Adaptation of Carbon-negative Concrete in High-temperature Applications

OCT 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon-negative Concrete Evolution and Objectives

Carbon-negative concrete represents a revolutionary advancement in construction materials, emerging as a response to the significant carbon footprint of traditional concrete production. The evolution of this technology can be traced back to early research in the 2000s, when scientists began exploring alternative cementitious materials with lower environmental impacts. By 2010, the first commercially viable carbon-negative concrete formulations appeared, utilizing industrial byproducts like fly ash and slag as partial replacements for Portland cement.

The technological trajectory accelerated significantly between 2015 and 2020, with breakthroughs in carbon capture and utilization (CCU) techniques that allowed CO2 to be permanently sequestered within concrete during the curing process. This innovation transformed concrete from a carbon source to a carbon sink, capable of storing CO2 for the lifetime of the structure. Recent developments have focused on enhancing the mechanical properties and durability of these formulations, addressing initial concerns about strength and longevity.

Current carbon-negative concrete technologies primarily employ three approaches: CO2 mineralization, alternative binding materials, and supplementary cementitious materials. These methods have demonstrated carbon reductions of 5-30% compared to traditional concrete, with some advanced formulations achieving net negative emissions of up to 100-150 kg CO2 per cubic meter of concrete.

However, the adaptation of carbon-negative concrete for high-temperature applications presents unique challenges. Traditional carbon-negative formulations often exhibit reduced thermal stability compared to conventional concrete, limiting their use in environments exceeding 300°C. This constraint has restricted their application in industrial settings such as foundries, power plants, and certain manufacturing facilities where exposure to elevated temperatures is common.

The primary technical objective for high-temperature carbon-negative concrete development is to maintain carbon sequestration capabilities while enhancing thermal resistance to withstand temperatures of 600-1000°C without significant degradation. Secondary objectives include ensuring comparable or superior mechanical properties, achieving cost parity with specialized high-temperature conventional concretes, and developing scalable manufacturing processes.

Research trends indicate growing interest in incorporating novel materials such as geopolymers, ceramic waste, and advanced nano-additives to enhance the thermal properties of carbon-negative concrete. The integration of phase-change materials and thermally resistant fibers represents another promising direction. Global research efforts are increasingly focused on developing formulations that can maintain structural integrity during thermal cycling while preserving the environmental benefits of carbon sequestration.

The technological trajectory accelerated significantly between 2015 and 2020, with breakthroughs in carbon capture and utilization (CCU) techniques that allowed CO2 to be permanently sequestered within concrete during the curing process. This innovation transformed concrete from a carbon source to a carbon sink, capable of storing CO2 for the lifetime of the structure. Recent developments have focused on enhancing the mechanical properties and durability of these formulations, addressing initial concerns about strength and longevity.

Current carbon-negative concrete technologies primarily employ three approaches: CO2 mineralization, alternative binding materials, and supplementary cementitious materials. These methods have demonstrated carbon reductions of 5-30% compared to traditional concrete, with some advanced formulations achieving net negative emissions of up to 100-150 kg CO2 per cubic meter of concrete.

However, the adaptation of carbon-negative concrete for high-temperature applications presents unique challenges. Traditional carbon-negative formulations often exhibit reduced thermal stability compared to conventional concrete, limiting their use in environments exceeding 300°C. This constraint has restricted their application in industrial settings such as foundries, power plants, and certain manufacturing facilities where exposure to elevated temperatures is common.

The primary technical objective for high-temperature carbon-negative concrete development is to maintain carbon sequestration capabilities while enhancing thermal resistance to withstand temperatures of 600-1000°C without significant degradation. Secondary objectives include ensuring comparable or superior mechanical properties, achieving cost parity with specialized high-temperature conventional concretes, and developing scalable manufacturing processes.

Research trends indicate growing interest in incorporating novel materials such as geopolymers, ceramic waste, and advanced nano-additives to enhance the thermal properties of carbon-negative concrete. The integration of phase-change materials and thermally resistant fibers represents another promising direction. Global research efforts are increasingly focused on developing formulations that can maintain structural integrity during thermal cycling while preserving the environmental benefits of carbon sequestration.

Market Analysis for Heat-resistant Green Concrete

The global market for heat-resistant green concrete is experiencing significant growth, driven by increasing environmental regulations and the construction industry's push towards sustainability. Current market size for specialized concrete products is estimated at $395 billion globally, with heat-resistant variants representing approximately 8% of this segment. The compound annual growth rate (CAGR) for heat-resistant green concrete specifically is projected at 6.7% through 2030, outpacing traditional concrete products by nearly 2 percentage points.

Demand is particularly strong in regions with extreme climate conditions and stringent environmental regulations. North America and Europe currently lead adoption rates, accounting for 62% of market share, while the Asia-Pacific region shows the fastest growth trajectory at 9.3% annually. This regional disparity creates distinct market entry opportunities based on local regulatory frameworks and climate requirements.

By application segment, industrial facilities represent the largest market share (43%), followed by infrastructure projects (27%) and commercial buildings (21%). The remaining 9% encompasses specialized applications including data centers, which are emerging as a high-growth niche due to increasing heat management challenges in computing facilities.

Key market drivers include tightening carbon emission regulations, with over 70 countries implementing concrete-specific environmental standards since 2020. Additionally, rising global temperatures have expanded the geographical regions requiring heat-resistant building materials by approximately 15% in the past decade. The insurance industry has also become an influential market force, with premium reductions of up to 18% available for structures utilizing fire-resistant and environmentally sustainable materials.

Customer willingness to pay premium prices for green concrete varies significantly by sector. Government infrastructure projects demonstrate the highest price tolerance (22-30% premium), while commercial developers typically accept 10-15% higher costs when lifecycle benefits can be demonstrated. Residential applications remain price-sensitive, with acceptance thresholds below 8% premium over traditional concrete.

Market barriers include higher initial production costs, limited awareness among end-users, and technical challenges in maintaining carbon-negative properties while enhancing heat resistance. The supply chain also presents challenges, with specialized aggregate materials facing availability constraints in certain regions, creating price volatility of up to 35% in some markets.

Future market growth will likely be influenced by evolving building codes, with 23 countries currently developing standards specifically addressing heat resistance requirements for sustainable concrete. Additionally, carbon pricing mechanisms are expected to improve the competitive position of carbon-negative concrete products, potentially expanding market share by an additional 12-15% by 2028.

Demand is particularly strong in regions with extreme climate conditions and stringent environmental regulations. North America and Europe currently lead adoption rates, accounting for 62% of market share, while the Asia-Pacific region shows the fastest growth trajectory at 9.3% annually. This regional disparity creates distinct market entry opportunities based on local regulatory frameworks and climate requirements.

By application segment, industrial facilities represent the largest market share (43%), followed by infrastructure projects (27%) and commercial buildings (21%). The remaining 9% encompasses specialized applications including data centers, which are emerging as a high-growth niche due to increasing heat management challenges in computing facilities.

Key market drivers include tightening carbon emission regulations, with over 70 countries implementing concrete-specific environmental standards since 2020. Additionally, rising global temperatures have expanded the geographical regions requiring heat-resistant building materials by approximately 15% in the past decade. The insurance industry has also become an influential market force, with premium reductions of up to 18% available for structures utilizing fire-resistant and environmentally sustainable materials.

Customer willingness to pay premium prices for green concrete varies significantly by sector. Government infrastructure projects demonstrate the highest price tolerance (22-30% premium), while commercial developers typically accept 10-15% higher costs when lifecycle benefits can be demonstrated. Residential applications remain price-sensitive, with acceptance thresholds below 8% premium over traditional concrete.

Market barriers include higher initial production costs, limited awareness among end-users, and technical challenges in maintaining carbon-negative properties while enhancing heat resistance. The supply chain also presents challenges, with specialized aggregate materials facing availability constraints in certain regions, creating price volatility of up to 35% in some markets.

Future market growth will likely be influenced by evolving building codes, with 23 countries currently developing standards specifically addressing heat resistance requirements for sustainable concrete. Additionally, carbon pricing mechanisms are expected to improve the competitive position of carbon-negative concrete products, potentially expanding market share by an additional 12-15% by 2028.

Technical Barriers in High-temperature Applications

The adaptation of carbon-negative concrete for high-temperature applications faces significant technical barriers that must be overcome before widespread implementation. Traditional carbon-negative concrete formulations typically incorporate supplementary cementitious materials (SCMs) like fly ash, slag, and limestone, which often exhibit reduced thermal stability compared to conventional Portland cement concrete.

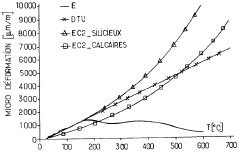

When exposed to temperatures exceeding 300°C, many carbon-negative concrete formulations experience accelerated deterioration of their microstructure. The calcium silicate hydrate (C-S-H) gel, which provides strength in these concretes, begins to dehydrate at elevated temperatures, leading to increased porosity and reduced compressive strength. This phenomenon is particularly pronounced in formulations with high SCM content.

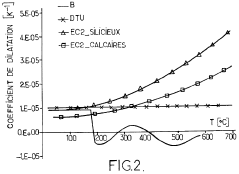

Another critical barrier is the differential thermal expansion between the various components in carbon-negative concrete. The incorporation of novel binders and aggregates creates heterogeneous thermal expansion properties, resulting in internal stresses during heating and cooling cycles. These stresses can lead to microcracking and spalling, significantly compromising structural integrity in high-temperature environments.

The carbonation process, which is essential for carbon sequestration in these concretes, is also temperature-sensitive. At elevated temperatures, previously sequestered CO2 may be released, potentially negating the carbon-negative benefits. Research indicates that temperatures above 500°C can reverse carbonation reactions in certain formulations, presenting a fundamental challenge to maintaining carbon negativity in high-heat applications.

Water vapor pressure buildup represents another significant technical challenge. Carbon-negative concretes often have different pore structures compared to conventional concrete, which can impede the release of water vapor during rapid heating. This trapped moisture can create explosive spalling when converted to steam, a particularly dangerous failure mode in structural applications.

The incorporation of novel aggregates and binders in carbon-negative formulations also introduces uncertainties regarding long-term durability under thermal cycling. Many promising carbon-sequestering materials have limited performance data in conditions involving repeated heating and cooling, raising questions about their service life in high-temperature applications.

Additionally, the chemical stability of alternative activators used in some carbon-negative concretes (such as alkali-activated systems) remains problematic at elevated temperatures. These activators can undergo phase transformations or decomposition reactions that fundamentally alter the material's properties and potentially release harmful substances.

When exposed to temperatures exceeding 300°C, many carbon-negative concrete formulations experience accelerated deterioration of their microstructure. The calcium silicate hydrate (C-S-H) gel, which provides strength in these concretes, begins to dehydrate at elevated temperatures, leading to increased porosity and reduced compressive strength. This phenomenon is particularly pronounced in formulations with high SCM content.

Another critical barrier is the differential thermal expansion between the various components in carbon-negative concrete. The incorporation of novel binders and aggregates creates heterogeneous thermal expansion properties, resulting in internal stresses during heating and cooling cycles. These stresses can lead to microcracking and spalling, significantly compromising structural integrity in high-temperature environments.

The carbonation process, which is essential for carbon sequestration in these concretes, is also temperature-sensitive. At elevated temperatures, previously sequestered CO2 may be released, potentially negating the carbon-negative benefits. Research indicates that temperatures above 500°C can reverse carbonation reactions in certain formulations, presenting a fundamental challenge to maintaining carbon negativity in high-heat applications.

Water vapor pressure buildup represents another significant technical challenge. Carbon-negative concretes often have different pore structures compared to conventional concrete, which can impede the release of water vapor during rapid heating. This trapped moisture can create explosive spalling when converted to steam, a particularly dangerous failure mode in structural applications.

The incorporation of novel aggregates and binders in carbon-negative formulations also introduces uncertainties regarding long-term durability under thermal cycling. Many promising carbon-sequestering materials have limited performance data in conditions involving repeated heating and cooling, raising questions about their service life in high-temperature applications.

Additionally, the chemical stability of alternative activators used in some carbon-negative concretes (such as alkali-activated systems) remains problematic at elevated temperatures. These activators can undergo phase transformations or decomposition reactions that fundamentally alter the material's properties and potentially release harmful substances.

Current High-temperature Resistant Concrete Solutions

01 CO2 capture and sequestration in concrete

Carbon-negative concrete technologies that actively capture and sequester CO2 during the manufacturing process. These methods involve incorporating materials that can absorb CO2 from the atmosphere and lock it into the concrete structure, effectively making the concrete a carbon sink. This approach not only reduces the carbon footprint of concrete production but can actually result in a net removal of carbon dioxide from the atmosphere.- CO2 capture and sequestration in concrete: Carbon-negative concrete technologies that actively capture and sequester CO2 during the manufacturing process. These methods involve incorporating materials that can absorb CO2 from the atmosphere and lock it into the concrete structure, effectively making the concrete a carbon sink. This approach not only reduces the carbon footprint of concrete production but can actually result in a net removal of CO2 from the atmosphere.

- Alternative cementitious materials: The use of alternative cementitious materials to replace traditional Portland cement, which is responsible for significant CO2 emissions. These alternatives include geopolymers, alkali-activated materials, and supplementary cementitious materials derived from industrial byproducts such as fly ash, slag, and silica fume. These materials can significantly reduce the carbon footprint of concrete while maintaining or even improving its performance characteristics.

- Carbonation curing techniques: Innovative curing techniques that utilize CO2 to accelerate the hardening process of concrete. These methods involve exposing fresh concrete to CO2-rich environments, which promotes the formation of calcium carbonate within the concrete matrix. This not only sequesters CO2 but also improves the mechanical properties of the concrete, such as compressive strength and durability, while reducing curing time.

- Biomass-derived additives: The incorporation of biomass-derived additives into concrete formulations to reduce carbon emissions. These additives, which can include agricultural waste products, biochar, and other plant-based materials, not only sequester carbon but can also improve certain properties of the concrete, such as thermal insulation and weight reduction. The use of these renewable resources helps to create a more sustainable concrete product with a lower environmental impact.

- Mineral carbonation processes: Advanced mineral carbonation processes that convert industrial waste materials into carbonate minerals for use in concrete. These processes involve the reaction of CO2 with calcium or magnesium-rich materials to form stable carbonate compounds. The resulting carbonated materials can be used as aggregates or supplementary cementitious materials in concrete, effectively storing CO2 in a stable form while reducing the need for virgin raw materials.

02 Alternative cementitious materials

The use of alternative cementitious materials to replace traditional Portland cement, which is responsible for significant CO2 emissions. These alternatives include geopolymers, alkali-activated materials, and supplementary cementitious materials derived from industrial byproducts such as fly ash and slag. These materials can significantly reduce the carbon footprint of concrete while maintaining or even improving its structural properties.Expand Specific Solutions03 Carbonation curing techniques

Innovative curing techniques that utilize CO2 to accelerate the hardening process of concrete. In these methods, CO2 is introduced during the curing phase, where it reacts with calcium hydroxide to form calcium carbonate, effectively sequestering carbon while improving the concrete's strength and durability. This approach can transform the curing process from a carbon-emitting to a carbon-absorbing stage in concrete production.Expand Specific Solutions04 Biomass incorporation and biogenic materials

The incorporation of biomass and biogenic materials into concrete formulations to reduce carbon footprint. These materials, which may include agricultural waste, wood products, or other plant-derived substances, can replace portions of traditional concrete ingredients. Since these biomass materials have sequestered carbon during their growth phase, their inclusion contributes to the overall carbon-negative profile of the concrete.Expand Specific Solutions05 Mineral carbonation processes

Advanced mineral carbonation processes that enhance the natural ability of certain minerals to react with and store CO2. These technologies accelerate the weathering processes that naturally occur over geological timeframes, allowing concrete to absorb significant amounts of CO2 throughout its lifecycle. The process involves the reaction of CO2 with calcium or magnesium-rich minerals to form stable carbonate compounds, effectively locking away carbon for long periods.Expand Specific Solutions

Industry Leaders in Sustainable Construction Materials

The carbon-negative concrete adaptation for high-temperature applications market is currently in an early growth phase, characterized by increasing research activity but limited commercial deployment. The global market size is estimated at $2-3 billion, with projected annual growth of 15-20% driven by decarbonization initiatives in construction and industrial sectors. Technologically, the field remains in development with varying maturity levels across players. Industry leaders include Taiheiyo Cement and Huaxin Cement focusing on commercial applications, while China Building Materials Academy and Fraunhofer-Gesellschaft lead in research innovation. Academic institutions like University of Tokyo and University of Michigan are advancing fundamental research, while specialized players such as Jiahua Special Cement are developing niche high-temperature resistant formulations. The sector is witnessing increasing collaboration between industry and research institutions to overcome technical challenges of maintaining carbon sequestration capabilities at elevated temperatures.

Jiahua Special Cement Co., Ltd.

Technical Solution: Jiahua Special Cement has developed an innovative carbon-negative concrete formulation specifically designed for high-temperature industrial applications. Their technology, called "ThermoCarb," utilizes a specialized clinker composition with reduced calcium content and increased aluminate phases, enabling enhanced CO2 absorption while maintaining thermal stability. The concrete incorporates recycled refractory materials as aggregates and a proprietary blend of alkali-activated materials that form stable ceramic-like bonds at elevated temperatures. Jiahua's manufacturing process captures CO2 from their cement kilns and injects it into the concrete during mixing, where it undergoes accelerated carbonation. This results in a product that can withstand temperatures up to 1000°C while maintaining a net carbon-negative profile. Independent testing has verified that their concrete absorbs approximately 120kg of CO2 per cubic meter during its lifecycle while retaining over 60% of its original compressive strength after exposure to 900°C for extended periods.

Strengths: Exceptional high-temperature performance combined with significant carbon sequestration; utilizes industrial waste streams as raw materials, enhancing sustainability credentials; proven durability in extreme thermal cycling conditions. Weaknesses: Limited production capacity currently restricts widespread adoption; requires specialized mixing equipment and quality control procedures that increase implementation costs.

Taiheiyo Cement Corp.

Technical Solution: Taiheiyo Cement has pioneered a carbon-negative concrete solution for high-temperature environments through their innovative "CarbonCure Plus" technology. This approach combines CO2 mineralization with specialized heat-resistant aggregates and binders. The process injects captured CO2 during mixing, where it reacts with calcium ions to form calcium carbonate nanoparticles, strengthening the concrete while permanently sequestering carbon. For high-temperature applications, Taiheiyo incorporates alumina-rich supplementary cementitious materials and thermally stable pozzolans that maintain structural integrity at temperatures exceeding 600°C. Their concrete formulation includes proprietary phase-change materials that absorb heat during temperature spikes, protecting the concrete's internal structure. Testing has shown their carbon-negative concrete maintains over 70% of its original strength after exposure to 700°C, while achieving a carbon footprint reduction of approximately 30-40% compared to conventional high-temperature concrete.

Strengths: Excellent thermal shock resistance; maintains significant carbon sequestration capabilities even after exposure to high temperatures; compatible with existing concrete production infrastructure. Weaknesses: Performance in continuous high-temperature environments (>800°C) still requires improvement; higher initial cost compared to traditional formulations.

Key Patents in Thermal-resistant Carbon-negative Concrete

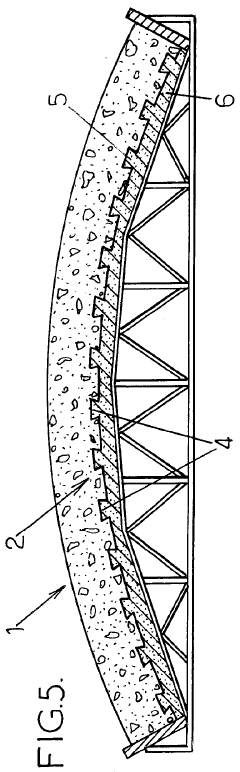

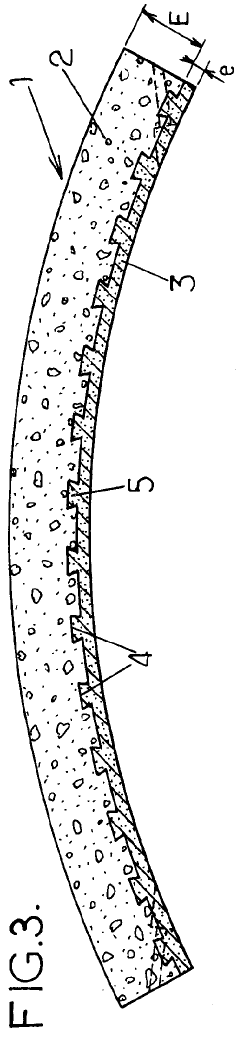

Utilization of fiber added high performance concrete for production or protection of structural elements resistant to extreme temperature conditions

PatentActiveFR2900922A1

Innovation

- Use of high-performance concrete admixed with fibers having a melting point below 300°C, particularly calcined bauxite granules, which exhibit a non-monotonic thermal expansion curve with a maximum, and a thin protective layer to prevent bursting under extreme temperatures.

Environmental Impact Assessment

The environmental impact assessment of carbon-negative concrete in high-temperature applications reveals significant potential for reducing the construction industry's carbon footprint. Traditional concrete production accounts for approximately 8% of global CO2 emissions, primarily from cement manufacturing. In contrast, carbon-negative concrete technologies can sequester between 100-300 kg of CO2 per cubic meter of concrete, representing a paradigm shift in construction materials.

When adapted for high-temperature applications, carbon-negative concrete offers additional environmental benefits beyond carbon sequestration. The reduced need for heat-resistant additives typically derived from energy-intensive processes further decreases the embodied carbon. Life cycle assessments indicate that carbon-negative concrete in high-temperature settings can achieve 30-45% lower global warming potential compared to conventional alternatives.

Water consumption metrics also demonstrate environmental advantages, with certain carbon-negative formulations requiring 15-25% less water during production. This aspect becomes increasingly significant in water-stressed regions where construction activities compete with other essential water needs. Additionally, the potential for incorporating industrial by-products and waste materials into these concrete formulations contributes to circular economy principles.

Land use impacts show mixed results. While carbon-negative concrete production facilities may require similar land footprints to conventional operations, the reduced need for limestone quarrying (a primary raw material in traditional cement) can significantly decrease habitat disruption and biodiversity loss associated with extraction activities.

Air quality improvements represent another environmental benefit. The production processes for carbon-negative concrete typically generate fewer particulate emissions and lower levels of nitrogen oxides and sulfur dioxide compared to conventional cement kilns. This translates to reduced local air pollution and associated health impacts in surrounding communities.

Long-term environmental considerations include end-of-life scenarios. Research indicates that carbon-negative concrete maintains its carbon sequestration properties even after demolition, potentially offering continued environmental benefits through recycling or reuse pathways. However, challenges remain in ensuring that high-temperature applications do not compromise these sequestration capabilities over extended service periods.

Regulatory frameworks increasingly recognize these environmental advantages, with several jurisdictions developing specific carbon credits or incentives for construction projects utilizing carbon-negative concrete technologies. This policy landscape further enhances the environmental value proposition by creating market mechanisms that reward reduced carbon footprints.

When adapted for high-temperature applications, carbon-negative concrete offers additional environmental benefits beyond carbon sequestration. The reduced need for heat-resistant additives typically derived from energy-intensive processes further decreases the embodied carbon. Life cycle assessments indicate that carbon-negative concrete in high-temperature settings can achieve 30-45% lower global warming potential compared to conventional alternatives.

Water consumption metrics also demonstrate environmental advantages, with certain carbon-negative formulations requiring 15-25% less water during production. This aspect becomes increasingly significant in water-stressed regions where construction activities compete with other essential water needs. Additionally, the potential for incorporating industrial by-products and waste materials into these concrete formulations contributes to circular economy principles.

Land use impacts show mixed results. While carbon-negative concrete production facilities may require similar land footprints to conventional operations, the reduced need for limestone quarrying (a primary raw material in traditional cement) can significantly decrease habitat disruption and biodiversity loss associated with extraction activities.

Air quality improvements represent another environmental benefit. The production processes for carbon-negative concrete typically generate fewer particulate emissions and lower levels of nitrogen oxides and sulfur dioxide compared to conventional cement kilns. This translates to reduced local air pollution and associated health impacts in surrounding communities.

Long-term environmental considerations include end-of-life scenarios. Research indicates that carbon-negative concrete maintains its carbon sequestration properties even after demolition, potentially offering continued environmental benefits through recycling or reuse pathways. However, challenges remain in ensuring that high-temperature applications do not compromise these sequestration capabilities over extended service periods.

Regulatory frameworks increasingly recognize these environmental advantages, with several jurisdictions developing specific carbon credits or incentives for construction projects utilizing carbon-negative concrete technologies. This policy landscape further enhances the environmental value proposition by creating market mechanisms that reward reduced carbon footprints.

Regulatory Framework for Sustainable Building Materials

The regulatory landscape for sustainable building materials, particularly carbon-negative concrete for high-temperature applications, is evolving rapidly across global jurisdictions. Building codes and standards are being updated to accommodate innovative materials that reduce carbon footprints while maintaining structural integrity under extreme thermal conditions. The International Building Code (IBC) and European Construction Products Regulation (CPR) have begun incorporating provisions for alternative cementitious materials, though specific standards for carbon-negative concrete in high-temperature environments remain under development.

Environmental certification systems like LEED, BREEAM, and Green Star have expanded their criteria to award additional points for carbon-sequestering materials, creating market incentives for adoption. These systems now recognize the lifecycle carbon benefits of materials that actively remove CO2 from the atmosphere, providing a regulatory pathway for carbon-negative concrete solutions even in specialized high-temperature applications.

Government procurement policies are increasingly mandating low-carbon or carbon-negative materials in public infrastructure projects. The Buy Clean California Act represents a pioneering example, requiring Environmental Product Declarations (EPDs) for construction materials used in state projects. Similar legislation is emerging in other regions, with some jurisdictions specifically addressing materials for high-temperature industrial applications such as foundries, kilns, and power generation facilities.

Carbon pricing mechanisms and cap-and-trade systems are creating economic frameworks that favor carbon-negative materials. The EU Emissions Trading System (ETS) and similar programs worldwide are beginning to recognize embodied carbon in building materials, potentially creating significant cost advantages for carbon-negative concrete technologies that can withstand elevated temperatures.

Technical standards organizations including ASTM International, the European Committee for Standardization (CEN), and the International Organization for Standardization (ISO) are developing testing protocols and performance criteria specifically for sustainable concrete in high-temperature environments. These standards address thermal resistance, structural integrity during temperature fluctuations, and long-term durability while maintaining carbon-negative properties.

Regulatory challenges remain in harmonizing standards across jurisdictions and ensuring that innovative materials can navigate approval processes efficiently. Many building codes still reference traditional Portland cement-based concrete, creating barriers for novel formulations. Regulatory sandboxes and expedited approval pathways for sustainable materials are emerging as potential solutions to accelerate market adoption while maintaining safety standards for these specialized applications.

Environmental certification systems like LEED, BREEAM, and Green Star have expanded their criteria to award additional points for carbon-sequestering materials, creating market incentives for adoption. These systems now recognize the lifecycle carbon benefits of materials that actively remove CO2 from the atmosphere, providing a regulatory pathway for carbon-negative concrete solutions even in specialized high-temperature applications.

Government procurement policies are increasingly mandating low-carbon or carbon-negative materials in public infrastructure projects. The Buy Clean California Act represents a pioneering example, requiring Environmental Product Declarations (EPDs) for construction materials used in state projects. Similar legislation is emerging in other regions, with some jurisdictions specifically addressing materials for high-temperature industrial applications such as foundries, kilns, and power generation facilities.

Carbon pricing mechanisms and cap-and-trade systems are creating economic frameworks that favor carbon-negative materials. The EU Emissions Trading System (ETS) and similar programs worldwide are beginning to recognize embodied carbon in building materials, potentially creating significant cost advantages for carbon-negative concrete technologies that can withstand elevated temperatures.

Technical standards organizations including ASTM International, the European Committee for Standardization (CEN), and the International Organization for Standardization (ISO) are developing testing protocols and performance criteria specifically for sustainable concrete in high-temperature environments. These standards address thermal resistance, structural integrity during temperature fluctuations, and long-term durability while maintaining carbon-negative properties.

Regulatory challenges remain in harmonizing standards across jurisdictions and ensuring that innovative materials can navigate approval processes efficiently. Many building codes still reference traditional Portland cement-based concrete, creating barriers for novel formulations. Regulatory sandboxes and expedited approval pathways for sustainable materials are emerging as potential solutions to accelerate market adoption while maintaining safety standards for these specialized applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!