Anti-rotation mechanism of moving cone of multi-cylinder hydraulic rolling cone crusher

A cone crushing and hydraulic technology, which is applied in the field of mining machinery and equipment, can solve the problems of reduced production efficiency, large energy waste, and large ore discharge particles, and achieve the effects of improving production efficiency, reducing energy waste, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

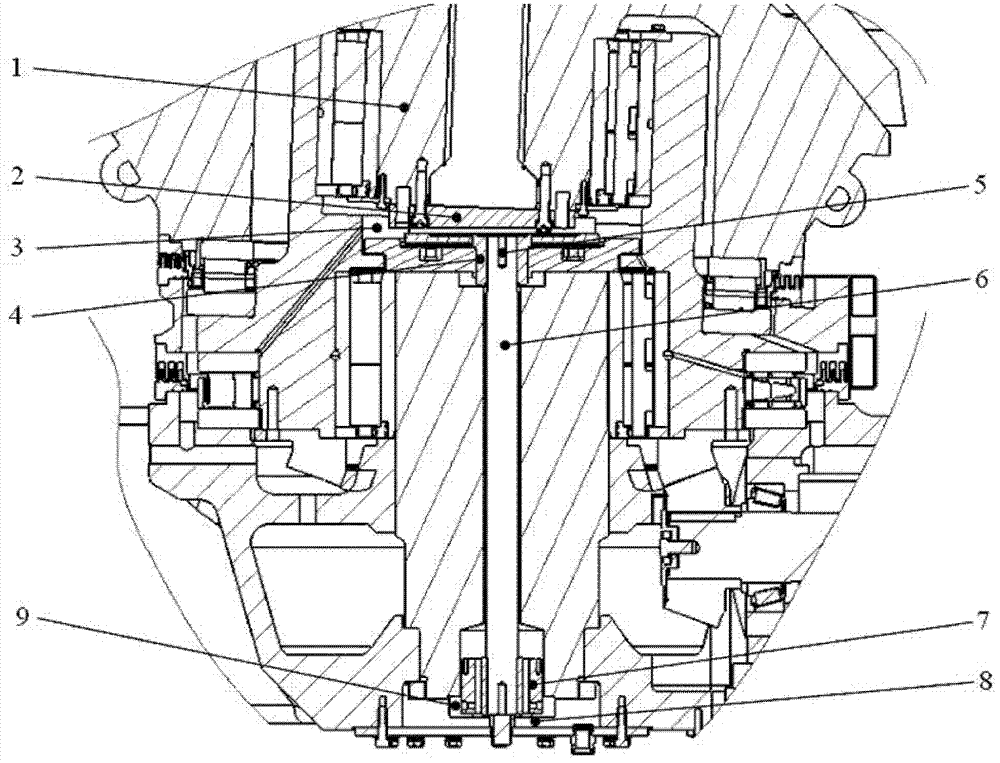

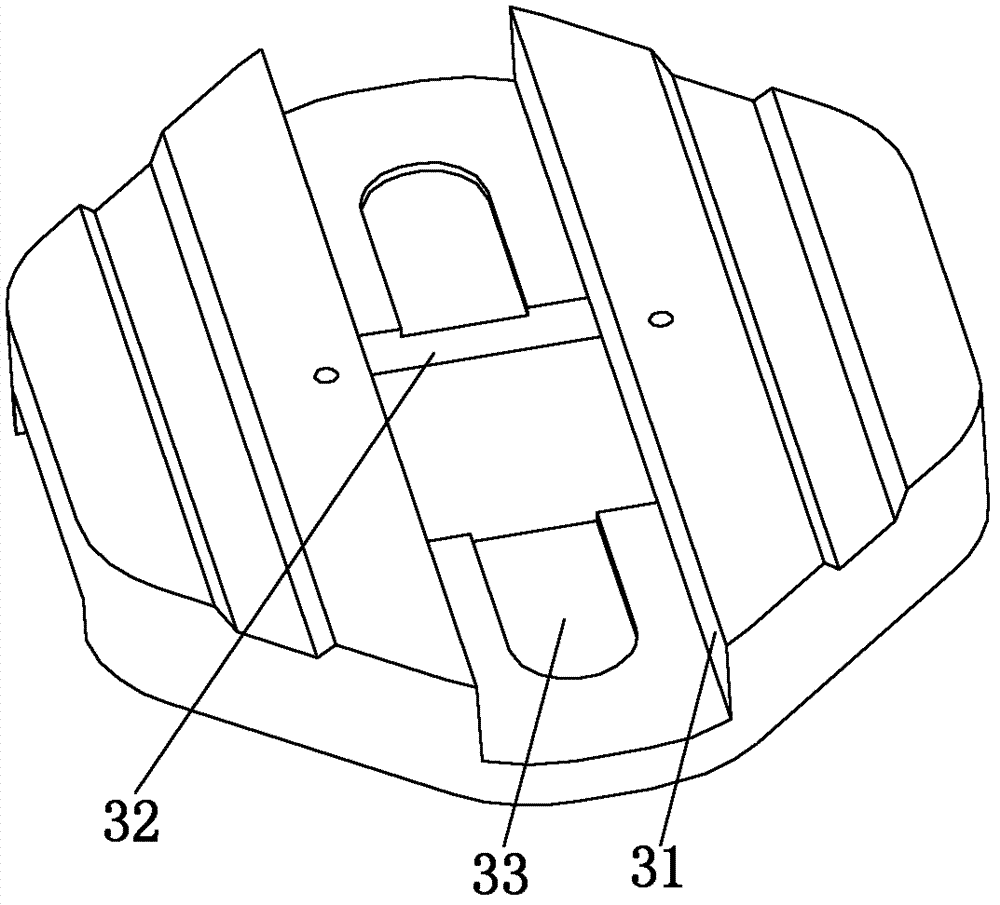

[0011] Such as figure 1 , 2 As shown, the multi-cylinder hydraulic rolling cone crusher motorized cone anti-rotation mechanism includes a brake shaft 6, a brake disc 4, an overrunning clutch 7, a cut-off screw 8, a guide ring 9, a universal floating disc 3, and a torque disc 2. The universal floating disc 3 has an upper working surface 31 and a lower working surface 32, and the overrunning clutch 7 has an inner ring and an outer ring. The taper handle 1 is connected, the lower working surface 32 of the universal floating disc 3 is in clearance fit with the brake shaft 6, one end of the brake shaft 6 is fixedly connected with the brake disc 4, and the brake disc 4 is installed in cooperation with the universal floating disc 3 , the other end of the brake shaft 6 is fixedly connected with the inner ring of the overrunning clutch 7, and the outer ring of the overrunning clutch 7 is connected with the guide ring 9 through the cutting screw 8. The brake shaft 6 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com