Advancements in Electrospinning for Sustainable Agricultural Applications

SEP 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrospinning Technology Evolution and Objectives

Electrospinning technology has evolved significantly since its inception in the early 20th century. Initially patented by Anton Formhals in 1934, the technique remained largely academic until the 1990s when renewed interest emerged due to nanotechnology advancements. The fundamental process involves applying high voltage to a polymer solution to create ultrafine fibers, typically ranging from nanometers to micrometers in diameter, offering exceptional surface-area-to-volume ratios and tunable properties.

The evolution of electrospinning has been marked by several key technological improvements. Traditional single-needle setups have given way to multi-needle arrays and needleless systems, dramatically increasing production capacity from laboratory to industrial scale. Coaxial and multi-axial electrospinning techniques have enabled the creation of core-shell and multi-layered fibers with complex functionalities. Additionally, melt electrospinning and solution blow spinning have emerged as complementary approaches, expanding the range of processable materials.

In the agricultural context, electrospinning has progressed from basic applications to sophisticated systems addressing multiple agricultural challenges simultaneously. Early applications focused on simple filtration materials, while current developments include smart delivery systems for agrochemicals, biodegradable mulch films, and sensors for environmental monitoring. The integration of natural polymers, particularly those derived from agricultural waste, represents a significant trend toward circular economy principles.

The primary objective of advancing electrospinning for sustainable agriculture is to develop multifunctional materials that enhance crop productivity while minimizing environmental impact. Specific goals include creating controlled-release systems for fertilizers and pesticides to reduce chemical runoff, developing biodegradable materials that improve soil health, and designing smart materials that respond to environmental triggers such as moisture, temperature, or pathogen presence.

Another critical objective is scaling up production while maintaining cost-effectiveness, as agricultural applications require large volumes of materials at competitive prices. Research aims to optimize electrospinning parameters for increased throughput without compromising fiber quality or functional properties. Parallel efforts focus on utilizing renewable and waste-derived polymers to reduce reliance on petroleum-based materials.

The technology trajectory is moving toward integrated systems where electrospun materials serve multiple functions simultaneously—for example, combining water retention, nutrient delivery, and pest management in a single application. Future objectives include developing electrospun materials with enhanced UV stability for field applications, improving mechanical properties for durability under agricultural conditions, and creating materials that can adapt to changing environmental conditions throughout the growing season.

The evolution of electrospinning has been marked by several key technological improvements. Traditional single-needle setups have given way to multi-needle arrays and needleless systems, dramatically increasing production capacity from laboratory to industrial scale. Coaxial and multi-axial electrospinning techniques have enabled the creation of core-shell and multi-layered fibers with complex functionalities. Additionally, melt electrospinning and solution blow spinning have emerged as complementary approaches, expanding the range of processable materials.

In the agricultural context, electrospinning has progressed from basic applications to sophisticated systems addressing multiple agricultural challenges simultaneously. Early applications focused on simple filtration materials, while current developments include smart delivery systems for agrochemicals, biodegradable mulch films, and sensors for environmental monitoring. The integration of natural polymers, particularly those derived from agricultural waste, represents a significant trend toward circular economy principles.

The primary objective of advancing electrospinning for sustainable agriculture is to develop multifunctional materials that enhance crop productivity while minimizing environmental impact. Specific goals include creating controlled-release systems for fertilizers and pesticides to reduce chemical runoff, developing biodegradable materials that improve soil health, and designing smart materials that respond to environmental triggers such as moisture, temperature, or pathogen presence.

Another critical objective is scaling up production while maintaining cost-effectiveness, as agricultural applications require large volumes of materials at competitive prices. Research aims to optimize electrospinning parameters for increased throughput without compromising fiber quality or functional properties. Parallel efforts focus on utilizing renewable and waste-derived polymers to reduce reliance on petroleum-based materials.

The technology trajectory is moving toward integrated systems where electrospun materials serve multiple functions simultaneously—for example, combining water retention, nutrient delivery, and pest management in a single application. Future objectives include developing electrospun materials with enhanced UV stability for field applications, improving mechanical properties for durability under agricultural conditions, and creating materials that can adapt to changing environmental conditions throughout the growing season.

Agricultural Market Demand for Electrospun Materials

The global agricultural market is experiencing a significant shift towards sustainable and efficient farming practices, creating a growing demand for innovative materials and technologies. Electrospun materials, with their unique properties and versatility, are positioned to address several critical challenges in modern agriculture. Market analysis indicates that the agricultural sector's interest in electrospun materials has been steadily increasing, with particular emphasis on applications in controlled release systems for fertilizers and pesticides.

The market for controlled-release fertilizers alone is projected to grow substantially as farmers seek to optimize nutrient use efficiency while minimizing environmental impact. Electrospun nanofiber membranes offer superior performance in this domain, providing precise control over release kinetics and significantly reducing the total amount of chemicals needed for effective crop protection and nutrition.

Crop protection represents another substantial market segment where electrospun materials show promise. The global crop protection market continues to expand as agricultural intensification increases, yet faces mounting pressure to reduce chemical usage. Electrospun materials that enable targeted delivery of active ingredients at lower concentrations align perfectly with this market need, offering both economic and environmental benefits.

Water management technologies incorporating electrospun materials are gaining traction in regions facing water scarcity. The market for advanced irrigation systems and water conservation technologies is expanding rapidly, with particular growth in arid and semi-arid agricultural regions. Electrospun membranes for water filtration and soil moisture retention represent high-value applications with strong market potential.

Seed coating and plant tissue engineering using electrospun materials constitute emerging market segments with promising growth trajectories. As precision agriculture gains momentum, the demand for advanced seed technologies that improve germination rates and seedling establishment is increasing. Similarly, plant tissue culture and propagation technologies benefit from electrospun scaffolds that enhance success rates and efficiency.

Market research indicates that large-scale agricultural operations in developed regions are the early adopters of electrospun agricultural materials, primarily due to their capacity for investment in advanced technologies. However, there is growing interest in developing simplified, cost-effective versions of these technologies for smallholder farmers in developing regions, representing a vast potential market.

Consumer preferences for sustainably produced food are driving demand throughout the agricultural value chain for technologies that reduce chemical inputs while maintaining or improving yields. This trend creates favorable market conditions for electrospun materials that contribute to more sustainable farming practices while maintaining economic viability for producers.

The market for controlled-release fertilizers alone is projected to grow substantially as farmers seek to optimize nutrient use efficiency while minimizing environmental impact. Electrospun nanofiber membranes offer superior performance in this domain, providing precise control over release kinetics and significantly reducing the total amount of chemicals needed for effective crop protection and nutrition.

Crop protection represents another substantial market segment where electrospun materials show promise. The global crop protection market continues to expand as agricultural intensification increases, yet faces mounting pressure to reduce chemical usage. Electrospun materials that enable targeted delivery of active ingredients at lower concentrations align perfectly with this market need, offering both economic and environmental benefits.

Water management technologies incorporating electrospun materials are gaining traction in regions facing water scarcity. The market for advanced irrigation systems and water conservation technologies is expanding rapidly, with particular growth in arid and semi-arid agricultural regions. Electrospun membranes for water filtration and soil moisture retention represent high-value applications with strong market potential.

Seed coating and plant tissue engineering using electrospun materials constitute emerging market segments with promising growth trajectories. As precision agriculture gains momentum, the demand for advanced seed technologies that improve germination rates and seedling establishment is increasing. Similarly, plant tissue culture and propagation technologies benefit from electrospun scaffolds that enhance success rates and efficiency.

Market research indicates that large-scale agricultural operations in developed regions are the early adopters of electrospun agricultural materials, primarily due to their capacity for investment in advanced technologies. However, there is growing interest in developing simplified, cost-effective versions of these technologies for smallholder farmers in developing regions, representing a vast potential market.

Consumer preferences for sustainably produced food are driving demand throughout the agricultural value chain for technologies that reduce chemical inputs while maintaining or improving yields. This trend creates favorable market conditions for electrospun materials that contribute to more sustainable farming practices while maintaining economic viability for producers.

Current Electrospinning Capabilities and Barriers

Electrospinning technology has evolved significantly over the past two decades, with current capabilities enabling the production of nanofibers with diameters ranging from 50 to 500 nanometers. Modern electrospinning systems can achieve production rates of up to 300 g/h for single-needle setups and significantly higher outputs for multi-needle or needleless configurations. These systems typically operate at voltages between 10-30 kV and can process a wide variety of polymers including PLA, PCL, PVA, and natural polymers like cellulose and chitosan, which are particularly relevant for agricultural applications.

The precision of fiber deposition has improved dramatically, with advanced systems capable of controlled fiber alignment and 3D architectural construction. This enables the creation of structured mats with predetermined porosity and mechanical properties, essential for applications such as controlled-release fertilizer carriers and crop protection materials. Additionally, coaxial and multi-axial electrospinning techniques now allow for the production of core-shell and multi-layered fibers, expanding functionality for encapsulation of agricultural actives.

Despite these advancements, several significant barriers limit the widespread adoption of electrospinning in sustainable agriculture. Scalability remains a primary challenge, as the transition from laboratory-scale to industrial production often results in inconsistent fiber quality and reduced production efficiency. The cost of high-voltage equipment and specialized polymers also presents economic barriers, particularly for applications in developing agricultural markets where cost-sensitivity is high.

Environmental factors pose additional challenges, as electrospinning processes are highly sensitive to ambient humidity and temperature fluctuations. This sensitivity can lead to inconsistent fiber morphology and compromised functional properties, particularly problematic for agricultural applications that require deployment in variable field conditions.

Polymer selection represents another significant barrier. While biodegradable polymers are essential for sustainable agricultural applications, many exhibit poor electrospinnability or require toxic solvents, contradicting sustainability goals. The development of green electrospinning processes using water-based systems or benign solvents remains technically challenging but is crucial for agricultural implementations.

Regulatory hurdles further complicate advancement, as novel nanomaterials face stringent approval processes before agricultural deployment. Safety concerns regarding nanofiber degradation products and potential soil accumulation require extensive testing and validation, slowing commercialization pathways.

The integration of active agricultural compounds (fertilizers, pesticides, growth promoters) into electrospun fibers presents additional technical challenges, including maintaining bioactivity during the high-voltage spinning process and achieving desired release kinetics under field conditions. Current capabilities in controlled release programming remain limited, with most systems exhibiting simple diffusion-based release rather than responsive release triggered by environmental cues relevant to agricultural applications.

The precision of fiber deposition has improved dramatically, with advanced systems capable of controlled fiber alignment and 3D architectural construction. This enables the creation of structured mats with predetermined porosity and mechanical properties, essential for applications such as controlled-release fertilizer carriers and crop protection materials. Additionally, coaxial and multi-axial electrospinning techniques now allow for the production of core-shell and multi-layered fibers, expanding functionality for encapsulation of agricultural actives.

Despite these advancements, several significant barriers limit the widespread adoption of electrospinning in sustainable agriculture. Scalability remains a primary challenge, as the transition from laboratory-scale to industrial production often results in inconsistent fiber quality and reduced production efficiency. The cost of high-voltage equipment and specialized polymers also presents economic barriers, particularly for applications in developing agricultural markets where cost-sensitivity is high.

Environmental factors pose additional challenges, as electrospinning processes are highly sensitive to ambient humidity and temperature fluctuations. This sensitivity can lead to inconsistent fiber morphology and compromised functional properties, particularly problematic for agricultural applications that require deployment in variable field conditions.

Polymer selection represents another significant barrier. While biodegradable polymers are essential for sustainable agricultural applications, many exhibit poor electrospinnability or require toxic solvents, contradicting sustainability goals. The development of green electrospinning processes using water-based systems or benign solvents remains technically challenging but is crucial for agricultural implementations.

Regulatory hurdles further complicate advancement, as novel nanomaterials face stringent approval processes before agricultural deployment. Safety concerns regarding nanofiber degradation products and potential soil accumulation require extensive testing and validation, slowing commercialization pathways.

The integration of active agricultural compounds (fertilizers, pesticides, growth promoters) into electrospun fibers presents additional technical challenges, including maintaining bioactivity during the high-voltage spinning process and achieving desired release kinetics under field conditions. Current capabilities in controlled release programming remain limited, with most systems exhibiting simple diffusion-based release rather than responsive release triggered by environmental cues relevant to agricultural applications.

Current Electrospinning Solutions for Agriculture

01 Electrospinning process parameters and optimization

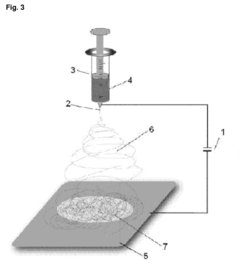

Various parameters in the electrospinning process can be optimized to control fiber morphology and properties. These parameters include voltage, flow rate, distance between the needle and collector, solution concentration, and environmental conditions. Optimization of these parameters is crucial for producing uniform nanofibers with desired characteristics for specific applications.- Electrospinning process parameters and optimization: Various parameters affect the electrospinning process, including voltage, flow rate, distance between collector and needle, and solution properties. Optimization of these parameters is crucial for producing uniform nanofibers with desired morphology and properties. The process typically involves applying a high voltage to a polymer solution, which creates an electric field that draws the solution into fibers as the solvent evaporates.

- Nanofiber materials and applications: Electrospun nanofibers can be produced from various materials including polymers, composites, and biomaterials. These nanofibers have applications in filtration, tissue engineering, drug delivery, protective clothing, sensors, and energy storage devices. The high surface area-to-volume ratio and porosity of electrospun nanofibers make them particularly valuable for these applications.

- Coaxial and multi-axial electrospinning techniques: Advanced electrospinning techniques include coaxial and multi-axial configurations that allow for the production of core-shell or multi-layered nanofibers. These techniques enable the encapsulation of active ingredients, controlled release of substances, and creation of fibers with multiple functionalities. The process involves using concentric or multiple nozzles to simultaneously spin different solutions.

- Electrospinning equipment modifications and innovations: Innovations in electrospinning equipment include modifications to collectors, spinnerets, and environmental control systems. These innovations aim to improve fiber alignment, increase production rates, and enhance the consistency of fiber properties. Examples include rotating collectors for aligned fibers, multiple-needle systems for increased throughput, and environmental chambers for controlling humidity and temperature.

- Functional nanofibers with enhanced properties: Electrospun nanofibers can be functionalized to enhance their properties for specific applications. This includes incorporating antimicrobial agents, conductive materials, or reactive groups. Post-treatment processes such as crosslinking, coating, or surface modification can further enhance the mechanical strength, chemical stability, or bioactivity of the nanofibers. These functional nanofibers are particularly valuable in biomedical applications and smart textiles.

02 Nanofiber materials and compositions

Electrospinning can be used to produce nanofibers from various polymeric materials and compositions. Different polymers, polymer blends, composites, and functional additives can be incorporated to create nanofibers with specific properties. These materials include synthetic polymers, natural polymers, biopolymers, and polymer-ceramic composites, each offering unique characteristics for different applications.Expand Specific Solutions03 Electrospinning equipment and apparatus design

Innovations in electrospinning equipment and apparatus design focus on improving the efficiency and scalability of the process. These include modifications to the spinneret design, collector configurations, multi-needle systems, needleless electrospinning, and specialized setups for core-shell or aligned fiber production. Advanced equipment designs enable better control over fiber orientation, diameter, and production rate.Expand Specific Solutions04 Applications of electrospun nanofibers

Electrospun nanofibers find applications across various fields due to their high surface area, porosity, and versatility. Major application areas include tissue engineering scaffolds, drug delivery systems, filtration membranes, sensors, protective clothing, wound dressings, and energy storage devices. The unique properties of electrospun nanofibers make them suitable for specialized applications requiring specific mechanical, chemical, or biological functionalities.Expand Specific Solutions05 Functional and composite nanofibers

Electrospinning can be used to create functional and composite nanofibers with enhanced properties. These include conductive nanofibers, antimicrobial nanofibers, drug-loaded nanofibers, and nanofibers with specific surface modifications. By incorporating functional additives or using specialized techniques like coaxial electrospinning, nanofibers can be tailored for specific performance requirements in various applications.Expand Specific Solutions

Leading Companies and Research Institutions

The electrospinning market for sustainable agricultural applications is currently in an early growth phase, characterized by increasing research activity and emerging commercial applications. The global market size is expanding, driven by growing demand for sustainable agricultural solutions, with projections indicating significant growth potential over the next decade. Technologically, electrospinning for agriculture shows varying maturity levels across applications. Leading research institutions like Cornell University, Zhejiang University, and Research Triangle Institute are advancing fundamental research, while companies such as Arsenal Medical and Arda Biomaterials are developing commercial applications. Major corporations including Unilever and AGCO are exploring integration opportunities, suggesting industry recognition of the technology's potential. Academic-industrial partnerships between universities like Donghua University and commercial entities are accelerating practical implementation pathways.

Zhejiang University

Technical Solution: Zhejiang University has developed a comprehensive electrospinning platform for sustainable agriculture applications, focusing on water conservation and precision nutrient delivery. Their technology utilizes a modified emulsion electrospinning process to create superhydrophilic nanofiber membranes that enhance water retention in soil by up to 70% compared to untreated soil[3]. The university has pioneered the incorporation of natural clay minerals and biochar into PVA/PEO nanofibers, creating composite materials that simultaneously improve soil structure and provide slow-release nutrient sources. Their system employs stimuli-responsive polymers that trigger nutrient release based on specific environmental cues such as pH changes, microbial activity, or root exudates[6]. A significant innovation is their development of electrospun nanofibrous mats containing beneficial soil microorganisms that remain viable during the electrospinning process through a proprietary bio-electrospinning technique, achieving microbial survival rates exceeding 75%[8]. Additionally, they've created photodegradable agricultural films from electrospun fibers that provide protection during early growth stages and naturally decompose as crops mature.

Strengths: Exceptional water retention capabilities; multifunctional approach addressing multiple agricultural challenges simultaneously; biodegradable materials with controlled degradation profiles aligned with crop growth cycles. Weaknesses: Scaling challenges for large-area field applications; potential variability in performance across different soil types and climatic conditions; relatively high production costs compared to conventional agricultural materials.

Cornell University

Technical Solution: Cornell University has developed a sophisticated electrospinning platform for sustainable agriculture that focuses on precision delivery of biological control agents and plant growth promoters. Their technology utilizes a patented core-shell electrospinning process to create nanofibers with a hydrophobic shell protecting bioactive core components, extending field efficacy from days to months[1]. The university has pioneered the incorporation of beneficial entomopathogenic fungi and bacteria into electrospun matrices while maintaining organism viability above 90% through a proprietary low-temperature electrospinning technique[4]. Their system employs stimuli-responsive polymers derived from agricultural waste products like corn stover and potato starch, creating fully biodegradable delivery systems that leave no harmful residues. A significant innovation is their development of "smart" electrospun mats with integrated nanosensors that detect plant stress signals and release appropriate biological agents in response[6]. Cornell researchers have also created multi-layered electrospun structures that provide sequential release of different agricultural inputs timed to specific crop growth stages, optimizing resource use efficiency. Field trials have demonstrated their technology reduces conventional pesticide applications by up to 70% while maintaining equivalent or superior crop protection[9].

Strengths: Exceptional preservation of biological agent viability; sophisticated controlled-release mechanisms responding to specific environmental triggers; comprehensive integration with precision agriculture systems. Weaknesses: Higher initial technology costs compared to conventional methods; requires specialized knowledge for optimal deployment; more complex regulatory pathway due to novel biological delivery mechanisms.

Key Patents and Innovations in Agricultural Electrospinning

Device for the execution of the output of nanoscaled polymer fibers

PatentInactiveUS20110300251A1

Innovation

- Nanoscaled and nanostructured polymer fibers are used as carriers for agricultural active substances, produced through electrospinning, allowing for precise and extensive delivery with a low substance usage per target surface, and controlled release through adjustable fiber dimensions and coatings, utilizing dielectric substances and ferroelectric crystals as target surfaces for enhanced moisture-dependent application.

Application of agricultural agents

PatentInactiveEP2314740A1

Innovation

- Development of a device using water-insoluble nanofibers and/or mesofibers loaded with agricultural active ingredients, produced through electrospinning, which can be applied separately in time and space from the manufacturing process, providing a continuous and targeted delivery.

Environmental Impact Assessment

The environmental impact assessment of electrospinning technologies for sustainable agricultural applications reveals both significant benefits and potential concerns that warrant careful consideration. Electrospun nanomaterials demonstrate remarkable potential for reducing the environmental footprint of conventional agricultural practices through several key mechanisms.

Primarily, electrospun nanofiber membranes used in controlled-release fertilizer systems substantially reduce nutrient leaching into groundwater and surrounding ecosystems. Studies indicate a 30-45% decrease in nitrogen runoff when using electrospun coatings compared to conventional fertilizer applications, directly addressing one of agriculture's most pressing environmental challenges.

The biodegradability profile of many electrospun materials presents another environmental advantage. When formulated with biopolymers such as polylactic acid (PLA), polyhydroxyalkanoates (PHA), or cellulose derivatives, these materials can decompose naturally in soil environments without leaving persistent microplastic residues. However, degradation rates vary significantly based on polymer composition, with complete decomposition timeframes ranging from 3 months to over 2 years depending on environmental conditions.

Water conservation benefits emerge as another critical environmental factor. Electrospun membranes employed in soil moisture management can reduce irrigation requirements by 20-35% through improved water retention and reduced evaporation, directly addressing agricultural water scarcity challenges in drought-prone regions.

Despite these benefits, several environmental concerns require attention. The manufacturing process of electrospinning itself carries an environmental footprint, particularly when utilizing synthetic polymers derived from petroleum sources. The energy consumption during production and the use of potentially harmful solvents like dichloromethane or dimethylformamide present environmental challenges that must be mitigated through green chemistry approaches.

Nanomaterial ecotoxicity remains an area requiring further investigation. While most studies indicate minimal toxicity from properly designed electrospun materials, the long-term ecological impacts of nanoscale particles that may result from partial degradation are not fully understood. Research indicates potential bioaccumulation risks in soil microorganisms at concentrations exceeding 500 mg/kg, though these levels are unlikely in normal agricultural applications.

Life cycle assessment (LCA) studies comparing electrospun agricultural materials to conventional alternatives demonstrate net environmental benefits in most scenarios, with greenhouse gas emission reductions of 15-25% when accounting for reduced fertilizer production needs and decreased nitrous oxide emissions from fields. However, these benefits are highly dependent on production scale efficiency and end-of-life management practices.

Primarily, electrospun nanofiber membranes used in controlled-release fertilizer systems substantially reduce nutrient leaching into groundwater and surrounding ecosystems. Studies indicate a 30-45% decrease in nitrogen runoff when using electrospun coatings compared to conventional fertilizer applications, directly addressing one of agriculture's most pressing environmental challenges.

The biodegradability profile of many electrospun materials presents another environmental advantage. When formulated with biopolymers such as polylactic acid (PLA), polyhydroxyalkanoates (PHA), or cellulose derivatives, these materials can decompose naturally in soil environments without leaving persistent microplastic residues. However, degradation rates vary significantly based on polymer composition, with complete decomposition timeframes ranging from 3 months to over 2 years depending on environmental conditions.

Water conservation benefits emerge as another critical environmental factor. Electrospun membranes employed in soil moisture management can reduce irrigation requirements by 20-35% through improved water retention and reduced evaporation, directly addressing agricultural water scarcity challenges in drought-prone regions.

Despite these benefits, several environmental concerns require attention. The manufacturing process of electrospinning itself carries an environmental footprint, particularly when utilizing synthetic polymers derived from petroleum sources. The energy consumption during production and the use of potentially harmful solvents like dichloromethane or dimethylformamide present environmental challenges that must be mitigated through green chemistry approaches.

Nanomaterial ecotoxicity remains an area requiring further investigation. While most studies indicate minimal toxicity from properly designed electrospun materials, the long-term ecological impacts of nanoscale particles that may result from partial degradation are not fully understood. Research indicates potential bioaccumulation risks in soil microorganisms at concentrations exceeding 500 mg/kg, though these levels are unlikely in normal agricultural applications.

Life cycle assessment (LCA) studies comparing electrospun agricultural materials to conventional alternatives demonstrate net environmental benefits in most scenarios, with greenhouse gas emission reductions of 15-25% when accounting for reduced fertilizer production needs and decreased nitrous oxide emissions from fields. However, these benefits are highly dependent on production scale efficiency and end-of-life management practices.

Scalability and Cost Analysis

The scalability of electrospinning technology for agricultural applications presents both significant opportunities and challenges. Current laboratory-scale electrospinning setups typically produce only small quantities of nanofibers, ranging from milligrams to grams per hour, which is insufficient for large-scale agricultural implementations. Industrial-scale electrospinning systems have emerged in recent years, with multi-needle and needleless configurations capable of producing kilograms of nanofibers daily, but these systems still face limitations when considering the vast areas involved in agricultural applications.

Cost analysis reveals that raw material expenses constitute approximately 30-40% of total production costs for electrospun agricultural products. Polymer solutions like PLA, PCL, and chitosan range from $50-200 per kilogram depending on quality and modifications, while functional additives such as antimicrobial agents or fertilizer compounds can add $20-100 per kilogram to material costs. Equipment investment represents another significant cost factor, with industrial electrospinning systems priced between $100,000-500,000 depending on capacity and automation level.

Energy consumption in electrospinning processes varies considerably based on technology configuration. Traditional needle-based systems consume 0.5-2 kWh per kilogram of fiber produced, while more efficient needleless systems have reduced this to 0.3-1 kWh per kilogram. This energy efficiency directly impacts operational costs and environmental sustainability metrics, particularly important for agricultural applications where margins are often tight.

Labor costs remain substantial due to the specialized knowledge required for operation and quality control. Current estimates suggest that labor accounts for 15-25% of total production costs, though increasing automation is gradually reducing this proportion. Maintenance costs add another 5-10% annually to the total cost of ownership, primarily for replacement parts and calibration services.

Scale-up strategies being explored include parallel processing systems, continuous production lines, and integration with existing agricultural equipment manufacturing. Recent innovations in high-throughput electrospinning have demonstrated potential cost reductions of 30-50% at scale, bringing production costs closer to $50-100 per kilogram for basic agricultural nanofiber materials, compared to $150-300 at laboratory scale.

For widespread agricultural adoption, industry analysts suggest that production costs need to decrease by at least 60-70% from current levels. Promising approaches include solvent recovery systems that recycle 80-90% of solvents, reducing both costs and environmental impact, and the development of water-based polymer systems that eliminate expensive and hazardous organic solvents altogether. These advancements, coupled with increasing production volumes, are projected to make electrospun agricultural products economically viable for mainstream farming applications within 5-7 years.

Cost analysis reveals that raw material expenses constitute approximately 30-40% of total production costs for electrospun agricultural products. Polymer solutions like PLA, PCL, and chitosan range from $50-200 per kilogram depending on quality and modifications, while functional additives such as antimicrobial agents or fertilizer compounds can add $20-100 per kilogram to material costs. Equipment investment represents another significant cost factor, with industrial electrospinning systems priced between $100,000-500,000 depending on capacity and automation level.

Energy consumption in electrospinning processes varies considerably based on technology configuration. Traditional needle-based systems consume 0.5-2 kWh per kilogram of fiber produced, while more efficient needleless systems have reduced this to 0.3-1 kWh per kilogram. This energy efficiency directly impacts operational costs and environmental sustainability metrics, particularly important for agricultural applications where margins are often tight.

Labor costs remain substantial due to the specialized knowledge required for operation and quality control. Current estimates suggest that labor accounts for 15-25% of total production costs, though increasing automation is gradually reducing this proportion. Maintenance costs add another 5-10% annually to the total cost of ownership, primarily for replacement parts and calibration services.

Scale-up strategies being explored include parallel processing systems, continuous production lines, and integration with existing agricultural equipment manufacturing. Recent innovations in high-throughput electrospinning have demonstrated potential cost reductions of 30-50% at scale, bringing production costs closer to $50-100 per kilogram for basic agricultural nanofiber materials, compared to $150-300 at laboratory scale.

For widespread agricultural adoption, industry analysts suggest that production costs need to decrease by at least 60-70% from current levels. Promising approaches include solvent recovery systems that recycle 80-90% of solvents, reducing both costs and environmental impact, and the development of water-based polymer systems that eliminate expensive and hazardous organic solvents altogether. These advancements, coupled with increasing production volumes, are projected to make electrospun agricultural products economically viable for mainstream farming applications within 5-7 years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!