Catalyst regeneration method

A catalyst and binder technology, applied in the field of catalyst regeneration, can solve problems such as performance degradation, activity and selectivity deterioration, and activity loss of spent catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The catalysts of the present invention can be prepared by methods known in the art. In an example of the present invention, the preparation method of described catalyst comprises the steps:

[0037] (i) According to the stoichiometric relationship of the required catalyst, dissolve Mo, V and W sources in water at 70-100°C to obtain A solution, and the Mo, V and W sources are oxides of Mo, V and W Or salts that can generate oxides by roasting, such as ammonium salts, nitrates, carbonates, hydroxides, etc.;

[0038] (ii) According to the stoichiometric relationship of the required catalyst, dissolve Cu, X and Y sources in water at 60-80°C to obtain B solution; the Cu, X and Y sources are the oxidation of Cu, X and Y elements substances or salts that can generate oxides by roasting, such as ammonium salts, nitrates, carbonates, hydroxides, etc.;

[0039] (iii) Pour the B solution into the A solution under the condition of 40-80° C., and obtain the C solution after mixing...

Embodiment 1

[0090] 1. Deteriorated catalyst

[0091] Take the composition as Mo 12 V 2 Cu 1.8 W 2.5 Sb 2.2 Ni 0.8 o fThe hollow cylindrical catalyst is used as the reaction catalyst.

[0092] The raw material gas volume is composed of about 7% by volume of acrolein, about 9% by volume of oxygen, about 15% by volume of water vapor and 1.3% by volume and the balance nitrogen, and the catalyst is the above-mentioned one with Mo 12 V 2 Cu 1.8 W 2.5 Sb 2.2 Ni 0.8 o f The composition of the hollow cylindrical catalyst, the reaction temperature is about 250 ℃, the reaction pressure is normal pressure, and the space velocity is 1200h -1 In the reaction system, it was initially observed that the conversion rate of acrolein was 99.6 mol%, the selectivity of acrylic acid was 96.0 mol%, and the yield of acrylic acid was 95.6 mol%.

[0093] When it was observed that the selectivity of acrylic acid dropped to 96.0 mol%, and the yield of acrylic acid dropped to 95.6 mol%, it was determined...

Embodiment 2

[0104] Adopt the same catalyst regeneration method as in Example 1, except that the roasting method is changed to roasting under 100% nitrogen for 5h in the method of regeneration catalyst.

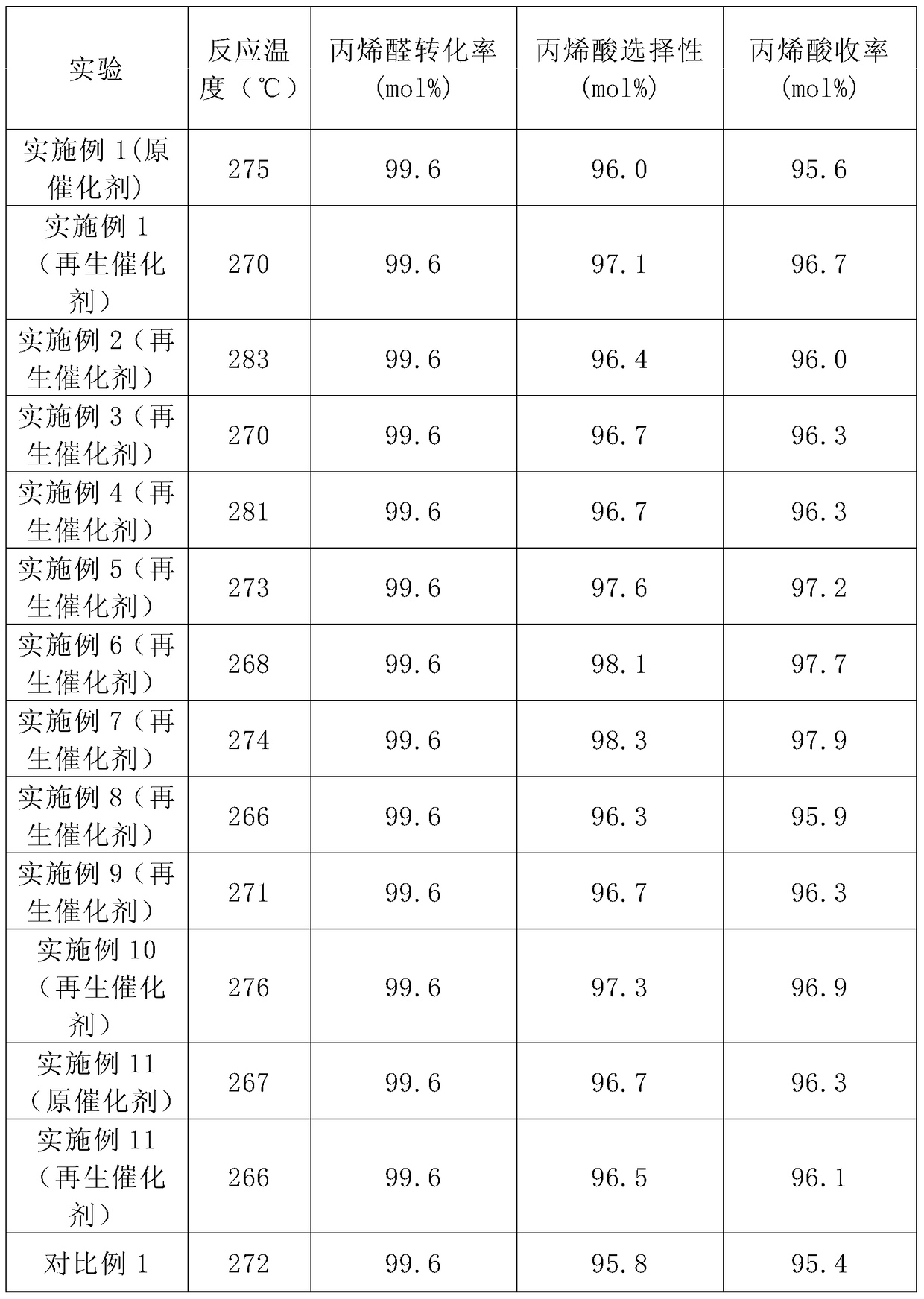

[0105] The evaluation results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com