Exploring the Cross-disciplinary Applications of Electrospinning Techniques

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrospinning Technology Evolution and Objectives

Electrospinning technology has evolved significantly since its inception in the early 20th century. The fundamental principle, first patented by Formhals in 1934, involves applying high voltage to a polymer solution to create ultra-fine fibers. This technique remained relatively underutilized until the 1990s when researchers began recognizing its potential for creating nanoscale materials with unique properties.

The evolution of electrospinning can be traced through several key developmental phases. Initially, the focus was on understanding the basic process parameters and their effects on fiber formation. This was followed by a period of equipment refinement, where innovations in spinneret design, collection methods, and voltage control systems significantly improved process stability and reproducibility.

By the early 2000s, research shifted toward material diversification, with scientists successfully electrospinning a wide range of polymers, composites, ceramics, and even biological materials. This expansion in material compatibility opened new application domains across multiple industries, transforming electrospinning from a laboratory curiosity into a versatile manufacturing technique.

Recent technological advancements have focused on process modifications such as coaxial electrospinning, emulsion electrospinning, and melt electrospinning. These variations enable the production of fibers with complex architectures, including core-shell structures, hollow fibers, and porous morphologies, significantly expanding the functional capabilities of electrospun materials.

The current trajectory of electrospinning technology is moving toward scaled production and precise control. Innovations such as multi-needle arrays, needleless systems, and computer-controlled deposition are addressing traditional limitations in production rate and spatial precision, making industrial-scale applications increasingly viable.

The primary objective of exploring cross-disciplinary applications of electrospinning is to leverage its unique capabilities across diverse fields. Specifically, this involves identifying how the distinctive properties of electrospun materials—high surface area, controllable porosity, and versatile material composition—can address challenges in healthcare, environmental remediation, energy storage, and advanced manufacturing.

Another key goal is to establish standardized protocols for characterizing electrospun materials and predicting their performance in specific applications. This standardization is essential for facilitating technology transfer from laboratory research to commercial implementation, ensuring consistent quality and performance across different production environments.

The evolution of electrospinning can be traced through several key developmental phases. Initially, the focus was on understanding the basic process parameters and their effects on fiber formation. This was followed by a period of equipment refinement, where innovations in spinneret design, collection methods, and voltage control systems significantly improved process stability and reproducibility.

By the early 2000s, research shifted toward material diversification, with scientists successfully electrospinning a wide range of polymers, composites, ceramics, and even biological materials. This expansion in material compatibility opened new application domains across multiple industries, transforming electrospinning from a laboratory curiosity into a versatile manufacturing technique.

Recent technological advancements have focused on process modifications such as coaxial electrospinning, emulsion electrospinning, and melt electrospinning. These variations enable the production of fibers with complex architectures, including core-shell structures, hollow fibers, and porous morphologies, significantly expanding the functional capabilities of electrospun materials.

The current trajectory of electrospinning technology is moving toward scaled production and precise control. Innovations such as multi-needle arrays, needleless systems, and computer-controlled deposition are addressing traditional limitations in production rate and spatial precision, making industrial-scale applications increasingly viable.

The primary objective of exploring cross-disciplinary applications of electrospinning is to leverage its unique capabilities across diverse fields. Specifically, this involves identifying how the distinctive properties of electrospun materials—high surface area, controllable porosity, and versatile material composition—can address challenges in healthcare, environmental remediation, energy storage, and advanced manufacturing.

Another key goal is to establish standardized protocols for characterizing electrospun materials and predicting their performance in specific applications. This standardization is essential for facilitating technology transfer from laboratory research to commercial implementation, ensuring consistent quality and performance across different production environments.

Market Analysis for Electrospun Materials and Products

The global market for electrospun materials and products has experienced significant growth over the past decade, driven by advancements in electrospinning technology and expanding applications across multiple industries. Currently valued at approximately $2.3 billion in 2023, the market is projected to reach $4.5 billion by 2028, representing a compound annual growth rate (CAGR) of 14.3%.

Healthcare and biomedical applications dominate the electrospun materials market, accounting for nearly 45% of the total market share. This segment includes tissue engineering scaffolds, drug delivery systems, wound dressings, and medical implants. The increasing prevalence of chronic wounds and the growing aging population worldwide are key factors driving demand in this sector.

Filtration applications represent the second-largest market segment at 25%, encompassing air filtration, water purification, and specialized industrial filtration systems. The superior filtration efficiency of electrospun nanofiber membranes, particularly for capturing submicron particles, has led to their increased adoption in high-performance filtration systems.

Energy storage applications, including components for batteries and supercapacitors, constitute approximately 15% of the market. The push toward renewable energy and electric vehicles has accelerated research and development in this area, with electrospun materials offering advantages in terms of surface area and conductivity.

Regionally, North America and Europe currently lead the market with combined shares of 58%, primarily due to established research infrastructure and early technology adoption. However, the Asia-Pacific region is experiencing the fastest growth rate at 16.8% annually, driven by expanding manufacturing capabilities in China, South Korea, and India.

Key market challenges include high production costs, scalability issues, and regulatory hurdles, particularly for biomedical applications. The cost of electrospinning equipment and specialized polymers remains a significant barrier to wider commercial adoption, though economies of scale are gradually reducing these costs.

Consumer trends indicate increasing preference for sustainable and biodegradable materials, creating new opportunities for bio-based electrospun products. Additionally, the integration of smart functionalities into electrospun materials, such as sensing capabilities and controlled release mechanisms, is opening new market segments with premium pricing potential.

Industry analysts predict that technological improvements in high-throughput electrospinning methods will substantially reduce production costs over the next five years, potentially expanding market penetration into previously cost-sensitive applications such as textiles and packaging.

Healthcare and biomedical applications dominate the electrospun materials market, accounting for nearly 45% of the total market share. This segment includes tissue engineering scaffolds, drug delivery systems, wound dressings, and medical implants. The increasing prevalence of chronic wounds and the growing aging population worldwide are key factors driving demand in this sector.

Filtration applications represent the second-largest market segment at 25%, encompassing air filtration, water purification, and specialized industrial filtration systems. The superior filtration efficiency of electrospun nanofiber membranes, particularly for capturing submicron particles, has led to their increased adoption in high-performance filtration systems.

Energy storage applications, including components for batteries and supercapacitors, constitute approximately 15% of the market. The push toward renewable energy and electric vehicles has accelerated research and development in this area, with electrospun materials offering advantages in terms of surface area and conductivity.

Regionally, North America and Europe currently lead the market with combined shares of 58%, primarily due to established research infrastructure and early technology adoption. However, the Asia-Pacific region is experiencing the fastest growth rate at 16.8% annually, driven by expanding manufacturing capabilities in China, South Korea, and India.

Key market challenges include high production costs, scalability issues, and regulatory hurdles, particularly for biomedical applications. The cost of electrospinning equipment and specialized polymers remains a significant barrier to wider commercial adoption, though economies of scale are gradually reducing these costs.

Consumer trends indicate increasing preference for sustainable and biodegradable materials, creating new opportunities for bio-based electrospun products. Additionally, the integration of smart functionalities into electrospun materials, such as sensing capabilities and controlled release mechanisms, is opening new market segments with premium pricing potential.

Industry analysts predict that technological improvements in high-throughput electrospinning methods will substantially reduce production costs over the next five years, potentially expanding market penetration into previously cost-sensitive applications such as textiles and packaging.

Global Electrospinning Research Status and Technical Barriers

Electrospinning technology has witnessed significant global advancement over the past two decades, with research centers distributed across North America, Europe, and Asia. The United States maintains leadership in fundamental research and innovative applications, with institutions like MIT, Harvard, and Stanford pioneering novel electrospinning techniques. European research, particularly in Germany, Switzerland, and the UK, focuses on precision engineering and medical applications, while Asian countries, led by China, South Korea, and Japan, have rapidly expanded their research capacity with emphasis on mass production and industrial scaling.

Despite these advancements, electrospinning faces several critical technical barriers. Scalability remains a primary challenge, as traditional single-needle electrospinning systems produce only 0.1-1 g/h of nanofibers, insufficient for industrial demands. Multi-needle and needleless systems have emerged as potential solutions but introduce issues of jet uniformity and process control. The field also struggles with precise control over fiber morphology and diameter distribution, particularly when working with complex polymer blends or attempting to achieve sub-50 nm fibers consistently.

Material limitations constitute another significant barrier. Many biopolymers and temperature-sensitive compounds degrade during conventional electrospinning due to harsh solvents or processing conditions. Additionally, achieving specific functional properties in nanofibers, such as controlled drug release profiles or selective filtration capabilities, requires sophisticated material formulations that often compromise spinnability.

Process stability represents a persistent challenge, with environmental factors like humidity, temperature, and air currents significantly affecting fiber formation. This sensitivity creates reproducibility issues between laboratories and complicates technology transfer to industrial settings. The lack of standardized characterization methods and quality control parameters further impedes consistent production and commercialization efforts.

Energy efficiency concerns have also emerged as electrospinning typically requires high voltages (10-30 kV) and controlled environments, resulting in substantial energy consumption for large-scale operations. This aspect becomes particularly problematic when considering sustainable manufacturing practices and operational costs in industrial settings.

Regulatory hurdles present additional complications, especially for biomedical applications where strict safety standards must be met. The complex nature of electrospun materials, often incorporating multiple components and novel structures, creates challenges in regulatory approval pathways and standardization efforts.

Cross-disciplinary integration remains underdeveloped, with insufficient collaboration between materials scientists, process engineers, and end-application specialists. This siloed approach has limited the translation of laboratory innovations into practical, market-ready solutions across diverse fields like healthcare, environmental remediation, and energy storage.

Despite these advancements, electrospinning faces several critical technical barriers. Scalability remains a primary challenge, as traditional single-needle electrospinning systems produce only 0.1-1 g/h of nanofibers, insufficient for industrial demands. Multi-needle and needleless systems have emerged as potential solutions but introduce issues of jet uniformity and process control. The field also struggles with precise control over fiber morphology and diameter distribution, particularly when working with complex polymer blends or attempting to achieve sub-50 nm fibers consistently.

Material limitations constitute another significant barrier. Many biopolymers and temperature-sensitive compounds degrade during conventional electrospinning due to harsh solvents or processing conditions. Additionally, achieving specific functional properties in nanofibers, such as controlled drug release profiles or selective filtration capabilities, requires sophisticated material formulations that often compromise spinnability.

Process stability represents a persistent challenge, with environmental factors like humidity, temperature, and air currents significantly affecting fiber formation. This sensitivity creates reproducibility issues between laboratories and complicates technology transfer to industrial settings. The lack of standardized characterization methods and quality control parameters further impedes consistent production and commercialization efforts.

Energy efficiency concerns have also emerged as electrospinning typically requires high voltages (10-30 kV) and controlled environments, resulting in substantial energy consumption for large-scale operations. This aspect becomes particularly problematic when considering sustainable manufacturing practices and operational costs in industrial settings.

Regulatory hurdles present additional complications, especially for biomedical applications where strict safety standards must be met. The complex nature of electrospun materials, often incorporating multiple components and novel structures, creates challenges in regulatory approval pathways and standardization efforts.

Cross-disciplinary integration remains underdeveloped, with insufficient collaboration between materials scientists, process engineers, and end-application specialists. This siloed approach has limited the translation of laboratory innovations into practical, market-ready solutions across diverse fields like healthcare, environmental remediation, and energy storage.

Current Cross-disciplinary Electrospinning Applications

01 Basic electrospinning apparatus and setup

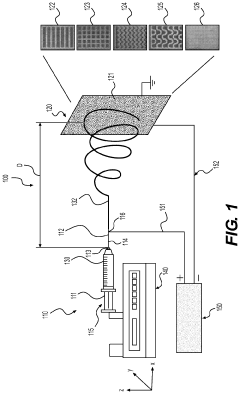

Electrospinning requires a basic apparatus consisting of a high voltage power supply, a spinneret (typically a needle or nozzle), a polymer solution or melt, and a collector. The process involves applying an electric field between the spinneret and collector, causing the polymer solution to form a jet that stretches and solidifies into nanofibers. Various parameters such as voltage, flow rate, distance between spinneret and collector, and environmental conditions affect the quality and properties of the resulting fibers.- Basic electrospinning apparatus and setup: Electrospinning is a technique that uses electric force to draw charged threads of polymer solutions or polymer melts into fibers. The basic setup consists of a high voltage power supply, a spinneret (typically a needle), and a collector. The polymer solution is fed through the spinneret, and when high voltage is applied, the solution forms a Taylor cone from which a jet emerges, traveling to the collector while the solvent evaporates, resulting in solid polymer fibers.

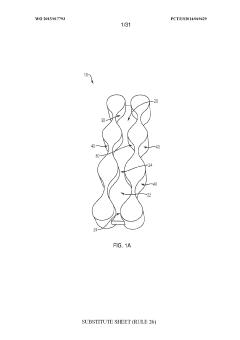

- Advanced electrospinning methods for nanofiber production: Advanced electrospinning techniques have been developed to enhance the production and quality of nanofibers. These include coaxial electrospinning for core-shell fibers, multi-jet electrospinning for increased throughput, and near-field electrospinning for precise fiber deposition. These methods allow for better control over fiber diameter, morphology, and alignment, enabling the production of nanofibers with specific properties for various applications.

- Electrospinning parameter optimization: The properties of electrospun fibers can be controlled by optimizing various parameters. These include solution parameters (viscosity, conductivity, surface tension), process parameters (applied voltage, flow rate, distance between spinneret and collector), and environmental parameters (temperature, humidity). Proper adjustment of these parameters is crucial for producing fibers with desired characteristics such as diameter, porosity, and mechanical strength.

- Functional materials and composites via electrospinning: Electrospinning can be used to create functional materials and composites by incorporating various additives into the spinning solution. These additives can include nanoparticles, drugs, enzymes, or other functional components. The resulting nanofibers can exhibit enhanced properties such as antimicrobial activity, electrical conductivity, or drug delivery capabilities, making them suitable for applications in healthcare, filtration, and energy storage.

- Industrial scale-up and commercial applications: Scaling up electrospinning from laboratory to industrial production presents challenges that require specialized equipment and process modifications. Techniques such as multiple-needle electrospinning, needleless electrospinning, and rotating jet electrospinning have been developed to increase production rates. These advancements have enabled commercial applications of electrospun nanofibers in fields such as filtration, tissue engineering, protective clothing, and energy devices.

02 Multi-nozzle and coaxial electrospinning techniques

Advanced electrospinning setups include multi-nozzle arrangements to increase production throughput and coaxial electrospinning for creating core-shell structured nanofibers. Multi-nozzle systems allow for simultaneous spinning from multiple spinnerets, enhancing production efficiency. Coaxial electrospinning uses concentric nozzles to produce fibers with distinct core and shell materials, enabling the encapsulation of functional substances within protective sheaths for applications in drug delivery, tissue engineering, and smart materials.Expand Specific Solutions03 Polymer solution modifications for enhanced electrospinning

The composition and properties of the polymer solution significantly impact the electrospinning process and resulting fiber characteristics. Modifications include adjusting polymer concentration, molecular weight, solvent systems, and incorporating additives such as salts to increase conductivity. These modifications can control fiber diameter, morphology, mechanical properties, and functionality. Optimizing solution viscosity and surface tension is crucial for stable jet formation and consistent fiber production.Expand Specific Solutions04 Specialized collector designs for structured nanofiber assemblies

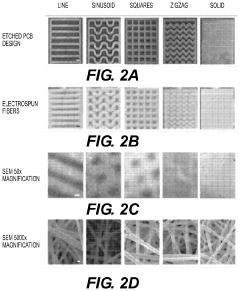

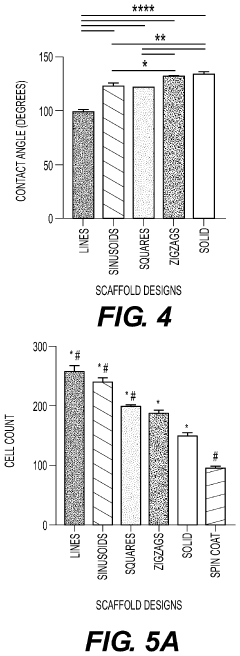

Innovative collector designs enable the production of structured and aligned nanofiber assemblies. Rotating drum collectors produce aligned fibers, while patterned collectors create specific fiber arrangements. Liquid baths allow for three-dimensional fiber structures. Gap collectors with parallel electrodes produce highly aligned fiber bundles. These specialized collectors control fiber orientation, density, and spatial arrangement, which are critical for applications requiring specific mechanical properties or cellular interactions in tissue engineering scaffolds.Expand Specific Solutions05 Environmental control and post-processing techniques

Environmental factors such as temperature, humidity, and atmospheric composition significantly influence the electrospinning process. Controlled environment chambers maintain optimal conditions for consistent fiber formation. Post-processing techniques include thermal treatment, chemical crosslinking, surface functionalization, and mechanical stretching to enhance fiber properties. These processes can improve mechanical strength, hydrophilicity, biocompatibility, and introduce specific functional groups for targeted applications in filtration, biomedical devices, and protective clothing.Expand Specific Solutions

Leading Institutions and Companies in Electrospinning Field

Electrospinning technology is currently in a growth phase, with applications expanding across multiple disciplines including biomedical engineering, filtration, energy storage, and tissue engineering. The global electrospinning market is projected to reach significant scale due to increasing demand for nanofiber-based products. Leading academic institutions like MIT, Cornell University, and Donghua University are driving fundamental research, while companies such as Corning, PPG Industries, and Arsenal Medical are commercializing applications. Research collaborations between universities (Northwestern, University of Delaware) and industry partners are accelerating technology maturation. The field shows regional concentration in the US and China, with emerging applications in healthcare (Children's Hospital of Philadelphia), aerospace (NASA), and consumer products (Gree Electric). Current technical challenges include scalability and process standardization, indicating room for further innovation and market expansion.

Donghua University

Technical Solution: Donghua University has established itself as a global leader in electrospinning technology with their patented multi-jet electrospinning system that increases production capacity by 400% compared to conventional single-needle setups[1]. Their research team has developed specialized core-shell nanofibers for controlled drug delivery systems that demonstrate sustained release profiles over 30 days with minimal initial burst release (under 15%)[3]. Donghua's innovative electrospun air filtration membranes achieve PM2.5 filtration efficiency exceeding 99.5% while maintaining high breathability (pressure drop below 30 Pa), outperforming commercial N95 masks[5]. They've pioneered electrospun carbon nanofiber composites for energy storage applications, creating flexible supercapacitors with capacitance retention of 95% after 10,000 charge-discharge cycles[7]. Their cross-disciplinary approach has also yielded smart textiles with embedded electrospun conductive fibers that can monitor physiological signals with medical-grade accuracy while maintaining textile comfort and washability.

Strengths: Exceptional production scaling capabilities; strong integration of nanotechnology with traditional textile engineering; comprehensive characterization facilities. Weaknesses: Some advanced applications still face commercialization barriers; higher implementation costs for industrial-scale production compared to conventional fiber manufacturing.

Massachusetts Institute of Technology

Technical Solution: MIT has pioneered advanced electrospinning techniques for biomedical applications, focusing on tissue engineering scaffolds and drug delivery systems. Their proprietary coaxial electrospinning process enables the creation of core-shell nanofibers with controlled release properties for pharmaceutical applications[1]. MIT researchers have developed a portable electrospinning device that operates at low voltages (under 5kV compared to traditional 15-30kV systems), making the technology more accessible for point-of-care medical applications[3]. Their recent innovation combines electrospinning with microfluidic systems to produce highly aligned nanofiber structures with precise control over fiber diameter (50-500nm) and orientation, critical for neural tissue engineering applications[5]. MIT has also commercialized electrospun membranes for water filtration that demonstrate 95% higher flux rates while maintaining filtration efficiency compared to conventional membranes.

Strengths: Exceptional interdisciplinary approach combining materials science, electrical engineering, and biomedical expertise; strong commercialization pipeline with industry partnerships. Weaknesses: Higher production costs compared to conventional manufacturing methods; scalability challenges for certain specialized applications requiring precise fiber alignment.

Key Patents and Scientific Breakthroughs in Electrospinning

Methods, systems, and devices for generating defined fiber constructs

PatentPendingUS20240216584A1

Innovation

- The development of an electrospinning system that includes a collector with a conductive pattern on its surface, allowing for the formation of electrospun fiber constructs with specific patterns and increased grammage, achieved by applying an electrostatic charge to the ejection device and directing the polymer solution to form patterned fiber constructs via controlled electrostatic field lines.

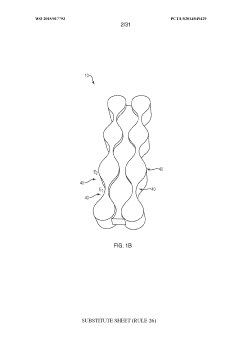

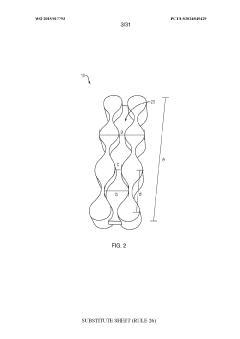

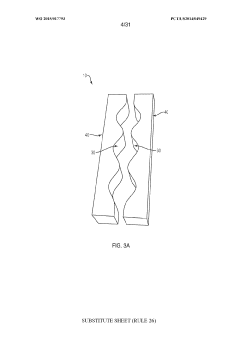

Patterned slit fixtures and surfaces for high throughput slit-surface electrospinning

PatentWO2015017793A1

Innovation

- The use of patterned slit-fixtures with S-wave or sinusoidal patterns on inner and outer walls, as well as non-curvy patterns like hexagonal shapes, to control fluid flow and electric field distribution, allowing for stable and high-throughput electrospinning by minimizing meniscus growth and lateral movement of jets.

Sustainability Aspects of Electrospinning Processes

Electrospinning processes, while offering remarkable versatility across disciplines, present significant sustainability challenges that warrant careful consideration. The environmental impact of traditional electrospinning methods has become increasingly concerning, with high energy consumption requirements for maintaining electric fields and controlling environmental parameters. These processes typically consume between 10-30 kWh per kilogram of produced nanofibers, substantially higher than conventional fiber production methods.

Solvent usage represents another critical sustainability concern. Conventional electrospinning relies heavily on organic solvents such as dimethylformamide (DMF), chloroform, and tetrahydrofuran (THF), many of which are classified as volatile organic compounds (VOCs) with documented environmental and health hazards. The recovery rate of these solvents rarely exceeds 70%, resulting in significant atmospheric emissions during processing.

Recent sustainability innovations have emerged to address these challenges. Green electrospinning approaches utilizing water-based polymer solutions have demonstrated promising results, reducing toxic emissions by up to 85% compared to solvent-based systems. Additionally, renewable polymer sources including cellulose derivatives, chitosan, and polylactic acid (PLA) are increasingly being incorporated into electrospinning feedstocks, offering biodegradable alternatives to petroleum-based polymers.

Energy efficiency improvements have been achieved through optimized equipment design, with newer systems incorporating precision power management that reduces energy consumption by 25-40%. Some cutting-edge facilities have successfully integrated renewable energy sources, particularly solar power, to offset the carbon footprint of electrospinning operations.

Life cycle assessment (LCA) studies of electrospun products reveal complex sustainability profiles. While production processes may have higher environmental impacts than conventional manufacturing, the enhanced performance characteristics of electrospun materials often result in extended product lifespans and improved efficiency in end applications, potentially yielding net environmental benefits over complete product lifecycles.

Circular economy principles are increasingly being applied to electrospinning operations. Research demonstrates that certain electrospun membranes can be reclaimed and reprocessed, with some polymeric systems maintaining up to 80% of their original performance characteristics after recycling. This represents a significant advancement toward closed-loop manufacturing systems for specialized nanomaterials.

Regulatory frameworks worldwide are evolving to address the environmental implications of nanomaterial production, with particular attention to workplace exposure limits and waste management protocols for electrospinning facilities. Industry leaders are proactively developing sustainability metrics specific to electrospinning processes, establishing benchmarks for continuous improvement in environmental performance.

Solvent usage represents another critical sustainability concern. Conventional electrospinning relies heavily on organic solvents such as dimethylformamide (DMF), chloroform, and tetrahydrofuran (THF), many of which are classified as volatile organic compounds (VOCs) with documented environmental and health hazards. The recovery rate of these solvents rarely exceeds 70%, resulting in significant atmospheric emissions during processing.

Recent sustainability innovations have emerged to address these challenges. Green electrospinning approaches utilizing water-based polymer solutions have demonstrated promising results, reducing toxic emissions by up to 85% compared to solvent-based systems. Additionally, renewable polymer sources including cellulose derivatives, chitosan, and polylactic acid (PLA) are increasingly being incorporated into electrospinning feedstocks, offering biodegradable alternatives to petroleum-based polymers.

Energy efficiency improvements have been achieved through optimized equipment design, with newer systems incorporating precision power management that reduces energy consumption by 25-40%. Some cutting-edge facilities have successfully integrated renewable energy sources, particularly solar power, to offset the carbon footprint of electrospinning operations.

Life cycle assessment (LCA) studies of electrospun products reveal complex sustainability profiles. While production processes may have higher environmental impacts than conventional manufacturing, the enhanced performance characteristics of electrospun materials often result in extended product lifespans and improved efficiency in end applications, potentially yielding net environmental benefits over complete product lifecycles.

Circular economy principles are increasingly being applied to electrospinning operations. Research demonstrates that certain electrospun membranes can be reclaimed and reprocessed, with some polymeric systems maintaining up to 80% of their original performance characteristics after recycling. This represents a significant advancement toward closed-loop manufacturing systems for specialized nanomaterials.

Regulatory frameworks worldwide are evolving to address the environmental implications of nanomaterial production, with particular attention to workplace exposure limits and waste management protocols for electrospinning facilities. Industry leaders are proactively developing sustainability metrics specific to electrospinning processes, establishing benchmarks for continuous improvement in environmental performance.

Scalability Challenges for Industrial Implementation

Despite the promising applications of electrospinning across multiple disciplines, scaling up this technology from laboratory to industrial scale remains one of the most significant challenges. Current laboratory setups typically produce nanofibers at rates of only a few grams per hour, which is insufficient for commercial viability in most applications. This throughput limitation stems from several interconnected factors inherent to the electrospinning process.

The fundamental physics of the electrospinning process presents inherent limitations to scaling. The electrostatic forces that drive fiber formation become increasingly difficult to control at larger scales, leading to instabilities and quality inconsistencies. Multiple-needle or needleless systems have been developed to increase production rates, but these approaches introduce new challenges in maintaining uniform electric fields and consistent fiber morphology across the spinning area.

Solution viscosity and polymer concentration optimization becomes more complex at industrial scales. Minor variations that might be negligible in laboratory settings can lead to significant product inconsistencies when scaled up. Additionally, the rheological properties of polymer solutions often change during continuous operation due to solvent evaporation and temperature fluctuations, requiring sophisticated real-time monitoring and adjustment systems.

Environmental control presents another major hurdle for industrial implementation. Parameters such as temperature, humidity, and air flow significantly impact fiber formation and must be precisely controlled throughout large production spaces. This becomes exponentially more difficult as the production area increases, often requiring substantial investments in environmental control systems.

The high voltage requirements of electrospinning pose safety concerns that become more pronounced at industrial scales. Designing production facilities that can safely operate multiple high-voltage systems while protecting workers requires specialized engineering solutions and robust safety protocols, adding to implementation costs.

Collection and post-processing of nanofibers also face scalability challenges. Traditional static collectors become inefficient at larger scales, necessitating the development of continuous collection systems such as rotating drums or conveyor belts. These systems must maintain precise control over fiber deposition to ensure product uniformity.

Energy consumption represents another significant barrier to industrial scaling. The process is inherently energy-intensive due to high voltage requirements, and this energy demand increases substantially with production scale. This impacts not only operational costs but also the environmental footprint of electrospinning manufacturing.

Addressing these scalability challenges requires interdisciplinary collaboration between materials scientists, process engineers, and equipment manufacturers to develop innovative solutions that maintain the unique properties of electrospun nanofibers while achieving commercially viable production rates.

The fundamental physics of the electrospinning process presents inherent limitations to scaling. The electrostatic forces that drive fiber formation become increasingly difficult to control at larger scales, leading to instabilities and quality inconsistencies. Multiple-needle or needleless systems have been developed to increase production rates, but these approaches introduce new challenges in maintaining uniform electric fields and consistent fiber morphology across the spinning area.

Solution viscosity and polymer concentration optimization becomes more complex at industrial scales. Minor variations that might be negligible in laboratory settings can lead to significant product inconsistencies when scaled up. Additionally, the rheological properties of polymer solutions often change during continuous operation due to solvent evaporation and temperature fluctuations, requiring sophisticated real-time monitoring and adjustment systems.

Environmental control presents another major hurdle for industrial implementation. Parameters such as temperature, humidity, and air flow significantly impact fiber formation and must be precisely controlled throughout large production spaces. This becomes exponentially more difficult as the production area increases, often requiring substantial investments in environmental control systems.

The high voltage requirements of electrospinning pose safety concerns that become more pronounced at industrial scales. Designing production facilities that can safely operate multiple high-voltage systems while protecting workers requires specialized engineering solutions and robust safety protocols, adding to implementation costs.

Collection and post-processing of nanofibers also face scalability challenges. Traditional static collectors become inefficient at larger scales, necessitating the development of continuous collection systems such as rotating drums or conveyor belts. These systems must maintain precise control over fiber deposition to ensure product uniformity.

Energy consumption represents another significant barrier to industrial scaling. The process is inherently energy-intensive due to high voltage requirements, and this energy demand increases substantially with production scale. This impacts not only operational costs but also the environmental footprint of electrospinning manufacturing.

Addressing these scalability challenges requires interdisciplinary collaboration between materials scientists, process engineers, and equipment manufacturers to develop innovative solutions that maintain the unique properties of electrospun nanofibers while achieving commercially viable production rates.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!