How Electrospinning Enhances Surface Functionalization of Nanostructures

SEP 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrospinning Technology Background and Objectives

Electrospinning technology emerged in the early 20th century, with the first patent filed by J.F. Cooley in 1902. However, it wasn't until the 1990s that this technique gained significant attention in the scientific community, primarily due to advancements in nanotechnology and increased demand for functional nanomaterials. The process fundamentally involves applying a high voltage to a polymer solution or melt, creating an electrically charged jet that stretches and thins as it travels toward a collector, resulting in fibers with diameters ranging from nanometers to micrometers.

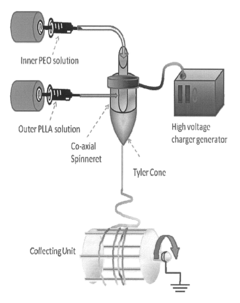

The evolution of electrospinning has been marked by several key developments, including the introduction of coaxial electrospinning in the early 2000s, which enabled the production of core-shell nanofibers, and the development of multi-jet electrospinning systems for increased production capacity. Recent advancements have focused on enhancing control over fiber morphology, orientation, and surface properties, which are crucial for surface functionalization applications.

Surface functionalization of nanostructures represents a critical frontier in materials science, enabling the tailoring of material properties for specific applications. Electrospinning offers unique advantages in this domain due to its versatility in processing various polymers, ceramics, and composite materials, as well as its ability to create high surface-area-to-volume ratio structures that maximize functionalization potential.

The primary technical objectives in this field include developing methods to precisely control the surface chemistry of electrospun nanofibers, enhancing the stability and durability of functionalized surfaces, and scaling up production processes while maintaining quality and consistency. Additionally, there is significant interest in creating multi-functional surfaces that can respond to environmental stimuli or perform multiple tasks simultaneously.

Current research trends indicate a growing focus on green electrospinning techniques that utilize environmentally friendly solvents and biodegradable polymers. There is also increasing emphasis on in-situ functionalization during the electrospinning process, which can simplify manufacturing and potentially enhance the integration of functional groups within the nanostructure rather than merely on its surface.

The convergence of electrospinning with other advanced technologies, such as 3D printing and microfluidics, is opening new avenues for creating hierarchical structures with precisely controlled surface properties. This integration represents a promising direction for next-generation materials with enhanced functionality and performance characteristics.

As we look toward future developments, the field is poised to address challenges related to scalability, reproducibility, and the development of standardized characterization methods for functionalized surfaces. The ultimate goal remains the creation of tailored nanostructured surfaces that can meet the demanding requirements of applications in healthcare, environmental remediation, energy storage, and advanced manufacturing.

The evolution of electrospinning has been marked by several key developments, including the introduction of coaxial electrospinning in the early 2000s, which enabled the production of core-shell nanofibers, and the development of multi-jet electrospinning systems for increased production capacity. Recent advancements have focused on enhancing control over fiber morphology, orientation, and surface properties, which are crucial for surface functionalization applications.

Surface functionalization of nanostructures represents a critical frontier in materials science, enabling the tailoring of material properties for specific applications. Electrospinning offers unique advantages in this domain due to its versatility in processing various polymers, ceramics, and composite materials, as well as its ability to create high surface-area-to-volume ratio structures that maximize functionalization potential.

The primary technical objectives in this field include developing methods to precisely control the surface chemistry of electrospun nanofibers, enhancing the stability and durability of functionalized surfaces, and scaling up production processes while maintaining quality and consistency. Additionally, there is significant interest in creating multi-functional surfaces that can respond to environmental stimuli or perform multiple tasks simultaneously.

Current research trends indicate a growing focus on green electrospinning techniques that utilize environmentally friendly solvents and biodegradable polymers. There is also increasing emphasis on in-situ functionalization during the electrospinning process, which can simplify manufacturing and potentially enhance the integration of functional groups within the nanostructure rather than merely on its surface.

The convergence of electrospinning with other advanced technologies, such as 3D printing and microfluidics, is opening new avenues for creating hierarchical structures with precisely controlled surface properties. This integration represents a promising direction for next-generation materials with enhanced functionality and performance characteristics.

As we look toward future developments, the field is poised to address challenges related to scalability, reproducibility, and the development of standardized characterization methods for functionalized surfaces. The ultimate goal remains the creation of tailored nanostructured surfaces that can meet the demanding requirements of applications in healthcare, environmental remediation, energy storage, and advanced manufacturing.

Market Applications of Functionalized Nanostructures

Functionalized nanostructures have emerged as transformative materials across multiple industries, with electrospinning-enhanced surface functionalization driving significant market growth. The healthcare sector represents the largest application area, with functionalized nanofibers being increasingly utilized in advanced wound dressings, drug delivery systems, and tissue engineering scaffolds. These materials offer superior drug loading capacity, controlled release profiles, and enhanced biocompatibility, addressing critical challenges in personalized medicine and regenerative therapies. Market analysts project the medical applications of functionalized nanostructures to reach substantial market value by 2028, with a compound annual growth rate exceeding industry averages.

Environmental remediation represents another rapidly expanding market segment, where electrospun nanofibers with functionalized surfaces demonstrate exceptional capabilities in water purification, air filtration, and contaminant adsorption. Their high surface-to-volume ratio and customizable surface chemistry enable selective removal of heavy metals, organic pollutants, and microbial contaminants with efficiency surpassing conventional materials. This application area is experiencing particularly strong growth in regions facing severe water scarcity and industrial pollution challenges.

The electronics and energy storage sectors have also embraced functionalized nanostructures for next-generation devices. Surface-modified electrospun nanofibers are being incorporated into flexible electronics, sensors, solar cells, and high-performance batteries. Their unique electrical, optical, and mechanical properties enable improvements in energy conversion efficiency, storage capacity, and device durability. Market adoption in these sectors is accelerating as manufacturers seek sustainable alternatives to traditional materials with enhanced performance characteristics.

Textile and protective equipment industries represent emerging application areas with significant growth potential. Functionalized nanostructures created through electrospinning are being integrated into smart textiles, providing properties such as antimicrobial protection, self-cleaning capabilities, UV resistance, and thermal regulation. The defense sector has shown particular interest in these materials for developing advanced protective gear with enhanced chemical and biological threat resistance.

Agricultural applications of functionalized nanostructures include controlled-release fertilizers, pesticide delivery systems, and soil remediation technologies. These solutions address growing concerns about agricultural sustainability and environmental impact while improving crop yields. Though currently a smaller market segment, it shows promising growth potential as agricultural practices increasingly emphasize precision and sustainability.

The automotive and aerospace industries are exploring functionalized nanostructures for lightweight composite materials, coatings with enhanced durability, and components with improved thermal and electrical properties. These applications aim to improve fuel efficiency, reduce emissions, and enhance overall performance of transportation systems, aligning with global sustainability initiatives and regulatory requirements.

Environmental remediation represents another rapidly expanding market segment, where electrospun nanofibers with functionalized surfaces demonstrate exceptional capabilities in water purification, air filtration, and contaminant adsorption. Their high surface-to-volume ratio and customizable surface chemistry enable selective removal of heavy metals, organic pollutants, and microbial contaminants with efficiency surpassing conventional materials. This application area is experiencing particularly strong growth in regions facing severe water scarcity and industrial pollution challenges.

The electronics and energy storage sectors have also embraced functionalized nanostructures for next-generation devices. Surface-modified electrospun nanofibers are being incorporated into flexible electronics, sensors, solar cells, and high-performance batteries. Their unique electrical, optical, and mechanical properties enable improvements in energy conversion efficiency, storage capacity, and device durability. Market adoption in these sectors is accelerating as manufacturers seek sustainable alternatives to traditional materials with enhanced performance characteristics.

Textile and protective equipment industries represent emerging application areas with significant growth potential. Functionalized nanostructures created through electrospinning are being integrated into smart textiles, providing properties such as antimicrobial protection, self-cleaning capabilities, UV resistance, and thermal regulation. The defense sector has shown particular interest in these materials for developing advanced protective gear with enhanced chemical and biological threat resistance.

Agricultural applications of functionalized nanostructures include controlled-release fertilizers, pesticide delivery systems, and soil remediation technologies. These solutions address growing concerns about agricultural sustainability and environmental impact while improving crop yields. Though currently a smaller market segment, it shows promising growth potential as agricultural practices increasingly emphasize precision and sustainability.

The automotive and aerospace industries are exploring functionalized nanostructures for lightweight composite materials, coatings with enhanced durability, and components with improved thermal and electrical properties. These applications aim to improve fuel efficiency, reduce emissions, and enhance overall performance of transportation systems, aligning with global sustainability initiatives and regulatory requirements.

Current Challenges in Nanostructure Surface Functionalization

Despite significant advancements in nanostructure fabrication, surface functionalization remains a critical bottleneck in realizing the full potential of nanomaterials. Current surface modification techniques often struggle with achieving uniform coverage, maintaining structural integrity, and ensuring precise control over functional group density. Traditional wet chemistry approaches frequently result in non-homogeneous distribution of functional groups, while physical methods like plasma treatment can damage delicate nanostructures.

A major challenge lies in the high surface energy of nanomaterials, which leads to aggregation during functionalization processes, reducing effective surface area and accessibility. This is particularly problematic for nanofibers and nanoparticles where maintaining dispersion during chemical treatment is essential. Additionally, characterization of functionalized surfaces at the nanoscale presents significant technical difficulties, making quality control and reproducibility problematic.

The scalability of current functionalization methods represents another substantial hurdle. Laboratory-scale techniques often fail to translate effectively to industrial production, creating a significant gap between research advancements and commercial applications. This scaling issue is compounded by the high cost of specialized equipment and reagents required for precise surface modification.

Stability of functionalized surfaces under various environmental conditions remains inadequate for many applications. Functional groups attached to nanostructures frequently degrade or detach when exposed to biological environments, varying pH levels, or elevated temperatures, limiting their practical utility in real-world scenarios.

Electrospinning-based functionalization approaches face specific challenges related to process control. The high voltages involved can affect certain functional molecules, while the rapid solvent evaporation during fiber formation can trap functional groups within the bulk material rather than positioning them at the surface where they are most effective.

The environmental and health implications of nanomaterial functionalization processes present growing concerns. Many current techniques employ toxic solvents or generate hazardous byproducts, creating regulatory hurdles and sustainability issues that impede widespread adoption.

Cross-disciplinary knowledge gaps further complicate advancement in this field. Effective surface functionalization requires expertise spanning materials science, chemistry, biology, and engineering—a combination rarely found within single research groups or companies. This fragmentation of knowledge slows innovation and practical implementation of novel functionalization strategies.

Addressing these multifaceted challenges requires innovative approaches that can simultaneously overcome technical limitations while meeting commercial viability requirements. The integration of electrospinning with complementary technologies may offer promising pathways to resolve these persistent obstacles in nanostructure surface functionalization.

A major challenge lies in the high surface energy of nanomaterials, which leads to aggregation during functionalization processes, reducing effective surface area and accessibility. This is particularly problematic for nanofibers and nanoparticles where maintaining dispersion during chemical treatment is essential. Additionally, characterization of functionalized surfaces at the nanoscale presents significant technical difficulties, making quality control and reproducibility problematic.

The scalability of current functionalization methods represents another substantial hurdle. Laboratory-scale techniques often fail to translate effectively to industrial production, creating a significant gap between research advancements and commercial applications. This scaling issue is compounded by the high cost of specialized equipment and reagents required for precise surface modification.

Stability of functionalized surfaces under various environmental conditions remains inadequate for many applications. Functional groups attached to nanostructures frequently degrade or detach when exposed to biological environments, varying pH levels, or elevated temperatures, limiting their practical utility in real-world scenarios.

Electrospinning-based functionalization approaches face specific challenges related to process control. The high voltages involved can affect certain functional molecules, while the rapid solvent evaporation during fiber formation can trap functional groups within the bulk material rather than positioning them at the surface where they are most effective.

The environmental and health implications of nanomaterial functionalization processes present growing concerns. Many current techniques employ toxic solvents or generate hazardous byproducts, creating regulatory hurdles and sustainability issues that impede widespread adoption.

Cross-disciplinary knowledge gaps further complicate advancement in this field. Effective surface functionalization requires expertise spanning materials science, chemistry, biology, and engineering—a combination rarely found within single research groups or companies. This fragmentation of knowledge slows innovation and practical implementation of novel functionalization strategies.

Addressing these multifaceted challenges requires innovative approaches that can simultaneously overcome technical limitations while meeting commercial viability requirements. The integration of electrospinning with complementary technologies may offer promising pathways to resolve these persistent obstacles in nanostructure surface functionalization.

Current Electrospinning Methods for Surface Functionalization

01 Electrospinning for biomedical applications

Electrospinning techniques are used to create functionalized surfaces for biomedical applications such as drug delivery, tissue engineering, and wound healing. The process involves incorporating bioactive compounds into polymer solutions before electrospinning or post-treatment of electrospun fibers to enhance biocompatibility and therapeutic properties. These functionalized surfaces can promote cell adhesion, proliferation, and differentiation, making them suitable for various medical applications.- Chemical functionalization of electrospun fibers: Electrospun fibers can be chemically functionalized to enhance their properties and applications. This involves treating the fiber surface with various chemical agents to introduce specific functional groups. The functionalization can improve biocompatibility, reactivity, or add antimicrobial properties to the fibers. Methods include plasma treatment, chemical vapor deposition, and wet chemical processes that modify the surface chemistry without affecting the bulk properties of the fibers.

- Biomolecule immobilization on electrospun surfaces: Electrospun nanofibers can be functionalized to immobilize biomolecules such as proteins, enzymes, and growth factors on their surfaces. This functionalization enhances the bioactivity and biocompatibility of the materials, making them suitable for tissue engineering, drug delivery, and biosensor applications. The process typically involves creating reactive sites on the fiber surface that can covalently bind to biomolecules or using physical adsorption techniques to attach the biomolecules to the fiber surface.

- Metal and metal oxide nanoparticle incorporation: Electrospun fibers can be functionalized with metal and metal oxide nanoparticles to impart specific properties such as antimicrobial activity, catalytic ability, or electrical conductivity. The nanoparticles can be incorporated during the electrospinning process (in-situ) or attached to the fiber surface post-spinning. This functionalization approach is particularly useful for environmental applications, catalysis, and sensing technologies where the high surface area of electrospun fibers combined with the properties of metal nanoparticles creates synergistic effects.

- Polymer grafting for surface modification: Surface functionalization of electrospun fibers can be achieved through polymer grafting techniques, where new polymer chains are attached to the fiber surface. This can be done via 'grafting-from' approaches where polymerization is initiated at the fiber surface, or 'grafting-to' approaches where pre-formed polymer chains are attached to the surface. These methods allow for precise control over surface properties such as hydrophilicity, charge, and reactivity, enabling tailored interactions with the surrounding environment for applications in filtration, tissue engineering, and smart materials.

- Stimuli-responsive surface functionalization: Electrospun fibers can be functionalized with stimuli-responsive materials that change their properties in response to external stimuli such as pH, temperature, light, or electrical signals. This smart functionalization enables the development of advanced materials with switchable surface properties for applications in controlled drug release, smart textiles, and environmental remediation. The responsive behavior can be achieved by incorporating stimuli-responsive polymers or molecules onto the fiber surface through various chemical modification techniques.

02 Chemical surface modification of electrospun fibers

Various chemical treatments can be applied to modify the surface properties of electrospun fibers. These include plasma treatment, chemical grafting, coating with functional polymers, and incorporation of reactive groups. Such modifications can enhance hydrophilicity, hydrophobicity, or introduce specific functional groups that enable further conjugation with biomolecules or other compounds. These chemical modifications significantly improve the performance of electrospun materials for specific applications.Expand Specific Solutions03 Nanoparticle incorporation for enhanced functionality

Electrospun fibers can be functionalized by incorporating various nanoparticles such as metal nanoparticles, carbon nanotubes, graphene, or metal oxides. These nanoparticles can be added to the polymer solution before electrospinning or attached to the fiber surface post-spinning. The resulting composite materials exhibit enhanced properties including antimicrobial activity, electrical conductivity, catalytic activity, or sensing capabilities, expanding their potential applications in various fields.Expand Specific Solutions04 Environmental and filtration applications

Surface-functionalized electrospun fibers are widely used in environmental applications such as water purification, air filtration, and contaminant removal. The fibers can be modified with specific functional groups or particles that selectively adsorb or degrade pollutants. The high surface area and porosity of electrospun membranes, combined with tailored surface chemistry, make them highly efficient for removing heavy metals, organic pollutants, and particulate matter from various media.Expand Specific Solutions05 Smart and responsive electrospun surfaces

Electrospun fibers can be functionalized to create smart and responsive surfaces that change their properties in response to external stimuli such as temperature, pH, light, or electrical signals. These responsive materials are created by incorporating stimuli-responsive polymers or functional groups during the electrospinning process or through post-treatment. Applications include controlled drug release, switchable wettability surfaces, shape-memory materials, and sensors that can detect and respond to environmental changes.Expand Specific Solutions

Leading Research Groups and Companies in Electrospinning

Electrospinning technology for surface functionalization of nanostructures is currently in a growth phase, with the global market expanding rapidly due to increasing applications in biomedical engineering, filtration, and energy storage. The market is projected to reach significant scale as industries recognize the advantages of electrospun nanofibers' high surface-to-volume ratio and customizable properties. Leading academic institutions like MIT, University of Akron, and Northwestern University are advancing fundamental research, while companies such as Matregenix, Poly-Med, and Innovative Surface Technologies are commercializing applications. Research collaborations between universities and industry partners are accelerating technology maturation, with significant innovations emerging from international institutions including Donghua University and Helmholtz-Zentrum Hereon. The technology is approaching commercial viability in several sectors, particularly in medical devices and advanced materials.

University of Akron

Technical Solution: The University of Akron has pioneered advanced electrospinning techniques for surface functionalization of nanostructures, particularly focusing on polymer-based nanofibers with controlled surface chemistry. Their approach involves a coaxial electrospinning system that enables the creation of core-shell nanofibers with precisely engineered surface properties. The university has developed methods to incorporate functional groups directly during the electrospinning process, allowing for one-step fabrication of surface-modified nanostructures. Their research demonstrates that by adjusting processing parameters such as voltage, flow rate, and solution properties, they can control the distribution and density of functional groups on nanofiber surfaces. This technology has been particularly successful in creating bioactive surfaces for tissue engineering applications, where they've achieved enhanced cell adhesion and proliferation through strategic placement of bioactive molecules on the fiber surface.

Strengths: Exceptional control over surface chemistry during the electrospinning process; ability to create gradient functionalization across fiber surfaces; established protocols for biomedical applications. Weaknesses: Requires specialized equipment for coaxial electrospinning; some functionalization approaches may reduce mechanical properties of the resulting nanofibers.

Massachusetts Institute of Technology

Technical Solution: MIT has developed revolutionary approaches to electrospinning-based surface functionalization through their patented "reactive electrospinning" technology. This process incorporates reactive chemical groups directly into the electrospinning solution, which become available for post-spinning modification. Their technique allows for unprecedented control over surface chemistry while maintaining the structural integrity of the nanofibers. MIT researchers have pioneered the use of click chemistry in conjunction with electrospinning, enabling highly specific surface modifications under mild conditions. Their work has demonstrated that electrospun nanofibers can be functionalized with complex biomolecules, including proteins and nucleic acids, while preserving their biological activity. MIT has also developed computational models that predict how electrospinning parameters affect the distribution and accessibility of functional groups on nanofiber surfaces, allowing for rational design of functionalized nanostructures for specific applications in energy storage, catalysis, and biomedical devices.

Strengths: Integration of advanced chemistry principles with electrospinning technology; ability to achieve high-density functional group presentation; computational tools for predicting functionalization outcomes. Weaknesses: Some approaches require multi-step processing; scalability challenges for certain high-precision functionalization methods.

Key Patents and Innovations in Electrospun Nanostructures

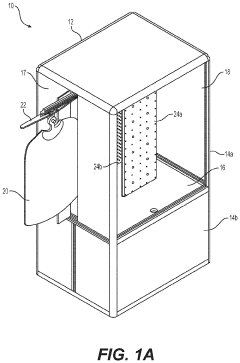

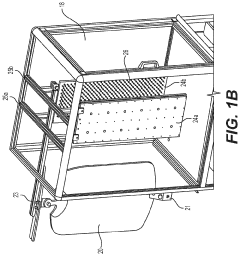

System for nano-coating a substrate

PatentActiveUS20200232122A1

Innovation

- A system with an insulated housing featuring moveable panels and solution dispensing nozzles, powered by a high voltage supply, which enables efficient electrospraying or electrospinning of polymeric nanostructures onto a collector for rapid production of breathable, waterproof, or drug-delivery products.

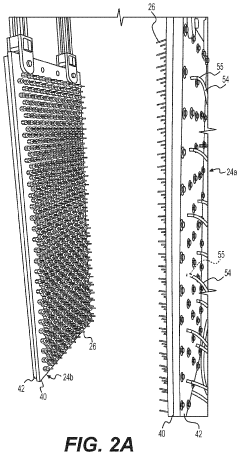

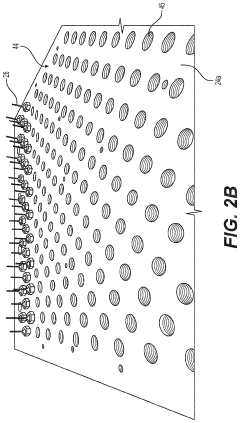

Electrostatic-assisted fiber spinning method and production of highly aligned and packed hollow fiber assembly and membrane

PatentActiveUS20110264235A1

Innovation

- The development of a method that uses coaxial electrospinning with a rotating drum collector to produce fibers with an orientation angle of no larger than ±5° and a packing density of at least 5 fibers per layer, maintaining a significant portion of the fiber weight during the electrospinning process to achieve highly aligned and closely packed hollow or solid fibers.

Scalability and Manufacturing Considerations

Scaling electrospinning processes from laboratory to industrial production presents significant challenges that must be addressed to fully realize the potential of this technology for surface functionalization of nanostructures. Traditional single-needle electrospinning setups, while effective for research purposes, typically produce only 0.1-0.5 g/h of nanofibers, which is insufficient for commercial applications. Multiple-needle systems have emerged as an intermediate solution, increasing throughput to 2-5 g/h, but they introduce complications related to needle clogging and maintaining uniform electric field distribution.

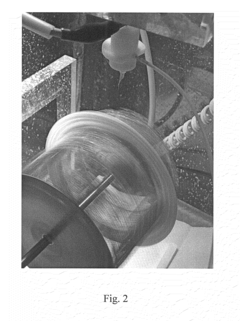

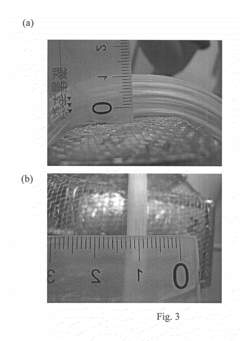

Needleless electrospinning technologies represent a promising advancement for industrial-scale production, with reported throughput rates of 10-300 g/h depending on the specific implementation. These systems utilize rotating drums, disks, or wire electrodes immersed in polymer solutions to generate multiple polymer jets simultaneously. However, they often sacrifice some degree of fiber diameter uniformity compared to single-needle approaches, which can affect the consistency of surface functionalization.

The integration of electrospinning into continuous manufacturing lines requires careful consideration of process parameters and environmental controls. Temperature, humidity, and air flow must be precisely regulated across larger production spaces to ensure consistent nanofiber morphology and functional properties. Variations in these parameters can significantly impact the surface chemistry and subsequent functionalization effectiveness of the produced nanostructures.

Energy consumption represents another critical consideration for scaled production. Industrial electrospinning systems typically operate at 30-100 kV, with power requirements increasing proportionally with production capacity. The development of more energy-efficient high-voltage power supplies and optimized collection systems could substantially improve the economic viability of large-scale operations.

Quality control methodologies must evolve alongside production scaling. In-line monitoring systems capable of real-time assessment of fiber diameter, orientation, and surface chemistry are essential for maintaining consistent functionalization quality. Advanced techniques such as integrated spectroscopic methods and automated image analysis are being developed to address this need, though their implementation in high-throughput environments remains challenging.

Regulatory considerations also impact scalability, particularly for applications in healthcare, food packaging, and environmental remediation. Manufacturing facilities must demonstrate consistent production of nanostructures with precisely controlled surface properties to meet increasingly stringent regulatory requirements. Documentation of process validation and quality assurance protocols becomes more complex as production scales increase.

Needleless electrospinning technologies represent a promising advancement for industrial-scale production, with reported throughput rates of 10-300 g/h depending on the specific implementation. These systems utilize rotating drums, disks, or wire electrodes immersed in polymer solutions to generate multiple polymer jets simultaneously. However, they often sacrifice some degree of fiber diameter uniformity compared to single-needle approaches, which can affect the consistency of surface functionalization.

The integration of electrospinning into continuous manufacturing lines requires careful consideration of process parameters and environmental controls. Temperature, humidity, and air flow must be precisely regulated across larger production spaces to ensure consistent nanofiber morphology and functional properties. Variations in these parameters can significantly impact the surface chemistry and subsequent functionalization effectiveness of the produced nanostructures.

Energy consumption represents another critical consideration for scaled production. Industrial electrospinning systems typically operate at 30-100 kV, with power requirements increasing proportionally with production capacity. The development of more energy-efficient high-voltage power supplies and optimized collection systems could substantially improve the economic viability of large-scale operations.

Quality control methodologies must evolve alongside production scaling. In-line monitoring systems capable of real-time assessment of fiber diameter, orientation, and surface chemistry are essential for maintaining consistent functionalization quality. Advanced techniques such as integrated spectroscopic methods and automated image analysis are being developed to address this need, though their implementation in high-throughput environments remains challenging.

Regulatory considerations also impact scalability, particularly for applications in healthcare, food packaging, and environmental remediation. Manufacturing facilities must demonstrate consistent production of nanostructures with precisely controlled surface properties to meet increasingly stringent regulatory requirements. Documentation of process validation and quality assurance protocols becomes more complex as production scales increase.

Environmental and Safety Implications of Electrospinning

The electrospinning process, while offering significant advantages for surface functionalization of nanostructures, presents several environmental and safety considerations that require careful attention. The production of electrospun nanofibers involves the use of polymer solutions containing organic solvents, which may release volatile organic compounds (VOCs) during the manufacturing process. These emissions can contribute to air pollution and pose potential health risks to workers in production facilities if proper ventilation systems are not implemented.

Additionally, the high voltage employed in electrospinning (typically 10-30 kV) creates electrical hazards that necessitate appropriate safety protocols and equipment. The electrical field generated during the process requires proper grounding and insulation to prevent accidental discharges that could harm operators or damage sensitive electronic equipment in the vicinity.

Nanoparticle release during electrospinning operations represents another significant concern. The potential for nanofiber fragments to become airborne during production, handling, or disposal stages raises questions about respiratory exposure risks. Current research indicates that inhaled nanoparticles may penetrate deep into lung tissue, with possible translocation to other organs, though the long-term health effects remain under investigation.

Waste management presents further challenges, particularly for electrospun materials incorporating antimicrobial agents, heavy metals, or other potentially toxic substances used for enhanced functionality. The environmental fate of these functionalized nanostructures after disposal requires consideration, as their high surface area-to-volume ratio may accelerate leaching of incorporated compounds into soil or water systems.

Recent regulatory frameworks have begun addressing these concerns, with organizations such as the National Institute for Occupational Safety and Health (NIOSH) developing specific guidelines for nanomaterial handling. The implementation of engineering controls, including closed production systems and local exhaust ventilation, has proven effective in minimizing exposure risks during electrospinning operations.

Sustainable approaches to electrospinning are emerging as promising solutions to these environmental challenges. The development of green electrospinning techniques utilizing water-based polymer solutions or ionic liquids as alternatives to conventional organic solvents represents a significant advancement. Furthermore, biodegradable polymers derived from renewable resources are increasingly being employed as base materials for electrospun nanofibers, reducing the environmental footprint of these technologies.

Life cycle assessment studies of electrospun products have highlighted opportunities for process optimization to reduce energy consumption and waste generation. These analyses suggest that the environmental benefits of electrospun materials in applications such as filtration or catalysis may outweigh the impacts of their production when designed with sustainability principles in mind.

Additionally, the high voltage employed in electrospinning (typically 10-30 kV) creates electrical hazards that necessitate appropriate safety protocols and equipment. The electrical field generated during the process requires proper grounding and insulation to prevent accidental discharges that could harm operators or damage sensitive electronic equipment in the vicinity.

Nanoparticle release during electrospinning operations represents another significant concern. The potential for nanofiber fragments to become airborne during production, handling, or disposal stages raises questions about respiratory exposure risks. Current research indicates that inhaled nanoparticles may penetrate deep into lung tissue, with possible translocation to other organs, though the long-term health effects remain under investigation.

Waste management presents further challenges, particularly for electrospun materials incorporating antimicrobial agents, heavy metals, or other potentially toxic substances used for enhanced functionality. The environmental fate of these functionalized nanostructures after disposal requires consideration, as their high surface area-to-volume ratio may accelerate leaching of incorporated compounds into soil or water systems.

Recent regulatory frameworks have begun addressing these concerns, with organizations such as the National Institute for Occupational Safety and Health (NIOSH) developing specific guidelines for nanomaterial handling. The implementation of engineering controls, including closed production systems and local exhaust ventilation, has proven effective in minimizing exposure risks during electrospinning operations.

Sustainable approaches to electrospinning are emerging as promising solutions to these environmental challenges. The development of green electrospinning techniques utilizing water-based polymer solutions or ionic liquids as alternatives to conventional organic solvents represents a significant advancement. Furthermore, biodegradable polymers derived from renewable resources are increasingly being employed as base materials for electrospun nanofibers, reducing the environmental footprint of these technologies.

Life cycle assessment studies of electrospun products have highlighted opportunities for process optimization to reduce energy consumption and waste generation. These analyses suggest that the environmental benefits of electrospun materials in applications such as filtration or catalysis may outweigh the impacts of their production when designed with sustainability principles in mind.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!