V6 Engine Turbo Boost Control: Techniques and Testing

SEP 4, 202511 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V6 Turbo Technology Evolution and Objectives

Turbocharging technology for V6 engines has undergone significant evolution since its commercial introduction in the automotive industry. Initially developed for aircraft engines in the early 20th century, turbocharging technology found its way into passenger vehicles during the 1970s oil crisis as manufacturers sought to improve fuel efficiency while maintaining performance. The V6 configuration, with its inherent balance between power output and packaging efficiency, became an ideal platform for turbocharging applications.

The evolution of V6 turbo technology can be traced through several distinct phases. The first generation of turbocharged V6 engines in the 1980s suffered from significant turbo lag and reliability issues. By the 1990s, improvements in materials science and electronic control systems led to the second generation, which offered better response characteristics and durability. The early 2000s saw the third generation emerge with variable geometry turbochargers (VGT) that substantially reduced lag and improved low-end torque.

Current state-of-the-art V6 turbo systems represent the fourth generation, featuring twin-scroll designs, electric assistance, and sophisticated boost control algorithms. These advancements have enabled manufacturers to extract unprecedented levels of performance and efficiency from relatively small displacement engines, supporting the global trend toward engine downsizing while meeting increasingly stringent emissions regulations.

The primary objectives of modern V6 turbo boost control systems center around four key areas: maximizing power density, optimizing fuel efficiency, ensuring emissions compliance, and enhancing drivability. Power density improvements aim to extract maximum performance from smaller displacement engines, with current systems achieving specific outputs exceeding 100 horsepower per liter. Efficiency objectives focus on reducing parasitic losses and optimizing boost pressure across the entire operating range.

Emissions compliance has become increasingly critical, with boost control systems playing a vital role in managing exhaust gas temperatures and composition to support effective aftertreatment operation. Modern systems must precisely balance boost pressure to maintain optimal air-fuel ratios that minimize both particulate matter and NOx emissions while maximizing combustion efficiency.

Drivability objectives address the historical challenges of turbocharging, particularly turbo lag. Contemporary boost control techniques aim to deliver linear throttle response and consistent torque delivery across the engine's operating range, creating a driving experience that combines the best aspects of naturally aspirated engines with the enhanced performance of forced induction.

Looking forward, the technology trajectory points toward further integration with electrification, with hybrid-assisted turbocharging systems emerging as a promising development path. These systems leverage electric motors to provide instantaneous boost response while the exhaust-driven turbine spools up, effectively eliminating turbo lag while further improving efficiency and emissions performance.

The evolution of V6 turbo technology can be traced through several distinct phases. The first generation of turbocharged V6 engines in the 1980s suffered from significant turbo lag and reliability issues. By the 1990s, improvements in materials science and electronic control systems led to the second generation, which offered better response characteristics and durability. The early 2000s saw the third generation emerge with variable geometry turbochargers (VGT) that substantially reduced lag and improved low-end torque.

Current state-of-the-art V6 turbo systems represent the fourth generation, featuring twin-scroll designs, electric assistance, and sophisticated boost control algorithms. These advancements have enabled manufacturers to extract unprecedented levels of performance and efficiency from relatively small displacement engines, supporting the global trend toward engine downsizing while meeting increasingly stringent emissions regulations.

The primary objectives of modern V6 turbo boost control systems center around four key areas: maximizing power density, optimizing fuel efficiency, ensuring emissions compliance, and enhancing drivability. Power density improvements aim to extract maximum performance from smaller displacement engines, with current systems achieving specific outputs exceeding 100 horsepower per liter. Efficiency objectives focus on reducing parasitic losses and optimizing boost pressure across the entire operating range.

Emissions compliance has become increasingly critical, with boost control systems playing a vital role in managing exhaust gas temperatures and composition to support effective aftertreatment operation. Modern systems must precisely balance boost pressure to maintain optimal air-fuel ratios that minimize both particulate matter and NOx emissions while maximizing combustion efficiency.

Drivability objectives address the historical challenges of turbocharging, particularly turbo lag. Contemporary boost control techniques aim to deliver linear throttle response and consistent torque delivery across the engine's operating range, creating a driving experience that combines the best aspects of naturally aspirated engines with the enhanced performance of forced induction.

Looking forward, the technology trajectory points toward further integration with electrification, with hybrid-assisted turbocharging systems emerging as a promising development path. These systems leverage electric motors to provide instantaneous boost response while the exhaust-driven turbine spools up, effectively eliminating turbo lag while further improving efficiency and emissions performance.

Market Demand Analysis for Turbocharged V6 Engines

The global market for turbocharged V6 engines has experienced significant growth over the past decade, driven by increasingly stringent emission regulations and consumer demand for vehicles that combine performance with fuel efficiency. According to industry reports, the global automotive turbocharger market reached approximately $12 billion in 2022, with a compound annual growth rate of 8.7% projected through 2028.

Turbocharged V6 engines occupy a strategic position in this market, particularly in mid-size to large passenger vehicles, luxury sedans, SUVs, and light commercial vehicles. These engines deliver an optimal balance between the power output traditionally associated with V8 engines and the fuel economy of smaller displacement engines, making them increasingly popular among consumers seeking performance without compromising efficiency.

Regional analysis reveals varying adoption rates and market dynamics. North America shows strong demand for turbocharged V6 engines in pickup trucks and SUVs, while European markets favor these powertrains in premium sedans and crossovers due to strict CO2 emission targets. The Asia-Pacific region, particularly China, represents the fastest-growing market segment, with increasing consumer preference for premium vehicles equipped with advanced powertrain technologies.

Consumer behavior studies indicate a growing willingness to pay premium prices for vehicles with turbocharged engines, with 67% of new car buyers considering turbocharging technology an important factor in their purchasing decisions. This trend is particularly pronounced in the 30-45 age demographic, who prioritize both performance and environmental considerations.

From an industry perspective, OEMs are increasingly investing in turbocharging technologies to meet fleet-wide efficiency standards while maintaining performance metrics that satisfy consumer expectations. The integration of advanced boost control systems has become a key differentiator in the competitive landscape, with manufacturers highlighting responsive power delivery and reduced turbo lag in their marketing communications.

Market forecasts suggest that by 2026, over 70% of new V6-equipped vehicles globally will feature some form of turbocharging technology. This growth trajectory is supported by technological advancements in materials science, electronic control systems, and manufacturing processes that have reduced production costs while improving reliability and performance characteristics.

The aftermarket segment for turbocharger components and upgrades also represents a substantial opportunity, with performance enthusiasts driving demand for advanced boost control solutions that can be retrofitted to existing engines or used to enhance factory turbocharging systems.

Turbocharged V6 engines occupy a strategic position in this market, particularly in mid-size to large passenger vehicles, luxury sedans, SUVs, and light commercial vehicles. These engines deliver an optimal balance between the power output traditionally associated with V8 engines and the fuel economy of smaller displacement engines, making them increasingly popular among consumers seeking performance without compromising efficiency.

Regional analysis reveals varying adoption rates and market dynamics. North America shows strong demand for turbocharged V6 engines in pickup trucks and SUVs, while European markets favor these powertrains in premium sedans and crossovers due to strict CO2 emission targets. The Asia-Pacific region, particularly China, represents the fastest-growing market segment, with increasing consumer preference for premium vehicles equipped with advanced powertrain technologies.

Consumer behavior studies indicate a growing willingness to pay premium prices for vehicles with turbocharged engines, with 67% of new car buyers considering turbocharging technology an important factor in their purchasing decisions. This trend is particularly pronounced in the 30-45 age demographic, who prioritize both performance and environmental considerations.

From an industry perspective, OEMs are increasingly investing in turbocharging technologies to meet fleet-wide efficiency standards while maintaining performance metrics that satisfy consumer expectations. The integration of advanced boost control systems has become a key differentiator in the competitive landscape, with manufacturers highlighting responsive power delivery and reduced turbo lag in their marketing communications.

Market forecasts suggest that by 2026, over 70% of new V6-equipped vehicles globally will feature some form of turbocharging technology. This growth trajectory is supported by technological advancements in materials science, electronic control systems, and manufacturing processes that have reduced production costs while improving reliability and performance characteristics.

The aftermarket segment for turbocharger components and upgrades also represents a substantial opportunity, with performance enthusiasts driving demand for advanced boost control solutions that can be retrofitted to existing engines or used to enhance factory turbocharging systems.

Current Turbo Boost Control Challenges

The current landscape of turbo boost control in V6 engines presents several significant technical challenges that require innovative solutions. Traditional boost control systems often struggle with response time limitations, particularly during rapid transient conditions when drivers demand sudden acceleration. This lag between throttle input and boost delivery creates a suboptimal driving experience and fails to maximize engine performance potential.

Precision control remains elusive across varying operating conditions. As ambient temperature, altitude, and humidity fluctuate, boost pressure can deviate from target levels, resulting in inconsistent engine performance. This variability is especially problematic in high-performance applications where predictable power delivery is essential for driver confidence and vehicle handling.

Heat management represents another critical challenge. Turbochargers operate in extreme thermal environments, with exhaust gas temperatures often exceeding 800°C. These conditions accelerate component wear and can lead to premature failure of actuators, sensors, and control mechanisms. The thermal expansion of components further complicates precise boost regulation.

Integration complexity with modern engine management systems poses significant hurdles. Contemporary V6 engines employ sophisticated electronic control units that must harmonize multiple subsystems including variable valve timing, direct injection, and emissions controls. Ensuring seamless communication between these systems and the turbocharger requires complex algorithms and robust hardware interfaces.

Calibration challenges persist across the engine's operating range. Engineers must develop boost maps that optimize performance while maintaining reliability and emissions compliance. This calibration process becomes exponentially more complex when dealing with twin-turbo or variable geometry turbocharger configurations common in modern V6 applications.

Durability concerns remain paramount as boost pressures continue to increase in pursuit of greater power density. Higher boost levels place additional stress on engine components, requiring more sophisticated protection strategies to prevent catastrophic failures during overboost conditions or sensor malfunctions.

Emissions compliance adds another layer of complexity to boost control development. Turbocharger operation significantly impacts exhaust gas composition, and control strategies must balance performance objectives with increasingly stringent emissions regulations across global markets.

Testing methodology limitations further complicate development efforts. Traditional dynamometer testing struggles to replicate real-world driving conditions, particularly the rapid transient states that most challenge boost control systems. This testing gap often results in control strategies that perform well in laboratory conditions but fall short in actual driving scenarios.

AI/ML: The current landscape of turbo boost control in V6 engines presents several significant technical challenges that require innovative solutions. Traditional boost control systems often struggle with response time limitations, particularly during rapid transient conditions when drivers demand sudden acceleration. This lag between throttle input and boost delivery creates a suboptimal driving experience and fails to maximize engine performance potential.

Precision control remains elusive across varying operating conditions. As ambient temperature, altitude, and humidity fluctuate, boost pressure can deviate from target levels, resulting in inconsistent engine performance. This variability is especially problematic in high-performance applications where predictable power delivery is essential for driver confidence and vehicle handling.

Heat management represents another critical challenge. Turbochargers operate in extreme thermal environments, with exhaust gas temperatures often exceeding 800°C. These conditions accelerate component wear and can lead to premature failure of actuators, sensors, and control mechanisms. The thermal expansion of components further complicates precise boost regulation.

Integration complexity with modern engine management systems poses significant hurdles. Contemporary V6 engines employ sophisticated electronic control units that must harmonize multiple subsystems including variable valve timing, direct injection, and emissions controls. Ensuring seamless communication between these systems and the turbocharger requires complex algorithms and robust hardware interfaces.

Calibration challenges persist across the engine's operating range. Engineers must develop boost maps that optimize performance while maintaining reliability and emissions compliance. This calibration process becomes exponentially more complex when dealing with twin-turbo or variable geometry turbocharger configurations common in modern V6 applications.

Durability concerns remain paramount as boost pressures continue to increase in pursuit of greater power density. Higher boost levels place additional stress on engine components, requiring more sophisticated protection strategies to prevent catastrophic failures during overboost conditions or sensor malfunctions.

Emissions compliance adds another layer of complexity to boost control development. Turbocharger operation significantly impacts exhaust gas composition, and control strategies must balance performance objectives with increasingly stringent emissions regulations across global markets.

Testing methodology limitations further complicate development efforts. Traditional dynamometer testing struggles to replicate real-world driving conditions, particularly the rapid transient states that most challenge boost control systems. This testing gap often results in control strategies that perform well in laboratory conditions but fall short in actual driving scenarios.

Precision control remains elusive across varying operating conditions. As ambient temperature, altitude, and humidity fluctuate, boost pressure can deviate from target levels, resulting in inconsistent engine performance. This variability is especially problematic in high-performance applications where predictable power delivery is essential for driver confidence and vehicle handling.

Heat management represents another critical challenge. Turbochargers operate in extreme thermal environments, with exhaust gas temperatures often exceeding 800°C. These conditions accelerate component wear and can lead to premature failure of actuators, sensors, and control mechanisms. The thermal expansion of components further complicates precise boost regulation.

Integration complexity with modern engine management systems poses significant hurdles. Contemporary V6 engines employ sophisticated electronic control units that must harmonize multiple subsystems including variable valve timing, direct injection, and emissions controls. Ensuring seamless communication between these systems and the turbocharger requires complex algorithms and robust hardware interfaces.

Calibration challenges persist across the engine's operating range. Engineers must develop boost maps that optimize performance while maintaining reliability and emissions compliance. This calibration process becomes exponentially more complex when dealing with twin-turbo or variable geometry turbocharger configurations common in modern V6 applications.

Durability concerns remain paramount as boost pressures continue to increase in pursuit of greater power density. Higher boost levels place additional stress on engine components, requiring more sophisticated protection strategies to prevent catastrophic failures during overboost conditions or sensor malfunctions.

Emissions compliance adds another layer of complexity to boost control development. Turbocharger operation significantly impacts exhaust gas composition, and control strategies must balance performance objectives with increasingly stringent emissions regulations across global markets.

Testing methodology limitations further complicate development efforts. Traditional dynamometer testing struggles to replicate real-world driving conditions, particularly the rapid transient states that most challenge boost control systems. This testing gap often results in control strategies that perform well in laboratory conditions but fall short in actual driving scenarios.

AI/ML: The current landscape of turbo boost control in V6 engines presents several significant technical challenges that require innovative solutions. Traditional boost control systems often struggle with response time limitations, particularly during rapid transient conditions when drivers demand sudden acceleration. This lag between throttle input and boost delivery creates a suboptimal driving experience and fails to maximize engine performance potential.

Precision control remains elusive across varying operating conditions. As ambient temperature, altitude, and humidity fluctuate, boost pressure can deviate from target levels, resulting in inconsistent engine performance. This variability is especially problematic in high-performance applications where predictable power delivery is essential for driver confidence and vehicle handling.

Heat management represents another critical challenge. Turbochargers operate in extreme thermal environments, with exhaust gas temperatures often exceeding 800°C. These conditions accelerate component wear and can lead to premature failure of actuators, sensors, and control mechanisms. The thermal expansion of components further complicates precise boost regulation.

Integration complexity with modern engine management systems poses significant hurdles. Contemporary V6 engines employ sophisticated electronic control units that must harmonize multiple subsystems including variable valve timing, direct injection, and emissions controls. Ensuring seamless communication between these systems and the turbocharger requires complex algorithms and robust hardware interfaces.

Calibration challenges persist across the engine's operating range. Engineers must develop boost maps that optimize performance while maintaining reliability and emissions compliance. This calibration process becomes exponentially more complex when dealing with twin-turbo or variable geometry turbocharger configurations common in modern V6 applications.

Durability concerns remain paramount as boost pressures continue to increase in pursuit of greater power density. Higher boost levels place additional stress on engine components, requiring more sophisticated protection strategies to prevent catastrophic failures during overboost conditions or sensor malfunctions.

Emissions compliance adds another layer of complexity to boost control development. Turbocharger operation significantly impacts exhaust gas composition, and control strategies must balance performance objectives with increasingly stringent emissions regulations across global markets.

Testing methodology limitations further complicate development efforts. Traditional dynamometer testing struggles to replicate real-world driving conditions, particularly the rapid transient states that most challenge boost control systems. This testing gap often results in control strategies that perform well in laboratory conditions but fall short in actual driving scenarios.

Contemporary Boost Control Solutions

01 Electronic turbo boost control systems

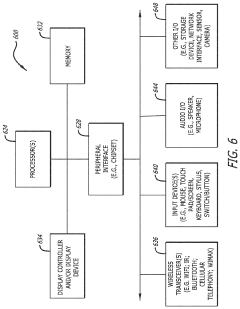

Electronic control systems for turbochargers in V6 engines that regulate boost pressure through sensors, actuators, and ECU programming. These systems monitor engine parameters and adjust boost levels accordingly to optimize performance while preventing engine damage. Advanced electronic controls can provide variable boost settings for different driving conditions and include safety features like overboost protection.- Electronic control systems for turbocharger boost pressure: Electronic control systems are used to regulate the boost pressure in turbocharged V6 engines. These systems typically include electronic control units (ECUs) that monitor various engine parameters such as intake air pressure, engine speed, and throttle position to adjust the turbocharger operation. By precisely controlling the boost pressure, these systems can optimize engine performance while preventing damage from excessive boost.

- Wastegate valve mechanisms for boost control: Wastegate valves are crucial components in turbocharger systems that regulate boost pressure by controlling the flow of exhaust gases to the turbine. When the desired boost pressure is reached, the wastegate opens to divert excess exhaust gas away from the turbine, preventing overboost. Various designs of wastegate mechanisms are employed in V6 engines, including pneumatic, electronic, and hydraulic actuators to achieve precise boost control across different operating conditions.

- Variable geometry turbocharger systems: Variable geometry turbocharger (VGT) systems provide enhanced boost control in V6 engines by adjusting the effective area of the turbine housing. By changing the angle of the vanes or nozzles in the turbine housing, these systems can optimize the exhaust gas flow at different engine speeds. This technology allows for quicker boost response at low engine speeds while preventing overboost at high engine speeds, resulting in improved overall engine performance and efficiency.

- Multi-stage turbocharging for V6 engines: Multi-stage turbocharging systems employ two or more turbochargers working in sequence or parallel to optimize boost pressure across the entire engine operating range. In V6 engines, these systems may include combinations of differently sized turbochargers or sequential turbocharging arrangements. The control systems for these configurations typically involve complex algorithms that determine which turbocharger(s) should be active based on engine load, speed, and desired performance characteristics.

- Integration of boost control with engine management systems: Modern V6 turbo engines feature integrated boost control systems that work in conjunction with the overall engine management system. These integrated systems coordinate boost control with other engine functions such as fuel injection timing, ignition timing, and valve timing to optimize performance, fuel efficiency, and emissions. Advanced control algorithms may include adaptive learning capabilities that adjust boost control parameters based on driving conditions, ambient temperature, and altitude changes.

02 Mechanical boost control mechanisms

Mechanical systems for controlling turbo boost in V6 engines using wastegates, bypass valves, and pressure-actuated components. These mechanisms provide reliable boost regulation through direct mechanical linkages that respond to pressure differentials. Components include spring-loaded valves, mechanical actuators, and pressure relief systems that maintain boost within safe operating parameters without requiring electronic intervention.Expand Specific Solutions03 Twin-turbo and sequential turbocharging systems

Specialized boost control solutions for V6 engines with multiple turbochargers, including twin-turbo and sequential setups. These systems manage the coordination between two or more turbochargers to eliminate turbo lag and provide optimal boost across the entire RPM range. Control mechanisms determine when each turbocharger activates based on engine load and speed, with sophisticated valving to direct exhaust gases appropriately.Expand Specific Solutions04 Variable geometry turbocharger control

Control systems for variable geometry turbochargers (VGT) in V6 engines that adjust the turbocharger's internal geometry to optimize boost at different engine speeds. These systems modify the angle of turbine vanes or adjust the effective size of the turbine housing to provide appropriate boost levels across the engine's operating range. The control mechanisms may be pneumatic, hydraulic, or electronic, responding to signals from the engine management system.Expand Specific Solutions05 Integrated boost control with engine management systems

Comprehensive boost control solutions that integrate with broader engine management systems in V6 engines. These systems coordinate boost control with other engine parameters such as fuel injection, ignition timing, and valve timing to optimize overall performance. Advanced implementations include adaptive learning capabilities that adjust boost strategies based on driving patterns, environmental conditions, and engine wear over time.Expand Specific Solutions

Key Manufacturers and Competition Landscape

The V6 Engine Turbo Boost Control technology market is currently in a growth phase, with an expanding global market driven by increasing demand for fuel-efficient, high-performance engines. Major automotive manufacturers including Ford, GM, Honda, Volkswagen, and Toyota are competing alongside specialized turbocharger technology providers like Garrett Motion and Honeywell International. The technology has reached moderate maturity in traditional applications but continues to evolve with advanced electronic control systems and integration with hybrid powertrains. European manufacturers (BMW, Audi, Renault) lead in sophisticated turbo implementations, while Asian companies (Great Wall Motor, SAIC) are rapidly advancing their capabilities. Component suppliers Robert Bosch and FEV Europe provide critical control systems that enhance performance across various applications, creating a competitive ecosystem balancing established players and innovative newcomers.

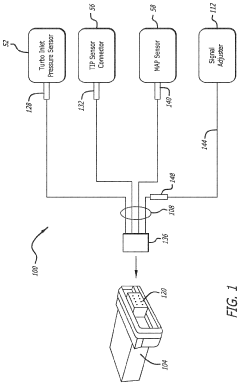

Ford Global Technologies LLC

Technical Solution: Ford has developed a comprehensive turbo boost control system for their EcoBoost V6 engines that combines electronic and pneumatic control elements. Their technology features a dual-loop control architecture where a primary electronic controller manages target boost based on engine load, speed, and ambient conditions, while a secondary pneumatic system provides fail-safe operation. Ford's system incorporates active wastegate control with position feedback and anticipatory algorithms that pre-position the wastegate based on predicted load changes. For testing, Ford employs a proprietary dynamometer setup that can simulate altitude changes from sea level to 12,000 feet while maintaining consistent temperature and humidity conditions to evaluate boost control performance across diverse environments[2]. Their V6 applications specifically utilize variable-geometry turbochargers on some models, controlled by high-precision stepper motors that adjust vane position in millisecond increments. Ford has also pioneered water-cooled charge air coolers for their high-output V6 turbo applications, which are integrated into the boost control strategy to optimize intake temperatures.

Strengths: Exceptional transient response characteristics with boost buildup rates optimized for real-world driving conditions; robust fail-safe mechanisms that maintain drivability even during sensor failures; comprehensive testing protocols that ensure reliability across extreme operating conditions. Weaknesses: Complex calibration requirements that increase development time; higher component count compared to simpler systems; potential for increased maintenance requirements due to additional cooling circuits and electronic components.

GM Global Technology Operations LLC

Technical Solution: GM has developed a sophisticated electronic wastegate control system for their twin-turbocharged V6 engines that utilizes model-based control algorithms. Their approach incorporates real-time computational fluid dynamics modeling that predicts airflow characteristics through the turbocharger based on current operating conditions. GM's system features dual electronic actuators with redundant position sensors that provide precise wastegate control with failsafe capabilities. For testing, GM employs a combination of high-altitude chambers and road testing at their Pikes Peak facility, where engineers can evaluate boost control performance under extreme conditions with oxygen levels approximately 30% lower than sea level[3]. Their V6 turbo applications utilize proprietary heat management strategies that actively control temperatures in the turbocharger housing to optimize boost response while protecting components from thermal damage. GM has also implemented machine learning algorithms in their latest generation systems that adapt boost control parameters based on individual driving patterns and environmental conditions, improving both performance and efficiency over the vehicle's lifetime.

Strengths: Advanced predictive modeling capabilities that minimize turbo lag across diverse operating conditions; sophisticated thermal management that extends component life while maintaining performance; adaptive control strategies that optimize for individual driving styles. Weaknesses: Higher computational requirements that necessitate more powerful ECUs; increased calibration complexity requiring specialized expertise; potential for reduced reliability due to the complexity of the electronic control systems.

Critical Patents in Turbo Boost Management

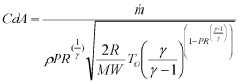

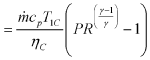

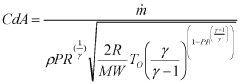

Power-based turbocharger boost control techniques

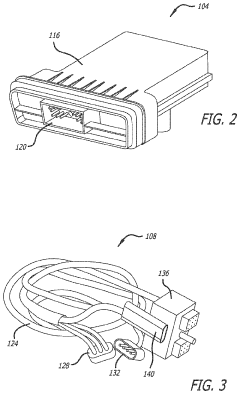

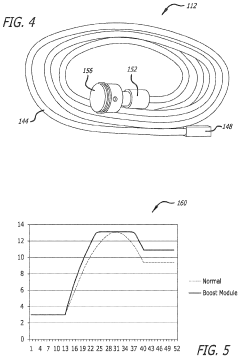

PatentWO2017213820A1

Innovation

- A power-based turbocharger boost control system using a complete physics-based model to determine the target positions and flows for the wastegate valve, compressor, and turbine, independent of engine configuration, allowing proactive management of exhaust gas energy and automatic compensation for changing conditions.

Turbo-boost control system

PatentActiveUS20230265804A1

Innovation

- A turbo-boost control system that includes a control module, wiring harness, and signal adjuster to increase manifold pressure before releasing it through the waste gate, allowing for greater control over engine power output, utilizing a microprocessor-based control module and rheostat for manual adjustment.

Emissions Regulations Impact on Turbo Technology

Emissions regulations worldwide have become increasingly stringent over the past two decades, fundamentally transforming turbocharger technology development for V6 engines. The European Union's Euro 6d standards, the United States' EPA Tier 3 requirements, and China's China 6 regulations have collectively pushed manufacturers toward more sophisticated turbo boost control systems that balance performance with environmental compliance.

These regulations have specifically targeted NOx, particulate matter, and CO2 emissions, compelling engineers to develop turbocharger systems with precise boost control capabilities. The implementation of Real Driving Emissions (RDE) testing has further complicated compliance, as turbochargers must now perform optimally across a wider range of operating conditions beyond traditional laboratory testing cycles.

Variable geometry turbochargers (VGT) have gained significant market share as a direct response to these regulatory pressures. Their ability to adjust turbine geometry based on engine load conditions allows for optimized exhaust flow management, reducing turbo lag while maintaining emissions compliance. This technology has become particularly valuable for V6 engines, where balanced performance across varying RPM ranges is critical.

Wastegate control strategies have also evolved considerably, transitioning from simple pneumatic actuators to sophisticated electronic systems with closed-loop feedback. Modern electronic wastegate controllers can make millisecond adjustments based on inputs from multiple sensors, including exhaust gas temperature, oxygen content, and boost pressure. This precision enables V6 engines to operate within increasingly narrow emissions compliance windows.

The integration of turbocharger systems with other emissions technologies has become standard practice. Exhaust Gas Recirculation (EGR) systems now work in concert with turbochargers, with boost control algorithms accounting for EGR rates to optimize combustion temperatures and minimize NOx formation. Similarly, Selective Catalytic Reduction (SCR) systems are calibrated in conjunction with turbocharger performance maps.

Manufacturers have also invested heavily in thermal management strategies for turbocharged V6 engines. Water-cooled turbochargers have become increasingly common, allowing for higher boost pressures while maintaining lower exhaust gas temperatures, thus reducing NOx formation. These systems require additional control parameters within the engine management system, further increasing the complexity of boost control algorithms.

Looking forward, upcoming Euro 7 and EPA regulations will likely drive further innovation in turbocharger technology, with increased focus on cold-start emissions and extended durability requirements. This regulatory trajectory suggests that future V6 turbo systems will require even more sophisticated boost control strategies, potentially incorporating predictive algorithms and machine learning to anticipate driving conditions and optimize emissions performance in real-time.

These regulations have specifically targeted NOx, particulate matter, and CO2 emissions, compelling engineers to develop turbocharger systems with precise boost control capabilities. The implementation of Real Driving Emissions (RDE) testing has further complicated compliance, as turbochargers must now perform optimally across a wider range of operating conditions beyond traditional laboratory testing cycles.

Variable geometry turbochargers (VGT) have gained significant market share as a direct response to these regulatory pressures. Their ability to adjust turbine geometry based on engine load conditions allows for optimized exhaust flow management, reducing turbo lag while maintaining emissions compliance. This technology has become particularly valuable for V6 engines, where balanced performance across varying RPM ranges is critical.

Wastegate control strategies have also evolved considerably, transitioning from simple pneumatic actuators to sophisticated electronic systems with closed-loop feedback. Modern electronic wastegate controllers can make millisecond adjustments based on inputs from multiple sensors, including exhaust gas temperature, oxygen content, and boost pressure. This precision enables V6 engines to operate within increasingly narrow emissions compliance windows.

The integration of turbocharger systems with other emissions technologies has become standard practice. Exhaust Gas Recirculation (EGR) systems now work in concert with turbochargers, with boost control algorithms accounting for EGR rates to optimize combustion temperatures and minimize NOx formation. Similarly, Selective Catalytic Reduction (SCR) systems are calibrated in conjunction with turbocharger performance maps.

Manufacturers have also invested heavily in thermal management strategies for turbocharged V6 engines. Water-cooled turbochargers have become increasingly common, allowing for higher boost pressures while maintaining lower exhaust gas temperatures, thus reducing NOx formation. These systems require additional control parameters within the engine management system, further increasing the complexity of boost control algorithms.

Looking forward, upcoming Euro 7 and EPA regulations will likely drive further innovation in turbocharger technology, with increased focus on cold-start emissions and extended durability requirements. This regulatory trajectory suggests that future V6 turbo systems will require even more sophisticated boost control strategies, potentially incorporating predictive algorithms and machine learning to anticipate driving conditions and optimize emissions performance in real-time.

Durability and Reliability Testing Methodologies

Durability and reliability testing forms a critical cornerstone in the development of V6 engine turbo boost control systems. These testing methodologies ensure that boost control mechanisms can withstand the harsh operating conditions encountered throughout the vehicle's lifecycle. The primary testing approaches include accelerated life testing, which subjects components to intensified stress conditions to simulate years of operation within a compressed timeframe. This methodology effectively identifies potential failure points in boost control actuators, sensors, and electronic control units.

Thermal cycling tests represent another essential methodology, where boost control components undergo repeated exposure to extreme temperature variations. These tests typically range from -40°C to 150°C, replicating the thermal stresses experienced in real-world driving scenarios from cold starts to high-load operations. The components' ability to maintain precise boost control across these temperature ranges directly impacts engine performance and emissions compliance.

Vibration testing methodologies employ multi-axis vibration tables that simulate the complex mechanical stresses encountered in various driving conditions. Modern testing protocols incorporate road-load data acquisition to replicate exact vibration profiles from different terrains and driving styles. This approach has proven particularly valuable for evaluating the durability of electronic boost control solenoids and wastegate actuators, which must maintain precise positioning despite constant vibration.

Corrosion resistance testing has evolved significantly, now incorporating salt spray, humidity cycling, and chemical exposure tests to evaluate the resilience of boost control components against environmental factors. These tests are particularly relevant for turbocharger wastegate mechanisms and actuator linkages exposed to underhood contaminants and road spray.

Endurance testing methodologies focus on continuous operation under varying load conditions. Industry standards typically require boost control systems to demonstrate reliable operation for the equivalent of 150,000 to 300,000 miles of operation. Advanced testing facilities employ automated test cells that can run 24/7, continuously monitoring boost pressure accuracy, response times, and system integrity throughout extended test cycles.

Statistical analysis plays an increasingly important role in reliability testing, with manufacturers employing Weibull analysis and other statistical tools to predict failure rates and establish confidence intervals for component lifespans. This data-driven approach enables more precise reliability predictions and helps establish appropriate service intervals for boost control system components.

Thermal cycling tests represent another essential methodology, where boost control components undergo repeated exposure to extreme temperature variations. These tests typically range from -40°C to 150°C, replicating the thermal stresses experienced in real-world driving scenarios from cold starts to high-load operations. The components' ability to maintain precise boost control across these temperature ranges directly impacts engine performance and emissions compliance.

Vibration testing methodologies employ multi-axis vibration tables that simulate the complex mechanical stresses encountered in various driving conditions. Modern testing protocols incorporate road-load data acquisition to replicate exact vibration profiles from different terrains and driving styles. This approach has proven particularly valuable for evaluating the durability of electronic boost control solenoids and wastegate actuators, which must maintain precise positioning despite constant vibration.

Corrosion resistance testing has evolved significantly, now incorporating salt spray, humidity cycling, and chemical exposure tests to evaluate the resilience of boost control components against environmental factors. These tests are particularly relevant for turbocharger wastegate mechanisms and actuator linkages exposed to underhood contaminants and road spray.

Endurance testing methodologies focus on continuous operation under varying load conditions. Industry standards typically require boost control systems to demonstrate reliable operation for the equivalent of 150,000 to 300,000 miles of operation. Advanced testing facilities employ automated test cells that can run 24/7, continuously monitoring boost pressure accuracy, response times, and system integrity throughout extended test cycles.

Statistical analysis plays an increasingly important role in reliability testing, with manufacturers employing Weibull analysis and other statistical tools to predict failure rates and establish confidence intervals for component lifespans. This data-driven approach enables more precise reliability predictions and helps establish appropriate service intervals for boost control system components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!