Electrospinning and its Applications in Protective Clothing Development

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrospinning Technology Evolution and Objectives

Electrospinning technology emerged in the early 20th century when Anton Formhals patented the process in 1934. However, it wasn't until the 1990s that this technology gained significant attention in the scientific community, primarily due to advancements in nanotechnology and increased demand for specialized materials with enhanced properties. The fundamental principle of electrospinning involves applying a high voltage to a polymer solution or melt, creating an electrically charged jet that stretches and thins as it travels toward a collector, resulting in nanoscale fibers.

The evolution of electrospinning has been marked by several key developments. Initially, the process was limited to simple setups with single-needle configurations and basic polymer solutions. By the early 2000s, researchers had developed multi-needle systems and coaxial electrospinning techniques, enabling the production of core-shell nanofibers with dual functionalities. The introduction of melt electrospinning in the mid-2000s eliminated the need for solvents, addressing environmental concerns and expanding the range of usable polymers.

Recent technological advancements include the development of near-field electrospinning for precise fiber deposition, electrohydrodynamic printing for controlled patterning, and needleless electrospinning systems that significantly increase production capacity. These innovations have transformed electrospinning from a laboratory technique to a viable industrial process capable of mass production.

In the context of protective clothing development, electrospinning technology aims to create advanced textile materials with superior protective properties while maintaining comfort and breathability. The primary objectives include developing nanofiber membranes with enhanced filtration efficiency for chemical and biological protection, creating superhydrophobic surfaces for liquid repellency, and incorporating functional additives for UV protection, antimicrobial properties, and flame retardancy.

Another critical goal is to scale up production while maintaining fiber quality and consistency, as protective clothing applications require large quantities of materials with uniform properties. Researchers are also focused on improving the mechanical durability of electrospun materials to withstand repeated use and laundering, which has traditionally been a limitation for nanofiber-based textiles.

The future trajectory of electrospinning technology in protective clothing is moving toward smart textiles with integrated sensing capabilities, stimuli-responsive materials that adapt to environmental conditions, and sustainable production methods using bio-based polymers and green solvents. These developments align with the broader industry trends toward multifunctional, sustainable, and user-centered protective clothing solutions.

The evolution of electrospinning has been marked by several key developments. Initially, the process was limited to simple setups with single-needle configurations and basic polymer solutions. By the early 2000s, researchers had developed multi-needle systems and coaxial electrospinning techniques, enabling the production of core-shell nanofibers with dual functionalities. The introduction of melt electrospinning in the mid-2000s eliminated the need for solvents, addressing environmental concerns and expanding the range of usable polymers.

Recent technological advancements include the development of near-field electrospinning for precise fiber deposition, electrohydrodynamic printing for controlled patterning, and needleless electrospinning systems that significantly increase production capacity. These innovations have transformed electrospinning from a laboratory technique to a viable industrial process capable of mass production.

In the context of protective clothing development, electrospinning technology aims to create advanced textile materials with superior protective properties while maintaining comfort and breathability. The primary objectives include developing nanofiber membranes with enhanced filtration efficiency for chemical and biological protection, creating superhydrophobic surfaces for liquid repellency, and incorporating functional additives for UV protection, antimicrobial properties, and flame retardancy.

Another critical goal is to scale up production while maintaining fiber quality and consistency, as protective clothing applications require large quantities of materials with uniform properties. Researchers are also focused on improving the mechanical durability of electrospun materials to withstand repeated use and laundering, which has traditionally been a limitation for nanofiber-based textiles.

The future trajectory of electrospinning technology in protective clothing is moving toward smart textiles with integrated sensing capabilities, stimuli-responsive materials that adapt to environmental conditions, and sustainable production methods using bio-based polymers and green solvents. These developments align with the broader industry trends toward multifunctional, sustainable, and user-centered protective clothing solutions.

Market Analysis for Electrospun Protective Clothing

The global market for electrospun protective clothing is experiencing significant growth, driven by increasing awareness of personal safety across various industries. The market size was valued at approximately $2.1 billion in 2022 and is projected to reach $3.8 billion by 2028, representing a compound annual growth rate (CAGR) of 10.3%. This growth trajectory is supported by stringent workplace safety regulations and growing demand for advanced protective solutions in healthcare, military, and industrial sectors.

Healthcare applications currently dominate the electrospun protective clothing market, accounting for nearly 38% of the total market share. The COVID-19 pandemic has substantially accelerated this trend, with unprecedented demand for high-performance personal protective equipment (PPE) that offers superior filtration efficiency while maintaining breathability. Hospitals, pharmaceutical companies, and research laboratories are primary consumers in this segment.

Military and defense applications represent the second-largest market segment at 27%, where electrospun materials are valued for their ability to provide protection against chemical and biological threats while maintaining lightweight properties. The industrial sector follows at 21%, with applications in chemical processing, oil and gas, and mining industries where workers face exposure to hazardous substances.

Geographically, North America leads the market with a 35% share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 12.7% during the forecast period, primarily due to rapid industrialization in countries like China and India, coupled with increasing safety awareness and regulatory frameworks.

Consumer preferences are shifting toward multifunctional protective clothing that offers not only protection but also comfort and sustainability. This has created a demand for electrospun materials that incorporate antimicrobial properties, self-cleaning capabilities, and environmentally friendly production processes. Market research indicates that 73% of professional end-users are willing to pay premium prices for protective clothing that offers enhanced functionality without compromising on comfort.

The competitive landscape features both established players and innovative startups. Major companies like DuPont, 3M, and Kimberly-Clark hold significant market shares, while specialized firms such as Elmarco and Revolution Fibres are gaining traction through technological innovation. Strategic partnerships between material manufacturers and clothing producers are becoming increasingly common to leverage complementary expertise and accelerate product development cycles.

Healthcare applications currently dominate the electrospun protective clothing market, accounting for nearly 38% of the total market share. The COVID-19 pandemic has substantially accelerated this trend, with unprecedented demand for high-performance personal protective equipment (PPE) that offers superior filtration efficiency while maintaining breathability. Hospitals, pharmaceutical companies, and research laboratories are primary consumers in this segment.

Military and defense applications represent the second-largest market segment at 27%, where electrospun materials are valued for their ability to provide protection against chemical and biological threats while maintaining lightweight properties. The industrial sector follows at 21%, with applications in chemical processing, oil and gas, and mining industries where workers face exposure to hazardous substances.

Geographically, North America leads the market with a 35% share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 12.7% during the forecast period, primarily due to rapid industrialization in countries like China and India, coupled with increasing safety awareness and regulatory frameworks.

Consumer preferences are shifting toward multifunctional protective clothing that offers not only protection but also comfort and sustainability. This has created a demand for electrospun materials that incorporate antimicrobial properties, self-cleaning capabilities, and environmentally friendly production processes. Market research indicates that 73% of professional end-users are willing to pay premium prices for protective clothing that offers enhanced functionality without compromising on comfort.

The competitive landscape features both established players and innovative startups. Major companies like DuPont, 3M, and Kimberly-Clark hold significant market shares, while specialized firms such as Elmarco and Revolution Fibres are gaining traction through technological innovation. Strategic partnerships between material manufacturers and clothing producers are becoming increasingly common to leverage complementary expertise and accelerate product development cycles.

Current Electrospinning Techniques and Barriers

Electrospinning technology has evolved significantly over the past few decades, with several distinct techniques now available for different applications. Conventional needle-based electrospinning remains the most widely used method, where a polymer solution is ejected through a needle under high voltage to form nanofibers. This technique offers precise control over fiber morphology but suffers from low production rates, typically 0.1-1 g/h, which significantly limits industrial scalability.

To address productivity limitations, needleless electrospinning technologies have emerged, including rotating drum, wire electrode, and bubble electrospinning. These methods can increase throughput by 10-20 times compared to conventional approaches. Notably, Elmarco's Nanospider technology utilizes a rotating electrode partially immersed in polymer solution, achieving production rates of up to 50 g/h per meter of electrode length.

Coaxial electrospinning represents another significant advancement, enabling the production of core-shell structured nanofibers. This technique is particularly valuable for protective clothing applications as it allows encapsulation of functional materials within fibers, such as phase-change materials or antimicrobial agents, while maintaining a protective outer shell.

Despite these advancements, several technical barriers persist in electrospinning for protective clothing. Solution property control remains challenging, as viscosity, surface tension, and conductivity must be precisely balanced to achieve consistent fiber formation. Environmental factors such as humidity and temperature significantly impact fiber quality, necessitating strictly controlled production environments that increase manufacturing costs.

Scalability continues to be a major hurdle, particularly for protective clothing which requires large fabric areas. While needleless technologies have improved throughput, maintaining uniform fiber quality across large production scales remains problematic. Current industrial systems still struggle with consistency in fiber diameter distribution when operating at high production rates.

Fiber alignment represents another significant challenge. Random fiber orientation is common in electrospun mats, but many protective applications require directional properties. Techniques such as rotating collectors and auxiliary electric fields can improve alignment but add complexity to the manufacturing process.

The transition from laboratory to industrial scale production faces additional barriers including solvent recovery systems, safety measures for high voltage operations, and quality control mechanisms. These factors contribute to high production costs, currently estimated at $1000-2000 per kilogram of electrospun material, significantly higher than conventional textile manufacturing processes.

To address productivity limitations, needleless electrospinning technologies have emerged, including rotating drum, wire electrode, and bubble electrospinning. These methods can increase throughput by 10-20 times compared to conventional approaches. Notably, Elmarco's Nanospider technology utilizes a rotating electrode partially immersed in polymer solution, achieving production rates of up to 50 g/h per meter of electrode length.

Coaxial electrospinning represents another significant advancement, enabling the production of core-shell structured nanofibers. This technique is particularly valuable for protective clothing applications as it allows encapsulation of functional materials within fibers, such as phase-change materials or antimicrobial agents, while maintaining a protective outer shell.

Despite these advancements, several technical barriers persist in electrospinning for protective clothing. Solution property control remains challenging, as viscosity, surface tension, and conductivity must be precisely balanced to achieve consistent fiber formation. Environmental factors such as humidity and temperature significantly impact fiber quality, necessitating strictly controlled production environments that increase manufacturing costs.

Scalability continues to be a major hurdle, particularly for protective clothing which requires large fabric areas. While needleless technologies have improved throughput, maintaining uniform fiber quality across large production scales remains problematic. Current industrial systems still struggle with consistency in fiber diameter distribution when operating at high production rates.

Fiber alignment represents another significant challenge. Random fiber orientation is common in electrospun mats, but many protective applications require directional properties. Techniques such as rotating collectors and auxiliary electric fields can improve alignment but add complexity to the manufacturing process.

The transition from laboratory to industrial scale production faces additional barriers including solvent recovery systems, safety measures for high voltage operations, and quality control mechanisms. These factors contribute to high production costs, currently estimated at $1000-2000 per kilogram of electrospun material, significantly higher than conventional textile manufacturing processes.

Current Electrospun Fiber Solutions for Protective Apparel

01 Electrospinning process parameters and optimization

The electrospinning process involves various parameters that can be optimized to control fiber formation. These parameters include voltage, flow rate, distance between the needle and collector, and solution properties. Optimization of these parameters is crucial for producing uniform nanofibers with desired characteristics. The process typically involves applying a high voltage to a polymer solution, which creates an electric field that draws the solution into fibers as the solvent evaporates.- Electrospinning process parameters and optimization: The electrospinning process involves various parameters that can be optimized to produce fibers with desired characteristics. These parameters include voltage, flow rate, distance between the needle and collector, and solution properties. By adjusting these parameters, researchers can control the diameter, morphology, and alignment of the resulting nanofibers. Optimization of these parameters is crucial for achieving consistent and high-quality fiber production in various applications.

- Nanofiber materials and compositions: Electrospinning can be used to produce nanofibers from various polymeric materials and compositions. Different polymers, including natural and synthetic ones, can be electrospun to create fibers with specific properties. Composite nanofibers can also be produced by incorporating functional additives, nanoparticles, or bioactive compounds into the spinning solution. The selection of materials significantly influences the mechanical, chemical, and biological properties of the resulting nanofibers, making them suitable for diverse applications.

- Advanced electrospinning equipment and modifications: Innovations in electrospinning equipment have led to improved fiber production capabilities. These advancements include multi-needle systems, needleless electrospinning, coaxial electrospinning for core-shell fibers, and rotating collectors for aligned fibers. Modified electrospinning setups can enhance productivity, enable the production of specialized fiber structures, and improve the scalability of the process for industrial applications.

- Applications of electrospun nanofibers: Electrospun nanofibers find applications across various fields due to their unique properties such as high surface area-to-volume ratio and porosity. They are used in tissue engineering as scaffolds for cell growth, in filtration systems for air and water purification, in drug delivery systems for controlled release, in wound dressings for enhanced healing, and in energy storage devices. The versatility of electrospun nanofibers makes them valuable in addressing challenges in healthcare, environmental protection, and energy sectors.

- Surface functionalization and post-treatment of electrospun fibers: Electrospun fibers can undergo various post-spinning treatments to enhance their functionality. Surface modification techniques include plasma treatment, chemical grafting, and coating with functional molecules. Post-treatments such as crosslinking, heat treatment, and solvent exposure can improve the mechanical properties, stability, and functionality of the fibers. These modifications enable the tailoring of fiber properties for specific applications, such as improving biocompatibility for medical uses or enhancing adsorption capabilities for environmental applications.

02 Nanofiber materials and compositions

Various materials can be used in electrospinning to create nanofibers with specific properties. These include synthetic polymers, natural polymers, composites, and hybrid materials. The composition of the spinning solution significantly affects the morphology, mechanical properties, and functionality of the resulting nanofibers. Different polymer blends and additives can be incorporated to enhance specific characteristics such as strength, biocompatibility, or conductivity.Expand Specific Solutions03 Electrospinning equipment and apparatus design

Specialized equipment and apparatus designs are essential for effective electrospinning. These include various types of spinnerets, collectors, and power supply systems. Innovations in apparatus design focus on improving fiber alignment, increasing production rates, and enabling the creation of complex fiber structures. Advanced systems may incorporate multiple jets, rotating collectors, or auxiliary electrodes to control the deposition pattern of the fibers.Expand Specific Solutions04 Applications of electrospun nanofibers

Electrospun nanofibers have diverse applications across multiple fields. They are used in tissue engineering scaffolds, drug delivery systems, filtration membranes, protective clothing, sensors, and energy storage devices. The high surface area-to-volume ratio, porosity, and customizable properties of electrospun nanofibers make them particularly valuable for these applications. Recent developments have expanded their use in environmental remediation, wound dressings, and smart textiles.Expand Specific Solutions05 Coaxial and multi-axial electrospinning techniques

Advanced electrospinning techniques include coaxial and multi-axial approaches that enable the production of nanofibers with complex structures. These techniques involve using multiple concentric needles to spin different solutions simultaneously, resulting in core-shell or multi-layered fibers. Such structures can encapsulate active ingredients, combine materials with different properties, or create gradient structures. These advanced techniques expand the functionality and application range of electrospun nanofibers.Expand Specific Solutions

Leading Manufacturers and Research Institutions

Electrospinning technology for protective clothing is currently in a growth phase, with increasing market adoption driven by demand for advanced personal protection solutions. The global market is expanding rapidly, estimated to reach significant scale as applications diversify across military, healthcare, and industrial sectors. Technologically, the field shows varying maturity levels among key players. Academic institutions like MIT, University of Akron, and Zhejiang University lead fundamental research, while companies such as BioSurfaces, Arsenal Medical, and Donaldson have commercialized specialized applications. Gentex and Bekaert demonstrate advanced manufacturing capabilities in protective textiles. The collaboration between educational institutions and industry partners is accelerating innovation, particularly in nanofiber development for enhanced protection against chemical, biological, and environmental hazards, positioning electrospinning as a transformative technology in protective clothing development.

University of Akron

Technical Solution: The University of Akron has pioneered advanced electrospinning techniques for protective clothing development, focusing on nanofiber-based materials with enhanced filtration and barrier properties. Their research includes multi-jet electrospinning systems that significantly increase production rates while maintaining fiber quality and uniformity. They've developed specialized polymer blends incorporating antimicrobial agents and phase-change materials directly into the electrospun fibers, creating multifunctional protective fabrics. Their work on coaxial electrospinning has produced core-shell nanofibers with improved mechanical strength and controlled release of functional compounds. The university has also made significant advances in creating superhydrophobic and oleophobic electrospun membranes for chemical protection garments, achieving contact angles exceeding 150° while maintaining breathability. Their research extends to incorporating carbon nanotubes and graphene into electrospun fibers to create electrically conductive protective fabrics with EMI shielding capabilities.

Strengths: Exceptional expertise in scaling up electrospinning for commercial applications while maintaining nanofiber quality; innovative polymer formulations for multifunctional protective properties. Weaknesses: Some of their advanced materials face challenges in durability during repeated laundering cycles; higher production costs compared to conventional textile manufacturing methods.

Zhejiang University

Technical Solution: Zhejiang University has developed a comprehensive electrospinning platform for protective clothing applications, focusing on environmental and biological protection. Their research team has pioneered multi-functional nanofiber membranes using a combination of natural and synthetic polymers to achieve superior filtration efficiency (>99.5% for PM2.5) while maintaining breathability. They've implemented a novel needleless electrospinning technique that increases production capacity by approximately 20 times compared to conventional methods, making industrial-scale manufacturing more feasible. Their protective clothing solutions incorporate specially designed core-shell nanofibers with antimicrobial agents in the core for sustained release, providing long-term protection against biological hazards. The university has also developed electrospun membranes with self-cleaning properties through the incorporation of photocatalytic nanoparticles, which can degrade chemical contaminants when exposed to sunlight. Their recent innovations include stimuli-responsive electrospun fabrics that can adapt their porosity and protection level based on environmental conditions.

Strengths: Exceptional balance between filtration efficiency and breathability; innovative scale-up solutions making industrial production more economically viable; integration of multiple protective functions in a single fabric layer. Weaknesses: Some of their advanced composite materials require complex manufacturing processes; durability under extreme conditions still needs improvement; higher material costs compared to conventional protective fabrics.

Key Patents and Innovations in Electrospinning

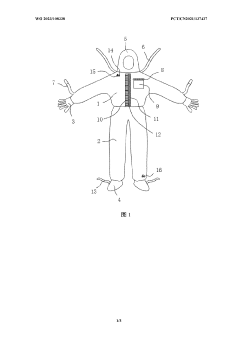

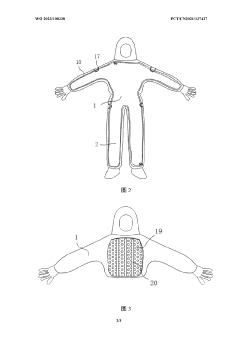

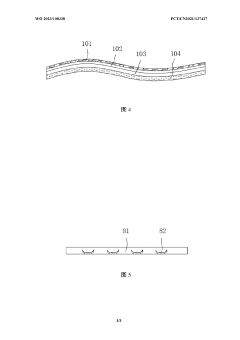

Anti-radiation-pollution protective clothing

PatentWO2023108338A1

Innovation

- Water storage pipes are installed in the upper and lower garments of the protective clothing. By adding low-temperature cooling water flow, a structure is formed that is lower than the body temperature and can absorb heat efficiently. It is combined with hollow gaskets and air cushion structures to achieve ventilation and heat dissipation.

Material Safety and Performance Standards

The development of protective clothing through electrospinning technology necessitates adherence to rigorous safety and performance standards. These standards ensure that the final products provide adequate protection against various hazards while maintaining comfort and durability. International organizations such as ISO, ASTM, and EN have established comprehensive frameworks for evaluating protective textiles.

For chemical protective clothing developed using electrospun nanofibers, standards like ASTM F1001 and ISO 16602 specify requirements for resistance against permeation by hazardous chemicals. These standards mandate specific testing methodologies including breakthrough detection times and permeation rates, which electrospun membranes must satisfy to qualify for commercial applications.

Thermal protection standards, including ISO 11612 and NFPA 2112, outline performance criteria for flame-resistant clothing. Electrospun materials intended for fire protection must undergo rigorous flame spread tests, heat transfer evaluations, and thermal stability assessments. The unique structure of electrospun nanofiber mats offers advantages in meeting these standards due to their high surface area and customizable composition.

Biological protection standards such as ASTM F1671 and EN 14126 address resistance to bloodborne pathogens and infectious agents. Electrospun membranes with appropriate pore sizes can effectively block microorganisms while maintaining breathability. Testing protocols involve challenging the materials with viral penetration tests using bacteriophages as surrogate organisms.

Mechanical performance standards including ASTM D5034 and ISO 13934 evaluate tensile strength, tear resistance, and abrasion resistance. These properties are particularly challenging for electrospun materials due to their inherently delicate structure. Consequently, researchers have developed various reinforcement techniques, including multi-layer composites and post-treatment processes to enhance mechanical durability.

Comfort-related standards like ASTM E96 and ISO 11092 measure water vapor transmission rates and thermal resistance. Electrospun materials often excel in these areas due to their high porosity and breathability, though maintaining these properties while achieving protective functions requires careful material selection and process optimization.

Environmental and sustainability standards are increasingly important, with ISO 14001 and OEKO-TEX certifications becoming essential for market acceptance. The electrospinning process must be evaluated for solvent emissions, energy consumption, and waste generation, with efforts to implement green solvents and recycled polymers gaining prominence in research.

Emerging standards for smart protective clothing are also relevant as electrospun materials increasingly incorporate functional additives for sensing and responsive capabilities. These standards address durability of electronic components, washing resistance, and reliability of sensing functions under various environmental conditions.

For chemical protective clothing developed using electrospun nanofibers, standards like ASTM F1001 and ISO 16602 specify requirements for resistance against permeation by hazardous chemicals. These standards mandate specific testing methodologies including breakthrough detection times and permeation rates, which electrospun membranes must satisfy to qualify for commercial applications.

Thermal protection standards, including ISO 11612 and NFPA 2112, outline performance criteria for flame-resistant clothing. Electrospun materials intended for fire protection must undergo rigorous flame spread tests, heat transfer evaluations, and thermal stability assessments. The unique structure of electrospun nanofiber mats offers advantages in meeting these standards due to their high surface area and customizable composition.

Biological protection standards such as ASTM F1671 and EN 14126 address resistance to bloodborne pathogens and infectious agents. Electrospun membranes with appropriate pore sizes can effectively block microorganisms while maintaining breathability. Testing protocols involve challenging the materials with viral penetration tests using bacteriophages as surrogate organisms.

Mechanical performance standards including ASTM D5034 and ISO 13934 evaluate tensile strength, tear resistance, and abrasion resistance. These properties are particularly challenging for electrospun materials due to their inherently delicate structure. Consequently, researchers have developed various reinforcement techniques, including multi-layer composites and post-treatment processes to enhance mechanical durability.

Comfort-related standards like ASTM E96 and ISO 11092 measure water vapor transmission rates and thermal resistance. Electrospun materials often excel in these areas due to their high porosity and breathability, though maintaining these properties while achieving protective functions requires careful material selection and process optimization.

Environmental and sustainability standards are increasingly important, with ISO 14001 and OEKO-TEX certifications becoming essential for market acceptance. The electrospinning process must be evaluated for solvent emissions, energy consumption, and waste generation, with efforts to implement green solvents and recycled polymers gaining prominence in research.

Emerging standards for smart protective clothing are also relevant as electrospun materials increasingly incorporate functional additives for sensing and responsive capabilities. These standards address durability of electronic components, washing resistance, and reliability of sensing functions under various environmental conditions.

Sustainability Aspects of Electrospun Materials

The sustainability of electrospun materials represents a critical dimension in the evolution of protective clothing development. Traditional textile manufacturing processes often involve significant environmental impacts through high energy consumption, chemical waste, and resource depletion. Electrospinning offers several sustainability advantages that position it as a potentially more environmentally responsible manufacturing approach.

Electrospun nanofibers can be produced from a wide range of biodegradable and renewable polymers, including polylactic acid (PLA), polyhydroxyalkanoates (PHA), and cellulose derivatives. These materials provide alternatives to petroleum-based synthetic fibers, reducing dependence on non-renewable resources. The biodegradability of these polymers ensures that protective clothing made from such materials can decompose naturally at the end of their lifecycle, minimizing landfill accumulation.

The electrospinning process itself demonstrates notable efficiency in material utilization. The technique requires minimal solvent compared to conventional wet-spinning methods, and recent advancements in solvent recovery systems have further reduced waste generation. Additionally, water-based electrospinning systems are emerging as alternatives to organic solvent-based approaches, significantly decreasing the environmental footprint of the manufacturing process.

Energy efficiency represents another sustainability advantage of electrospinning. The process operates at ambient temperature and pressure conditions, requiring substantially less energy than melt-spinning or other thermal processing techniques. Research indicates that electrospinning consumes approximately 30-40% less energy per unit of material produced compared to conventional textile manufacturing methods.

Lifecycle assessment studies of electrospun protective clothing have demonstrated reduced carbon footprints when compared to traditional protective wear. The lightweight nature of electrospun materials contributes to this advantage by reducing transportation emissions and resources required for packaging. Furthermore, the extended durability of properly engineered electrospun protective materials can increase product lifespan, reducing replacement frequency and associated resource consumption.

Challenges remain in scaling sustainable electrospinning practices for commercial production. Current limitations include the need for more efficient solvent recovery systems, development of completely water-based electrospinning formulations, and optimization of energy consumption in large-scale operations. Research efforts are increasingly focused on green electrospinning approaches that eliminate toxic solvents and incorporate principles of circular economy into the manufacturing process.

The integration of recycled polymers into electrospinning feedstock represents a promising direction for enhancing sustainability. Recent studies have successfully demonstrated electrospinning of nanofibers from recycled PET and other post-consumer plastics, creating a potential pathway for upcycling waste materials into high-performance protective clothing.

Electrospun nanofibers can be produced from a wide range of biodegradable and renewable polymers, including polylactic acid (PLA), polyhydroxyalkanoates (PHA), and cellulose derivatives. These materials provide alternatives to petroleum-based synthetic fibers, reducing dependence on non-renewable resources. The biodegradability of these polymers ensures that protective clothing made from such materials can decompose naturally at the end of their lifecycle, minimizing landfill accumulation.

The electrospinning process itself demonstrates notable efficiency in material utilization. The technique requires minimal solvent compared to conventional wet-spinning methods, and recent advancements in solvent recovery systems have further reduced waste generation. Additionally, water-based electrospinning systems are emerging as alternatives to organic solvent-based approaches, significantly decreasing the environmental footprint of the manufacturing process.

Energy efficiency represents another sustainability advantage of electrospinning. The process operates at ambient temperature and pressure conditions, requiring substantially less energy than melt-spinning or other thermal processing techniques. Research indicates that electrospinning consumes approximately 30-40% less energy per unit of material produced compared to conventional textile manufacturing methods.

Lifecycle assessment studies of electrospun protective clothing have demonstrated reduced carbon footprints when compared to traditional protective wear. The lightweight nature of electrospun materials contributes to this advantage by reducing transportation emissions and resources required for packaging. Furthermore, the extended durability of properly engineered electrospun protective materials can increase product lifespan, reducing replacement frequency and associated resource consumption.

Challenges remain in scaling sustainable electrospinning practices for commercial production. Current limitations include the need for more efficient solvent recovery systems, development of completely water-based electrospinning formulations, and optimization of energy consumption in large-scale operations. Research efforts are increasingly focused on green electrospinning approaches that eliminate toxic solvents and incorporate principles of circular economy into the manufacturing process.

The integration of recycled polymers into electrospinning feedstock represents a promising direction for enhancing sustainability. Recent studies have successfully demonstrated electrospinning of nanofibers from recycled PET and other post-consumer plastics, creating a potential pathway for upcycling waste materials into high-performance protective clothing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!