Advanced Thermoelectric Generator Materials For High ZT Values

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Materials Evolution and Research Objectives

Thermoelectric materials have evolved significantly since their discovery in the early 19th century when Thomas Johann Seebeck first observed the phenomenon of converting temperature differences directly into electrical voltage. The field remained relatively dormant until the mid-20th century when semiconductor physics advanced sufficiently to enable practical applications. The 1950s marked a turning point with the development of bismuth telluride (Bi2Te3) compounds, which became the first commercially viable thermoelectric materials with ZT values approaching 1.

The 1990s witnessed a renaissance in thermoelectric research with the introduction of nanostructuring concepts. Theoretical predictions by Hicks and Dresselhaus suggested that quantum confinement effects could dramatically enhance ZT values beyond the historical barrier of 1. This sparked intensive research into low-dimensional thermoelectric systems, including quantum wells, superlattices, and nanocomposites, leading to significant improvements in ZT values reaching 1.5-2.0 in laboratory settings.

The 21st century has seen the emergence of several promising material classes. Complex bulk materials such as skutterudites, clathrates, and half-Heusler alloys have demonstrated enhanced phonon scattering while maintaining good electrical properties. Simultaneously, organic thermoelectric materials have gained attention for their flexibility, abundance, and eco-friendliness, though their efficiency remains lower than inorganic counterparts.

Most recently, hybrid organic-inorganic materials and two-dimensional materials like graphene and transition metal dichalcogenides have shown promising thermoelectric properties. The discovery of topological insulators with their unique surface electronic states has opened new avenues for thermoelectric research, potentially enabling materials with intrinsically low thermal conductivity while maintaining high electrical conductivity.

The primary research objective in this field is to develop materials with ZT values consistently exceeding 3 at practical operating temperatures, which would make thermoelectric generators competitive with traditional power generation technologies. This requires simultaneous optimization of three interdependent parameters: maximizing electrical conductivity and Seebeck coefficient while minimizing thermal conductivity—a challenging task known as the "thermoelectric paradox."

Additional objectives include developing materials that are environmentally benign, abundant, and cost-effective to replace current high-performance materials containing toxic or rare elements like tellurium, lead, and bismuth. Researchers also aim to create materials with stable performance across wide temperature ranges and long operational lifetimes under thermal cycling conditions. The ultimate goal is to enable widespread adoption of thermoelectric technology for waste heat recovery in industrial processes, automotive applications, and distributed power generation, contributing significantly to global energy efficiency improvements.

The 1990s witnessed a renaissance in thermoelectric research with the introduction of nanostructuring concepts. Theoretical predictions by Hicks and Dresselhaus suggested that quantum confinement effects could dramatically enhance ZT values beyond the historical barrier of 1. This sparked intensive research into low-dimensional thermoelectric systems, including quantum wells, superlattices, and nanocomposites, leading to significant improvements in ZT values reaching 1.5-2.0 in laboratory settings.

The 21st century has seen the emergence of several promising material classes. Complex bulk materials such as skutterudites, clathrates, and half-Heusler alloys have demonstrated enhanced phonon scattering while maintaining good electrical properties. Simultaneously, organic thermoelectric materials have gained attention for their flexibility, abundance, and eco-friendliness, though their efficiency remains lower than inorganic counterparts.

Most recently, hybrid organic-inorganic materials and two-dimensional materials like graphene and transition metal dichalcogenides have shown promising thermoelectric properties. The discovery of topological insulators with their unique surface electronic states has opened new avenues for thermoelectric research, potentially enabling materials with intrinsically low thermal conductivity while maintaining high electrical conductivity.

The primary research objective in this field is to develop materials with ZT values consistently exceeding 3 at practical operating temperatures, which would make thermoelectric generators competitive with traditional power generation technologies. This requires simultaneous optimization of three interdependent parameters: maximizing electrical conductivity and Seebeck coefficient while minimizing thermal conductivity—a challenging task known as the "thermoelectric paradox."

Additional objectives include developing materials that are environmentally benign, abundant, and cost-effective to replace current high-performance materials containing toxic or rare elements like tellurium, lead, and bismuth. Researchers also aim to create materials with stable performance across wide temperature ranges and long operational lifetimes under thermal cycling conditions. The ultimate goal is to enable widespread adoption of thermoelectric technology for waste heat recovery in industrial processes, automotive applications, and distributed power generation, contributing significantly to global energy efficiency improvements.

Market Analysis for High-Efficiency Thermoelectric Applications

The global thermoelectric generator (TEG) market is experiencing significant growth, driven by increasing demand for energy-efficient technologies and waste heat recovery systems. Current market valuations place the TEG sector at approximately 460 million USD in 2022, with projections indicating a compound annual growth rate (CAGR) of 8.3% through 2030. This growth trajectory is primarily fueled by industrial sectors seeking to improve energy efficiency and reduce carbon footprints.

High-efficiency thermoelectric applications are gaining traction across multiple industries. The automotive sector represents the largest market segment, with TEGs being integrated into vehicle exhaust systems to convert waste heat into usable electricity, thereby improving fuel efficiency by 3-5%. Major automotive manufacturers including BMW, Ford, and Toyota have ongoing research programs focused on thermoelectric integration.

Industrial manufacturing constitutes the second-largest market segment, where high-temperature processes generate substantial waste heat that can be harvested using advanced thermoelectric materials. Companies operating continuous production facilities in steel, glass, and cement industries stand to benefit significantly from high-ZT thermoelectric solutions, with potential energy recovery of 5-15% of total energy consumption.

Consumer electronics represents an emerging market with substantial growth potential. As devices become more power-hungry and thermal management more challenging, thermoelectric solutions offer dual benefits of cooling and power generation. Market research indicates consumer willingness to pay premium prices for devices with extended battery life, creating a viable entry point for thermoelectric technologies.

Geographic distribution of market demand shows North America and Europe leading in adoption rates, collectively accounting for 58% of the global market. However, Asia-Pacific regions, particularly China, Japan, and South Korea, are experiencing the fastest growth rates at 10.2% annually, driven by government initiatives promoting energy efficiency and substantial investments in advanced materials research.

Market barriers include high initial costs, with current high-performance thermoelectric modules priced at 5-10 USD per watt of generation capacity. This represents a significant hurdle for mass-market adoption. Additionally, customer awareness remains limited outside specialized industrial applications, necessitating educational marketing approaches.

The competitive landscape features established players like Gentherm, Laird Thermal Systems, and II-VI Marlow dominating with 45% market share, alongside emerging startups focused on novel materials development. Recent market entrants emphasizing high-ZT materials have secured substantial venture capital funding, indicating strong investor confidence in next-generation thermoelectric technologies.

High-efficiency thermoelectric applications are gaining traction across multiple industries. The automotive sector represents the largest market segment, with TEGs being integrated into vehicle exhaust systems to convert waste heat into usable electricity, thereby improving fuel efficiency by 3-5%. Major automotive manufacturers including BMW, Ford, and Toyota have ongoing research programs focused on thermoelectric integration.

Industrial manufacturing constitutes the second-largest market segment, where high-temperature processes generate substantial waste heat that can be harvested using advanced thermoelectric materials. Companies operating continuous production facilities in steel, glass, and cement industries stand to benefit significantly from high-ZT thermoelectric solutions, with potential energy recovery of 5-15% of total energy consumption.

Consumer electronics represents an emerging market with substantial growth potential. As devices become more power-hungry and thermal management more challenging, thermoelectric solutions offer dual benefits of cooling and power generation. Market research indicates consumer willingness to pay premium prices for devices with extended battery life, creating a viable entry point for thermoelectric technologies.

Geographic distribution of market demand shows North America and Europe leading in adoption rates, collectively accounting for 58% of the global market. However, Asia-Pacific regions, particularly China, Japan, and South Korea, are experiencing the fastest growth rates at 10.2% annually, driven by government initiatives promoting energy efficiency and substantial investments in advanced materials research.

Market barriers include high initial costs, with current high-performance thermoelectric modules priced at 5-10 USD per watt of generation capacity. This represents a significant hurdle for mass-market adoption. Additionally, customer awareness remains limited outside specialized industrial applications, necessitating educational marketing approaches.

The competitive landscape features established players like Gentherm, Laird Thermal Systems, and II-VI Marlow dominating with 45% market share, alongside emerging startups focused on novel materials development. Recent market entrants emphasizing high-ZT materials have secured substantial venture capital funding, indicating strong investor confidence in next-generation thermoelectric technologies.

Global Status and Challenges in High ZT Material Development

The global landscape of high ZT thermoelectric materials has witnessed significant advancements in recent years, with research efforts concentrated in North America, Europe, and East Asia. The United States maintains leadership through institutions like Northwestern University and MIT, where breakthrough research on skutterudites and half-Heusler alloys has achieved ZT values approaching 1.5. Meanwhile, China has rapidly expanded its research capacity, particularly at the Chinese Academy of Sciences and Tsinghua University, focusing on nanostructured bismuth telluride and silicon-germanium alloys.

European contributions remain substantial, with Germany and France pioneering work on organic thermoelectric materials and oxide-based systems that offer environmental advantages despite moderate ZT values. Japan continues its traditional strength in thin-film thermoelectric technologies, with Toyota and Panasonic developing proprietary materials for automotive waste heat recovery applications.

Despite these advancements, the field faces persistent challenges in achieving commercially viable high ZT materials. The fundamental "phonon-glass electron-crystal" paradigm presents an inherent contradiction, as optimizing one thermoelectric parameter often degrades others. Most high-performance materials still contain toxic or scarce elements like tellurium, lead, and antimony, raising sustainability concerns for large-scale deployment.

Manufacturing scalability represents another significant hurdle. Laboratory-scale synthesis methods that produce record ZT values—such as molecular beam epitaxy or spark plasma sintering—often prove prohibitively expensive or technically challenging for industrial production. The resulting performance gap between laboratory samples and mass-produced materials can exceed 30-40%.

Thermal stability and mechanical robustness present additional challenges, particularly for applications involving thermal cycling or high-temperature operation. Many high-ZT materials exhibit performance degradation after extended operation, with oxidation, sublimation, and phase separation emerging as common failure mechanisms.

Measurement standardization remains problematic across the field, with different laboratories employing varied techniques for determining thermal conductivity, electrical resistivity, and Seebeck coefficients. This inconsistency complicates meaningful comparison between reported ZT values and slows consensus-building around promising material systems.

Recent theoretical models suggest that practical ZT limits may reach 3-4 for bulk materials, though experimental validation remains elusive. The highest reproducible ZT values currently hover around 2.0-2.2 for specialized nanostructured materials under carefully controlled conditions, highlighting the substantial gap between theoretical potential and practical achievement in thermoelectric material development.

European contributions remain substantial, with Germany and France pioneering work on organic thermoelectric materials and oxide-based systems that offer environmental advantages despite moderate ZT values. Japan continues its traditional strength in thin-film thermoelectric technologies, with Toyota and Panasonic developing proprietary materials for automotive waste heat recovery applications.

Despite these advancements, the field faces persistent challenges in achieving commercially viable high ZT materials. The fundamental "phonon-glass electron-crystal" paradigm presents an inherent contradiction, as optimizing one thermoelectric parameter often degrades others. Most high-performance materials still contain toxic or scarce elements like tellurium, lead, and antimony, raising sustainability concerns for large-scale deployment.

Manufacturing scalability represents another significant hurdle. Laboratory-scale synthesis methods that produce record ZT values—such as molecular beam epitaxy or spark plasma sintering—often prove prohibitively expensive or technically challenging for industrial production. The resulting performance gap between laboratory samples and mass-produced materials can exceed 30-40%.

Thermal stability and mechanical robustness present additional challenges, particularly for applications involving thermal cycling or high-temperature operation. Many high-ZT materials exhibit performance degradation after extended operation, with oxidation, sublimation, and phase separation emerging as common failure mechanisms.

Measurement standardization remains problematic across the field, with different laboratories employing varied techniques for determining thermal conductivity, electrical resistivity, and Seebeck coefficients. This inconsistency complicates meaningful comparison between reported ZT values and slows consensus-building around promising material systems.

Recent theoretical models suggest that practical ZT limits may reach 3-4 for bulk materials, though experimental validation remains elusive. The highest reproducible ZT values currently hover around 2.0-2.2 for specialized nanostructured materials under carefully controlled conditions, highlighting the substantial gap between theoretical potential and practical achievement in thermoelectric material development.

Current High ZT Material Solutions and Approaches

01 High ZT value bismuth telluride-based materials

Bismuth telluride (Bi2Te3) and its alloys are among the most efficient thermoelectric materials for near-room temperature applications. These materials can be doped or alloyed with elements like antimony, selenium, and lead to enhance their ZT values. Nanostructuring techniques such as ball milling, melt spinning, and hot pressing are employed to reduce thermal conductivity while maintaining electrical conductivity, resulting in improved ZT values typically ranging from 1.0 to 1.5 at room temperature.- High ZT value bismuth telluride-based materials: Bismuth telluride (Bi2Te3) and its alloys are among the most efficient thermoelectric materials for near-room temperature applications. These materials have been extensively studied and modified to achieve higher ZT values through various techniques such as nanostructuring, doping, and composition optimization. The incorporation of selenium or antimony into bismuth telluride structures has shown significant improvements in thermoelectric performance, with some compositions reaching ZT values above 1 at room temperature.

- Lead telluride and other chalcogenide-based thermoelectric materials: Lead telluride (PbTe) and related chalcogenide compounds represent an important class of mid-to-high temperature thermoelectric materials. These materials can achieve high ZT values through band structure engineering, introduction of nanoscale precipitates, and careful control of carrier concentration. Advanced processing techniques have enabled the development of PbTe-based materials with enhanced phonon scattering and optimized electronic properties, resulting in ZT values exceeding 1.5 at elevated temperatures.

- Silicon-germanium and other semiconductor thermoelectric materials: Silicon-germanium (SiGe) alloys and related semiconductor materials are valuable for high-temperature thermoelectric applications, particularly in space power generation. These materials offer good thermal stability and oxidation resistance at elevated temperatures. Research has focused on nanostructuring approaches, including the incorporation of nanoparticles and formation of nanograined structures, to reduce thermal conductivity while maintaining electrical conductivity, thereby increasing ZT values at high temperatures.

- Novel nanostructured thermoelectric materials with enhanced ZT: Nanostructuring techniques have revolutionized thermoelectric materials by introducing interfaces that selectively scatter phonons while allowing electron transport. These approaches include quantum dot superlattices, nanowires, nanocomposites, and hierarchical architectures with features at multiple length scales. Such nanostructured materials demonstrate significantly reduced thermal conductivity and enhanced ZT values compared to their bulk counterparts, with some systems achieving ZT values approaching 2 under optimal conditions.

- Skutterudite and half-Heusler thermoelectric compounds: Skutterudites and half-Heusler compounds represent promising classes of thermoelectric materials for intermediate to high-temperature applications. These materials feature complex crystal structures that inherently reduce thermal conductivity. The thermoelectric performance of skutterudites can be further enhanced through filling the structural voids with rattling atoms, while half-Heusler compounds benefit from band structure engineering and microstructural modifications. Both material classes have demonstrated ZT values exceeding 1 at elevated temperatures, making them candidates for waste heat recovery applications.

02 Advanced skutterudite and half-Heusler compounds

Skutterudite compounds (CoSb3-based) and half-Heusler alloys represent promising mid-to-high temperature thermoelectric materials. These materials feature complex crystal structures that inherently scatter phonons while maintaining good electrical properties. Filling the voids in skutterudites with rare earth or alkaline earth elements further reduces thermal conductivity. These materials can achieve ZT values of 1.5-1.8 in the temperature range of 400-700°C, making them suitable for waste heat recovery applications in automotive and industrial settings.Expand Specific Solutions03 Silicon-germanium and silicon-based thermoelectric materials

Silicon-germanium (SiGe) alloys and nanostructured silicon-based materials are effective for high-temperature thermoelectric applications, particularly in space power generation. These materials offer excellent thermal stability and oxidation resistance at temperatures above 800°C. Nanostructuring approaches, including the incorporation of silicide phases and nanoinclusions, help to reduce the inherently high thermal conductivity of silicon-based materials. Recent advancements have pushed ZT values from traditional 0.7 to over 1.0 at high temperatures.Expand Specific Solutions04 Novel organic and hybrid thermoelectric materials

Organic and hybrid organic-inorganic thermoelectric materials represent an emerging class with advantages including flexibility, low cost, and environmental friendliness. Conducting polymers such as PEDOT:PSS and polyaniline, as well as carbon-based materials like graphene and carbon nanotubes, show promising thermoelectric properties. While their ZT values are generally lower than inorganic counterparts (typically 0.2-0.6), their performance can be enhanced through doping, composite formation, and interface engineering strategies.Expand Specific Solutions05 Nanostructured and low-dimensional thermoelectric materials

Nanostructuring approaches significantly enhance ZT values by decoupling electrical and thermal transport properties. Quantum wells, superlattices, nanowires, and quantum dot structures create energy filtering effects and phonon scattering interfaces. Materials systems including PbTe, SnSe, and MgAgSb benefit particularly from these approaches. Advanced fabrication techniques such as molecular beam epitaxy, chemical vapor deposition, and solution-based methods enable precise control of nanostructures, resulting in record ZT values exceeding 2.0 in some systems.Expand Specific Solutions

Leading Organizations in Advanced Thermoelectric Research

The thermoelectric generator materials market for high ZT values is currently in a growth phase, with increasing demand driven by energy harvesting applications. The competitive landscape features a mix of academic institutions, corporations, and government agencies collaborating on advanced material development. Leading players include Wuhan University of Technology, California Institute of Technology, and Northwestern University pioneering fundamental research, while corporations like Corning, DuPont, and Sumitomo Chemical focus on commercialization. International ThermoDyne represents specialized market entrants with proprietary technologies like PHELTEX. Government agencies including NASA and DLR provide critical research funding and application development. The technology maturity varies across material classes, with established bismuth telluride compounds reaching commercial deployment while newer nanomaterials and organic thermoelectrics remain in early development stages.

National Aeronautics & Space Administration

Technical Solution: NASA has developed specialized high-temperature thermoelectric materials optimized for deep space missions and extreme environment applications. Their advanced radioisotope thermoelectric generators (RTGs) utilize silicon-germanium alloys and skutterudite-based materials capable of operating reliably at temperatures exceeding 1000°C with stable ZT values around 1.0-1.2. NASA's materials research has focused on enhancing long-term stability and reliability under harsh conditions rather than maximizing peak ZT values. Their proprietary manufacturing techniques include zone melting, hot pressing, and advanced joining methods to create robust thermoelectric modules with minimal degradation over decades of operation. Recent developments include segmented thermoelectric couples that optimize efficiency across wide temperature gradients by utilizing different materials in their respective optimal temperature ranges, significantly improving overall system efficiency despite using materials with moderate individual ZT values.

Strengths: Unparalleled expertise in developing thermoelectric systems with exceptional reliability and longevity under extreme conditions; comprehensive testing capabilities simulating space environments. Weaknesses: Their materials are optimized for reliability over maximum efficiency, resulting in lower peak ZT values compared to laboratory-optimized materials; extremely high production costs limit applications primarily to specialized space missions.

California Institute of Technology

Technical Solution: Caltech has developed pioneering approaches to thermoelectric materials through fundamental understanding of electron and phonon transport physics. Their research team has created advanced skutterudite compounds with carefully engineered "rattler" atoms that selectively scatter phonons while preserving electronic transport, achieving ZT values exceeding 1.7 in the mid-temperature range. They've also made significant breakthroughs in half-Heusler compounds through band engineering and nanostructuring, reaching ZT values approaching 1.5 in materials composed of relatively abundant elements. Caltech's innovative approach includes the development of complex chalcogenides with intrinsically low thermal conductivity due to their disordered crystal structures. Their materials science group has further pioneered computational methods for predicting thermoelectric properties, accelerating the discovery of novel compounds with potentially high ZT values through high-throughput screening of thousands of candidate materials before experimental validation.

Strengths: Exceptional fundamental understanding of transport phenomena enabling rational design of high-performance materials; strong integration of computational and experimental approaches. Weaknesses: Some of their most promising materials involve complex synthesis procedures that present challenges for scaling to commercial production; focus on scientific understanding sometimes prioritized over practical implementation considerations.

Key Patents and Breakthroughs in Thermoelectric Materials

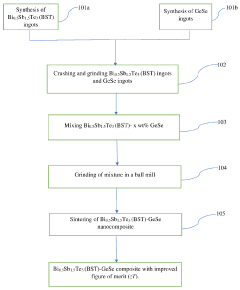

A method for improving figure of merit (ZT) of bi0.5sb1.5te3 (BST) and a bi0.5sb1.5te3 (BST)-gese composite product thereof

PatentActiveIN202131024500A

Innovation

- A method involving the synthesis of phase pure polycrystalline Bi0.5Sb1.5Te3 and GeSe, followed by grinding and ball milling to form a nanocomposite, which is then sintered under controlled conditions to enhance power factor and reduce thermal conductivity, resulting in an improved figure of merit (zT) of ~1.65 at 323 K.

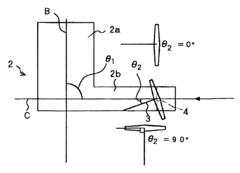

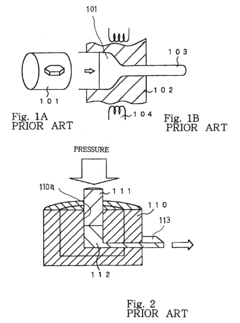

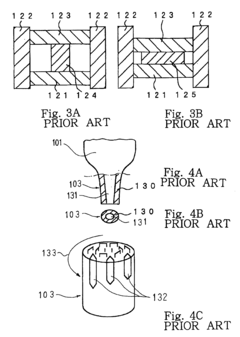

Thermoelectric material improved in figure of merit, process for producing thereof and peltier module using the same

PatentInactiveUS6743973B2

Innovation

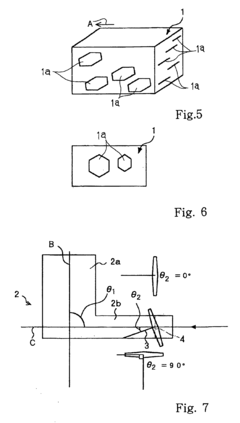

- A thermoelectric material with crystal grains having [001] directions oriented at 45 degrees or less, occupying less than 10% of the section perpendicular to the current flow direction, produced through a process involving liquid quenching and extrusion using a die with obliquely extending inlet and outlet portions, ensuring a shearing force is applied, resulting in fine and homogeneous crystal grains with improved thermoelectric properties.

Environmental Impact and Sustainability of Thermoelectric Materials

The environmental impact of thermoelectric materials represents a critical consideration in their development and deployment. Traditional thermoelectric materials often contain toxic or rare elements such as tellurium, lead, and bismuth, raising significant environmental concerns regarding their extraction, processing, and disposal. The mining operations for these elements frequently result in habitat destruction, water pollution, and substantial carbon emissions, contradicting the clean energy benefits that thermoelectric generators aim to provide.

Recent advancements in thermoelectric materials research have increasingly focused on developing environmentally benign alternatives with high ZT values. Skutterudites and half-Heusler alloys, for instance, can be engineered to reduce or eliminate toxic components while maintaining performance. Silicon-germanium alloys, though containing the relatively scarce germanium, present lower toxicity profiles compared to lead-based alternatives.

Life cycle assessment (LCA) studies of thermoelectric materials reveal that environmental impacts vary significantly across different material classes. While the operational phase of thermoelectric generators produces minimal environmental impact due to their solid-state nature, the manufacturing and end-of-life phases present substantial environmental challenges. The energy-intensive production processes for high-purity thermoelectric materials can offset some of the environmental benefits gained during operation.

Recycling and recovery strategies for thermoelectric materials remain underdeveloped, presenting both a challenge and an opportunity. The complex composition of advanced thermoelectric materials often complicates recycling efforts, but emerging technologies for selective recovery of valuable elements show promise. Establishing closed-loop systems for thermoelectric material recovery could significantly enhance their sustainability profile.

The sustainability of thermoelectric materials must also be evaluated in terms of resource availability. Many high-performance thermoelectric materials rely on tellurium, which faces supply constraints due to its limited geological abundance and status as a by-product of copper refining. Research into earth-abundant alternatives, such as magnesium silicide and zinc antimonide, represents a crucial direction for ensuring long-term sustainability.

Carbon footprint analyses indicate that despite manufacturing impacts, thermoelectric generators can achieve net environmental benefits when deployed in waste heat recovery applications. By converting otherwise wasted thermal energy into electricity, these systems can offset their embodied carbon and contribute to industrial decarbonization efforts, particularly in energy-intensive sectors like steel production and petrochemicals.

Recent advancements in thermoelectric materials research have increasingly focused on developing environmentally benign alternatives with high ZT values. Skutterudites and half-Heusler alloys, for instance, can be engineered to reduce or eliminate toxic components while maintaining performance. Silicon-germanium alloys, though containing the relatively scarce germanium, present lower toxicity profiles compared to lead-based alternatives.

Life cycle assessment (LCA) studies of thermoelectric materials reveal that environmental impacts vary significantly across different material classes. While the operational phase of thermoelectric generators produces minimal environmental impact due to their solid-state nature, the manufacturing and end-of-life phases present substantial environmental challenges. The energy-intensive production processes for high-purity thermoelectric materials can offset some of the environmental benefits gained during operation.

Recycling and recovery strategies for thermoelectric materials remain underdeveloped, presenting both a challenge and an opportunity. The complex composition of advanced thermoelectric materials often complicates recycling efforts, but emerging technologies for selective recovery of valuable elements show promise. Establishing closed-loop systems for thermoelectric material recovery could significantly enhance their sustainability profile.

The sustainability of thermoelectric materials must also be evaluated in terms of resource availability. Many high-performance thermoelectric materials rely on tellurium, which faces supply constraints due to its limited geological abundance and status as a by-product of copper refining. Research into earth-abundant alternatives, such as magnesium silicide and zinc antimonide, represents a crucial direction for ensuring long-term sustainability.

Carbon footprint analyses indicate that despite manufacturing impacts, thermoelectric generators can achieve net environmental benefits when deployed in waste heat recovery applications. By converting otherwise wasted thermal energy into electricity, these systems can offset their embodied carbon and contribute to industrial decarbonization efforts, particularly in energy-intensive sectors like steel production and petrochemicals.

Manufacturing Scalability and Cost Analysis

The scalability of manufacturing processes for advanced thermoelectric materials represents a critical challenge in transitioning from laboratory-scale production to commercial viability. Current manufacturing methods for high-ZT thermoelectric materials often involve complex synthesis procedures, including high-temperature solid-state reactions, spark plasma sintering, and hot pressing techniques. These processes typically require specialized equipment and precise control of processing parameters, limiting mass production capabilities and increasing production costs.

Material costs constitute a significant portion of the overall expense in thermoelectric generator production. High-performance thermoelectric materials frequently incorporate rare or expensive elements such as tellurium, bismuth, and various rare earth elements. Market analysis indicates that tellurium prices have fluctuated significantly over the past decade, with prices ranging from $30 to $450 per kilogram, creating uncertainty in production cost forecasting and potentially limiting widespread adoption.

Process optimization presents opportunities for cost reduction. Recent advancements in manufacturing techniques, such as solution-based processing and additive manufacturing, show promise for reducing production costs by up to 30-40% compared to traditional methods. These approaches enable more efficient material utilization and reduced energy consumption during fabrication, though they currently face challenges in maintaining the high ZT values achieved through conventional processing routes.

Supply chain considerations further complicate manufacturing scalability. The geographical concentration of critical raw materials in specific regions introduces supply risks and potential price volatility. For instance, China currently controls approximately 85% of the global rare earth element production, while tellurium production is largely tied to copper refining operations, creating dependency on mining activities primarily focused on other metals.

Economic analysis reveals that current production costs for high-performance thermoelectric modules range from $8-20 per watt of generating capacity, significantly higher than competing energy technologies. Achieving price parity with conventional power generation technologies would require reducing costs to below $3 per watt, necessitating both material innovations and manufacturing process improvements.

Industry projections suggest that economies of scale could potentially reduce manufacturing costs by 50-60% if annual production volumes increase to millions of units. However, this creates a challenging market entry barrier, as substantial investment in manufacturing infrastructure is required before competitive pricing can be achieved.

Material costs constitute a significant portion of the overall expense in thermoelectric generator production. High-performance thermoelectric materials frequently incorporate rare or expensive elements such as tellurium, bismuth, and various rare earth elements. Market analysis indicates that tellurium prices have fluctuated significantly over the past decade, with prices ranging from $30 to $450 per kilogram, creating uncertainty in production cost forecasting and potentially limiting widespread adoption.

Process optimization presents opportunities for cost reduction. Recent advancements in manufacturing techniques, such as solution-based processing and additive manufacturing, show promise for reducing production costs by up to 30-40% compared to traditional methods. These approaches enable more efficient material utilization and reduced energy consumption during fabrication, though they currently face challenges in maintaining the high ZT values achieved through conventional processing routes.

Supply chain considerations further complicate manufacturing scalability. The geographical concentration of critical raw materials in specific regions introduces supply risks and potential price volatility. For instance, China currently controls approximately 85% of the global rare earth element production, while tellurium production is largely tied to copper refining operations, creating dependency on mining activities primarily focused on other metals.

Economic analysis reveals that current production costs for high-performance thermoelectric modules range from $8-20 per watt of generating capacity, significantly higher than competing energy technologies. Achieving price parity with conventional power generation technologies would require reducing costs to below $3 per watt, necessitating both material innovations and manufacturing process improvements.

Industry projections suggest that economies of scale could potentially reduce manufacturing costs by 50-60% if annual production volumes increase to millions of units. However, this creates a challenging market entry barrier, as substantial investment in manufacturing infrastructure is required before competitive pricing can be achieved.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!