Calibration device and method

A technology of a calibration device and a calibration method, which is applied in the direction of metal processing equipment, measuring/indicating equipment, metal processing machinery parts, etc., can solve problems such as the influence of processing operation accuracy, and achieve the effect of avoiding tilt and ensuring correctness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

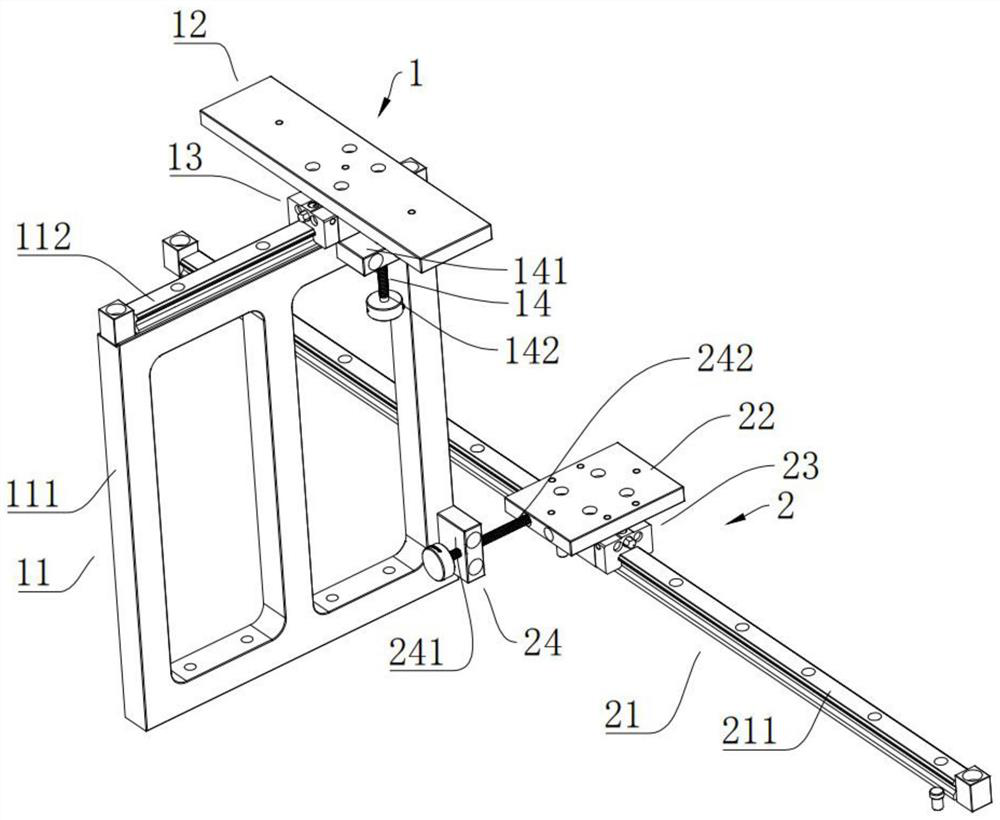

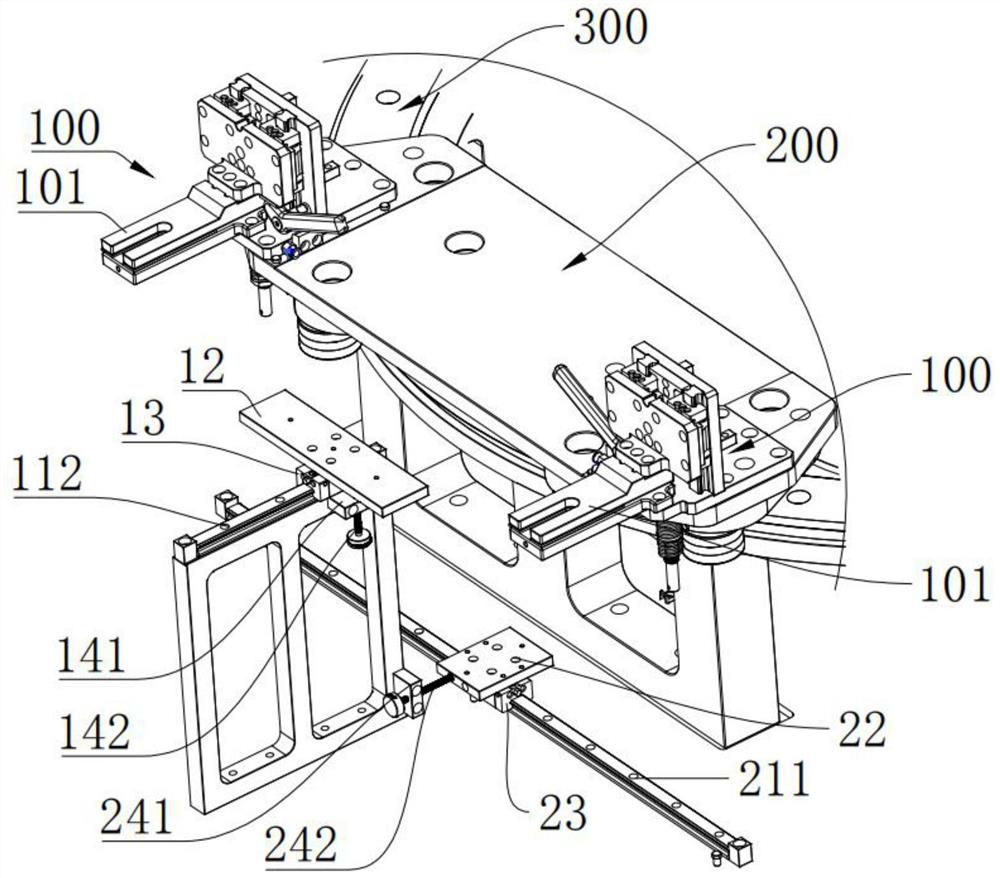

[0033] refer to figure 1 , figure 1 It is a structural schematic diagram of the calibration device in the first embodiment. The calibration device in this embodiment includes a horizontal calibration mechanism 1 . The horizontal calibration mechanism 1 includes a first bearing component 11 , a horizontal reference component 12 and a horizontal installation component 13 . The horizontal reference component 12 is disposed on the first carrier component 11 through the horizontal installation component 13 . The horizontal installation assembly 13 is used for the horizontal installation of the horizontal reference assembly 12, so that the horizontal reference assembly 12 is in a horizontal state, and the workpiece is horizontally calibrated with the horizontal reference assembly 12 as a reference.

[0034] Through the cooperation of the first bearing assembly 11, the horizontal reference assembly 12 and the horizontal installation assembly 13, the horizontal state of the horizon...

Embodiment 2

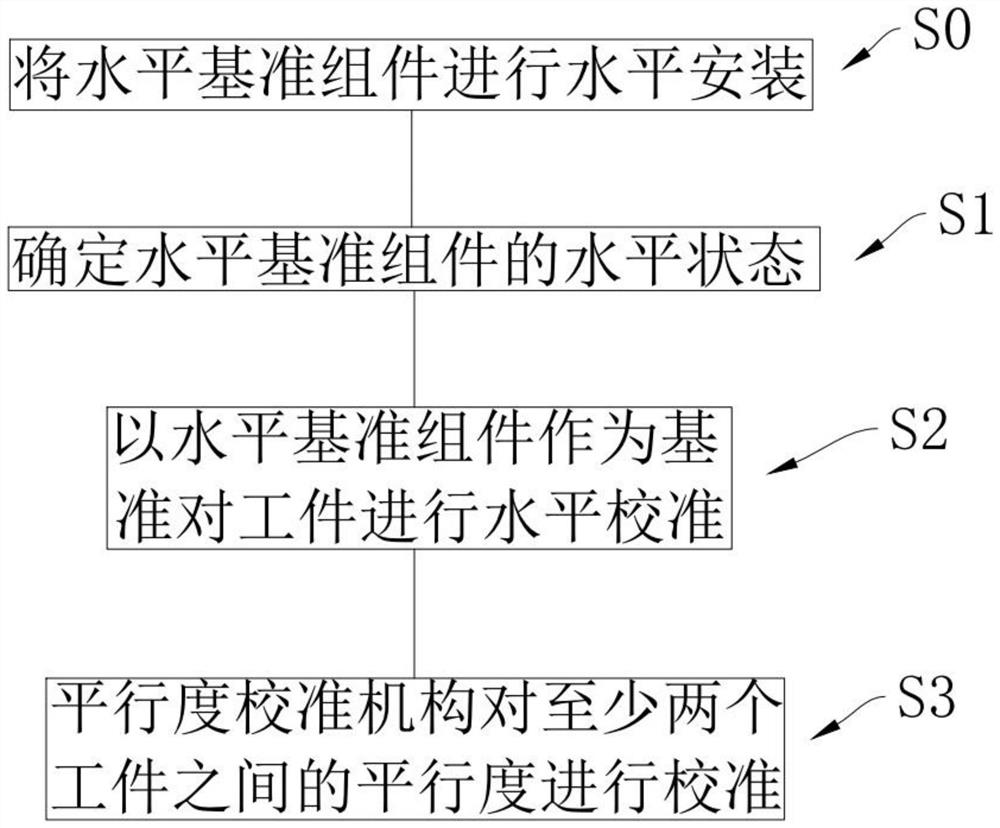

[0048] refer to image 3 , image 3 It is a flowchart of the calibration method in the second embodiment. The calibration method in this embodiment can be realized by the calibration device in Embodiment 1, which specifically includes the following steps:

[0049] S1, determining the horizontal state of the horizontal reference component 12 .

[0050] S2, the workpiece is horizontally calibrated using the horizontal reference assembly 12 as a reference.

[0051] By first establishing the horizontal state of the horizontal reference assembly 12, and then performing precise horizontal calibration on the workpiece with the horizontal reference assembly 12 as a reference, the posture of the workpiece is avoided from tilting, thereby ensuring the correctness of the posture of the workpiece carrying the product.

[0052] Preferably, the calibration method in this embodiment also includes:

[0053] S3, the parallelism calibration mechanism 2 calibrates the parallelism between at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com