Advanced Material Application in Pintle Hitch Corrosion Prevention

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Material Evolution

The evolution of materials for pintle hitch corrosion prevention has been a journey of continuous innovation and improvement. Traditional materials such as carbon steel, while strong and cost-effective, have long been susceptible to corrosion in harsh environments. This vulnerability led to the exploration of more resistant materials and protective coatings.

In the early stages, galvanized steel emerged as a popular choice, offering improved corrosion resistance through a zinc coating. This advancement significantly extended the lifespan of pintle hitches, particularly in marine and industrial applications. However, the limitations of galvanization, including potential chipping and wear, prompted further research into more durable solutions.

The introduction of stainless steel marked a significant milestone in material evolution for pintle hitches. Grades such as 304 and 316 stainless steel provided superior corrosion resistance, especially in saltwater environments. These alloys, containing chromium and nickel, form a passive oxide layer that self-heals when damaged, offering long-term protection against rust and corrosion.

As technology advanced, composite materials entered the scene, offering a combination of strength, lightweight properties, and corrosion resistance. Fiber-reinforced polymers (FRPs), for instance, began to be utilized in certain pintle hitch components, providing excellent durability without the risk of rust. These materials, however, often came with higher production costs and potential limitations in load-bearing capacity compared to their metal counterparts.

Recent years have seen the development of advanced coatings and surface treatments. Ceramic coatings, for example, have shown promise in providing a hard, corrosion-resistant layer that can be applied to various base materials. Similarly, nanotechnology has enabled the creation of ultra-thin, highly effective protective layers that can significantly enhance the corrosion resistance of traditional materials.

The latest frontier in material evolution for pintle hitches involves smart materials and self-healing coatings. These innovative solutions can detect and respond to environmental changes or damage, potentially repairing minor corrosion issues autonomously. While still in the early stages of development, such materials represent the cutting edge of corrosion prevention technology.

As environmental concerns grow, there's also a trend towards more sustainable and eco-friendly materials. Researchers are exploring biodegradable coatings and recyclable composites that can offer corrosion protection while minimizing environmental impact. This shift reflects the industry's growing commitment to sustainability alongside performance and durability.

In the early stages, galvanized steel emerged as a popular choice, offering improved corrosion resistance through a zinc coating. This advancement significantly extended the lifespan of pintle hitches, particularly in marine and industrial applications. However, the limitations of galvanization, including potential chipping and wear, prompted further research into more durable solutions.

The introduction of stainless steel marked a significant milestone in material evolution for pintle hitches. Grades such as 304 and 316 stainless steel provided superior corrosion resistance, especially in saltwater environments. These alloys, containing chromium and nickel, form a passive oxide layer that self-heals when damaged, offering long-term protection against rust and corrosion.

As technology advanced, composite materials entered the scene, offering a combination of strength, lightweight properties, and corrosion resistance. Fiber-reinforced polymers (FRPs), for instance, began to be utilized in certain pintle hitch components, providing excellent durability without the risk of rust. These materials, however, often came with higher production costs and potential limitations in load-bearing capacity compared to their metal counterparts.

Recent years have seen the development of advanced coatings and surface treatments. Ceramic coatings, for example, have shown promise in providing a hard, corrosion-resistant layer that can be applied to various base materials. Similarly, nanotechnology has enabled the creation of ultra-thin, highly effective protective layers that can significantly enhance the corrosion resistance of traditional materials.

The latest frontier in material evolution for pintle hitches involves smart materials and self-healing coatings. These innovative solutions can detect and respond to environmental changes or damage, potentially repairing minor corrosion issues autonomously. While still in the early stages of development, such materials represent the cutting edge of corrosion prevention technology.

As environmental concerns grow, there's also a trend towards more sustainable and eco-friendly materials. Researchers are exploring biodegradable coatings and recyclable composites that can offer corrosion protection while minimizing environmental impact. This shift reflects the industry's growing commitment to sustainability alongside performance and durability.

Market Analysis

The market for advanced materials in pintle hitch corrosion prevention is experiencing significant growth, driven by the increasing demand for durable and long-lasting towing equipment across various industries. The automotive and transportation sectors, in particular, are major contributors to this market expansion. As vehicle owners and fleet operators seek to extend the lifespan of their towing equipment and reduce maintenance costs, the adoption of corrosion-resistant materials for pintle hitches has become a priority.

The global market for corrosion prevention in automotive components, including pintle hitches, is projected to grow steadily over the next five years. This growth is attributed to the rising awareness of the economic impact of corrosion on vehicle maintenance and the increasing focus on safety in towing applications. The market is also benefiting from stringent regulations regarding vehicle safety and environmental protection, which are pushing manufacturers to invest in advanced materials that offer superior corrosion resistance.

North America and Europe currently dominate the market for advanced materials in pintle hitch corrosion prevention, owing to their large automotive industries and high adoption rates of advanced technologies. However, the Asia-Pacific region is expected to witness the fastest growth in this market, driven by the rapid expansion of the automotive sector in countries like China and India, as well as increasing investments in transportation infrastructure.

The market is characterized by a growing preference for eco-friendly and sustainable corrosion prevention solutions. This trend is creating opportunities for materials that not only provide excellent corrosion resistance but also have minimal environmental impact. Manufacturers are increasingly focusing on developing advanced coatings and alloys that meet these criteria, responding to both regulatory pressures and consumer preferences.

In terms of end-user segments, the commercial vehicle sector represents a significant portion of the market for advanced materials in pintle hitch corrosion prevention. This is due to the higher frequency of use and exposure to harsh environmental conditions experienced by commercial vehicles. The agricultural and construction equipment sectors are also emerging as key growth areas, as these industries rely heavily on towing capabilities in challenging environments.

The market is witnessing a shift towards integrated solutions that combine advanced materials with smart technologies. This includes the development of pintle hitches with built-in sensors that can monitor corrosion levels and alert users to potential issues, enhancing both safety and maintenance efficiency. This integration of materials science with digital technology is expected to be a key driver of market growth in the coming years.

The global market for corrosion prevention in automotive components, including pintle hitches, is projected to grow steadily over the next five years. This growth is attributed to the rising awareness of the economic impact of corrosion on vehicle maintenance and the increasing focus on safety in towing applications. The market is also benefiting from stringent regulations regarding vehicle safety and environmental protection, which are pushing manufacturers to invest in advanced materials that offer superior corrosion resistance.

North America and Europe currently dominate the market for advanced materials in pintle hitch corrosion prevention, owing to their large automotive industries and high adoption rates of advanced technologies. However, the Asia-Pacific region is expected to witness the fastest growth in this market, driven by the rapid expansion of the automotive sector in countries like China and India, as well as increasing investments in transportation infrastructure.

The market is characterized by a growing preference for eco-friendly and sustainable corrosion prevention solutions. This trend is creating opportunities for materials that not only provide excellent corrosion resistance but also have minimal environmental impact. Manufacturers are increasingly focusing on developing advanced coatings and alloys that meet these criteria, responding to both regulatory pressures and consumer preferences.

In terms of end-user segments, the commercial vehicle sector represents a significant portion of the market for advanced materials in pintle hitch corrosion prevention. This is due to the higher frequency of use and exposure to harsh environmental conditions experienced by commercial vehicles. The agricultural and construction equipment sectors are also emerging as key growth areas, as these industries rely heavily on towing capabilities in challenging environments.

The market is witnessing a shift towards integrated solutions that combine advanced materials with smart technologies. This includes the development of pintle hitches with built-in sensors that can monitor corrosion levels and alert users to potential issues, enhancing both safety and maintenance efficiency. This integration of materials science with digital technology is expected to be a key driver of market growth in the coming years.

Corrosion Challenges

Corrosion poses significant challenges in the application of pintle hitches, particularly in harsh environments where these critical components are exposed to various corrosive elements. The primary corrosion challenges stem from the constant exposure to moisture, road salt, and other environmental contaminants that accelerate the degradation of traditional materials used in pintle hitch construction.

One of the most pressing issues is galvanic corrosion, which occurs when dissimilar metals come into contact in the presence of an electrolyte. This is particularly problematic in pintle hitches due to the variety of metals often used in their construction, such as steel, aluminum, and brass. The resulting electrochemical reaction can lead to rapid deterioration of the weaker metal, compromising the structural integrity of the hitch.

Crevice corrosion presents another significant challenge, especially in the intricate design of pintle hitches. The small gaps and crevices inherent in the hitch's structure can trap moisture and corrosive agents, creating localized areas of accelerated corrosion. This type of corrosion is particularly insidious as it can progress undetected, potentially leading to sudden failure of the component.

Stress corrosion cracking (SCC) is a concern in pintle hitches due to the combination of tensile stress and corrosive environment. The constant loading and unloading cycles, coupled with exposure to corrosive elements, can initiate and propagate cracks in the material, significantly reducing the hitch's service life and safety.

Pitting corrosion, characterized by the formation of small, deep cavities in the metal surface, is another challenge faced in pintle hitch applications. This form of localized corrosion can rapidly penetrate the material, leading to structural weakening and potential failure points.

The dynamic nature of pintle hitch usage also contributes to erosion-corrosion, where mechanical wear combines with chemical attack to accelerate material loss. This is particularly evident in areas of high fluid flow or where abrasive particles are present, such as in off-road or industrial applications.

Temperature fluctuations and extreme weather conditions further exacerbate corrosion challenges. Thermal cycling can lead to the breakdown of protective coatings and create micro-cracks that serve as initiation points for corrosion. Additionally, freeze-thaw cycles can trap moisture in small crevices, intensifying localized corrosion.

Addressing these corrosion challenges requires a multifaceted approach, combining advanced material selection, innovative design strategies, and cutting-edge protective coatings. The development of corrosion-resistant alloys, implementation of cathodic protection systems, and application of nanotechnology-based coatings are among the potential solutions being explored to enhance the durability and reliability of pintle hitches in corrosive environments.

One of the most pressing issues is galvanic corrosion, which occurs when dissimilar metals come into contact in the presence of an electrolyte. This is particularly problematic in pintle hitches due to the variety of metals often used in their construction, such as steel, aluminum, and brass. The resulting electrochemical reaction can lead to rapid deterioration of the weaker metal, compromising the structural integrity of the hitch.

Crevice corrosion presents another significant challenge, especially in the intricate design of pintle hitches. The small gaps and crevices inherent in the hitch's structure can trap moisture and corrosive agents, creating localized areas of accelerated corrosion. This type of corrosion is particularly insidious as it can progress undetected, potentially leading to sudden failure of the component.

Stress corrosion cracking (SCC) is a concern in pintle hitches due to the combination of tensile stress and corrosive environment. The constant loading and unloading cycles, coupled with exposure to corrosive elements, can initiate and propagate cracks in the material, significantly reducing the hitch's service life and safety.

Pitting corrosion, characterized by the formation of small, deep cavities in the metal surface, is another challenge faced in pintle hitch applications. This form of localized corrosion can rapidly penetrate the material, leading to structural weakening and potential failure points.

The dynamic nature of pintle hitch usage also contributes to erosion-corrosion, where mechanical wear combines with chemical attack to accelerate material loss. This is particularly evident in areas of high fluid flow or where abrasive particles are present, such as in off-road or industrial applications.

Temperature fluctuations and extreme weather conditions further exacerbate corrosion challenges. Thermal cycling can lead to the breakdown of protective coatings and create micro-cracks that serve as initiation points for corrosion. Additionally, freeze-thaw cycles can trap moisture in small crevices, intensifying localized corrosion.

Addressing these corrosion challenges requires a multifaceted approach, combining advanced material selection, innovative design strategies, and cutting-edge protective coatings. The development of corrosion-resistant alloys, implementation of cathodic protection systems, and application of nanotechnology-based coatings are among the potential solutions being explored to enhance the durability and reliability of pintle hitches in corrosive environments.

Current Solutions

01 Corrosion-resistant coatings for pintle hitches

Various coatings can be applied to pintle hitches to protect against corrosion. These may include galvanization, powder coating, or specialized anti-corrosion paints. Such coatings form a protective barrier between the metal surface and corrosive elements, extending the lifespan of the hitch.- Corrosion-resistant coatings for pintle hitches: Various coatings can be applied to pintle hitches to protect against corrosion. These may include zinc-based coatings, powder coatings, or specialized anti-corrosion paints. The coatings form a protective barrier between the metal surface and corrosive elements, extending the lifespan of the hitch.

- Stainless steel or corrosion-resistant alloy construction: Manufacturing pintle hitches from stainless steel or other corrosion-resistant alloys can significantly reduce the risk of corrosion. These materials have inherent properties that make them less susceptible to oxidation and rust, ensuring longer-lasting performance in various environmental conditions.

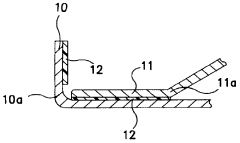

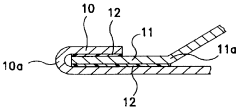

- Sealed or enclosed designs to prevent moisture ingress: Innovative designs that seal or enclose vulnerable parts of the pintle hitch can prevent moisture and corrosive elements from reaching critical components. This may include sealed bearings, enclosed locking mechanisms, or protective covers that shield the hitch from environmental exposure.

- Sacrificial anodes for cathodic protection: Incorporating sacrificial anodes into the pintle hitch design can provide cathodic protection against corrosion. These anodes, made of a more reactive metal, corrode preferentially, protecting the main structure of the hitch. This method is particularly effective in marine or high-salt environments.

- Regular maintenance and lubrication practices: Implementing regular maintenance routines, including cleaning and lubrication, can significantly reduce corrosion in pintle hitches. This may involve the use of specialized lubricants, periodic inspection for signs of corrosion, and prompt treatment of any affected areas to prevent further degradation.

02 Corrosion-resistant materials for pintle hitch construction

Using corrosion-resistant materials in the construction of pintle hitches can significantly reduce the risk of corrosion. Materials such as stainless steel, aluminum alloys, or high-strength low-alloy (HSLA) steels offer improved resistance to rust and corrosion compared to traditional carbon steel.Expand Specific Solutions03 Sealing and lubrication systems for pintle hitches

Implementing effective sealing and lubrication systems can help prevent corrosion in pintle hitches. This may include using weatherproof seals, grease fittings, or self-lubricating components to keep moisture and contaminants out while maintaining proper lubrication of moving parts.Expand Specific Solutions04 Design modifications for improved corrosion resistance

Modifying the design of pintle hitches can enhance their resistance to corrosion. This may involve incorporating drainage channels, reducing areas where water can accumulate, or designing components with smooth surfaces that are less prone to trapping moisture and debris.Expand Specific Solutions05 Regular maintenance and cleaning practices

Implementing regular maintenance and cleaning practices can significantly reduce corrosion in pintle hitches. This includes routine inspection, cleaning of debris and salt deposits, reapplication of protective coatings, and proper storage when not in use to minimize exposure to corrosive elements.Expand Specific Solutions

Industry Leaders

The advanced material application in pintle hitch corrosion prevention market is in a growth phase, driven by increasing demand for durable and long-lasting automotive components. The market size is expanding as more vehicle manufacturers and aftermarket suppliers adopt advanced corrosion prevention solutions. Technologically, the field is evolving rapidly, with companies like PPG Industries Ohio, Inc., KCC Corp., and BASF Coatings GmbH leading innovation in protective coatings and materials. These firms are developing sophisticated anti-corrosion technologies, leveraging nanotechnology and advanced polymer science to enhance durability and performance. The competitive landscape is characterized by a mix of established chemical companies and specialized coating manufacturers, all vying to develop more effective and environmentally friendly solutions.

PPG Industries Ohio, Inc.

Technical Solution: PPG Industries Ohio, Inc. has pioneered an innovative approach to pintle hitch corrosion prevention through their advanced material applications. Their solution involves a proprietary zinc-rich epoxy primer combined with a high-performance polyurethane topcoat[2]. The zinc-rich primer provides cathodic protection, sacrificially corroding to protect the underlying metal. The polyurethane topcoat offers excellent UV resistance and chemical resistance, ensuring long-term durability. PPG has also developed smart coatings that incorporate corrosion-sensing pigments, which change color when corrosion begins, allowing for early detection and maintenance[4]. Furthermore, they have introduced nano-ceramic particles into their coatings, significantly improving abrasion resistance and extending the service life of the pintle hitch[6].

Strengths: Excellent corrosion protection, smart sensing capabilities, and enhanced abrasion resistance. Weaknesses: May be more expensive than conventional coatings and could require specialized application techniques.

Xtalic Corp.

Technical Solution: Xtalic Corp. has developed a groundbreaking approach to pintle hitch corrosion prevention using their patented nanostructured alloy technology[1]. Their solution involves electrodepositing nanocrystalline alloys, particularly nickel-tungsten alloys, onto the pintle hitch surface. These nanostructured coatings exhibit grain sizes typically less than 100 nanometers, resulting in exceptional hardness, wear resistance, and corrosion protection[3]. Xtalic's process allows for precise control of alloy composition and microstructure, enabling tailored properties for specific environmental conditions. They have also developed a multi-layer coating system that combines different nanostructured alloys to provide optimized performance[5]. Additionally, Xtalic has introduced self-lubricating nanocomposite coatings that incorporate solid lubricants within the nanostructured matrix, reducing friction and enhancing durability in high-wear applications[7].

Strengths: Superior hardness and wear resistance, customizable properties, and potential for self-lubricating coatings. Weaknesses: May require specialized equipment for deposition and could be more expensive than conventional coating methods.

Key Innovations

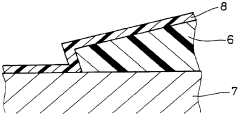

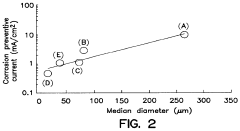

Method of corrosion prevention and corrosion preventive material suitable for use therein

PatentInactiveUS5985957A

Innovation

- A corrosion preventive material comprising 65% or more zinc powder by weight with a grain diameter of 150 μm or larger dispersed in a synthetic resin base material, which reduces contact resistance and increases corrosion preventive current, combined with an adhesive resin for sacrificial corrosion prevention and electrodeposition coating for enhanced protection.

Corrosion inhibiting pigment comprising nanoreservoirs of corrosion inhibitor

PatentActiveEP1832629A1

Innovation

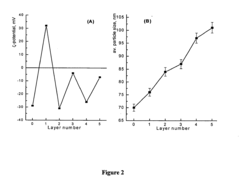

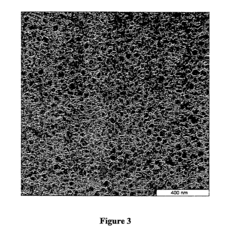

- The development of nanoscale reservoirs with a polymer or polyelectrolyte shell that can store and release corrosion inhibitors in response to specific triggers, such as pH changes, using the layer-by-layer deposition method to create a 'smart' coating that maintains the stability of the coating matrix and provides intelligent release of inhibitors.

Environmental Impact

The environmental impact of advanced material applications in pintle hitch corrosion prevention is a critical consideration in the development and implementation of these technologies. The use of innovative materials and coatings to protect pintle hitches from corrosion can have both positive and negative effects on the environment.

One of the primary environmental benefits of advanced corrosion prevention materials is the extended lifespan of pintle hitches. By effectively protecting these components from corrosion, the need for frequent replacements is significantly reduced. This, in turn, leads to a decrease in the consumption of raw materials and energy required for manufacturing new parts. Additionally, the reduction in waste generated from discarded corroded hitches contributes to lower environmental impact.

However, the production and application of advanced materials for corrosion prevention may also have environmental drawbacks. Some high-performance coatings and materials may contain chemicals that are potentially harmful to ecosystems if not properly managed. The manufacturing processes for these advanced materials might require more energy or produce more emissions compared to traditional methods, potentially offsetting some of the environmental gains achieved through increased durability.

Water pollution is another concern associated with corrosion prevention technologies. Certain anti-corrosion treatments may leach chemicals into surrounding water bodies, affecting aquatic life and water quality. This is particularly relevant for pintle hitches used in marine environments or frequently exposed to water.

The disposal of pintle hitches treated with advanced materials presents another environmental challenge. While these components last longer, they may be more difficult to recycle or dispose of safely at the end of their life cycle. The presence of complex chemical compounds in the coatings or materials may require specialized recycling processes or disposal methods to prevent environmental contamination.

On the positive side, many advanced materials being developed for corrosion prevention are focusing on eco-friendly alternatives. These include bio-based coatings, nanomaterials with lower environmental impact, and smart coatings that can self-heal, further extending the lifespan of the pintle hitch without additional chemical treatments.

The overall environmental impact of these advanced materials also depends on their effectiveness in preventing corrosion-related accidents and spills. By maintaining the integrity of pintle hitches, especially in transportation of hazardous materials, these technologies indirectly contribute to environmental protection by reducing the risk of environmentally damaging incidents.

As research in this field progresses, there is an increasing emphasis on developing corrosion prevention solutions that balance performance with environmental sustainability. This includes exploring materials that are not only effective in preventing corrosion but also biodegradable or easily recyclable. The goal is to create a circular economy approach to pintle hitch manufacturing and maintenance, where materials can be reused or safely returned to the environment at the end of their lifecycle.

One of the primary environmental benefits of advanced corrosion prevention materials is the extended lifespan of pintle hitches. By effectively protecting these components from corrosion, the need for frequent replacements is significantly reduced. This, in turn, leads to a decrease in the consumption of raw materials and energy required for manufacturing new parts. Additionally, the reduction in waste generated from discarded corroded hitches contributes to lower environmental impact.

However, the production and application of advanced materials for corrosion prevention may also have environmental drawbacks. Some high-performance coatings and materials may contain chemicals that are potentially harmful to ecosystems if not properly managed. The manufacturing processes for these advanced materials might require more energy or produce more emissions compared to traditional methods, potentially offsetting some of the environmental gains achieved through increased durability.

Water pollution is another concern associated with corrosion prevention technologies. Certain anti-corrosion treatments may leach chemicals into surrounding water bodies, affecting aquatic life and water quality. This is particularly relevant for pintle hitches used in marine environments or frequently exposed to water.

The disposal of pintle hitches treated with advanced materials presents another environmental challenge. While these components last longer, they may be more difficult to recycle or dispose of safely at the end of their life cycle. The presence of complex chemical compounds in the coatings or materials may require specialized recycling processes or disposal methods to prevent environmental contamination.

On the positive side, many advanced materials being developed for corrosion prevention are focusing on eco-friendly alternatives. These include bio-based coatings, nanomaterials with lower environmental impact, and smart coatings that can self-heal, further extending the lifespan of the pintle hitch without additional chemical treatments.

The overall environmental impact of these advanced materials also depends on their effectiveness in preventing corrosion-related accidents and spills. By maintaining the integrity of pintle hitches, especially in transportation of hazardous materials, these technologies indirectly contribute to environmental protection by reducing the risk of environmentally damaging incidents.

As research in this field progresses, there is an increasing emphasis on developing corrosion prevention solutions that balance performance with environmental sustainability. This includes exploring materials that are not only effective in preventing corrosion but also biodegradable or easily recyclable. The goal is to create a circular economy approach to pintle hitch manufacturing and maintenance, where materials can be reused or safely returned to the environment at the end of their lifecycle.

Regulatory Compliance

Regulatory compliance plays a crucial role in the application of advanced materials for pintle hitch corrosion prevention. The automotive industry is subject to stringent regulations aimed at ensuring safety, environmental protection, and product quality. These regulations directly impact the selection and implementation of corrosion prevention technologies for pintle hitches.

In the United States, the National Highway Traffic Safety Administration (NHTSA) sets standards for vehicle safety, including requirements for towing equipment. The Federal Motor Vehicle Safety Standards (FMVSS) No. 571.108 specifically addresses lighting and reflective devices for trailers, which includes pintle hitches. Manufacturers must ensure that any advanced materials used in corrosion prevention do not interfere with the visibility or functionality of these safety features.

Environmental regulations also significantly influence material selection for corrosion prevention. The Environmental Protection Agency (EPA) enforces strict guidelines on the use of potentially harmful substances. Many traditional corrosion prevention methods rely on heavy metals or volatile organic compounds (VOCs), which are increasingly restricted due to their environmental impact. Advanced materials must comply with regulations such as the Toxic Substances Control Act (TSCA) and the Clean Air Act to be considered viable alternatives.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation imposes additional requirements on the use of chemical substances in products. This regulation affects the global supply chain, as manufacturers exporting to the EU must ensure compliance. Advanced materials used in pintle hitch corrosion prevention must be registered and evaluated under REACH if they contain substances of concern.

The automotive industry's shift towards sustainability has led to the development of regulations promoting the use of recyclable and eco-friendly materials. The End-of-Life Vehicle (ELV) Directive in the EU, for instance, sets targets for the reuse, recycling, and recovery of vehicle components. Advanced materials used in corrosion prevention must be designed with these end-of-life considerations in mind to meet regulatory requirements and industry sustainability goals.

Compliance with international standards such as ISO 9227 for corrosion testing and ISO 12944 for protective paint systems is essential for ensuring the effectiveness and durability of advanced materials in corrosion prevention. These standards provide guidelines for testing procedures and performance criteria that manufacturers must adhere to when developing new corrosion prevention solutions for pintle hitches.

As regulations continue to evolve, manufacturers must stay informed about upcoming changes and adapt their material selection and application processes accordingly. This may involve investing in research and development to create advanced materials that not only prevent corrosion effectively but also meet or exceed current and future regulatory requirements across different markets and jurisdictions.

In the United States, the National Highway Traffic Safety Administration (NHTSA) sets standards for vehicle safety, including requirements for towing equipment. The Federal Motor Vehicle Safety Standards (FMVSS) No. 571.108 specifically addresses lighting and reflective devices for trailers, which includes pintle hitches. Manufacturers must ensure that any advanced materials used in corrosion prevention do not interfere with the visibility or functionality of these safety features.

Environmental regulations also significantly influence material selection for corrosion prevention. The Environmental Protection Agency (EPA) enforces strict guidelines on the use of potentially harmful substances. Many traditional corrosion prevention methods rely on heavy metals or volatile organic compounds (VOCs), which are increasingly restricted due to their environmental impact. Advanced materials must comply with regulations such as the Toxic Substances Control Act (TSCA) and the Clean Air Act to be considered viable alternatives.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation imposes additional requirements on the use of chemical substances in products. This regulation affects the global supply chain, as manufacturers exporting to the EU must ensure compliance. Advanced materials used in pintle hitch corrosion prevention must be registered and evaluated under REACH if they contain substances of concern.

The automotive industry's shift towards sustainability has led to the development of regulations promoting the use of recyclable and eco-friendly materials. The End-of-Life Vehicle (ELV) Directive in the EU, for instance, sets targets for the reuse, recycling, and recovery of vehicle components. Advanced materials used in corrosion prevention must be designed with these end-of-life considerations in mind to meet regulatory requirements and industry sustainability goals.

Compliance with international standards such as ISO 9227 for corrosion testing and ISO 12944 for protective paint systems is essential for ensuring the effectiveness and durability of advanced materials in corrosion prevention. These standards provide guidelines for testing procedures and performance criteria that manufacturers must adhere to when developing new corrosion prevention solutions for pintle hitches.

As regulations continue to evolve, manufacturers must stay informed about upcoming changes and adapt their material selection and application processes accordingly. This may involve investing in research and development to create advanced materials that not only prevent corrosion effectively but also meet or exceed current and future regulatory requirements across different markets and jurisdictions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!