Zirconia's Role in Advanced Fuel Cell Technologies

Zirconia in Fuel Cells: Background and Objectives

Zirconia has emerged as a critical material in the development of advanced fuel cell technologies, playing a pivotal role in enhancing their efficiency and durability. The evolution of zirconia's application in fuel cells can be traced back to the 1960s when its potential as a solid electrolyte was first recognized. Since then, continuous research and development efforts have propelled zirconia to the forefront of fuel cell innovation.

The primary objective of incorporating zirconia in fuel cells is to improve their overall performance and longevity. Zirconia, particularly in its yttria-stabilized form (YSZ), exhibits excellent oxygen ion conductivity at high temperatures, making it an ideal electrolyte material for solid oxide fuel cells (SOFCs). This property allows for efficient oxygen ion transport, which is crucial for the electrochemical reactions that generate electricity in fuel cells.

As the fuel cell industry progresses, the goals for zirconia-based technologies have expanded. Current objectives include reducing the operating temperature of SOFCs to enhance their commercial viability, improving the mechanical strength of zirconia components to increase durability, and exploring novel compositions and manufacturing techniques to optimize performance.

The technological trajectory of zirconia in fuel cells is closely aligned with the global push for cleaner and more efficient energy solutions. As countries worldwide strive to reduce carbon emissions and transition to sustainable energy sources, fuel cells powered by hydrogen and other clean fuels are gaining prominence. Zirconia's role in this context is expected to grow, driving research into advanced materials and designs that can meet the increasing demands for high-performance, cost-effective fuel cell systems.

Recent trends in zirconia research for fuel cells focus on nanostructured materials, composite electrolytes, and thin-film technologies. These advancements aim to address key challenges such as reducing internal resistance, improving ionic conductivity at lower temperatures, and enhancing the overall system efficiency. The integration of zirconia with other advanced materials is also being explored to create hybrid systems that leverage the strengths of multiple components.

Looking ahead, the development of zirconia-based fuel cell technologies is expected to contribute significantly to the realization of a hydrogen economy and the broader adoption of fuel cell systems across various sectors, including transportation, stationary power generation, and portable electronics. The ongoing research in this field promises to unlock new possibilities for clean energy production and storage, positioning zirconia as a cornerstone material in the future of sustainable energy technologies.

Market Analysis for Zirconia-based Fuel Cells

The market for zirconia-based fuel cells has shown significant growth potential in recent years, driven by increasing demand for clean energy solutions and advancements in fuel cell technology. The global fuel cell market, which includes zirconia-based systems, is projected to reach substantial market value in the coming years, with a compound annual growth rate (CAGR) exceeding industry averages.

Zirconia-based fuel cells, particularly solid oxide fuel cells (SOFCs), have gained traction in various sectors due to their high efficiency, fuel flexibility, and potential for long-term cost-effectiveness. The stationary power generation sector represents the largest market segment for these fuel cells, with applications in residential, commercial, and industrial settings. This segment is expected to maintain its dominant position in the foreseeable future.

The transportation sector is emerging as a promising market for zirconia-based fuel cells, particularly in heavy-duty vehicles, marine applications, and auxiliary power units for long-haul trucks. The ability of these fuel cells to operate on various fuels, including hydrogen and natural gas, makes them attractive for diverse transportation needs.

Geographically, North America and Europe currently lead the market for zirconia-based fuel cells, owing to supportive government policies, substantial research and development investments, and a growing focus on renewable energy sources. However, the Asia-Pacific region is anticipated to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing energy demand, and government initiatives to promote clean energy technologies.

Key market drivers include the growing emphasis on reducing carbon emissions, increasing energy security concerns, and the need for reliable power sources in remote and off-grid locations. The declining costs of fuel cell systems, coupled with improvements in durability and performance, are also contributing to market expansion.

Despite the positive outlook, several challenges persist in the zirconia-based fuel cell market. High initial costs compared to conventional power generation technologies remain a significant barrier to widespread adoption. Additionally, the lack of hydrogen infrastructure in many regions poses a challenge for fuel cell deployment, particularly in the transportation sector.

Looking ahead, the market for zirconia-based fuel cells is expected to benefit from ongoing technological advancements, increasing investment in hydrogen infrastructure, and growing awareness of the environmental benefits of fuel cell technology. As economies of scale are achieved and manufacturing processes improve, the cost competitiveness of these systems is likely to enhance, further driving market growth.

Current Challenges in Zirconia Fuel Cell Technology

Despite significant advancements in zirconia-based fuel cell technologies, several challenges persist in their widespread adoption and optimal performance. One of the primary issues is the high operating temperature required for solid oxide fuel cells (SOFCs) utilizing zirconia electrolytes. Traditional yttria-stabilized zirconia (YSZ) electrolytes typically operate at temperatures between 800°C and 1000°C, which leads to increased material degradation, thermal stress, and system complexity.

The high-temperature operation also necessitates the use of expensive interconnect and sealing materials, limiting the economic viability of these fuel cells for large-scale applications. Researchers are actively working on developing intermediate-temperature SOFCs that can operate efficiently at lower temperatures (600-800°C), but this remains a significant challenge for zirconia-based systems.

Another critical issue is the ionic conductivity of zirconia electrolytes at lower temperatures. While YSZ exhibits excellent oxygen ion conductivity at high temperatures, its performance decreases significantly as the temperature drops. This reduction in ionic conductivity leads to increased ohmic losses and reduced overall cell efficiency. Efforts to improve the ionic conductivity of zirconia-based electrolytes at intermediate temperatures through doping and nanostructuring have shown promise but have not yet achieved the desired performance levels.

The mechanical stability of zirconia electrolytes under thermal cycling and long-term operation is also a concern. Thermal expansion mismatches between the electrolyte and electrode materials can lead to cracking and delamination, compromising the cell's integrity and performance over time. Developing more robust and thermally compatible materials remains an active area of research.

Furthermore, the chemical compatibility between zirconia electrolytes and electrode materials, particularly at the cathode-electrolyte interface, poses challenges. Reactions between YSZ and common cathode materials like lanthanum strontium manganite (LSM) can lead to the formation of insulating phases, increasing interfacial resistance and degrading cell performance over time.

Lastly, the cost-effective manufacturing of thin, dense, and defect-free zirconia electrolytes at scale remains a challenge. Current fabrication techniques often struggle to produce consistently high-quality electrolyte layers, which is crucial for achieving high performance and long-term stability in fuel cell systems.

Addressing these challenges requires a multidisciplinary approach, combining materials science, electrochemistry, and advanced manufacturing techniques to develop next-generation zirconia-based fuel cell technologies that can operate efficiently at lower temperatures, exhibit enhanced durability, and be produced cost-effectively at scale.

Existing Zirconia Fuel Cell Solutions

01 Zirconia synthesis and processing

Various methods for synthesizing and processing zirconia materials, including techniques for controlling particle size, crystalline structure, and purity. This encompasses sol-gel methods, hydrothermal synthesis, and advanced processing techniques to achieve desired properties for specific applications.- Zirconia synthesis and processing methods: Various methods for synthesizing and processing zirconia are explored, including sol-gel techniques, hydrothermal synthesis, and powder metallurgy. These processes aim to control the particle size, crystalline structure, and purity of zirconia for different applications.

- Zirconia-based dental materials: Zirconia is widely used in dental applications due to its biocompatibility and mechanical properties. Innovations in this field include improved zirconia-based ceramics for dental implants, crowns, and bridges, as well as coloring techniques for better aesthetics.

- Stabilized zirconia for high-temperature applications: Stabilized zirconia, particularly yttria-stabilized zirconia (YSZ), is developed for use in high-temperature environments such as thermal barrier coatings, solid oxide fuel cells, and refractory materials. Research focuses on improving thermal stability and mechanical properties.

- Zirconia nanoparticles and composites: The development of zirconia nanoparticles and their incorporation into composite materials is explored. These nanocomposites offer enhanced mechanical, thermal, and optical properties for applications in electronics, optics, and advanced materials.

- Zirconia in catalysis and environmental applications: Zirconia-based materials are investigated for their catalytic properties and use in environmental applications. This includes the development of zirconia-supported catalysts for various chemical processes and the use of zirconia in water treatment and pollution control.

02 Zirconia-based ceramics and composites

Development of zirconia-based ceramic materials and composites with enhanced mechanical, thermal, and chemical properties. This includes the incorporation of other elements or compounds to improve specific characteristics such as strength, toughness, and wear resistance for use in various industrial and medical applications.Expand Specific Solutions03 Dental and biomedical applications of zirconia

Utilization of zirconia in dental and biomedical fields, particularly for prosthetics, implants, and other medical devices. This involves tailoring zirconia properties for biocompatibility, aesthetics, and long-term stability in the human body.Expand Specific Solutions04 Zirconia in catalysis and fuel cells

Application of zirconia materials in catalysis and fuel cell technologies, focusing on their unique properties as catalyst supports or electrolytes. This includes modifications to enhance catalytic activity, ionic conductivity, and stability under various operating conditions.Expand Specific Solutions05 Zirconia coatings and thin films

Development of zirconia-based coatings and thin films for various applications, including thermal barrier coatings, optical coatings, and protective layers. This encompasses different deposition techniques and methods to control film properties such as thickness, density, and adhesion.Expand Specific Solutions

Key Players in Zirconia Fuel Cell Industry

The advanced fuel cell technology sector, particularly focusing on zirconia's role, is in a growth phase with increasing market size and technological maturity. The global fuel cell market is projected to expand significantly, driven by clean energy initiatives and automotive applications. Companies like Bloom Energy Corp. and NGK Insulators, Ltd. are at the forefront, developing and commercializing solid oxide fuel cell technologies. Research institutions such as the University of Connecticut and Dalian Institute of Chemical Physics are advancing zirconia-based materials for fuel cells. Automotive giants Honda Motor Co., Ltd. and Nissan Motor Co., Ltd. are integrating these technologies into their vehicle designs, indicating a shift towards mainstream adoption. The involvement of diverse players from materials science, energy, and automotive sectors suggests a competitive landscape with high potential for innovation and market growth.

Bloom Energy Corp.

CoorsTek, Inc.

Core Innovations in Zirconia Fuel Cell Research

- Incorporating ceria and at least one of yttria and ytterbia into the SSZ composition to stabilize the cubic phase and prevent the cubic to tetragonal phase transformation, thereby reducing ionic conductivity degradation, with specific doping levels and thermal expansion coefficients optimized for compatibility with interconnects in fuel cell stacks.

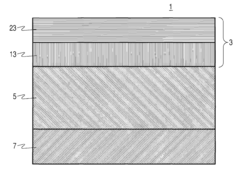

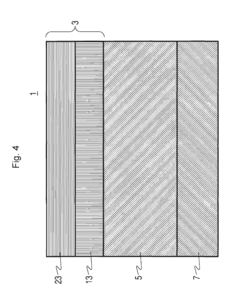

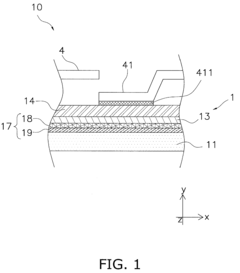

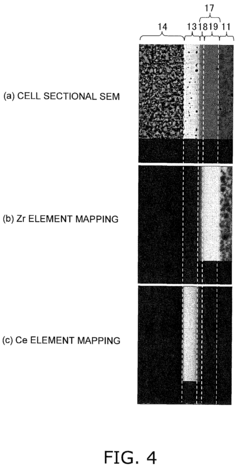

- Introduction of at least two intermediate layers containing zirconia between the electrolyte layer and the anode, with varying zirconia concentrations.

- Use of a ceria-based solid electrolyte layer in combination with zirconia-containing intermediate layers to improve high-temperature operation and durability.

- Gradual transition of material composition from the electrolyte layer to the anode through strategically designed intermediate layers.

Environmental Impact of Zirconia Fuel Cells

The environmental impact of zirconia fuel cells is a critical consideration in the advancement of clean energy technologies. These fuel cells offer significant advantages in terms of reduced greenhouse gas emissions compared to traditional fossil fuel-based power generation systems. When operating on hydrogen fuel, zirconia fuel cells produce only water vapor as a byproduct, resulting in near-zero direct emissions of carbon dioxide and other pollutants.

The production of zirconia itself, however, does have environmental implications. Mining and processing zirconium ores can lead to land disturbance, water usage, and energy consumption. Nevertheless, the long lifespan and high efficiency of zirconia fuel cells can offset these initial environmental costs over time. The durability of zirconia components contributes to extended operational lifetimes, reducing the frequency of replacement and associated material demands.

In terms of resource efficiency, zirconia fuel cells demonstrate superior performance. Their high operating temperatures enable internal reforming of hydrocarbon fuels, eliminating the need for external reformers and simplifying system design. This characteristic not only improves overall system efficiency but also reduces the material and energy requirements for fuel processing infrastructure.

The potential for fuel flexibility in zirconia-based fuel cells further enhances their environmental profile. These systems can operate on a variety of fuels, including biogas and syngas derived from renewable sources. This versatility supports the transition to cleaner energy sources and promotes the utilization of locally available, sustainable fuel options.

End-of-life considerations for zirconia fuel cells are also favorable from an environmental perspective. The materials used in these fuel cells, including zirconia, are generally non-toxic and can be recycled or repurposed. Proper recycling processes can recover valuable materials, reducing the demand for virgin resources and minimizing waste.

In the context of a circular economy, zirconia fuel cells align well with sustainability principles. Their long operational life, coupled with the potential for material recovery, contributes to a more efficient use of resources. As manufacturing processes for zirconia components continue to improve, the environmental footprint of production is expected to decrease further.

The integration of zirconia fuel cells into distributed energy systems offers additional environmental benefits. By enabling on-site power generation, these fuel cells can reduce transmission losses and improve overall grid efficiency. This decentralized approach to energy production can also enhance resilience and reduce the need for extensive power distribution infrastructure, potentially minimizing environmental disruption associated with large-scale energy projects.

Zirconia Fuel Cell Manufacturing Processes

The manufacturing processes for zirconia-based fuel cells involve several critical steps, each contributing to the overall performance and durability of the final product. The process typically begins with the preparation of zirconia powder, which is often doped with other elements such as yttria to enhance its ionic conductivity. This powder is then carefully processed to achieve the desired particle size distribution and morphology, crucial factors in determining the fuel cell's efficiency.

The next stage involves the formation of the electrolyte layer, which is commonly achieved through tape casting or screen printing techniques. These methods allow for precise control over the thickness and uniformity of the zirconia electrolyte, typically ranging from 10 to 50 micrometers. The green electrolyte layer is then subjected to a high-temperature sintering process, usually above 1400°C, to densify the material and eliminate porosity, ensuring optimal ionic conductivity.

Electrode fabrication is another critical aspect of zirconia fuel cell manufacturing. The cathode and anode materials, often composites containing zirconia and other active components, are applied to the electrolyte using techniques such as screen printing or spray coating. These electrodes are then sintered at temperatures lower than that of the electrolyte to maintain their porous structure, essential for gas diffusion and electrochemical reactions.

The assembly of the cell components is a delicate process that requires precise alignment and bonding. This may involve the use of sealing materials to ensure gas-tight connections between the electrolyte and electrodes. Advanced manufacturing techniques, such as co-sintering of multiple layers or plasma spraying, are being explored to improve the interfacial properties and reduce production costs.

Quality control is paramount throughout the manufacturing process. Techniques such as X-ray diffraction, scanning electron microscopy, and impedance spectroscopy are employed to assess the structural integrity, composition, and electrochemical performance of the fuel cells at various stages of production. These analytical methods help in optimizing process parameters and ensuring consistency in cell performance.

Recent advancements in manufacturing technologies have focused on scalability and cost reduction. Additive manufacturing techniques, including 3D printing of zirconia-based components, are being investigated for their potential to produce complex geometries and reduce material waste. Additionally, continuous processing methods and automated production lines are being developed to increase throughput and reduce labor costs in large-scale manufacturing of zirconia fuel cells.