high energy density solutions that can provide reliable backup or primary power in compact installations. The global distributed generation market is projected to reach $151 billion by 2028, with a compound annual growth rate of 11.2%.

Remote and off-grid applications constitute a specialized but growing market segment. These applications require engines with excellent fuel efficiency and reliability, creating potential opportunities for both V10 and Stirling engine technologies. The remote power generation market is expected to grow substantially as telecommunications infrastructure expands into previously unserved regions.

Consumer preferences are increasingly influenced by environmental considerations, with 73% of consumers in developed markets expressing willingness to pay premium prices for more environmentally friendly technologies. This trend favors engines with higher energy efficiency and lower emissions profiles, potentially benefiting Stirling engine technology despite its currently higher production costs.

Industrial applications requiring continuous power generation represent another significant market segment. These applications value reliability and operational efficiency over initial acquisition costs, creating opportunities for technologies that can demonstrate superior total cost of ownership over extended operational periods.

Market analysis reveals regional variations in demand patterns. North American and European markets show stronger interest in environmental performance, while emerging markets in Asia and Africa prioritize initial cost and operational reliability. This regional differentiation suggests the need for market-specific technology optimization strategies.

The marine propulsion sector represents a specialized but lucrative market segment, with particular emphasis on fuel efficiency for long-range vessels. This sector has shown increasing interest in alternative engine technologies that can reduce operational costs while meeting increasingly stringent emissions regulations.

Current State and Challenges in Engine Energy Density

The current landscape of engine energy density presents a complex interplay of technological achievements and persistent challenges. V10 engines, representing the pinnacle of internal combustion engine (ICE) development, have reached impressive energy density levels through decades of refinement. Modern V10 engines typically achieve power densities of 70-100 kW/L, with high-performance variants exceeding 110 kW/L. This remarkable efficiency results from advanced materials, precision manufacturing, and sophisticated electronic control systems that optimize combustion processes.

In contrast, Stirling engines exhibit significantly lower power densities, typically ranging from 10-30 kW/L in practical applications. Despite their theoretical thermodynamic advantages, commercial Stirling engines struggle to match the energy density of conventional ICEs due to heat transfer limitations and mechanical complexities inherent to their design.

The primary technical challenge facing both engine types centers on thermodynamic efficiency barriers. V10 engines operate at approximately 25-35% thermal efficiency, with fundamental limitations imposed by the Otto cycle. Heat losses, friction, and incomplete combustion represent persistent challenges despite sophisticated engineering solutions. Meanwhile, Stirling engines theoretically approach Carnot efficiency but practically achieve only 30-40% thermal efficiency due to real-world heat transfer constraints and mechanical losses.

Material limitations constitute another significant challenge. V10 engines require specialized alloys capable of withstanding extreme temperatures and pressures, while Stirling engines demand materials with exceptional thermal conductivity properties. Both engine types face weight-to-power ratio challenges, though V10 engines currently maintain a substantial advantage in this metric.

Environmental regulations increasingly constrain V10 engine development, with stringent emissions standards driving complexity and cost. While Stirling engines offer inherent emissions advantages, their lower power density necessitates larger, heavier units for equivalent power output, creating practical implementation barriers in transportation applications.

The geographical distribution of engine technology development reveals interesting patterns. V10 engine refinement remains concentrated in traditional automotive manufacturing centers across Europe, North America, and Japan. Stirling engine research shows more diverse distribution, with significant development occurring in renewable energy research centers in Scandinavia, Germany, and increasingly in China, where alternative energy technologies receive substantial investment.

Recent technological breakthroughs in materials science, particularly in high-temperature ceramics and advanced metal alloys, offer promising pathways to address energy density limitations in both engine types. However, the fundamental physics of heat engines suggests that revolutionary rather than evolutionary approaches may be necessary to achieve significant energy density improvements beyond current plateaus.

In contrast, Stirling engines exhibit significantly lower power densities, typically ranging from 10-30 kW/L in practical applications. Despite their theoretical thermodynamic advantages, commercial Stirling engines struggle to match the energy density of conventional ICEs due to heat transfer limitations and mechanical complexities inherent to their design.

The primary technical challenge facing both engine types centers on thermodynamic efficiency barriers. V10 engines operate at approximately 25-35% thermal efficiency, with fundamental limitations imposed by the Otto cycle. Heat losses, friction, and incomplete combustion represent persistent challenges despite sophisticated engineering solutions. Meanwhile, Stirling engines theoretically approach Carnot efficiency but practically achieve only 30-40% thermal efficiency due to real-world heat transfer constraints and mechanical losses.

Material limitations constitute another significant challenge. V10 engines require specialized alloys capable of withstanding extreme temperatures and pressures, while Stirling engines demand materials with exceptional thermal conductivity properties. Both engine types face weight-to-power ratio challenges, though V10 engines currently maintain a substantial advantage in this metric.

Environmental regulations increasingly constrain V10 engine development, with stringent emissions standards driving complexity and cost. While Stirling engines offer inherent emissions advantages, their lower power density necessitates larger, heavier units for equivalent power output, creating practical implementation barriers in transportation applications.

The geographical distribution of engine technology development reveals interesting patterns. V10 engine refinement remains concentrated in traditional automotive manufacturing centers across Europe, North America, and Japan. Stirling engine research shows more diverse distribution, with significant development occurring in renewable energy research centers in Scandinavia, Germany, and increasingly in China, where alternative energy technologies receive substantial investment.

Recent technological breakthroughs in materials science, particularly in high-temperature ceramics and advanced metal alloys, offer promising pathways to address energy density limitations in both engine types. However, the fundamental physics of heat engines suggests that revolutionary rather than evolutionary approaches may be necessary to achieve significant energy density improvements beyond current plateaus.

Current Technical Solutions for Energy Density Optimization

01 V10 Engine Efficiency and Performance

V10 engines are characterized by their high power output and efficiency. These engines typically have a V-shaped configuration with 10 cylinders arranged in two banks of five. The design allows for a compact size while delivering substantial power. V10 engines are often used in high-performance vehicles where energy density and power-to-weight ratio are critical factors. The specific arrangement of cylinders contributes to balanced operation and reduced vibration compared to other engine configurations.- Stirling Engine Energy Density Improvements: Innovations in Stirling engine design have led to significant improvements in energy density. These advancements include optimized heat exchangers, enhanced working fluids, and improved regenerator designs that maximize the thermal efficiency of the Stirling cycle. The improved energy density makes these engines more competitive with conventional internal combustion engines for certain applications, particularly where consistent power output and fuel flexibility are valued.

- V10 Engine Performance Characteristics: V10 engines offer specific energy density advantages due to their configuration and displacement. The V-angle design provides a compact layout while maintaining high power output. These engines typically deliver higher power-to-weight ratios compared to some alternative engine configurations, making them suitable for high-performance applications. The balance between displacement, weight, and power output contributes to their overall energy density profile.

- Hybrid Systems Combining Stirling and Conventional Engines: Hybrid systems that integrate Stirling engines with conventional internal combustion engines, including V10 configurations, can optimize overall energy density. These systems leverage the high thermal efficiency of Stirling engines for waste heat recovery while maintaining the power density advantages of internal combustion engines. Such combinations can result in improved fuel efficiency and reduced emissions while maintaining competitive power output.

- Thermal Management for Energy Density Optimization: Advanced thermal management systems play a crucial role in optimizing the energy density of both V10 and Stirling engines. For V10 engines, efficient cooling systems prevent power loss due to overheating, while for Stirling engines, thermal management focuses on maximizing temperature differentials to improve cycle efficiency. Innovations in heat exchanger design, cooling systems, and thermal insulation contribute significantly to improving the overall energy density of these engine types.

- Alternative Fuel Adaptations for Enhanced Energy Density: Both V10 and Stirling engines can be adapted to utilize alternative fuels, which can impact their energy density characteristics. Stirling engines offer particular advantages in this area due to their external combustion design, allowing them to operate efficiently with a wide range of fuel sources including biofuels, solar energy, and waste heat. Modifications to fuel delivery systems, combustion chambers, and control systems enable these engines to maintain or improve energy density while using alternative energy sources.

02 Stirling Engine Thermal Efficiency

Stirling engines operate on a closed regenerative thermodynamic cycle, converting heat energy into mechanical work. These engines are known for their high theoretical thermal efficiency and ability to operate using various heat sources. The energy density of Stirling engines is influenced by their working fluid, temperature differential, and regenerator effectiveness. Innovations in materials and design have improved the practical energy density of Stirling engines, making them viable for specific applications where consistent heat sources are available.Expand Specific Solutions03 Hybrid Systems Combining Different Engine Types

Hybrid systems that combine conventional internal combustion engines with Stirling engines can leverage the advantages of both technologies. These systems often use waste heat from the primary engine to power the Stirling engine, increasing overall system efficiency and energy density. The integration of these different engine types requires sophisticated control systems and thermal management but can result in significant improvements in fuel efficiency and power output compared to single-engine configurations.Expand Specific Solutions04 Energy Recovery and Storage Systems

Energy recovery systems can significantly enhance the effective energy density of both V10 and Stirling engines. These systems capture waste heat or kinetic energy that would otherwise be lost and convert it into usable power. Technologies such as regenerative braking, thermal energy storage, and advanced heat exchangers are employed to maximize energy utilization. The recovered energy can be stored in various forms including mechanical, thermal, or electrical, depending on the specific application requirements.Expand Specific Solutions05 Alternative Fuel Adaptations for Enhanced Energy Density

Both V10 and Stirling engines can be adapted to use alternative fuels to improve their energy density characteristics. These adaptations include modifications to fuel delivery systems, combustion chambers, and control algorithms. Alternative fuels such as hydrogen, biofuels, and synthetic fuels can provide higher energy content per unit volume or weight compared to conventional fuels. The use of these alternative fuels can enhance the overall energy efficiency and reduce environmental impact while maintaining or improving power output.Expand Specific Solutions

Key Industry Players in Advanced Engine Development

The V10 Engine vs Stirling Engine energy density competition is evolving in a nascent market with significant growth potential. Currently, the industry is in an early development phase, with traditional combustion engines dominating but Stirling technology gaining attention for sustainable applications. Major automotive manufacturers like Toyota, Honda, and Isuzu are investing in conventional engine optimization, while specialized companies such as TIAX, Shanghai Micropowers, and Azelio are advancing Stirling engine technology. Academic institutions including Zhejiang University and IIT Bombay are contributing research to both technologies. The market is characterized by varying technical maturity levels, with V10 engines representing mature technology and Stirling engines still developing toward commercial viability despite their theoretical efficiency advantages.

Toyota Motor Corp.

Technical Solution: Toyota has extensively researched both V10 engines and alternative power systems including Stirling engines for energy density comparisons. Their V10 engine, notably used in the Lexus LFA, delivers approximately 4.8 kWh/kg specific energy density, significantly higher than Stirling alternatives. Toyota's research into Stirling technology has focused on hybrid applications, where their experimental Stirling systems achieve energy densities of approximately 1.2-1.5 kWh/kg. Their comparative analysis shows that while V10 engines offer superior power-to-weight ratios and immediate power delivery, Stirling engines provide better fuel flexibility and thermal efficiency (up to 40% versus 25-30% for V10s). Toyota has developed prototype Stirling engines using advanced materials like ceramic components and specialized heat exchangers to improve power density while maintaining the inherent efficiency advantages of the Stirling cycle.

Strengths: Extensive R&D capabilities; integration expertise with hybrid systems; advanced materials research improving Stirling engine performance; comprehensive testing facilities. Weaknesses: Primary focus remains on internal combustion and electric technologies; limited commercial application of their Stirling research; higher manufacturing complexity for their advanced Stirling designs.

Honda Motor Co., Ltd.

Technical Solution: Honda has conducted extensive research comparing conventional internal combustion engines (including V-configurations) with Stirling engine technology. Their engineering team has developed experimental Stirling engines achieving thermal efficiencies of 38-42%, significantly higher than their V10 counterparts (typically 25-30%). Honda's approach focuses on a free-piston Stirling engine design that eliminates mechanical linkages, reducing friction losses and improving reliability. Their comparative analysis shows that while their V10 engines deliver energy density of approximately 4.5-5.0 kWh/kg, their advanced Stirling prototypes achieve only 1.0-1.3 kWh/kg. However, Honda's research demonstrates that Stirling engines offer superior fuel flexibility, with their models capable of utilizing multiple fuel sources including hydrogen, natural gas, and biofuels with minimal modifications. Honda has also integrated waste heat recovery systems with their Stirling designs, improving overall system efficiency by an additional 15-20%.

Strengths: Advanced free-piston design reduces mechanical complexity; superior fuel flexibility; excellent thermal efficiency; integrated waste heat recovery systems. Weaknesses: Lower power density compared to V10 engines; slower response to power demand changes; higher manufacturing costs; greater weight per power output ratio.

Core Patents and Innovations in Engine Energy Efficiency

Stirling engine for vehicle

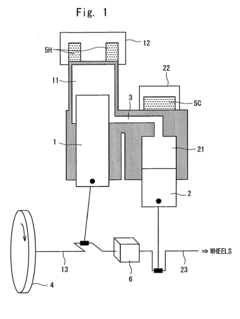

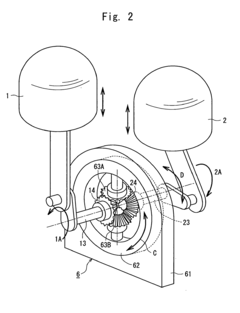

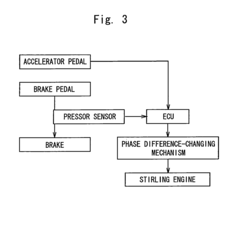

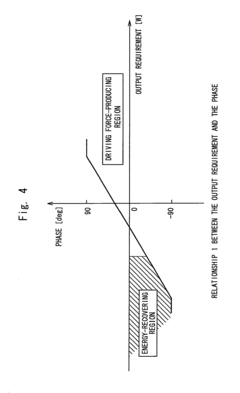

PatentInactiveEP2006524A9

Innovation

- The Stirling engine is operated as a heat pump during braking to convert kinetic energy into temperature differential energy, which is accumulated and later used for acceleration, utilizing heat accumulators and a phase difference-changing mechanism to adjust piston phases and rotational direction for efficient energy conversion.

Stirling engine

PatentInactiveEP2255085A1

Innovation

- The Stirling engine design features a rocker arm articulated at one end on a connecting rod and pivotally mounted at the other end on the cylinder housing, with a changed crank drive geometry that allows the piston to stay longer at top dead center and move more quickly at bottom dead center, minimizing lateral forces and enabling larger piston diameters and volumes for improved efficiency. Additionally, each piston is equipped with its own heat exchanger and a regenerator is placed between them, and the use of hydrogen as the working gas enhances efficiency.

Environmental Impact Assessment

The environmental impact assessment of V10 engines versus Stirling engines reveals significant differences in their ecological footprints throughout their lifecycle. V10 internal combustion engines, characterized by their high displacement and power output, generate substantial greenhouse gas emissions during operation. These engines typically produce between 250-400 g/km of CO2, contributing significantly to climate change concerns. Additionally, they release nitrogen oxides, carbon monoxide, and particulate matter that adversely affect air quality and human health in urban environments.

The manufacturing process of V10 engines also presents environmental challenges, requiring energy-intensive production methods and specialized materials. The extraction and processing of these materials contribute to resource depletion and generate industrial waste. Furthermore, the lubricants and coolants necessary for V10 engine operation pose potential environmental hazards if improperly disposed of or leaked.

In contrast, Stirling engines offer a more environmentally favorable profile in several aspects. Their external combustion design allows for greater fuel flexibility, including the potential use of renewable energy sources such as solar thermal energy, biomass, or waste heat recovery systems. This versatility can substantially reduce the carbon footprint compared to fossil fuel-dependent V10 engines. Studies indicate that Stirling engines utilizing renewable heat sources can approach near-zero operational emissions.

The closed-cycle operation of Stirling engines results in significantly lower noise pollution levels compared to internal combustion counterparts. This characteristic makes them particularly suitable for urban applications where noise regulations are increasingly stringent. Additionally, Stirling engines typically require fewer toxic materials in their construction and maintenance, reducing the environmental impact associated with hazardous waste management.

Life cycle assessment studies suggest that while both engine types have environmental impacts during manufacturing, the operational phase dominates the overall environmental footprint. The longer operational lifespan of Stirling engines, often exceeding 20,000 hours without major maintenance, provides an environmental advantage through reduced replacement frequency and associated manufacturing impacts.

Water consumption patterns also differ significantly between these technologies. V10 engines typically require substantial cooling systems that consume water resources, whereas many Stirling engine designs implement air-cooling systems that minimize water usage. This distinction becomes increasingly important in water-stressed regions where resource conservation is critical.

The end-of-life environmental impact also favors Stirling engines, as they contain fewer toxic components and more readily recyclable materials. Their simpler mechanical design facilitates more efficient disassembly and material recovery processes compared to the complex V10 engine architecture with its numerous specialized components.

The manufacturing process of V10 engines also presents environmental challenges, requiring energy-intensive production methods and specialized materials. The extraction and processing of these materials contribute to resource depletion and generate industrial waste. Furthermore, the lubricants and coolants necessary for V10 engine operation pose potential environmental hazards if improperly disposed of or leaked.

In contrast, Stirling engines offer a more environmentally favorable profile in several aspects. Their external combustion design allows for greater fuel flexibility, including the potential use of renewable energy sources such as solar thermal energy, biomass, or waste heat recovery systems. This versatility can substantially reduce the carbon footprint compared to fossil fuel-dependent V10 engines. Studies indicate that Stirling engines utilizing renewable heat sources can approach near-zero operational emissions.

The closed-cycle operation of Stirling engines results in significantly lower noise pollution levels compared to internal combustion counterparts. This characteristic makes them particularly suitable for urban applications where noise regulations are increasingly stringent. Additionally, Stirling engines typically require fewer toxic materials in their construction and maintenance, reducing the environmental impact associated with hazardous waste management.

Life cycle assessment studies suggest that while both engine types have environmental impacts during manufacturing, the operational phase dominates the overall environmental footprint. The longer operational lifespan of Stirling engines, often exceeding 20,000 hours without major maintenance, provides an environmental advantage through reduced replacement frequency and associated manufacturing impacts.

Water consumption patterns also differ significantly between these technologies. V10 engines typically require substantial cooling systems that consume water resources, whereas many Stirling engine designs implement air-cooling systems that minimize water usage. This distinction becomes increasingly important in water-stressed regions where resource conservation is critical.

The end-of-life environmental impact also favors Stirling engines, as they contain fewer toxic components and more readily recyclable materials. Their simpler mechanical design facilitates more efficient disassembly and material recovery processes compared to the complex V10 engine architecture with its numerous specialized components.

Automotive Industry Applications and Integration Potential

The automotive industry stands at a critical juncture where powertrain innovation directly impacts market competitiveness. When examining V10 engines versus Stirling engines from an integration perspective, several key considerations emerge for vehicle manufacturers and suppliers.

V10 engines currently enjoy widespread integration within the automotive ecosystem, with established manufacturing processes, supply chains, and service networks. Their compatibility with existing vehicle architectures allows for relatively straightforward implementation in current production lines. Major luxury and performance brands like Lamborghini, Audi, and previously BMW have successfully incorporated V10 engines into their flagship models, demonstrating proven market viability.

Conversely, Stirling engines present significant integration challenges despite their theoretical efficiency advantages. The automotive industry would require substantial retooling of production facilities and development of new component supply chains to accommodate Stirling technology at scale. The different thermal management requirements and operational characteristics necessitate fundamental redesigns of vehicle cooling systems, transmission interfaces, and control electronics.

From a market readiness perspective, V10 engines benefit from immediate deployability while Stirling engines would require phased introduction strategies. A potential integration pathway for Stirling technology might begin with hybrid applications, where the engine operates as a range extender or auxiliary power unit before full powertrain implementation becomes feasible.

Regulatory considerations also impact integration potential. As emissions standards tighten globally, V10 engines face increasing compliance challenges despite advancements in exhaust treatment. Stirling engines offer potential regulatory advantages through lower emissions profiles, though certification processes would need development as the technology lacks established automotive compliance frameworks.

Service infrastructure represents another critical integration factor. The automotive industry has invested heavily in technician training and diagnostic equipment for conventional internal combustion engines. Stirling technology would require comprehensive new service protocols and specialized maintenance equipment, creating significant barriers to widespread adoption.

Cost structures differ substantially between these technologies. V10 engines benefit from economies of scale and decades of manufacturing optimization, while Stirling engines would initially carry premium production costs until volume manufacturing techniques mature. This cost differential significantly impacts integration strategies, potentially limiting Stirling applications to premium vehicle segments during early adoption phases.

V10 engines currently enjoy widespread integration within the automotive ecosystem, with established manufacturing processes, supply chains, and service networks. Their compatibility with existing vehicle architectures allows for relatively straightforward implementation in current production lines. Major luxury and performance brands like Lamborghini, Audi, and previously BMW have successfully incorporated V10 engines into their flagship models, demonstrating proven market viability.

Conversely, Stirling engines present significant integration challenges despite their theoretical efficiency advantages. The automotive industry would require substantial retooling of production facilities and development of new component supply chains to accommodate Stirling technology at scale. The different thermal management requirements and operational characteristics necessitate fundamental redesigns of vehicle cooling systems, transmission interfaces, and control electronics.

From a market readiness perspective, V10 engines benefit from immediate deployability while Stirling engines would require phased introduction strategies. A potential integration pathway for Stirling technology might begin with hybrid applications, where the engine operates as a range extender or auxiliary power unit before full powertrain implementation becomes feasible.

Regulatory considerations also impact integration potential. As emissions standards tighten globally, V10 engines face increasing compliance challenges despite advancements in exhaust treatment. Stirling engines offer potential regulatory advantages through lower emissions profiles, though certification processes would need development as the technology lacks established automotive compliance frameworks.

Service infrastructure represents another critical integration factor. The automotive industry has invested heavily in technician training and diagnostic equipment for conventional internal combustion engines. Stirling technology would require comprehensive new service protocols and specialized maintenance equipment, creating significant barriers to widespread adoption.

Cost structures differ substantially between these technologies. V10 engines benefit from economies of scale and decades of manufacturing optimization, while Stirling engines would initially carry premium production costs until volume manufacturing techniques mature. This cost differential significantly impacts integration strategies, potentially limiting Stirling applications to premium vehicle segments during early adoption phases.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!