Why High-Throughput Experimentation is Critical for New Alloy Development

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High-Throughput Experimentation Background and Objectives

High-throughput experimentation (HTE) represents a paradigm shift in materials science, particularly in the development of new alloys. This approach emerged in the late 1990s and early 2000s as a response to the limitations of traditional trial-and-error methods in materials discovery. The evolution of HTE has been closely linked with advancements in automation, robotics, and computational capabilities, enabling researchers to conduct thousands of experiments simultaneously rather than sequentially.

The fundamental principle behind HTE is the parallel synthesis and characterization of large libraries of materials with systematically varied compositions and processing conditions. This methodology dramatically accelerates the materials discovery process by orders of magnitude compared to conventional approaches. Historical milestones include the development of combinatorial thin film deposition techniques in the 1990s, followed by the integration of high-throughput characterization methods in the early 2000s, and more recently, the incorporation of machine learning algorithms for data analysis and prediction.

In the context of alloy development, HTE addresses the inherent complexity of multicomponent systems. Traditional alloy design typically explores only a small fraction of possible compositional combinations due to time and resource constraints. HTE overcomes this limitation by enabling the rapid exploration of vast compositional spaces, including regions that might be overlooked in conventional approaches.

The primary technical objectives of HTE in alloy development include: accelerating the discovery of novel alloy compositions with superior properties; establishing comprehensive structure-property-processing relationships across compositional gradients; reducing the time and cost associated with materials development; and enabling the exploration of non-intuitive compositional spaces that may yield unexpected property combinations.

Current technological trends in HTE for alloys include the integration of in-situ characterization techniques to monitor property evolution during processing, the development of advanced data analytics for extracting meaningful patterns from large experimental datasets, and the coupling of experimental HTE with computational methods such as CALPHAD (CALculation of PHAse Diagrams) and density functional theory calculations.

The ultimate goal of HTE in alloy development extends beyond mere acceleration of discovery. It aims to fundamentally transform the materials innovation cycle by establishing a data-rich ecosystem where experimental results feed into predictive models, which in turn guide subsequent experiments in an iterative process. This approach promises to not only expedite the discovery of new alloys but also to deepen our understanding of the underlying physical principles governing alloy behavior.

The fundamental principle behind HTE is the parallel synthesis and characterization of large libraries of materials with systematically varied compositions and processing conditions. This methodology dramatically accelerates the materials discovery process by orders of magnitude compared to conventional approaches. Historical milestones include the development of combinatorial thin film deposition techniques in the 1990s, followed by the integration of high-throughput characterization methods in the early 2000s, and more recently, the incorporation of machine learning algorithms for data analysis and prediction.

In the context of alloy development, HTE addresses the inherent complexity of multicomponent systems. Traditional alloy design typically explores only a small fraction of possible compositional combinations due to time and resource constraints. HTE overcomes this limitation by enabling the rapid exploration of vast compositional spaces, including regions that might be overlooked in conventional approaches.

The primary technical objectives of HTE in alloy development include: accelerating the discovery of novel alloy compositions with superior properties; establishing comprehensive structure-property-processing relationships across compositional gradients; reducing the time and cost associated with materials development; and enabling the exploration of non-intuitive compositional spaces that may yield unexpected property combinations.

Current technological trends in HTE for alloys include the integration of in-situ characterization techniques to monitor property evolution during processing, the development of advanced data analytics for extracting meaningful patterns from large experimental datasets, and the coupling of experimental HTE with computational methods such as CALPHAD (CALculation of PHAse Diagrams) and density functional theory calculations.

The ultimate goal of HTE in alloy development extends beyond mere acceleration of discovery. It aims to fundamentally transform the materials innovation cycle by establishing a data-rich ecosystem where experimental results feed into predictive models, which in turn guide subsequent experiments in an iterative process. This approach promises to not only expedite the discovery of new alloys but also to deepen our understanding of the underlying physical principles governing alloy behavior.

Market Demand Analysis for Advanced Alloy Development

The global market for advanced alloys is experiencing unprecedented growth, driven by increasing demands across multiple industries for materials with superior performance characteristics. The aerospace sector remains a primary driver, with projections indicating market expansion from $37.5 billion in 2023 to approximately $54.2 billion by 2028, representing a compound annual growth rate of 7.6%. This growth is fueled by the aviation industry's push for lighter, stronger, and more heat-resistant components that can improve fuel efficiency and reduce emissions.

Automotive manufacturing represents another significant market segment, particularly with the transition toward electric vehicles. The demand for specialized alloys that combine lightweight properties with high strength has increased by 22% over the past three years. These materials are essential for extending battery range while maintaining structural integrity and safety standards. Industry analysts predict this segment will continue to grow at double-digit rates through 2030.

The energy sector, especially renewable energy and nuclear power, presents substantial opportunities for advanced alloy applications. Wind turbine manufacturers require materials that can withstand extreme environmental conditions while maintaining structural integrity over decades of operation. Similarly, solar energy systems benefit from alloys that offer enhanced thermal conductivity and corrosion resistance, with the market for these specialized materials growing at 15.3% annually.

Medical device manufacturing has emerged as a high-value niche market for specialized alloys. Biocompatible materials for implants and surgical instruments command premium prices, with the global market valued at $12.3 billion in 2022. The aging global population and increasing prevalence of chronic conditions requiring medical interventions suggest continued strong demand in this sector.

Defense applications continue to drive innovation in high-performance alloys, with requirements for materials that can withstand extreme conditions while offering enhanced ballistic protection. Government spending on advanced materials research and procurement has increased by 8.7% annually over the past five years, reflecting the strategic importance of these materials.

The electronics industry represents another significant market, with demand for specialized alloys used in semiconductor manufacturing, connectors, and thermal management systems growing steadily. As devices become smaller and more powerful, the need for materials with precise electrical and thermal properties continues to expand, creating opportunities for novel alloy development.

Regional analysis indicates that Asia-Pacific markets, particularly China and India, are experiencing the fastest growth in advanced alloy consumption, driven by rapid industrialization and infrastructure development. North America and Europe maintain strong positions in high-value applications, particularly in aerospace and medical sectors.

Automotive manufacturing represents another significant market segment, particularly with the transition toward electric vehicles. The demand for specialized alloys that combine lightweight properties with high strength has increased by 22% over the past three years. These materials are essential for extending battery range while maintaining structural integrity and safety standards. Industry analysts predict this segment will continue to grow at double-digit rates through 2030.

The energy sector, especially renewable energy and nuclear power, presents substantial opportunities for advanced alloy applications. Wind turbine manufacturers require materials that can withstand extreme environmental conditions while maintaining structural integrity over decades of operation. Similarly, solar energy systems benefit from alloys that offer enhanced thermal conductivity and corrosion resistance, with the market for these specialized materials growing at 15.3% annually.

Medical device manufacturing has emerged as a high-value niche market for specialized alloys. Biocompatible materials for implants and surgical instruments command premium prices, with the global market valued at $12.3 billion in 2022. The aging global population and increasing prevalence of chronic conditions requiring medical interventions suggest continued strong demand in this sector.

Defense applications continue to drive innovation in high-performance alloys, with requirements for materials that can withstand extreme conditions while offering enhanced ballistic protection. Government spending on advanced materials research and procurement has increased by 8.7% annually over the past five years, reflecting the strategic importance of these materials.

The electronics industry represents another significant market, with demand for specialized alloys used in semiconductor manufacturing, connectors, and thermal management systems growing steadily. As devices become smaller and more powerful, the need for materials with precise electrical and thermal properties continues to expand, creating opportunities for novel alloy development.

Regional analysis indicates that Asia-Pacific markets, particularly China and India, are experiencing the fastest growth in advanced alloy consumption, driven by rapid industrialization and infrastructure development. North America and Europe maintain strong positions in high-value applications, particularly in aerospace and medical sectors.

Current State and Challenges in Alloy Experimentation

The global landscape of alloy development is currently experiencing a significant transformation, with traditional experimental methods proving increasingly inadequate for meeting modern industrial demands. Conventional alloy development typically follows a sequential, iterative process that can span several years from concept to commercialization. This time-intensive approach has become a critical bottleneck in addressing urgent market needs for advanced materials with specific property combinations.

High-throughput experimentation (HTE) has emerged as a revolutionary methodology in materials science, yet its implementation in alloy development remains fragmented and inconsistent across different regions. In North America and Europe, several research institutions and corporations have established sophisticated HTE facilities, while Asia—particularly China and Japan—has made substantial investments in large-scale HTE infrastructure over the past decade.

The current technical challenges in alloy experimentation are multifaceted. Sample preparation for compositionally complex alloys presents significant difficulties, especially when attempting to create precise composition gradients or when working with elements that have vastly different melting points or densities. Rapid characterization techniques, while advancing, still struggle to match the speed of sample production, creating analytical bottlenecks in the experimental pipeline.

Data management represents another substantial hurdle. The volume of data generated through HTE approaches can easily reach terabytes for a single experimental campaign, overwhelming traditional materials databases and analysis tools. This has led to inconsistent data formatting and storage practices across the field, hampering collaborative efforts and knowledge sharing.

Standardization remains notably absent in HTE methodologies for alloys. Different research groups employ varying experimental protocols, making direct comparison of results challenging and often impossible. This lack of standardization extends to reporting practices, where critical experimental parameters may be omitted or inconsistently documented in published literature.

Resource limitations further constrain progress, with the high capital investment required for comprehensive HTE platforms restricting access primarily to major research institutions and large corporations. This creates an innovation gap where smaller entities and developing nations struggle to participate in cutting-edge alloy development.

Perhaps most critically, there exists a significant skills gap in the workforce. The interdisciplinary nature of HTE for alloy development demands expertise spanning materials science, robotics, data science, and machine learning—a combination rarely found in traditionally trained metallurgists or materials scientists. Educational programs have been slow to adapt to this emerging need, creating a shortage of qualified personnel capable of designing, implementing, and interpreting high-throughput alloy experiments.

High-throughput experimentation (HTE) has emerged as a revolutionary methodology in materials science, yet its implementation in alloy development remains fragmented and inconsistent across different regions. In North America and Europe, several research institutions and corporations have established sophisticated HTE facilities, while Asia—particularly China and Japan—has made substantial investments in large-scale HTE infrastructure over the past decade.

The current technical challenges in alloy experimentation are multifaceted. Sample preparation for compositionally complex alloys presents significant difficulties, especially when attempting to create precise composition gradients or when working with elements that have vastly different melting points or densities. Rapid characterization techniques, while advancing, still struggle to match the speed of sample production, creating analytical bottlenecks in the experimental pipeline.

Data management represents another substantial hurdle. The volume of data generated through HTE approaches can easily reach terabytes for a single experimental campaign, overwhelming traditional materials databases and analysis tools. This has led to inconsistent data formatting and storage practices across the field, hampering collaborative efforts and knowledge sharing.

Standardization remains notably absent in HTE methodologies for alloys. Different research groups employ varying experimental protocols, making direct comparison of results challenging and often impossible. This lack of standardization extends to reporting practices, where critical experimental parameters may be omitted or inconsistently documented in published literature.

Resource limitations further constrain progress, with the high capital investment required for comprehensive HTE platforms restricting access primarily to major research institutions and large corporations. This creates an innovation gap where smaller entities and developing nations struggle to participate in cutting-edge alloy development.

Perhaps most critically, there exists a significant skills gap in the workforce. The interdisciplinary nature of HTE for alloy development demands expertise spanning materials science, robotics, data science, and machine learning—a combination rarely found in traditionally trained metallurgists or materials scientists. Educational programs have been slow to adapt to this emerging need, creating a shortage of qualified personnel capable of designing, implementing, and interpreting high-throughput alloy experiments.

Current High-Throughput Experimentation Techniques

01 Automated systems for high-throughput experimentation

Automated systems are designed to increase the throughput of experimental processes by minimizing human intervention. These systems incorporate robotics, automated sample handling, and integrated data management to perform multiple experiments simultaneously. The automation allows for consistent execution of experimental protocols, reduces manual errors, and significantly increases the number of experiments that can be conducted in a given timeframe, thereby enhancing overall experimental throughput.- Automated laboratory systems for high-throughput experimentation: Automated laboratory systems enable high-throughput experimentation by integrating robotics, liquid handling systems, and data management software. These systems can perform multiple experiments simultaneously, significantly increasing the throughput of experimental processes. The automation reduces human error, increases reproducibility, and allows for continuous operation, making it possible to conduct thousands of experiments in the time traditionally required for just a few manual experiments.

- Parallel processing techniques for experimental data analysis: Parallel processing techniques enable the simultaneous analysis of large datasets generated by high-throughput experimentation. By distributing computational tasks across multiple processors or computing nodes, these techniques significantly reduce the time required for data analysis. This approach is particularly valuable for complex analyses involving machine learning algorithms, statistical modeling, or simulation, allowing researchers to quickly extract meaningful insights from experimental results.

- Microfluidic platforms for accelerated experimentation: Microfluidic platforms miniaturize experimental setups, allowing for the manipulation of small volumes of fluids in channels with dimensions of tens to hundreds of micrometers. These platforms enable parallel processing of multiple samples, reduce reagent consumption, and accelerate reaction times. The integration of sensors and detection systems within microfluidic devices provides real-time monitoring of experimental parameters, further enhancing throughput and efficiency in various applications including drug discovery and materials science.

- Cloud-based infrastructure for collaborative high-throughput research: Cloud-based infrastructure facilitates collaborative high-throughput experimentation by providing shared access to computational resources, data storage, and analysis tools. These platforms enable geographically dispersed research teams to work together efficiently, sharing experimental designs, results, and insights in real-time. The scalability of cloud resources allows researchers to dynamically adjust computational capacity based on experimental needs, optimizing resource utilization and accelerating the pace of discovery.

- Machine learning algorithms for experimental design optimization: Machine learning algorithms enhance high-throughput experimentation by optimizing experimental design and predicting outcomes. These algorithms analyze patterns in existing data to suggest the most informative experiments to perform next, reducing the total number of experiments needed to reach a conclusion. Adaptive experimental design approaches continuously refine the experimental strategy based on incoming results, maximizing information gain and accelerating the discovery process in complex parameter spaces.

02 Parallel processing techniques for data analysis

Parallel processing techniques enable the simultaneous analysis of multiple experimental datasets, significantly increasing throughput in high-throughput experimentation. By distributing computational tasks across multiple processors or computing nodes, these techniques reduce the time required for data analysis. This approach is particularly valuable when dealing with large volumes of experimental data generated through high-throughput methods, allowing researchers to obtain results more quickly and make faster decisions about subsequent experiments.Expand Specific Solutions03 Microfluidic platforms for enhanced experimental throughput

Microfluidic platforms utilize miniaturized fluid handling systems to perform multiple experiments simultaneously on a small scale. These platforms enable the manipulation of small volumes of reagents, reducing material consumption while increasing experimental throughput. The integration of multiple reaction chambers, detection systems, and automated fluid handling on a single chip allows for parallel processing of samples, significantly enhancing the efficiency of high-throughput experimentation across various scientific disciplines.Expand Specific Solutions04 Advanced data management systems for high-throughput workflows

Advanced data management systems are essential for handling the large volumes of data generated in high-throughput experimentation. These systems incorporate specialized software for data acquisition, storage, processing, and analysis, enabling researchers to efficiently manage experimental workflows. Features such as automated data capture, real-time analysis, and integration with laboratory information management systems (LIMS) help streamline the experimental process, reduce bottlenecks, and maximize throughput in research environments.Expand Specific Solutions05 Machine learning algorithms for optimizing experimental design

Machine learning algorithms can significantly enhance the throughput of experimental processes by optimizing experimental design and predicting outcomes. These algorithms analyze patterns in existing experimental data to suggest optimal conditions for future experiments, reducing the number of iterations required to achieve desired results. By intelligently guiding the experimental process, machine learning approaches help researchers focus on the most promising experimental conditions, thereby increasing efficiency and throughput in high-throughput experimentation.Expand Specific Solutions

Key Players in High-Throughput Alloy Research

High-throughput experimentation (HTE) has become a critical enabler for new alloy development in today's competitive landscape. The market is experiencing rapid growth, with an estimated CAGR of 15-20% as industries demand advanced materials with superior properties. Currently in its growth phase, the HTE sector is witnessing increased adoption across aerospace, automotive, and energy sectors. Leading companies like Boeing, Rolls-Royce, and Haynes International are investing heavily in HTE platforms to accelerate alloy discovery and optimization. Academic institutions including Northwestern University and the Institute of Metal Research Chinese Academy of Sciences are partnering with industry to bridge fundamental research with commercial applications. While the technology is maturing rapidly, standardization of methodologies and data management systems remains a challenge for broader implementation across the materials development ecosystem.

ROLLS ROYCE PLC

Technical Solution: Rolls-Royce has developed a sophisticated high-throughput experimentation (HTE) platform specifically tailored for superalloy development in aerospace applications. Their system employs gradient casting techniques that create specimens with continuously varying compositions across a single sample, allowing simultaneous evaluation of numerous alloy formulations. This approach is complemented by automated microstructural characterization using electron microscopy with energy-dispersive X-ray spectroscopy mapping and nanoindentation arrays to rapidly assess mechanical properties across compositional gradients. Rolls-Royce's HTE methodology incorporates specialized high-temperature testing capabilities critical for turbine applications, including oxidation resistance screening and creep behavior assessment. Their digital framework integrates experimental results with thermodynamic modeling and machine learning to accelerate the identification of optimal compositions for specific operating conditions. This system has enabled them to develop next-generation nickel-based superalloys with enhanced temperature capabilities and extended service life for jet engine components.

Strengths: Specialized expertise in high-temperature alloys for demanding aerospace applications; advanced capabilities for testing under service-relevant conditions; strong integration with computational modeling. Weaknesses: Highly specialized focus on aerospace applications may limit broader materials discovery; significant capital investment requirements for specialized testing equipment.

Institute of Metal Research Chinese Academy of Sciences

Technical Solution: The Institute of Metal Research (IMR) has established a comprehensive high-throughput experimentation platform for alloy development that combines materials genome approaches with advanced manufacturing techniques. Their system features multi-target magnetron co-sputtering capabilities for creating compositionally graded thin film libraries, allowing exploration of complex multi-component alloy systems. IMR's approach integrates rapid characterization methods including automated X-ray diffraction, scanning electron microscopy with electron backscatter diffraction, and high-throughput nanoindentation to quickly map structure-property relationships across compositional spaces. Their methodology incorporates in-situ characterization techniques to observe phase transformations and microstructural evolution under various conditions. The institute has pioneered the development of machine learning algorithms specifically designed to extract meaningful patterns from high-dimensional alloy data, enabling the discovery of non-intuitive compositional relationships. This integrated approach has led to breakthroughs in high-entropy alloys, bulk metallic glasses, and lightweight high-strength alloys for transportation and energy applications.

Strengths: Exceptional fundamental research capabilities; advanced thin-film synthesis techniques for rapid composition screening; strong integration of computational and experimental approaches. Weaknesses: Potential gaps in scaling discoveries from thin-film libraries to bulk production; primarily research-focused rather than direct industrial application.

Critical Technologies in Combinatorial Materials Science

High throughput research workflow

PatentInactiveUS20110029439A1

Innovation

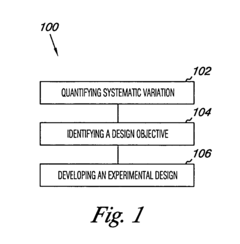

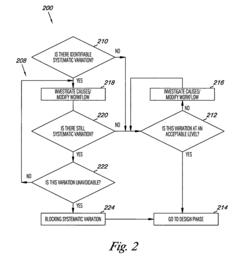

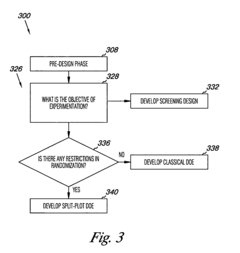

- The method involves quantifying systematic variation through variance component analysis, identifying design objectives, and developing experimental designs such as screening, split-plot, or classical designs to account for systematic variation, and modifying sources of variation to achieve statistically defensible results, using computer-readable mediums and computing devices to implement these steps.

Materials Informatics and AI Integration

Materials Informatics and AI integration represent a transformative approach in high-throughput experimentation (HTE) for new alloy development. The convergence of massive experimental data with advanced computational methods has created unprecedented opportunities for accelerating materials discovery. Machine learning algorithms can now process thousands of experimental results simultaneously, identifying patterns and correlations that would be impossible to detect through traditional analysis methods.

The application of artificial intelligence in materials science has evolved from simple data mining to sophisticated predictive modeling. Deep learning networks can now forecast material properties based on compositional and processing parameters, significantly reducing the number of physical experiments required. This capability is particularly valuable in alloy development, where the compositional space is virtually infinite and traditional trial-and-error approaches are prohibitively time-consuming.

Materials informatics platforms integrate experimental data, computational predictions, and literature knowledge into unified frameworks. These systems enable researchers to navigate complex materials spaces efficiently, suggesting promising compositions for targeted properties. The integration of natural language processing further enhances these capabilities by automatically extracting relevant information from scientific literature and patents, incorporating historical knowledge into current research efforts.

Cloud-based collaborative platforms have emerged as critical infrastructure for materials informatics. These systems allow research teams across different locations to contribute to and benefit from shared experimental databases. Real-time data processing capabilities enable immediate analysis of high-throughput experiments, facilitating rapid decision-making about subsequent experimental directions.

Bayesian optimization techniques have proven particularly effective in guiding high-throughput experimentation. By continuously updating probabilistic models based on incoming experimental results, these methods can intelligently suggest which experiments would yield the most informative outcomes, maximizing knowledge gain while minimizing resource expenditure.

The integration of physics-based models with data-driven approaches represents the frontier of materials informatics. These hybrid methods leverage scientific understanding of underlying physical principles while capitalizing on the pattern-recognition capabilities of machine learning. For alloy development, this means that fundamental metallurgical principles can inform and constrain AI predictions, resulting in more reliable and physically meaningful outcomes.

As computational power continues to increase and algorithms become more sophisticated, the synergy between high-throughput experimentation and AI will likely become the dominant paradigm in materials research, fundamentally changing how new alloys are discovered and optimized.

The application of artificial intelligence in materials science has evolved from simple data mining to sophisticated predictive modeling. Deep learning networks can now forecast material properties based on compositional and processing parameters, significantly reducing the number of physical experiments required. This capability is particularly valuable in alloy development, where the compositional space is virtually infinite and traditional trial-and-error approaches are prohibitively time-consuming.

Materials informatics platforms integrate experimental data, computational predictions, and literature knowledge into unified frameworks. These systems enable researchers to navigate complex materials spaces efficiently, suggesting promising compositions for targeted properties. The integration of natural language processing further enhances these capabilities by automatically extracting relevant information from scientific literature and patents, incorporating historical knowledge into current research efforts.

Cloud-based collaborative platforms have emerged as critical infrastructure for materials informatics. These systems allow research teams across different locations to contribute to and benefit from shared experimental databases. Real-time data processing capabilities enable immediate analysis of high-throughput experiments, facilitating rapid decision-making about subsequent experimental directions.

Bayesian optimization techniques have proven particularly effective in guiding high-throughput experimentation. By continuously updating probabilistic models based on incoming experimental results, these methods can intelligently suggest which experiments would yield the most informative outcomes, maximizing knowledge gain while minimizing resource expenditure.

The integration of physics-based models with data-driven approaches represents the frontier of materials informatics. These hybrid methods leverage scientific understanding of underlying physical principles while capitalizing on the pattern-recognition capabilities of machine learning. For alloy development, this means that fundamental metallurgical principles can inform and constrain AI predictions, resulting in more reliable and physically meaningful outcomes.

As computational power continues to increase and algorithms become more sophisticated, the synergy between high-throughput experimentation and AI will likely become the dominant paradigm in materials research, fundamentally changing how new alloys are discovered and optimized.

Sustainability Factors in Modern Alloy Development

Sustainability has emerged as a critical consideration in modern alloy development, driven by increasing environmental concerns, resource scarcity, and regulatory pressures. The traditional alloy development process often involves energy-intensive manufacturing methods and relies heavily on rare or environmentally problematic elements. High-throughput experimentation (HTE) offers a pathway to more sustainable alloy development by significantly reducing material waste and energy consumption during the research and development phase.

The environmental footprint of alloy production represents a substantial challenge for the materials industry. By employing HTE methodologies, researchers can simultaneously test hundreds or thousands of compositional variations using minimal material quantities, dramatically reducing the raw material requirements compared to conventional bulk testing approaches. This miniaturization of experimentation not only conserves valuable resources but also minimizes the generation of hazardous waste materials that would otherwise require special handling and disposal.

Energy efficiency constitutes another crucial sustainability factor that HTE addresses effectively. Traditional alloy development typically requires multiple large-scale melts and processing steps, each consuming significant energy. HTE platforms can evaluate numerous compositions with a fraction of the energy input, often utilizing techniques such as thin-film deposition or micro-scale processing that require substantially less power than conventional methods. The energy savings compound as fewer iterations are needed to reach optimal formulations.

Resource conservation extends beyond the experimental phase to implementation. HTE enables the development of alloys that utilize more abundant elements as substitutes for critical or rare materials. For instance, the automotive and aerospace industries are actively seeking alternatives to cobalt and rare earth elements through high-throughput screening of potential replacement compositions. This approach helps mitigate supply chain vulnerabilities while reducing dependence on materials with problematic mining practices.

Lifecycle considerations have become increasingly important in materials development. HTE facilitates the creation of alloys designed specifically for recyclability and end-of-life recovery. By rapidly testing how compositional variations affect recyclability parameters, researchers can optimize alloys not just for performance but also for circular economy compatibility. This represents a paradigm shift from traditional development approaches that primarily focused on in-service properties without considering full lifecycle impacts.

Regulatory compliance and anticipation of future environmental legislation also drive sustainability factors in modern alloy development. HTE allows companies to proactively develop alternatives to materials facing potential restrictions, such as those containing toxic elements like lead, cadmium, or hexavalent chromium. The ability to rapidly screen compliant alternatives provides competitive advantages while ensuring business continuity in an increasingly regulated landscape.

The environmental footprint of alloy production represents a substantial challenge for the materials industry. By employing HTE methodologies, researchers can simultaneously test hundreds or thousands of compositional variations using minimal material quantities, dramatically reducing the raw material requirements compared to conventional bulk testing approaches. This miniaturization of experimentation not only conserves valuable resources but also minimizes the generation of hazardous waste materials that would otherwise require special handling and disposal.

Energy efficiency constitutes another crucial sustainability factor that HTE addresses effectively. Traditional alloy development typically requires multiple large-scale melts and processing steps, each consuming significant energy. HTE platforms can evaluate numerous compositions with a fraction of the energy input, often utilizing techniques such as thin-film deposition or micro-scale processing that require substantially less power than conventional methods. The energy savings compound as fewer iterations are needed to reach optimal formulations.

Resource conservation extends beyond the experimental phase to implementation. HTE enables the development of alloys that utilize more abundant elements as substitutes for critical or rare materials. For instance, the automotive and aerospace industries are actively seeking alternatives to cobalt and rare earth elements through high-throughput screening of potential replacement compositions. This approach helps mitigate supply chain vulnerabilities while reducing dependence on materials with problematic mining practices.

Lifecycle considerations have become increasingly important in materials development. HTE facilitates the creation of alloys designed specifically for recyclability and end-of-life recovery. By rapidly testing how compositional variations affect recyclability parameters, researchers can optimize alloys not just for performance but also for circular economy compatibility. This represents a paradigm shift from traditional development approaches that primarily focused on in-service properties without considering full lifecycle impacts.

Regulatory compliance and anticipation of future environmental legislation also drive sustainability factors in modern alloy development. HTE allows companies to proactively develop alternatives to materials facing potential restrictions, such as those containing toxic elements like lead, cadmium, or hexavalent chromium. The ability to rapidly screen compliant alternatives provides competitive advantages while ensuring business continuity in an increasingly regulated landscape.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!