Zirconia's Importance in Engineering and Scientific Research

Zirconia Evolution

Zirconia, a remarkable ceramic material, has undergone significant evolution since its discovery in the late 18th century. Initially recognized for its refractory properties, zirconia's journey through technological advancements has been marked by several key milestones.

In the early 20th century, researchers began to explore zirconia's potential beyond its heat-resistant qualities. The discovery of zirconia's polymorphism in the 1920s laid the foundation for its diverse applications. This breakthrough revealed that zirconia exists in three crystalline forms: monoclinic, tetragonal, and cubic, each with distinct properties and potential uses.

The 1960s and 1970s saw a surge in zirconia research, particularly in the field of solid electrolytes. Scientists discovered that doping zirconia with certain oxides could stabilize its cubic form at room temperature, leading to the development of yttria-stabilized zirconia (YSZ). This innovation opened up new possibilities in fuel cell technology and oxygen sensors.

The 1980s marked a turning point in zirconia's evolution with the introduction of transformation toughening. This mechanism, which exploits zirconia's phase transformations to enhance its mechanical properties, revolutionized the material's use in structural applications. Consequently, partially stabilized zirconia (PSZ) and tetragonal zirconia polycrystals (TZP) emerged as high-performance engineering ceramics.

In the following decades, zirconia's evolution continued with refinements in processing techniques and the development of nanostructured zirconia materials. These advancements led to improved mechanical properties and expanded applications in fields such as biomedicine and advanced optics.

The 21st century has seen further diversification in zirconia's applications. The material's biocompatibility and aesthetic properties have made it a popular choice in dentistry, while its high refractive index and durability have found use in optical components and jewelry. Ongoing research focuses on enhancing zirconia's properties through novel composites and surface treatments, pushing the boundaries of its capabilities in extreme environments and specialized applications.

Throughout its evolution, zirconia has transitioned from a niche refractory material to a versatile advanced ceramic with applications spanning multiple industries. This journey reflects not only technological progress but also the material's inherent versatility and the ingenuity of researchers in harnessing its unique properties for diverse applications.

Market Demand Analysis

The market demand for zirconia in engineering and scientific research has been steadily increasing over the past decade, driven by its unique properties and versatile applications. In the dental industry, zirconia has become a preferred material for crowns, bridges, and implants due to its biocompatibility, durability, and aesthetic appeal. The global dental zirconia market is expected to grow significantly, with a projected compound annual growth rate of 9.8% from 2021 to 2028.

In the aerospace and automotive sectors, zirconia's high strength, thermal resistance, and low thermal conductivity make it an ideal material for thermal barrier coatings and engine components. The increasing focus on fuel efficiency and emission reduction in these industries is further boosting the demand for zirconia-based materials. The global thermal barrier coatings market, where zirconia plays a crucial role, is anticipated to expand at a CAGR of 6.5% from 2021 to 2026.

The electronics industry is another major consumer of zirconia, particularly in the production of solid oxide fuel cells (SOFCs) and oxygen sensors. As the world shifts towards cleaner energy sources, the demand for SOFCs is expected to rise, consequently driving the need for zirconia. The global SOFC market is projected to grow at a CAGR of 13.2% from 2021 to 2028, indicating a substantial increase in zirconia demand for this application.

In the field of advanced ceramics, zirconia's exceptional mechanical properties and chemical stability have led to its widespread use in cutting tools, wear-resistant components, and structural ceramics. The global advanced ceramics market, which includes zirconia-based products, is forecasted to reach $75.8 billion by 2025, growing at a CAGR of 4.8% from 2020 to 2025.

The medical industry is also contributing to the growing demand for zirconia, particularly in orthopedic implants and surgical instruments. Zirconia's biocompatibility and resistance to wear and corrosion make it an excellent choice for these applications. The global orthopedic implants market, where zirconia plays a significant role, is expected to reach $64 billion by 2026, growing at a CAGR of 4.3% from 2021 to 2026.

As research in nanotechnology and advanced materials progresses, the demand for high-purity zirconia in scientific research is also on the rise. Zirconia nanoparticles and thin films are being explored for various applications, including catalysis, sensors, and energy storage devices, further expanding the market potential for this versatile material.

Technical Challenges

Despite zirconia's widespread use in engineering and scientific research, several technical challenges persist in its application and development. One of the primary issues is the material's inherent brittleness, which limits its use in high-stress environments. This brittleness can lead to sudden and catastrophic failure, particularly in applications where reliability is crucial, such as in aerospace components or medical implants.

Another significant challenge lies in the stabilization of zirconia's crystal structure. Zirconia exists in different crystalline phases depending on temperature, and the transformation between these phases can cause volume changes and stress within the material. This phase transformation, while beneficial for some applications like transformation-toughening, can be detrimental in others, leading to microcracking and reduced mechanical properties.

The sintering process of zirconia presents additional difficulties. Achieving full densification without excessive grain growth is a delicate balance that requires precise control of sintering parameters. Overgrowth of grains can lead to reduced mechanical properties and compromised performance of the final product.

In the field of solid oxide fuel cells (SOFCs), where zirconia is commonly used as an electrolyte, researchers face challenges in reducing the operating temperature while maintaining high ionic conductivity. The high temperatures currently required for efficient operation limit the widespread adoption of this technology and pose materials compatibility issues.

Surface modification and functionalization of zirconia also present technical hurdles. Improving the material's biocompatibility for medical implants or enhancing its catalytic properties for industrial applications often requires complex surface treatments that can be difficult to implement consistently on a large scale.

The development of zirconia-based composites introduces additional complexities. While combining zirconia with other materials can enhance its properties, achieving uniform dispersion and strong interfacial bonding between components remains challenging. This is particularly true when attempting to incorporate nanomaterials or create gradient structures within zirconia matrices.

Lastly, the environmental impact of zirconia production and processing is an emerging concern. Current manufacturing methods can be energy-intensive and may involve the use of hazardous chemicals. Developing more sustainable and eco-friendly production techniques without compromising the material's quality and performance is a significant challenge facing researchers and industry professionals.

Current Applications

01 Zirconia synthesis and processing methods

Various methods for synthesizing and processing zirconia are described, including techniques for controlling particle size, morphology, and crystalline structure. These methods aim to produce zirconia with specific properties for different applications, such as improved mechanical strength or thermal stability.- Zirconia synthesis and processing methods: Various methods for synthesizing and processing zirconia are described, including techniques for controlling particle size, crystalline structure, and purity. These methods can involve different precursors, reaction conditions, and post-processing steps to achieve desired properties for specific applications.

- Zirconia-based composites and coatings: Zirconia is used in composite materials and coatings to enhance properties such as strength, wear resistance, and thermal insulation. These composites can be tailored for applications in aerospace, automotive, and industrial sectors by combining zirconia with other materials or applying it as a protective coating.

- Dental and biomedical applications of zirconia: Zirconia is widely used in dental and biomedical applications due to its biocompatibility, strength, and aesthetic properties. It is employed in dental implants, crowns, bridges, and other prosthetic devices, as well as in orthopedic implants and surgical instruments.

- Zirconia in fuel cells and energy applications: Zirconia, particularly yttria-stabilized zirconia, plays a crucial role in solid oxide fuel cells and other energy-related applications. Its unique properties, such as high ionic conductivity at elevated temperatures, make it suitable for use as an electrolyte material in these devices.

- Zirconia in optical and electronic applications: Zirconia is utilized in various optical and electronic applications due to its high refractive index, transparency, and dielectric properties. It is used in optical coatings, fiber optics, and as a dielectric material in electronic components and devices.

02 Zirconia-based composites and coatings

Development of zirconia-based composites and coatings for enhanced performance in various applications. These materials combine zirconia with other substances to improve properties such as wear resistance, thermal insulation, or chemical stability. Applications include protective coatings for industrial equipment and components for aerospace.Expand Specific Solutions03 Zirconia in dental and medical applications

Use of zirconia in dental and medical fields, particularly for prosthetics and implants. Zirconia's biocompatibility, strength, and aesthetic properties make it suitable for dental crowns, bridges, and orthopedic implants. Research focuses on improving its longevity and integration with biological tissues.Expand Specific Solutions04 Stabilized zirconia and phase transformation

Studies on stabilizing zirconia in its various crystalline phases and controlling phase transformation. This research aims to enhance zirconia's mechanical and thermal properties for high-temperature applications, such as in fuel cells, sensors, and refractory materials.Expand Specific Solutions05 Zirconia in catalysis and environmental applications

Exploration of zirconia's potential in catalysis and environmental remediation. This includes its use as a catalyst support, in pollution control systems, and for water treatment. Research focuses on modifying zirconia's surface properties and porosity to enhance its catalytic activity and adsorption capabilities.Expand Specific Solutions

Key Industry Players

The field of zirconia engineering and scientific research is in a mature growth phase, with a global market size expected to reach $2.1 billion by 2026. The technology's maturity varies across applications, from well-established dental and structural ceramics to emerging fields like fuel cells and sensors. Key players such as 3M Innovative Properties Co., Saint-Gobain Ceramics & Plastics, Inc., and Tosoh Corp. are driving innovation in advanced zirconia materials. Companies like Kyocera Corp. and Kuraray Noritake Dental, Inc. are focusing on specialized applications, while research institutions like Harbin Institute of Technology and University of Connecticut are pushing the boundaries of zirconia's potential in cutting-edge scientific research.

Kuraray Noritake Dental, Inc.

Saint-Gobain Ceramics & Plastics, Inc.

Zirconia Innovations

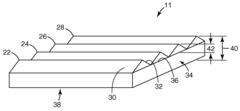

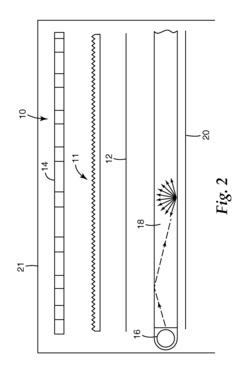

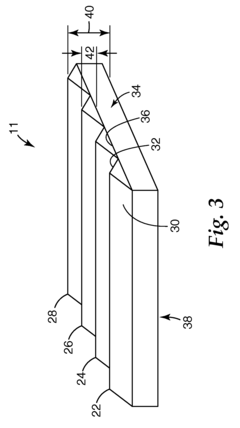

- Incorporating colloidal, crystalline zirconia particles with specific surface modifications into the optical layer of light management films to enhance durability and optical performance, including the use of a zirconia sol formed through hydrothermal treatments and surface modification agents.

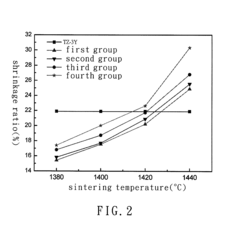

- A method involving wet mixing of silicon-containing zirconia powder with sodium carbonate and tetraethoxysilane, followed by calcination at reduced temperatures (900-1200°C) and subsequent sintering at 1415-1450°C to produce a silicon-containing zirconia calcined and sintered body with increased compactness and structural strength.

Environmental Impact

The environmental impact of zirconia production and usage is a critical consideration in its widespread application across engineering and scientific research fields. The extraction and processing of zirconium minerals, primarily zircon sand, involve energy-intensive operations that contribute to greenhouse gas emissions. Mining activities can lead to habitat disruption and soil erosion, while the refining process may generate hazardous waste materials that require careful management.

However, zirconia's durability and longevity in various applications can offset some of these initial environmental costs. Its use in advanced ceramics and refractory materials extends the lifespan of industrial equipment, reducing the frequency of replacements and associated resource consumption. In the automotive industry, zirconia-based oxygen sensors contribute to improved fuel efficiency and reduced emissions, aligning with global efforts to combat climate change.

The nuclear industry's use of zirconium alloys in fuel rod cladding presents both benefits and challenges from an environmental perspective. While nuclear power is considered a low-carbon energy source, the long-term management of radioactive waste remains a significant environmental concern. Zirconia's role in enhancing the safety and efficiency of nuclear reactors must be balanced against the potential risks associated with nuclear waste disposal.

In scientific research, zirconia's applications in advanced materials and catalysis may lead to breakthroughs in clean energy technologies and environmental remediation. Its use in solid oxide fuel cells, for instance, could contribute to more efficient and cleaner energy production systems. Additionally, zirconia-based materials show promise in water purification technologies, potentially addressing global water scarcity issues.

The recycling and end-of-life management of zirconia-containing products are emerging areas of focus. While zirconia itself is not toxic, the composite materials it is often part of can pose recycling challenges. Developing efficient recycling processes for zirconia-based products could significantly reduce the environmental footprint of its lifecycle.

As environmental regulations become more stringent globally, the zirconia industry is likely to face increased pressure to adopt more sustainable practices. This may drive innovation in cleaner production methods, more efficient resource utilization, and the development of circular economy models for zirconia-based products. Balancing the material's technological benefits with its environmental impact will be crucial for its continued importance in engineering and scientific research.

Regulatory Framework

The regulatory framework surrounding zirconia in engineering and scientific research is multifaceted, encompassing various aspects of its production, use, and disposal. International standards organizations, such as ISO and ASTM, have established specific guidelines for zirconia materials, ensuring consistency and quality across different applications. These standards cover aspects like chemical composition, physical properties, and testing methods.

In the medical field, regulatory bodies like the FDA in the United States and the EMA in Europe have set stringent requirements for zirconia-based medical devices. These regulations focus on biocompatibility, mechanical properties, and long-term stability of zirconia implants and prosthetics. Manufacturers must adhere to Good Manufacturing Practices (GMP) and provide extensive documentation on material safety and efficacy.

Environmental regulations also play a crucial role in zirconia's industrial use. Many countries have implemented strict controls on the mining and processing of zirconium minerals to minimize environmental impact. These regulations often include requirements for land reclamation, waste management, and emissions control during zirconia production.

In the nuclear industry, where zirconia is used in fuel rod cladding, regulatory frameworks are particularly rigorous. Nuclear regulatory agencies worldwide have established detailed guidelines for the use of zirconium alloys in nuclear reactors, focusing on material purity, corrosion resistance, and radiation stability. Compliance with these regulations is critical for ensuring nuclear safety.

The use of zirconia in advanced ceramics and coatings is subject to regulations governing material performance and safety in specific applications. For instance, in aerospace, zirconia-based thermal barrier coatings must meet strict standards set by aviation authorities regarding thermal resistance and durability.

Occupational health and safety regulations also apply to industries working with zirconia. These include guidelines for handling zirconia powders, which can pose inhalation risks, and safety measures for high-temperature processing of zirconia materials.

As research into new applications of zirconia continues, regulatory frameworks are evolving to address emerging concerns. This includes regulations on nanomaterials, where zirconia nanoparticles are finding increasing use. Regulatory bodies are developing new guidelines to assess the potential environmental and health impacts of these novel materials.