Water Use And Brine Disposition Strategies For Sustainable Lithium Recovery

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Recovery Technology Background and Objectives

Lithium has emerged as a critical element in the global transition to clean energy, primarily due to its essential role in rechargeable batteries for electric vehicles and renewable energy storage systems. The historical development of lithium recovery technologies began with conventional mining from hard rock deposits, predominantly spodumene, which requires energy-intensive processing. Since the 1990s, the industry has increasingly shifted toward brine-based extraction methods, which offer potentially lower costs and environmental impacts.

The evolution of lithium recovery technology has been marked by significant advancements in extraction efficiency and sustainability. Traditional evaporation pond methods, while still widely used, require 12-18 months of processing time and achieve only 50% recovery rates. These methods also consume substantial water resources—approximately 500,000 gallons per ton of lithium—in regions often characterized by water scarcity.

Current technological trends are moving toward direct lithium extraction (DLE) methods, which promise higher recovery rates (80-90%), dramatically reduced processing times (hours to days), and significantly lower water consumption. These innovations represent a critical response to the projected 40-fold increase in lithium demand by 2040, driven primarily by the electric vehicle revolution and grid-scale energy storage requirements.

The primary objective of sustainable lithium recovery technology development is to address the water-energy nexus challenges inherent in current extraction processes. This includes minimizing freshwater consumption, developing closed-loop water systems, and implementing effective brine management strategies that prevent environmental contamination while maximizing resource recovery.

Secondary objectives include reducing the carbon footprint of lithium production, decreasing land disturbance compared to traditional evaporation methods, and developing economically viable processes that can operate in diverse geological and hydrological conditions. These goals align with broader sustainability imperatives and the increasing ESG (Environmental, Social, and Governance) requirements from investors and regulatory bodies.

The technological trajectory aims to develop systems that can process lower-concentration brines economically, utilize renewable energy for extraction processes, and potentially integrate with geothermal energy production or other mineral recovery operations for improved efficiency. Achieving these objectives would transform lithium production from a water-intensive, environmentally challenging process into a cornerstone of sustainable clean energy transition.

The evolution of lithium recovery technology has been marked by significant advancements in extraction efficiency and sustainability. Traditional evaporation pond methods, while still widely used, require 12-18 months of processing time and achieve only 50% recovery rates. These methods also consume substantial water resources—approximately 500,000 gallons per ton of lithium—in regions often characterized by water scarcity.

Current technological trends are moving toward direct lithium extraction (DLE) methods, which promise higher recovery rates (80-90%), dramatically reduced processing times (hours to days), and significantly lower water consumption. These innovations represent a critical response to the projected 40-fold increase in lithium demand by 2040, driven primarily by the electric vehicle revolution and grid-scale energy storage requirements.

The primary objective of sustainable lithium recovery technology development is to address the water-energy nexus challenges inherent in current extraction processes. This includes minimizing freshwater consumption, developing closed-loop water systems, and implementing effective brine management strategies that prevent environmental contamination while maximizing resource recovery.

Secondary objectives include reducing the carbon footprint of lithium production, decreasing land disturbance compared to traditional evaporation methods, and developing economically viable processes that can operate in diverse geological and hydrological conditions. These goals align with broader sustainability imperatives and the increasing ESG (Environmental, Social, and Governance) requirements from investors and regulatory bodies.

The technological trajectory aims to develop systems that can process lower-concentration brines economically, utilize renewable energy for extraction processes, and potentially integrate with geothermal energy production or other mineral recovery operations for improved efficiency. Achieving these objectives would transform lithium production from a water-intensive, environmentally challenging process into a cornerstone of sustainable clean energy transition.

Market Analysis for Sustainable Lithium Extraction

The global lithium market is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Current market valuations place the lithium industry at approximately $7.5 billion, with projections indicating a compound annual growth rate (CAGR) of 12-15% over the next decade. This remarkable growth trajectory underscores the critical importance of developing sustainable lithium extraction methodologies that address both economic and environmental concerns.

Traditional lithium extraction methods, particularly evaporation ponds, have dominated the industry but face increasing scrutiny due to their substantial water consumption and environmental impact. Market analysis reveals that regions with significant lithium reserves, such as the "Lithium Triangle" of South America (Chile, Argentina, and Bolivia), are often located in water-stressed areas, creating a fundamental tension between resource extraction and environmental sustainability.

The demand-side dynamics show that battery manufacturers and automotive companies are increasingly prioritizing sustainably sourced materials in their supply chains. This shift is evidenced by premium pricing for responsibly extracted lithium, with some manufacturers willing to pay 5-8% above market rates for materials produced with reduced water consumption and environmental footprint. This price differential is creating market incentives for innovation in water-efficient extraction technologies.

Regulatory frameworks are evolving rapidly across major markets, with the European Union's Battery Directive and similar initiatives in North America establishing increasingly stringent sustainability requirements for battery materials. These regulatory developments are accelerating the market transition toward more sustainable extraction methodologies, creating both challenges and opportunities for industry participants.

Investor sentiment analysis indicates growing reluctance to fund projects utilizing traditional water-intensive extraction methods, with venture capital and private equity firms increasingly directing investment toward companies developing direct lithium extraction (DLE) and other water-efficient technologies. This capital flow is reshaping competitive dynamics within the industry and accelerating the commercialization timeline for innovative extraction approaches.

Market segmentation analysis reveals emerging differentiation between commodity lithium and "green lithium" – material extracted using sustainable practices with minimal water impact. This segmentation is creating new market opportunities for producers able to demonstrate superior environmental performance, particularly in serving premium segments of the EV and consumer electronics markets.

The competitive landscape is evolving rapidly, with established mining companies facing competition from technology-focused entrants specializing in sustainable extraction methodologies. This competitive pressure is driving industry-wide innovation and creating partnership opportunities between resource holders and technology providers focused on water-efficient extraction solutions.

Traditional lithium extraction methods, particularly evaporation ponds, have dominated the industry but face increasing scrutiny due to their substantial water consumption and environmental impact. Market analysis reveals that regions with significant lithium reserves, such as the "Lithium Triangle" of South America (Chile, Argentina, and Bolivia), are often located in water-stressed areas, creating a fundamental tension between resource extraction and environmental sustainability.

The demand-side dynamics show that battery manufacturers and automotive companies are increasingly prioritizing sustainably sourced materials in their supply chains. This shift is evidenced by premium pricing for responsibly extracted lithium, with some manufacturers willing to pay 5-8% above market rates for materials produced with reduced water consumption and environmental footprint. This price differential is creating market incentives for innovation in water-efficient extraction technologies.

Regulatory frameworks are evolving rapidly across major markets, with the European Union's Battery Directive and similar initiatives in North America establishing increasingly stringent sustainability requirements for battery materials. These regulatory developments are accelerating the market transition toward more sustainable extraction methodologies, creating both challenges and opportunities for industry participants.

Investor sentiment analysis indicates growing reluctance to fund projects utilizing traditional water-intensive extraction methods, with venture capital and private equity firms increasingly directing investment toward companies developing direct lithium extraction (DLE) and other water-efficient technologies. This capital flow is reshaping competitive dynamics within the industry and accelerating the commercialization timeline for innovative extraction approaches.

Market segmentation analysis reveals emerging differentiation between commodity lithium and "green lithium" – material extracted using sustainable practices with minimal water impact. This segmentation is creating new market opportunities for producers able to demonstrate superior environmental performance, particularly in serving premium segments of the EV and consumer electronics markets.

The competitive landscape is evolving rapidly, with established mining companies facing competition from technology-focused entrants specializing in sustainable extraction methodologies. This competitive pressure is driving industry-wide innovation and creating partnership opportunities between resource holders and technology providers focused on water-efficient extraction solutions.

Water Management Challenges in Lithium Production

Lithium production processes, particularly those involving brine extraction, face significant water management challenges that impact both operational efficiency and environmental sustainability. In arid regions where many lithium operations are located, such as the "Lithium Triangle" of Argentina, Bolivia, and Chile, water is already a scarce resource. Traditional lithium extraction from brines requires pumping large volumes of groundwater, which can deplete local aquifers and disrupt fragile ecosystems.

The evaporation pond method, which remains the dominant approach for lithium recovery from brines, is particularly water-intensive. This process involves pumping lithium-rich brine into large evaporation ponds where it remains for 12-18 months, during which time significant water loss occurs through evaporation. Studies indicate that producing one ton of lithium carbonate can require between 500,000 and 2 million gallons of water, depending on local conditions and operational efficiency.

Water quality issues compound these challenges. Brine processing generates high-salinity wastewater containing various contaminants including boron, magnesium, calcium, and potentially toxic elements like arsenic. Managing these waste streams requires sophisticated treatment systems to prevent contamination of surrounding water bodies and groundwater resources.

Climate change further exacerbates water management difficulties by increasing the frequency and severity of droughts in many lithium-producing regions. This not only reduces water availability but also affects the efficiency of evaporation-based processes, creating operational uncertainties and potentially extending production timelines.

Regulatory frameworks around water usage in lithium production are becoming increasingly stringent globally. Many jurisdictions now require comprehensive water management plans, regular monitoring, and reporting of water usage and impacts. Companies must navigate complex permitting processes that often involve demonstrating minimal impact on local water resources and communities.

Social license considerations have emerged as a critical factor in lithium operations. Local communities, particularly indigenous populations, frequently oppose lithium projects due to concerns about water depletion and contamination. Several high-profile projects have faced significant delays or cancellations due to community opposition centered on water issues.

The industry's rapid growth trajectory, driven by escalating demand for lithium-ion batteries, intensifies these challenges. Projections suggest lithium demand could increase by 400-800% by 2030, potentially placing unsustainable pressure on water resources in production regions without significant technological innovation in water management approaches.

The evaporation pond method, which remains the dominant approach for lithium recovery from brines, is particularly water-intensive. This process involves pumping lithium-rich brine into large evaporation ponds where it remains for 12-18 months, during which time significant water loss occurs through evaporation. Studies indicate that producing one ton of lithium carbonate can require between 500,000 and 2 million gallons of water, depending on local conditions and operational efficiency.

Water quality issues compound these challenges. Brine processing generates high-salinity wastewater containing various contaminants including boron, magnesium, calcium, and potentially toxic elements like arsenic. Managing these waste streams requires sophisticated treatment systems to prevent contamination of surrounding water bodies and groundwater resources.

Climate change further exacerbates water management difficulties by increasing the frequency and severity of droughts in many lithium-producing regions. This not only reduces water availability but also affects the efficiency of evaporation-based processes, creating operational uncertainties and potentially extending production timelines.

Regulatory frameworks around water usage in lithium production are becoming increasingly stringent globally. Many jurisdictions now require comprehensive water management plans, regular monitoring, and reporting of water usage and impacts. Companies must navigate complex permitting processes that often involve demonstrating minimal impact on local water resources and communities.

Social license considerations have emerged as a critical factor in lithium operations. Local communities, particularly indigenous populations, frequently oppose lithium projects due to concerns about water depletion and contamination. Several high-profile projects have faced significant delays or cancellations due to community opposition centered on water issues.

The industry's rapid growth trajectory, driven by escalating demand for lithium-ion batteries, intensifies these challenges. Projections suggest lithium demand could increase by 400-800% by 2030, potentially placing unsustainable pressure on water resources in production regions without significant technological innovation in water management approaches.

Current Water Conservation Strategies

01 Direct Lithium Extraction (DLE) Technologies

Direct Lithium Extraction technologies enable the selective removal of lithium from brines while minimizing water consumption. These methods typically use ion exchange, adsorption, or membrane-based processes to extract lithium ions from brine solutions. DLE technologies can significantly reduce the environmental footprint compared to traditional evaporation ponds by allowing for the return of processed brine to its source, thereby conserving water resources and minimizing disruption to local ecosystems.- Direct lithium extraction (DLE) technologies: Direct lithium extraction technologies offer more efficient methods for recovering lithium from brines while reducing water consumption compared to traditional evaporation ponds. These technologies typically use selective adsorbents, ion exchange materials, or membranes to extract lithium ions directly from brine solutions. DLE processes can significantly reduce the environmental footprint by minimizing land use, accelerating extraction timeframes, and enabling the return of processed brine to its source, thereby maintaining hydrological balance in sensitive ecosystems.

- Brine treatment and recycling systems: Advanced brine treatment and recycling systems focus on managing the spent brine after lithium extraction to minimize environmental impact and maximize water reuse. These systems typically involve filtration, purification, and concentration processes that remove impurities and adjust the chemical composition of the brine before reinjection or further processing. By implementing closed-loop systems, operations can significantly reduce freshwater consumption and minimize waste discharge, addressing concerns related to groundwater contamination and ecosystem disruption in lithium-rich regions.

- Water conservation in lithium processing: Water conservation techniques in lithium processing focus on minimizing freshwater usage through innovative approaches such as high-efficiency evaporation systems, water recovery from processing steps, and alternative cooling methods. These techniques include membrane-based water recovery systems, advanced evaporation technologies that reduce water loss, and process optimizations that decrease overall water requirements. By implementing these water conservation strategies, lithium producers can operate more sustainably in water-scarce regions while maintaining production efficiency.

- Brine concentration and impurity management: Brine concentration and impurity management technologies focus on efficiently separating lithium from other elements present in brine solutions while managing the concentration of dissolved solids. These processes typically involve selective precipitation, crystallization, or membrane filtration to remove unwanted elements such as magnesium, calcium, boron, and sodium. Advanced impurity management systems enable higher lithium recovery rates while producing cleaner brine streams that can be more easily processed or safely returned to the environment, reducing the overall environmental impact of lithium extraction operations.

- Zero liquid discharge and sustainable brine disposition: Zero liquid discharge (ZLD) approaches aim to eliminate wastewater discharge from lithium recovery operations by treating and reusing all process water and extracting valuable byproducts from brine. These systems typically combine multiple technologies such as evaporation, crystallization, and mineral recovery to process brine completely, leaving only solid residues. By implementing ZLD strategies, lithium producers can minimize environmental impacts, comply with stringent regulations, and potentially generate additional revenue streams from recovered minerals such as potassium, magnesium, and boron compounds.

02 Brine Treatment and Recycling Systems

Advanced brine treatment and recycling systems focus on processing spent brines after lithium extraction to enable water reuse and proper disposition. These systems typically involve filtration, purification, and concentration steps to remove impurities and prepare the brine for recycling or safe disposal. By implementing closed-loop systems, operations can significantly reduce freshwater consumption and minimize discharge of process water, addressing environmental concerns related to brine management in lithium recovery operations.Expand Specific Solutions03 Water Conservation in Lithium Extraction Processes

Water conservation techniques in lithium extraction focus on minimizing freshwater usage through efficient process design and water recovery systems. These approaches include implementing water recycling loops, utilizing alternative water sources, and optimizing process parameters to reduce overall water consumption. Advanced technologies enable the recovery of process water from various stages of lithium production, significantly reducing the water footprint of operations in water-scarce regions where many lithium resources are located.Expand Specific Solutions04 Zero Liquid Discharge Systems for Lithium Recovery

Zero Liquid Discharge (ZLD) systems aim to eliminate liquid waste streams in lithium recovery operations by treating and recycling all process water. These systems typically incorporate evaporation, crystallization, and filtration technologies to recover water and convert dissolved solids into dry waste products. By implementing ZLD approaches, lithium producers can achieve complete water recycling, minimize environmental impact, and potentially recover additional valuable minerals from waste streams, enhancing the sustainability of lithium production.Expand Specific Solutions05 Sustainable Brine Management and Disposition

Sustainable brine management focuses on environmentally responsible handling of processed brines after lithium extraction. This includes techniques for brine reinjection into source aquifers, beneficial reuse applications, and methods to minimize impact on local hydrology. Advanced approaches involve selective recovery of other valuable minerals from spent brines, reducing waste volume while creating additional revenue streams. These integrated management strategies help maintain hydrogeological balance and protect groundwater resources in regions where lithium extraction occurs.Expand Specific Solutions

Key Industry Players in Lithium Recovery

The lithium recovery market is in a growth phase, characterized by increasing demand for sustainable water use and brine management solutions. The global market is expanding rapidly due to electric vehicle battery production requirements, with projections exceeding $10 billion by 2030. Technologically, the field shows varying maturity levels across different extraction methods. Companies like Energy Exploration Technologies and Standard Lithium are pioneering direct lithium extraction technologies, while established players such as Schlumberger and BYD are leveraging their expertise in resource extraction and battery production. Academic institutions including MIT, Monash University, and Central South University are advancing research in membrane technologies and electrochemical processes, creating a competitive landscape where collaboration between industry and academia is driving innovation in sustainable lithium recovery methods.

Schlumberger Technologies, Inc.

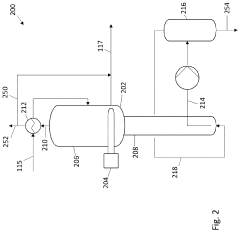

Technical Solution: Schlumberger has developed an innovative Direct Lithium Extraction (DLE) technology that significantly reduces water consumption compared to traditional evaporation methods. Their approach uses selective adsorption materials that can extract lithium ions directly from brine without extensive evaporation ponds. The process incorporates a closed-loop water recycling system where over 90% of process water is recovered and reused[1]. Their technology also features advanced membrane filtration systems to separate lithium from other elements while minimizing freshwater requirements. Schlumberger's solution includes a brine reinjection strategy that returns processed brine to the source aquifer, maintaining hydrological balance and reducing environmental impact[2]. The company has implemented real-time monitoring systems to optimize water usage throughout the extraction process, allowing for adaptive management based on environmental conditions.

Strengths: Significantly reduced water footprint compared to evaporation ponds (up to 90% less water consumption); maintains aquifer balance through reinjection; higher recovery rates of lithium (70-90% versus 30-50% for traditional methods). Weaknesses: Higher initial capital expenditure; requires specialized expertise to operate; energy requirements for the adsorption and filtration processes can be substantial.

Energy Exploration Technologies, Inc.

Technical Solution: Energy Exploration Technologies (EnergyX) has pioneered LiTAS™ (Lithium Ionic Transport and Separation), a revolutionary membrane-based direct lithium extraction technology. This system utilizes specialized Mixed Matrix Membranes (MMMs) incorporating metal-organic frameworks that selectively filter lithium ions from brine solutions[3]. The process operates at ambient temperature and pressure, dramatically reducing water consumption by eliminating evaporation ponds that typically lose millions of gallons to evaporation. EnergyX's technology can process brines with varying concentrations and compositions, achieving lithium recovery rates of up to 90% while using minimal freshwater inputs[4]. Their closed-loop system recirculates process water and returns depleted brine to source aquifers, maintaining hydrological balance. The company has also developed modular, scalable units that can be deployed in various environments with minimal footprint, allowing for flexible implementation based on local water constraints.

Strengths: Extremely water-efficient compared to traditional methods (reduces water usage by up to 95%); operates with minimal chemical additives; rapid processing time (hours versus months); adaptable to various brine chemistries. Weaknesses: Technology still scaling to commercial levels; membrane fouling can occur in certain brine compositions requiring additional maintenance; higher energy requirements for membrane filtration processes.

Innovative Brine Treatment Technologies

Lithium extraction method

PatentWO2025137291A1

Innovation

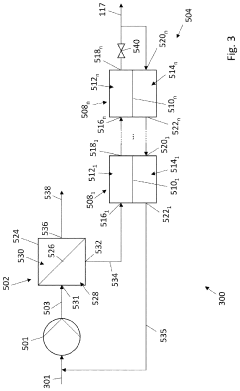

- A process combining separation technologies such as lithium adsorbents, nanofiltration, and reverse osmosis to selectively extract lithium from brine solutions with reduced energy consumption and improved water utilization.

Lithium recovery using aqueous sources

PatentActiveUS20240165539A1

Innovation

- The method involves direct lithium extraction using ion withdrawal or electrochemical separation processes, followed by concentration through counter-flow reverse osmosis and impurity removal stages to produce a purified lithium stream, effectively handling dilute sources like seawater and other low-concentration aqueous sources.

Environmental Impact Assessment

The environmental impact of lithium recovery operations represents a critical consideration for sustainable industry development. Traditional lithium extraction methods have historically generated significant ecological footprints, particularly regarding water consumption and brine disposition. In arid regions where lithium-rich brines are commonly found, such as the "Lithium Triangle" of South America, water usage presents a fundamental sustainability challenge, often competing directly with local communities' needs and natural ecosystem requirements.

Water extraction for lithium processing can lead to substantial groundwater depletion, affecting regional hydrological systems and dependent ecosystems. Studies indicate that conventional evaporative pond methods may consume between 500,000 to 2 million gallons of water per ton of lithium carbonate produced, creating long-term sustainability concerns in water-stressed regions.

Brine disposition strategies present additional environmental challenges. The discharge of processed brine with altered chemical composition can impact soil salinity, disrupt aquatic ecosystems, and potentially contaminate freshwater resources. Chemical additives used during processing may introduce toxins that bioaccumulate in local food chains, affecting biodiversity and ecosystem health.

Air quality impacts must also be considered, as evaporation ponds release particulate matter and potentially harmful aerosols. These emissions can affect local air quality and contribute to respiratory health concerns in nearby communities. Furthermore, the large land footprint required for traditional evaporation ponds results in habitat fragmentation and disruption of natural landscapes.

Climate change implications are increasingly relevant, as water-intensive extraction methods may become less viable with shifting precipitation patterns and increased drought frequency in many lithium-producing regions. The carbon footprint associated with pumping, processing, and transporting water and brine also contributes to the overall environmental impact assessment.

Emerging direct lithium extraction (DLE) technologies offer promising alternatives with potentially reduced environmental impacts. These approaches can decrease water consumption by 50-90% compared to traditional methods, while also minimizing land disturbance and chemical usage. However, comprehensive life-cycle assessments are needed to fully evaluate their environmental performance across all impact categories.

Regulatory frameworks governing environmental impacts vary significantly across lithium-producing regions, creating inconsistent protection standards. Developing standardized environmental impact metrics specific to lithium recovery operations would enable more effective industry benchmarking and improvement tracking over time.

Water extraction for lithium processing can lead to substantial groundwater depletion, affecting regional hydrological systems and dependent ecosystems. Studies indicate that conventional evaporative pond methods may consume between 500,000 to 2 million gallons of water per ton of lithium carbonate produced, creating long-term sustainability concerns in water-stressed regions.

Brine disposition strategies present additional environmental challenges. The discharge of processed brine with altered chemical composition can impact soil salinity, disrupt aquatic ecosystems, and potentially contaminate freshwater resources. Chemical additives used during processing may introduce toxins that bioaccumulate in local food chains, affecting biodiversity and ecosystem health.

Air quality impacts must also be considered, as evaporation ponds release particulate matter and potentially harmful aerosols. These emissions can affect local air quality and contribute to respiratory health concerns in nearby communities. Furthermore, the large land footprint required for traditional evaporation ponds results in habitat fragmentation and disruption of natural landscapes.

Climate change implications are increasingly relevant, as water-intensive extraction methods may become less viable with shifting precipitation patterns and increased drought frequency in many lithium-producing regions. The carbon footprint associated with pumping, processing, and transporting water and brine also contributes to the overall environmental impact assessment.

Emerging direct lithium extraction (DLE) technologies offer promising alternatives with potentially reduced environmental impacts. These approaches can decrease water consumption by 50-90% compared to traditional methods, while also minimizing land disturbance and chemical usage. However, comprehensive life-cycle assessments are needed to fully evaluate their environmental performance across all impact categories.

Regulatory frameworks governing environmental impacts vary significantly across lithium-producing regions, creating inconsistent protection standards. Developing standardized environmental impact metrics specific to lithium recovery operations would enable more effective industry benchmarking and improvement tracking over time.

Regulatory Compliance Framework

The regulatory landscape governing lithium extraction and brine management varies significantly across jurisdictions, creating a complex compliance framework that industry participants must navigate. At the federal level in the United States, the Environmental Protection Agency (EPA) oversees water discharge permits through the National Pollutant Discharge Elimination System (NPDES), which regulates the release of treated brine back into surface waters. Additionally, the Bureau of Land Management (BLM) and the U.S. Geological Survey (USGS) maintain oversight of lithium extraction activities on federal lands, particularly in regions like Nevada's Clayton Valley.

State-level regulations introduce further complexity, with California's stringent water quality standards under the Porter-Cologne Water Quality Control Act imposing more rigorous requirements than federal baselines. Similarly, Nevada's Division of Environmental Protection has developed specific protocols for brine management in its substantial lithium operations, focusing on groundwater protection and sustainable aquifer management.

International frameworks add another dimension to compliance considerations. Chile's comprehensive regulatory system requires detailed water management plans and environmental impact assessments before lithium extraction permits are granted. The country's water code specifically addresses brine as a distinct resource category with specialized management requirements. Australia has implemented a risk-based regulatory approach that scales compliance requirements according to project size and potential environmental impact.

Emerging regulatory trends indicate a shift toward more integrated water management approaches. Recent policy developments in major lithium-producing regions increasingly emphasize closed-loop systems that minimize freshwater consumption and maximize brine recycling. The European Union's Battery Directive, currently undergoing revision, is expected to include specific provisions for sustainable water use in battery material extraction, potentially establishing new global benchmarks.

Compliance certification systems are also evolving, with the Initiative for Responsible Mining Assurance (IRMA) and the International Council on Mining and Metals (ICMM) developing water stewardship standards specifically addressing brine operations. These voluntary frameworks are increasingly referenced in regulatory requirements and customer procurement specifications, effectively transforming them into de facto compliance obligations.

For lithium developers, early engagement with regulatory authorities has proven critical to project success. Companies that proactively develop comprehensive water management plans aligned with regulatory expectations typically experience fewer permitting delays and more favorable stakeholder relations. The regulatory compliance landscape continues to evolve rapidly, with increasing emphasis on water conservation, community water rights protection, and long-term aquifer sustainability.

State-level regulations introduce further complexity, with California's stringent water quality standards under the Porter-Cologne Water Quality Control Act imposing more rigorous requirements than federal baselines. Similarly, Nevada's Division of Environmental Protection has developed specific protocols for brine management in its substantial lithium operations, focusing on groundwater protection and sustainable aquifer management.

International frameworks add another dimension to compliance considerations. Chile's comprehensive regulatory system requires detailed water management plans and environmental impact assessments before lithium extraction permits are granted. The country's water code specifically addresses brine as a distinct resource category with specialized management requirements. Australia has implemented a risk-based regulatory approach that scales compliance requirements according to project size and potential environmental impact.

Emerging regulatory trends indicate a shift toward more integrated water management approaches. Recent policy developments in major lithium-producing regions increasingly emphasize closed-loop systems that minimize freshwater consumption and maximize brine recycling. The European Union's Battery Directive, currently undergoing revision, is expected to include specific provisions for sustainable water use in battery material extraction, potentially establishing new global benchmarks.

Compliance certification systems are also evolving, with the Initiative for Responsible Mining Assurance (IRMA) and the International Council on Mining and Metals (ICMM) developing water stewardship standards specifically addressing brine operations. These voluntary frameworks are increasingly referenced in regulatory requirements and customer procurement specifications, effectively transforming them into de facto compliance obligations.

For lithium developers, early engagement with regulatory authorities has proven critical to project success. Companies that proactively develop comprehensive water management plans aligned with regulatory expectations typically experience fewer permitting delays and more favorable stakeholder relations. The regulatory compliance landscape continues to evolve rapidly, with increasing emphasis on water conservation, community water rights protection, and long-term aquifer sustainability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!