Achieving Perfect Uniformity in Mini LED Screens

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mini LED Technology Background and Objectives

Mini LED technology represents a significant advancement in display technology, bridging the gap between traditional LED backlighting and the more advanced Micro LED displays. Emerging in the mid-2010s, Mini LEDs are semiconductor light sources with dimensions typically ranging from 100 to 200 micrometers, substantially smaller than conventional LEDs but larger than Micro LEDs. This technology has evolved from the broader LED industry's continuous pursuit of miniaturization and enhanced performance characteristics.

The evolution of Mini LED technology has been driven by the limitations of existing display technologies. Traditional LCD displays with conventional LED backlighting suffer from limited contrast ratios and imprecise local dimming capabilities. OLED displays, while offering superior contrast and color reproduction, face challenges related to brightness limitations, burn-in issues, and production costs. Mini LED technology emerged as a solution that combines the brightness and longevity advantages of LEDs with improved contrast ratios through more precise local dimming zones.

The primary objective in Mini LED development is achieving perfect uniformity across the display panel. Uniformity refers to the consistency of brightness, color, and contrast across the entire screen surface. Non-uniformity manifests as visible hotspots, dark regions, or color variations that significantly degrade viewing experience and display quality. As display resolutions increase and applications become more demanding, the tolerance for such imperfections has dramatically decreased.

Technical objectives for Mini LED uniformity include eliminating brightness variations between adjacent Mini LEDs, ensuring consistent color temperature across the panel, minimizing the "halo effect" around bright objects on dark backgrounds, and maintaining uniformity throughout the display's operational lifetime. These objectives are particularly challenging due to the inherent variability in semiconductor manufacturing processes and the complex thermal and electrical behaviors of densely packed Mini LED arrays.

The industry has established specific metrics for measuring and quantifying display uniformity, including brightness uniformity ratio, color deviation (ΔE), and mura detection standards. Meeting these increasingly stringent requirements necessitates innovations across the entire Mini LED supply chain, from chip manufacturing to panel assembly and control algorithms.

Recent technological milestones include the development of mass transfer techniques for precise LED placement, advanced driver ICs capable of individual LED control, and sophisticated compensation algorithms that can correct for manufacturing variations. The ultimate goal is to create Mini LED displays that offer perfect visual uniformity indistinguishable from ideal display conditions, while maintaining the technology's advantages in brightness, contrast ratio, and energy efficiency.

The evolution of Mini LED technology has been driven by the limitations of existing display technologies. Traditional LCD displays with conventional LED backlighting suffer from limited contrast ratios and imprecise local dimming capabilities. OLED displays, while offering superior contrast and color reproduction, face challenges related to brightness limitations, burn-in issues, and production costs. Mini LED technology emerged as a solution that combines the brightness and longevity advantages of LEDs with improved contrast ratios through more precise local dimming zones.

The primary objective in Mini LED development is achieving perfect uniformity across the display panel. Uniformity refers to the consistency of brightness, color, and contrast across the entire screen surface. Non-uniformity manifests as visible hotspots, dark regions, or color variations that significantly degrade viewing experience and display quality. As display resolutions increase and applications become more demanding, the tolerance for such imperfections has dramatically decreased.

Technical objectives for Mini LED uniformity include eliminating brightness variations between adjacent Mini LEDs, ensuring consistent color temperature across the panel, minimizing the "halo effect" around bright objects on dark backgrounds, and maintaining uniformity throughout the display's operational lifetime. These objectives are particularly challenging due to the inherent variability in semiconductor manufacturing processes and the complex thermal and electrical behaviors of densely packed Mini LED arrays.

The industry has established specific metrics for measuring and quantifying display uniformity, including brightness uniformity ratio, color deviation (ΔE), and mura detection standards. Meeting these increasingly stringent requirements necessitates innovations across the entire Mini LED supply chain, from chip manufacturing to panel assembly and control algorithms.

Recent technological milestones include the development of mass transfer techniques for precise LED placement, advanced driver ICs capable of individual LED control, and sophisticated compensation algorithms that can correct for manufacturing variations. The ultimate goal is to create Mini LED displays that offer perfect visual uniformity indistinguishable from ideal display conditions, while maintaining the technology's advantages in brightness, contrast ratio, and energy efficiency.

Market Demand Analysis for High-Uniformity Displays

The demand for high-uniformity displays has witnessed exponential growth across multiple sectors in recent years. This surge is primarily driven by the increasing consumer expectations for premium visual experiences in both professional and personal devices. Market research indicates that the global high-end display market, where uniformity is a critical factor, is expanding at a compound annual growth rate of approximately 15%, significantly outpacing the overall display market growth.

Consumer electronics represents the largest segment driving this demand, with high-end smartphones, tablets, and laptops requiring displays that deliver consistent brightness and color across the entire screen. The premium smartphone market particularly values display uniformity as a differentiating feature, with manufacturers competing intensely on visual performance metrics.

The professional market segment presents another substantial demand vector. Content creation industries including film production, photography, graphic design, and digital art require displays with exceptional uniformity for color-critical work. Medical imaging represents a specialized but high-value segment where display uniformity directly impacts diagnostic accuracy, with regulatory requirements increasingly specifying uniformity standards.

Emerging technologies are further amplifying market demand for uniform displays. Virtual reality and augmented reality applications require exceptional display uniformity to maintain immersion and prevent user discomfort. The automotive industry's shift toward digital dashboards and entertainment systems has created another growth segment where uniformity across curved and irregular display surfaces presents unique challenges.

Regional analysis reveals that East Asian markets, particularly Japan and South Korea, demonstrate the highest consumer sensitivity to display uniformity issues, followed by North American and European markets. This regional variation influences product development strategies for global manufacturers.

Price sensitivity analysis indicates that consumers are increasingly willing to pay premium prices for displays with superior uniformity characteristics. This trend is most pronounced in the professional and prosumer segments but is gradually extending to mainstream consumer products as awareness of display quality metrics grows.

Market forecasts suggest that Mini LED technology, with its potential to deliver superior uniformity compared to conventional LCD displays, could capture a significant market share in the premium display segment within the next five years. The technology's ability to address the uniformity challenges while offering other benefits such as improved contrast and energy efficiency positions it favorably against competing technologies like OLED and Micro LED in certain application segments.

Consumer electronics represents the largest segment driving this demand, with high-end smartphones, tablets, and laptops requiring displays that deliver consistent brightness and color across the entire screen. The premium smartphone market particularly values display uniformity as a differentiating feature, with manufacturers competing intensely on visual performance metrics.

The professional market segment presents another substantial demand vector. Content creation industries including film production, photography, graphic design, and digital art require displays with exceptional uniformity for color-critical work. Medical imaging represents a specialized but high-value segment where display uniformity directly impacts diagnostic accuracy, with regulatory requirements increasingly specifying uniformity standards.

Emerging technologies are further amplifying market demand for uniform displays. Virtual reality and augmented reality applications require exceptional display uniformity to maintain immersion and prevent user discomfort. The automotive industry's shift toward digital dashboards and entertainment systems has created another growth segment where uniformity across curved and irregular display surfaces presents unique challenges.

Regional analysis reveals that East Asian markets, particularly Japan and South Korea, demonstrate the highest consumer sensitivity to display uniformity issues, followed by North American and European markets. This regional variation influences product development strategies for global manufacturers.

Price sensitivity analysis indicates that consumers are increasingly willing to pay premium prices for displays with superior uniformity characteristics. This trend is most pronounced in the professional and prosumer segments but is gradually extending to mainstream consumer products as awareness of display quality metrics grows.

Market forecasts suggest that Mini LED technology, with its potential to deliver superior uniformity compared to conventional LCD displays, could capture a significant market share in the premium display segment within the next five years. The technology's ability to address the uniformity challenges while offering other benefits such as improved contrast and energy efficiency positions it favorably against competing technologies like OLED and Micro LED in certain application segments.

Current Uniformity Challenges in Mini LED Technology

Despite significant advancements in Mini LED technology, achieving perfect uniformity across displays remains one of the most persistent challenges facing manufacturers today. The primary issue stems from inherent variations in LED brightness and color characteristics, even within the same production batch. These variations become particularly problematic when thousands of Mini LEDs are packed into a single display panel, creating noticeable inconsistencies in brightness and color that detract from the viewing experience.

The manufacturing process itself introduces several uniformity challenges. During the mass transfer process, where thousands of Mini LED chips are simultaneously placed onto the backplane, positioning errors as small as a few microns can lead to significant uniformity issues. These errors affect not only the physical placement but also the electrical connections and thermal interfaces, resulting in inconsistent performance across the display.

Thermal management presents another critical uniformity challenge. Mini LEDs generate heat during operation, and uneven heat distribution across the panel can cause differential aging and performance degradation. Areas of the display that consistently run hotter may experience accelerated brightness decay compared to cooler regions, gradually worsening uniformity over the product's lifetime.

Current driving circuits also contribute significantly to uniformity problems. Traditional passive matrix driving schemes struggle to deliver precisely consistent current to each Mini LED in large arrays. Even advanced active matrix systems face challenges in maintaining uniform electrical characteristics across thousands of thin-film transistors (TFTs) that control individual LEDs.

The binning process, where LEDs are sorted based on brightness and color characteristics, has limitations in achieving perfect uniformity. While manufacturers typically sort LEDs into bins with similar specifications, the granularity of these bins is constrained by economic factors. Finer binning would improve uniformity but dramatically increase production costs and complexity.

Optical components in the display stack further complicate uniformity issues. Light diffusers, color filters, and polarizers can introduce their own variations or may not perfectly compensate for the inherent non-uniformities of the Mini LED array. The interaction between these optical elements and the Mini LED light sources creates complex patterns that are difficult to predict and correct.

Current compensation algorithms attempt to address these issues through calibration and real-time adjustments, but they face fundamental limitations. These software solutions can only partially mitigate hardware-based non-uniformities and often come with tradeoffs in terms of power consumption, processing requirements, and dynamic range. Additionally, as displays age, the effectiveness of initial calibration diminishes, requiring more sophisticated adaptive compensation techniques.

The manufacturing process itself introduces several uniformity challenges. During the mass transfer process, where thousands of Mini LED chips are simultaneously placed onto the backplane, positioning errors as small as a few microns can lead to significant uniformity issues. These errors affect not only the physical placement but also the electrical connections and thermal interfaces, resulting in inconsistent performance across the display.

Thermal management presents another critical uniformity challenge. Mini LEDs generate heat during operation, and uneven heat distribution across the panel can cause differential aging and performance degradation. Areas of the display that consistently run hotter may experience accelerated brightness decay compared to cooler regions, gradually worsening uniformity over the product's lifetime.

Current driving circuits also contribute significantly to uniformity problems. Traditional passive matrix driving schemes struggle to deliver precisely consistent current to each Mini LED in large arrays. Even advanced active matrix systems face challenges in maintaining uniform electrical characteristics across thousands of thin-film transistors (TFTs) that control individual LEDs.

The binning process, where LEDs are sorted based on brightness and color characteristics, has limitations in achieving perfect uniformity. While manufacturers typically sort LEDs into bins with similar specifications, the granularity of these bins is constrained by economic factors. Finer binning would improve uniformity but dramatically increase production costs and complexity.

Optical components in the display stack further complicate uniformity issues. Light diffusers, color filters, and polarizers can introduce their own variations or may not perfectly compensate for the inherent non-uniformities of the Mini LED array. The interaction between these optical elements and the Mini LED light sources creates complex patterns that are difficult to predict and correct.

Current compensation algorithms attempt to address these issues through calibration and real-time adjustments, but they face fundamental limitations. These software solutions can only partially mitigate hardware-based non-uniformities and often come with tradeoffs in terms of power consumption, processing requirements, and dynamic range. Additionally, as displays age, the effectiveness of initial calibration diminishes, requiring more sophisticated adaptive compensation techniques.

Current Uniformity Enhancement Solutions

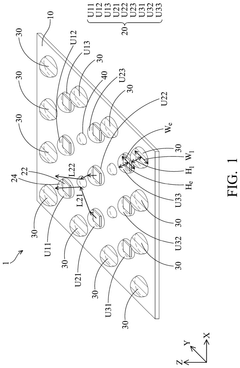

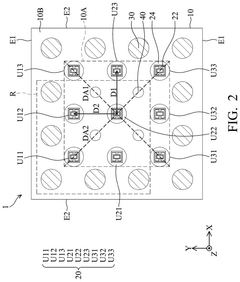

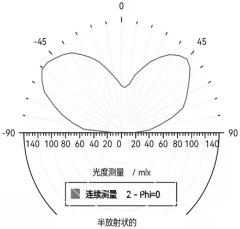

01 Backlight uniformity control for Mini LED displays

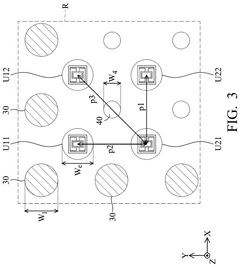

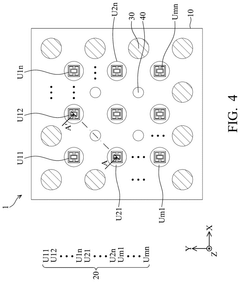

Various technologies are employed to ensure uniform brightness across Mini LED backlight displays. These include optimized LED arrangement patterns, specialized diffuser plates, and local dimming control algorithms that compensate for brightness variations. These methods help eliminate hotspots and dark areas, resulting in consistent illumination across the entire screen surface.- Backlight uniformity control for Mini LED displays: Various technologies are employed to ensure uniform brightness across Mini LED screens. These include optimized LED arrangement patterns, specialized diffuser plates, and local dimming control algorithms that adjust individual LED zones. These methods help eliminate hotspots and dark areas, resulting in consistent illumination across the entire display surface.

- Color uniformity enhancement techniques: Color consistency across Mini LED screens is achieved through color calibration systems, compensation algorithms, and specialized optical films. These technologies correct color variations between individual LEDs, ensuring consistent color reproduction across the entire display. Advanced color management systems analyze and adjust color parameters in real-time to maintain uniformity under different operating conditions.

- Thermal management for display uniformity: Thermal solutions are critical for maintaining Mini LED screen uniformity, as temperature variations can affect LED performance. Heat dissipation structures, thermal conductive materials, and active cooling systems help maintain consistent operating temperatures across the display. These thermal management approaches prevent brightness and color shifts that would otherwise occur due to temperature gradients.

- Manufacturing processes for uniform Mini LED panels: Specialized manufacturing techniques ensure uniformity in Mini LED displays from production. These include precision mounting methods, automated optical inspection systems, and statistical process control. Advanced bonding technologies and substrate materials are employed to maintain consistent LED positioning and electrical characteristics, which directly impact display uniformity.

- Optical film structures for light distribution: Multi-layer optical film stacks are designed to enhance Mini LED screen uniformity through controlled light diffusion and distribution. These include specialized diffuser films, brightness enhancement films, and light guide plates that work together to spread light evenly across the display surface. The optical structures help eliminate visible LED patterns and ensure consistent luminance across viewing angles.

02 Color uniformity enhancement techniques

Color uniformity in Mini LED screens is achieved through precise color calibration systems, color temperature adjustment algorithms, and specialized optical films. These technologies work together to minimize color shifts across the display and ensure consistent color reproduction from edge to edge, which is particularly important for high-end display applications requiring color accuracy.Expand Specific Solutions03 Thermal management for uniformity preservation

Thermal management systems are critical for maintaining Mini LED screen uniformity over time. These include heat dissipation structures, temperature sensors, and thermal compensation algorithms that adjust LED performance based on temperature variations. By preventing thermal gradients across the display, these systems ensure consistent brightness and color performance even during extended operation.Expand Specific Solutions04 Optical film and diffuser technologies

Specialized optical films and diffuser technologies are employed to enhance Mini LED screen uniformity. These include multi-layer diffuser structures, light guide plates with optimized patterns, and micro-lens arrays that help distribute light evenly across the display surface. These optical components minimize the visibility of individual LED light sources and create a more uniform viewing experience.Expand Specific Solutions05 Driving circuit and signal processing for uniformity

Advanced driving circuits and signal processing algorithms are implemented to improve Mini LED screen uniformity. These include compensation circuits that adjust individual LED brightness based on real-time measurements, gamma correction techniques, and precision current control systems. These electronic solutions help overcome manufacturing variations in LED components and ensure consistent performance across the entire display.Expand Specific Solutions

Key Industry Players in Mini LED Manufacturing

The Mini LED screen uniformity market is in a growth phase, with increasing demand driven by consumer electronics applications. The market is expected to reach significant scale as technology matures from current early-commercial stage to mainstream adoption. Key players include BOE Technology Group and TCL subsidiaries (China Star Optoelectronics) leading in display manufacturing, while specialized companies like Xian NovaStar Tech and Refond Optoelectronics focus on control systems and LED packaging respectively. Apple's entry has accelerated market development, with Chinese manufacturers like Magicray developing specialized inspection equipment. Technical challenges in achieving perfect uniformity remain, creating competitive differentiation opportunities as companies balance cost with performance in this rapidly evolving segment.

BOE Technology Group Co., Ltd.

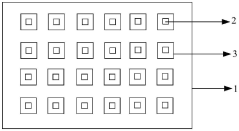

Technical Solution: BOE has developed a comprehensive Mini LED backlight solution that addresses uniformity challenges through a multi-layered approach. Their technology employs advanced chip-scale packaging (CSP) with precise die-attach processes that maintain positional accuracy within ±10μm[1]. BOE's Active Matrix driving technology enables individual control of thousands of Mini LED zones with 16-bit grayscale precision, allowing for real-time compensation of brightness variations. Their proprietary optical design incorporates specialized diffuser films and light guide plates that work together to eliminate hotspots and ensure uniform light distribution across the entire display surface. Additionally, BOE implements an AI-driven calibration system that uses high-precision cameras to detect brightness inconsistencies during manufacturing, creating compensation maps that are stored in each panel's firmware to dynamically adjust LED current based on temperature and aging factors[2].

Strengths: BOE's solution offers exceptional local dimming capabilities with over 2000 dimming zones, providing superior contrast ratio and HDR performance. Their AI calibration system ensures long-term uniformity maintenance even as LEDs age differently. Weaknesses: The complex multi-zone control system requires sophisticated thermal management to prevent temperature-induced variations, and the high-precision manufacturing processes result in higher production costs compared to conventional LCD technologies.

Apple, Inc.

Technical Solution: Apple has developed a sophisticated Mini LED uniformity solution for their high-end displays branded as "Liquid Retina XDR." Their approach combines hardware precision with advanced software algorithms to achieve exceptional brightness uniformity. At the hardware level, Apple employs custom-designed Mini LEDs with tightly controlled specifications and a proprietary mounting technique that ensures consistent height and orientation across thousands of LEDs[5]. Their system features over 10,000 Mini LEDs organized into more than 2,500 individually controlled dimming zones. Apple's solution includes a multi-layer optical stack with specialized diffuser films that have been computationally optimized to eliminate hotspots while maintaining high optical efficiency. The most distinctive aspect of Apple's approach is their advanced calibration system that combines factory-time and real-time compensation. During manufacturing, each display undergoes precision photometric mapping, generating a unique compensation profile. During operation, temperature sensors continuously monitor the display and adjust LED currents to maintain uniformity as thermal conditions change[6]. Apple also implements sophisticated algorithms that analyze on-screen content to predict and prevent potential uniformity issues before they become visible.

Strengths: Apple's solution achieves exceptional brightness uniformity while maintaining industry-leading 1,000,000:1 contrast ratio and peak brightness of 1,600 nits. Their real-time thermal compensation ensures consistent performance regardless of usage conditions. Weaknesses: The complex system requires significant processing power for the real-time compensation algorithms, and the high component count contributes to premium pricing and potential reliability challenges over extended use.

Critical Patents and Innovations in Uniformity Control

Light-emitting device and display device including the same

PatentPendingUS20250169249A1

Innovation

- A light-emitting device is designed with a substrate, a light-emitting array, and a plurality of first color conversion points. The light-emitting array consists of light-emitting units with LED dies and encapsulating portions, while the color conversion points, made of a wavelength conversion material, surround the array to enhance brightness and color uniformity.

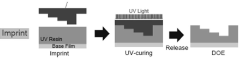

MiniLED structure capable of improving light emitting uniformity

PatentActiveCN220753466U

Innovation

- A rectangular ink frame is made on the substrate and connected to the LED light chip. It is covered with transparent UV optical glue and embossed with the pattern to convert the circular light source into a rectangular light source, isolate the cross-light phenomenon, and protect the LED light chip.

Manufacturing Process Optimization Strategies

Manufacturing process optimization represents a critical frontier in achieving perfect uniformity in Mini LED screens. Current manufacturing processes face significant challenges in maintaining consistent quality across large production volumes. The primary optimization strategies focus on enhancing precision control at each manufacturing stage, from chip fabrication to final assembly.

Advanced epitaxial growth techniques have emerged as fundamental optimization approaches. By implementing temperature gradient control systems during the Metal-Organic Chemical Vapor Deposition (MOCVD) process, manufacturers can achieve more uniform crystal growth, resulting in LEDs with consistent electrical and optical properties. Statistical Process Control (SPC) methodologies integrated with real-time monitoring systems enable immediate adjustments to growth parameters, reducing batch-to-batch variations significantly.

Transfer processes represent another critical optimization area. The implementation of high-precision pick-and-place equipment with optical recognition systems has improved placement accuracy to within ±5μm. Advanced vacuum handling systems minimize physical stress on the chips during transfer, reducing defect rates by approximately 30% compared to conventional methods.

Bonding optimization strategies have evolved to address uniformity challenges at the connection level. Pulse-heated thermocompression bonding techniques provide more consistent thermal profiles across the substrate, while pressure distribution systems ensure uniform force application during the bonding process. These improvements have reduced connection failures by up to 40% in high-volume production environments.

Automated optical inspection (AOI) systems integrated directly into production lines represent a transformative optimization strategy. These systems employ machine learning algorithms to detect subtle uniformity variations that might escape traditional quality control measures. The implementation of closed-loop feedback mechanisms allows for real-time process adjustments based on inspection results, creating a self-correcting manufacturing ecosystem.

Material consistency management has emerged as a crucial optimization factor. Implementing strict supplier qualification processes and incoming material verification protocols ensures that raw materials meet precise specifications. Advanced material characterization techniques, including X-ray diffraction and spectroscopic analysis, help identify potential uniformity issues before materials enter the production process.

Environmental control systems throughout the manufacturing facility provide stable temperature, humidity, and particulate levels, eliminating external variables that could affect uniformity. Clean room classification upgrades from ISO Class 7 to ISO Class 5 have demonstrated measurable improvements in yield rates for high-density Mini LED arrays, particularly for premium display applications requiring perfect uniformity.

Advanced epitaxial growth techniques have emerged as fundamental optimization approaches. By implementing temperature gradient control systems during the Metal-Organic Chemical Vapor Deposition (MOCVD) process, manufacturers can achieve more uniform crystal growth, resulting in LEDs with consistent electrical and optical properties. Statistical Process Control (SPC) methodologies integrated with real-time monitoring systems enable immediate adjustments to growth parameters, reducing batch-to-batch variations significantly.

Transfer processes represent another critical optimization area. The implementation of high-precision pick-and-place equipment with optical recognition systems has improved placement accuracy to within ±5μm. Advanced vacuum handling systems minimize physical stress on the chips during transfer, reducing defect rates by approximately 30% compared to conventional methods.

Bonding optimization strategies have evolved to address uniformity challenges at the connection level. Pulse-heated thermocompression bonding techniques provide more consistent thermal profiles across the substrate, while pressure distribution systems ensure uniform force application during the bonding process. These improvements have reduced connection failures by up to 40% in high-volume production environments.

Automated optical inspection (AOI) systems integrated directly into production lines represent a transformative optimization strategy. These systems employ machine learning algorithms to detect subtle uniformity variations that might escape traditional quality control measures. The implementation of closed-loop feedback mechanisms allows for real-time process adjustments based on inspection results, creating a self-correcting manufacturing ecosystem.

Material consistency management has emerged as a crucial optimization factor. Implementing strict supplier qualification processes and incoming material verification protocols ensures that raw materials meet precise specifications. Advanced material characterization techniques, including X-ray diffraction and spectroscopic analysis, help identify potential uniformity issues before materials enter the production process.

Environmental control systems throughout the manufacturing facility provide stable temperature, humidity, and particulate levels, eliminating external variables that could affect uniformity. Clean room classification upgrades from ISO Class 7 to ISO Class 5 have demonstrated measurable improvements in yield rates for high-density Mini LED arrays, particularly for premium display applications requiring perfect uniformity.

Quality Control and Testing Methodologies

Quality control and testing methodologies represent critical components in achieving perfect uniformity in Mini LED screens. The manufacturing process requires rigorous inspection protocols at multiple stages to ensure consistent brightness, color accuracy, and overall display performance. Automated optical inspection (AOI) systems have emerged as the industry standard, utilizing high-resolution cameras and advanced image processing algorithms to detect defects as small as 10 micrometers. These systems can identify issues such as dead pixels, brightness variations, and color inconsistencies at production speeds exceeding 60 panels per hour.

Statistical Process Control (SPC) methodologies have been adapted specifically for Mini LED production, with manufacturers implementing control charts that monitor key uniformity parameters in real-time. This approach enables early detection of process drift before it results in visible uniformity issues. Leading manufacturers typically maintain process capability indices (Cpk) above 1.33 for critical uniformity parameters, ensuring consistent quality across production batches.

Spectroradiometric testing has evolved significantly to address the unique challenges of Mini LED displays. Modern testing equipment can now measure luminance uniformity across thousands of zones with precision better than ±2%. Color uniformity testing has similarly advanced, with Delta-E measurements below 1.5 becoming the industry benchmark for premium displays. These measurements are typically conducted at multiple brightness levels to ensure uniformity across the entire operating range.

Accelerated aging tests have been developed to predict long-term uniformity performance. These tests subject Mini LED panels to elevated temperatures and humidity levels while cycling through various brightness patterns. The industry standard now includes 1,000-hour testing protocols that can identify potential uniformity degradation that might occur after years of normal use. Manufacturers use these results to refine their LED binning strategies and driver circuit designs.

Emerging technologies in quality control include AI-powered defect classification systems that can distinguish between critical uniformity issues and minor cosmetic defects. These systems reduce false rejection rates while ensuring no significant uniformity problems reach consumers. Additionally, quantum efficiency testing at the individual LED level has become more accessible, allowing manufacturers to better match LEDs with similar performance characteristics before panel assembly.

The integration of these quality control methodologies throughout the production process has significantly improved yield rates, with leading manufacturers reporting defect rates below 0.5% for uniformity-related issues. This systematic approach to testing and quality control represents a critical enabler for the continued advancement and market adoption of Mini LED display technology.

Statistical Process Control (SPC) methodologies have been adapted specifically for Mini LED production, with manufacturers implementing control charts that monitor key uniformity parameters in real-time. This approach enables early detection of process drift before it results in visible uniformity issues. Leading manufacturers typically maintain process capability indices (Cpk) above 1.33 for critical uniformity parameters, ensuring consistent quality across production batches.

Spectroradiometric testing has evolved significantly to address the unique challenges of Mini LED displays. Modern testing equipment can now measure luminance uniformity across thousands of zones with precision better than ±2%. Color uniformity testing has similarly advanced, with Delta-E measurements below 1.5 becoming the industry benchmark for premium displays. These measurements are typically conducted at multiple brightness levels to ensure uniformity across the entire operating range.

Accelerated aging tests have been developed to predict long-term uniformity performance. These tests subject Mini LED panels to elevated temperatures and humidity levels while cycling through various brightness patterns. The industry standard now includes 1,000-hour testing protocols that can identify potential uniformity degradation that might occur after years of normal use. Manufacturers use these results to refine their LED binning strategies and driver circuit designs.

Emerging technologies in quality control include AI-powered defect classification systems that can distinguish between critical uniformity issues and minor cosmetic defects. These systems reduce false rejection rates while ensuring no significant uniformity problems reach consumers. Additionally, quantum efficiency testing at the individual LED level has become more accessible, allowing manufacturers to better match LEDs with similar performance characteristics before panel assembly.

The integration of these quality control methodologies throughout the production process has significantly improved yield rates, with leading manufacturers reporting defect rates below 0.5% for uniformity-related issues. This systematic approach to testing and quality control represents a critical enabler for the continued advancement and market adoption of Mini LED display technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!