Comparative Study of Electrospinning and Electrospinning-Plus Techniques

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrospinning Technology Evolution and Objectives

Electrospinning technology emerged in the early 20th century when Anton Formhals patented the process in 1934. However, it wasn't until the 1990s that this technique gained significant attention in the scientific community, primarily due to the growing interest in nanotechnology. The fundamental principle of electrospinning involves applying a high voltage to a polymer solution or melt, creating an electrically charged jet that stretches and thins as it travels toward a grounded collector, ultimately forming nanofibers.

The evolution of electrospinning has been marked by several key developments. Initially, the process was limited to simple single-needle setups with minimal control over fiber morphology. By the early 2000s, researchers had begun to modify the basic setup to enhance productivity and fiber quality, leading to the development of multi-needle systems and needleless electrospinning techniques.

The introduction of coaxial electrospinning in the mid-2000s represented a significant advancement, enabling the production of core-shell structured nanofibers. This innovation expanded the application potential of electrospun materials in drug delivery systems, tissue engineering, and advanced filtration technologies.

More recently, the emergence of "Electrospinning-Plus" techniques has marked a new era in the field. These hybrid approaches combine conventional electrospinning with complementary processes such as electrospraying, melt blowing, or 3D printing. The integration of these technologies aims to overcome the inherent limitations of traditional electrospinning, particularly regarding production scale, fiber alignment, and structural complexity.

The primary objectives of current electrospinning research focus on several key areas. First, enhancing process control to achieve more uniform fiber morphology and precise deposition patterns. Second, increasing production rates to bridge the gap between laboratory research and industrial application. Third, expanding material compatibility to include a wider range of polymers, composites, and functional additives.

For Electrospinning-Plus techniques specifically, research objectives include developing seamless integration protocols between different fabrication methods, optimizing process parameters for hybrid systems, and establishing standardized characterization methods for the resulting materials. Additionally, there is significant interest in creating scalable and cost-effective manufacturing platforms that can leverage the advantages of multiple techniques simultaneously.

The technological trajectory suggests a continued convergence of electrospinning with other nanofabrication methods, driven by the demand for increasingly sophisticated nanostructured materials with tailored properties and functionalities. This evolution reflects the broader trend in materials science toward multifunctional, hierarchically structured materials designed for specific applications.

The evolution of electrospinning has been marked by several key developments. Initially, the process was limited to simple single-needle setups with minimal control over fiber morphology. By the early 2000s, researchers had begun to modify the basic setup to enhance productivity and fiber quality, leading to the development of multi-needle systems and needleless electrospinning techniques.

The introduction of coaxial electrospinning in the mid-2000s represented a significant advancement, enabling the production of core-shell structured nanofibers. This innovation expanded the application potential of electrospun materials in drug delivery systems, tissue engineering, and advanced filtration technologies.

More recently, the emergence of "Electrospinning-Plus" techniques has marked a new era in the field. These hybrid approaches combine conventional electrospinning with complementary processes such as electrospraying, melt blowing, or 3D printing. The integration of these technologies aims to overcome the inherent limitations of traditional electrospinning, particularly regarding production scale, fiber alignment, and structural complexity.

The primary objectives of current electrospinning research focus on several key areas. First, enhancing process control to achieve more uniform fiber morphology and precise deposition patterns. Second, increasing production rates to bridge the gap between laboratory research and industrial application. Third, expanding material compatibility to include a wider range of polymers, composites, and functional additives.

For Electrospinning-Plus techniques specifically, research objectives include developing seamless integration protocols between different fabrication methods, optimizing process parameters for hybrid systems, and establishing standardized characterization methods for the resulting materials. Additionally, there is significant interest in creating scalable and cost-effective manufacturing platforms that can leverage the advantages of multiple techniques simultaneously.

The technological trajectory suggests a continued convergence of electrospinning with other nanofabrication methods, driven by the demand for increasingly sophisticated nanostructured materials with tailored properties and functionalities. This evolution reflects the broader trend in materials science toward multifunctional, hierarchically structured materials designed for specific applications.

Market Applications and Demand Analysis for Nanofiber Technologies

The global nanofiber market has experienced significant growth, with a market value reaching $1.2 billion in 2022 and projected to exceed $3.5 billion by 2028, representing a compound annual growth rate of approximately 19.6%. This robust growth is primarily driven by increasing applications across diverse industries including healthcare, filtration, energy storage, and textiles. The demand for electrospun nanofibers specifically has surged due to their unique properties such as high surface-to-volume ratio, controllable porosity, and exceptional mechanical strength.

In the healthcare sector, nanofibers produced through electrospinning and advanced electrospinning-plus techniques are witnessing substantial demand for wound dressings, drug delivery systems, and tissue engineering scaffolds. The market for medical-grade nanofibers alone is expected to grow at 22% annually through 2027, outpacing the overall nanofiber market growth.

Filtration applications represent another significant market driver, with air and water filtration solutions increasingly incorporating nanofiber technologies. The enhanced filtration efficiency achieved through electrospun nanofibers has created a market segment valued at $450 million in 2022, with particularly strong growth in regions facing severe air pollution challenges such as East Asia and industrial centers globally.

The energy storage sector has emerged as a rapidly expanding application area, with nanofiber-based components for batteries and supercapacitors showing promising performance improvements. Market analysis indicates that energy-related applications could constitute 25% of the total nanofiber market by 2030, up from approximately 12% in 2022.

Regional market distribution shows North America leading with 35% market share, followed by Europe (28%) and Asia-Pacific (27%), with the latter demonstrating the fastest growth rate. This geographic distribution correlates strongly with regional R&D investments in advanced manufacturing technologies.

Consumer demand trends indicate increasing preference for sustainable and high-performance materials, creating market pull for electrospinning-plus techniques that can incorporate biodegradable polymers and natural materials. The sustainable nanofiber segment is growing at 24% annually, reflecting broader market shifts toward environmentally responsible technologies.

Industry surveys reveal that manufacturers are increasingly willing to invest in advanced electrospinning equipment, with 68% of respondents in a 2022 industry survey indicating plans to upgrade their nanofiber production capabilities within the next three years. This investment readiness signals strong confidence in continued market expansion and technological advancement in the nanofiber production space.

In the healthcare sector, nanofibers produced through electrospinning and advanced electrospinning-plus techniques are witnessing substantial demand for wound dressings, drug delivery systems, and tissue engineering scaffolds. The market for medical-grade nanofibers alone is expected to grow at 22% annually through 2027, outpacing the overall nanofiber market growth.

Filtration applications represent another significant market driver, with air and water filtration solutions increasingly incorporating nanofiber technologies. The enhanced filtration efficiency achieved through electrospun nanofibers has created a market segment valued at $450 million in 2022, with particularly strong growth in regions facing severe air pollution challenges such as East Asia and industrial centers globally.

The energy storage sector has emerged as a rapidly expanding application area, with nanofiber-based components for batteries and supercapacitors showing promising performance improvements. Market analysis indicates that energy-related applications could constitute 25% of the total nanofiber market by 2030, up from approximately 12% in 2022.

Regional market distribution shows North America leading with 35% market share, followed by Europe (28%) and Asia-Pacific (27%), with the latter demonstrating the fastest growth rate. This geographic distribution correlates strongly with regional R&D investments in advanced manufacturing technologies.

Consumer demand trends indicate increasing preference for sustainable and high-performance materials, creating market pull for electrospinning-plus techniques that can incorporate biodegradable polymers and natural materials. The sustainable nanofiber segment is growing at 24% annually, reflecting broader market shifts toward environmentally responsible technologies.

Industry surveys reveal that manufacturers are increasingly willing to invest in advanced electrospinning equipment, with 68% of respondents in a 2022 industry survey indicating plans to upgrade their nanofiber production capabilities within the next three years. This investment readiness signals strong confidence in continued market expansion and technological advancement in the nanofiber production space.

Current Challenges in Electrospinning and Electrospinning-Plus Methods

Despite significant advancements in electrospinning technology over the past decades, both conventional electrospinning and the more advanced electrospinning-plus techniques face several persistent challenges that limit their broader industrial application and technological advancement.

In conventional electrospinning, process stability remains a critical issue. Environmental factors such as humidity, temperature, and air flow significantly affect fiber formation and consistency. Even minor fluctuations in these parameters can lead to substantial variations in fiber morphology and quality, making reproducibility difficult to achieve across different production batches.

Scalability presents another major hurdle. While electrospinning works efficiently at laboratory scale, transitioning to industrial-scale production introduces complications in maintaining uniform electric fields across larger collection areas. The inherently low production rate of conventional electrospinning (typically 0.1-1 g/h) makes it economically challenging for mass production scenarios.

The electrospinning-plus family of techniques, while offering enhanced capabilities, introduces its own set of challenges. These hybrid approaches often require more complex equipment setups and precise parameter control. For instance, coaxial electrospinning demands precise alignment of multiple spinnerets and careful matching of solution viscosities, while melt electrospinning requires sophisticated temperature control systems.

Material limitations affect both conventional and advanced techniques. Not all polymers are suitable for electrospinning due to solubility constraints, molecular weight requirements, or solution conductivity issues. Finding appropriate solvent systems that balance volatility, conductivity, and biocompatibility remains challenging, particularly for biomedical applications.

For electrospinning-plus methods, parameter optimization becomes exponentially more complex. The interdependence of multiple variables (voltage, flow rate, distance, solution properties, and additional parameters specific to each technique) creates a vast parameter space that is difficult to navigate systematically. This complexity often leads to empirical rather than theoretical approaches to process optimization.

Safety concerns persist across all electrospinning methods. The high voltages employed (typically 10-30 kV) present electrical hazards, while solvent evaporation during the process creates potential for toxic vapor accumulation, requiring sophisticated ventilation systems.

The characterization of nanofiber structures, particularly in complex architectures produced by electrospinning-plus techniques, remains technically challenging. Current analytical methods often struggle to fully capture the three-dimensional organization, internal structure, and functional properties of these advanced materials.

Finally, standardization across the field is notably lacking. The absence of universally accepted protocols for process parameters, material characterization, and performance evaluation makes cross-comparison between different research outputs difficult and hinders technology transfer from laboratory to industry.

In conventional electrospinning, process stability remains a critical issue. Environmental factors such as humidity, temperature, and air flow significantly affect fiber formation and consistency. Even minor fluctuations in these parameters can lead to substantial variations in fiber morphology and quality, making reproducibility difficult to achieve across different production batches.

Scalability presents another major hurdle. While electrospinning works efficiently at laboratory scale, transitioning to industrial-scale production introduces complications in maintaining uniform electric fields across larger collection areas. The inherently low production rate of conventional electrospinning (typically 0.1-1 g/h) makes it economically challenging for mass production scenarios.

The electrospinning-plus family of techniques, while offering enhanced capabilities, introduces its own set of challenges. These hybrid approaches often require more complex equipment setups and precise parameter control. For instance, coaxial electrospinning demands precise alignment of multiple spinnerets and careful matching of solution viscosities, while melt electrospinning requires sophisticated temperature control systems.

Material limitations affect both conventional and advanced techniques. Not all polymers are suitable for electrospinning due to solubility constraints, molecular weight requirements, or solution conductivity issues. Finding appropriate solvent systems that balance volatility, conductivity, and biocompatibility remains challenging, particularly for biomedical applications.

For electrospinning-plus methods, parameter optimization becomes exponentially more complex. The interdependence of multiple variables (voltage, flow rate, distance, solution properties, and additional parameters specific to each technique) creates a vast parameter space that is difficult to navigate systematically. This complexity often leads to empirical rather than theoretical approaches to process optimization.

Safety concerns persist across all electrospinning methods. The high voltages employed (typically 10-30 kV) present electrical hazards, while solvent evaporation during the process creates potential for toxic vapor accumulation, requiring sophisticated ventilation systems.

The characterization of nanofiber structures, particularly in complex architectures produced by electrospinning-plus techniques, remains technically challenging. Current analytical methods often struggle to fully capture the three-dimensional organization, internal structure, and functional properties of these advanced materials.

Finally, standardization across the field is notably lacking. The absence of universally accepted protocols for process parameters, material characterization, and performance evaluation makes cross-comparison between different research outputs difficult and hinders technology transfer from laboratory to industry.

Comparative Analysis of Current Electrospinning Techniques

01 Basic electrospinning techniques and apparatus

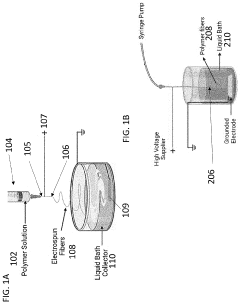

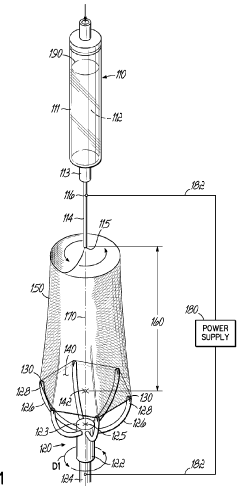

Electrospinning is a fiber production method that uses electric force to draw charged threads of polymer solutions or polymer melts into fibers with diameters ranging from nanometers to micrometers. The basic apparatus includes a high voltage power supply, a spinneret (typically a needle), and a collector. The technique involves applying an electric field to a polymer solution or melt, causing it to form a jet that stretches and solidifies into fibers as it travels to the collector. This method is widely used for producing nanofibers for various applications.- Basic electrospinning techniques and apparatus: Electrospinning is a technique that uses electric force to draw charged threads of polymer solutions or polymer melts into fibers. The basic apparatus consists of a high voltage power supply, a spinneret (typically a needle), and a collector. The process involves applying an electric field to a polymer solution or melt, causing it to form a jet that stretches and thins as it travels to the collector, resulting in nanoscale or microscale fibers. Various parameters such as voltage, flow rate, distance between spinneret and collector affect the fiber morphology and properties.

- Advanced electrospinning-plus techniques: Electrospinning-plus techniques refer to enhanced or modified electrospinning methods that overcome limitations of conventional electrospinning. These include coaxial electrospinning for core-shell fibers, multi-jet electrospinning for increased productivity, near-field electrospinning for precise fiber deposition, and melt electrospinning for polymer melts without solvents. These advanced techniques enable the production of fibers with complex structures, improved properties, or specific functionalities that cannot be achieved through conventional electrospinning.

- Nanofiber materials and compositions: Various materials can be processed through electrospinning to produce nanofibers with unique properties. These include synthetic polymers (such as PVA, PEO, PCL), natural polymers (like collagen, chitosan, cellulose derivatives), composites incorporating nanoparticles, carbon-based materials, and ceramic precursors. The selection of materials and their compositions significantly influence the mechanical properties, biocompatibility, electrical conductivity, and other functional characteristics of the resulting nanofibers, making them suitable for specific applications.

- Process parameters and optimization: Successful electrospinning requires careful optimization of various process parameters. These include solution parameters (concentration, viscosity, conductivity, surface tension), process parameters (applied voltage, flow rate, distance between needle and collector), and environmental parameters (temperature, humidity). Advanced control systems and monitoring techniques are employed to maintain consistent fiber quality. Optimization strategies often involve statistical design of experiments to identify the most significant parameters and their interactions for specific applications.

- Applications of electrospun nanofibers: Electrospun nanofibers find applications across diverse fields due to their high surface area, porosity, and versatility. In biomedical engineering, they serve as scaffolds for tissue engineering, drug delivery systems, and wound dressings. In environmental applications, they function as filtration membranes and adsorbents for water and air purification. Other applications include energy storage devices (batteries, supercapacitors), sensors, protective clothing, and catalysis. The ability to tailor fiber properties through material selection and processing conditions enables customization for specific end-use requirements.

02 Advanced electrospinning-plus techniques

Electrospinning-plus techniques refer to enhanced or modified electrospinning methods that overcome limitations of conventional electrospinning. These include coaxial electrospinning, multi-jet electrospinning, melt electrospinning, and near-field electrospinning. These advanced techniques allow for the production of fibers with complex structures, improved properties, or specific functionalities. They often involve modifications to the spinneret design, collector configuration, or the application of additional forces during the spinning process.Expand Specific Solutions03 Electrospun nanofiber applications in filtration and medical fields

Electrospun nanofibers have significant applications in filtration systems and medical devices due to their high surface area-to-volume ratio, porosity, and ability to be functionalized. In filtration, these nanofibers are used in air filters, water purification systems, and oil-water separation membranes. In the medical field, applications include wound dressings, drug delivery systems, tissue engineering scaffolds, and biosensors. The fiber properties can be tailored by adjusting electrospinning parameters to meet specific requirements for these applications.Expand Specific Solutions04 Polymer solutions and materials for electrospinning

The selection of polymer solutions and materials is crucial for successful electrospinning. Various natural and synthetic polymers can be used, including polyvinyl alcohol (PVA), polylactic acid (PLA), polyethylene oxide (PEO), chitosan, and collagen. The solution properties such as viscosity, conductivity, and surface tension significantly affect the electrospinning process and the resulting fiber morphology. Additives can be incorporated to modify these properties or to functionalize the fibers. The concentration of polymer in the solution is also a critical parameter that influences fiber formation.Expand Specific Solutions05 Process parameters and control systems in electrospinning

Process parameters and control systems play a vital role in determining the quality and properties of electrospun fibers. Key parameters include applied voltage, solution flow rate, distance between spinneret and collector, ambient conditions (temperature and humidity), and collector rotation speed. Advanced control systems can monitor and adjust these parameters in real-time to ensure consistent fiber production. Computer-aided design and automation have been integrated into modern electrospinning setups to improve reproducibility and enable large-scale manufacturing of nanofibers with uniform properties.Expand Specific Solutions

Leading Research Institutions and Commercial Manufacturers

The electrospinning technology market is currently in a growth phase, with the comparative study of traditional electrospinning versus electrospinning-plus techniques revealing significant competitive dynamics. The global market is expanding rapidly, estimated at $2.1 billion with projected 7-9% CAGR through 2027, driven by applications in healthcare, filtration, and textiles. Technical maturity varies across implementations, with established players like Novellus Systems and Corning offering mature industrial solutions, while academic institutions (University of Delaware, Tianjin University) drive innovation. Research-focused companies like Arsenal Medical and Elektrofi are advancing nanofiber applications, while Medprin and Stora Enso are commercializing specialized applications. The competitive landscape features increasing collaboration between academic institutions and industry partners to bridge fundamental research and commercial applications.

Jiangsu New Vision Advanced Functional Fiber Innovation Center

Technical Solution: Jiangsu New Vision Advanced Functional Fiber Innovation Center has developed a comprehensive electrospinning-plus technology platform that significantly enhances traditional electrospinning capabilities. Their system features a multi-nozzle array with independent temperature and flow rate control for each spinneret, enabling the simultaneous production of different fiber types in a single process. A distinctive innovation is their integration of in-line fiber drawing and annealing stations that apply controlled mechanical stress and thermal treatment to freshly formed fibers, resulting in enhanced molecular alignment and crystallinity[9]. The center has pioneered a hybrid electrospinning technique that incorporates conductive additives and applies alternating electric fields during spinning, producing fibers with aligned internal structures and anisotropic properties. Their technology also includes an advanced collection system with programmable movement patterns and electrostatic field manipulation, allowing the creation of 3D fiber architectures with controlled porosity and fiber orientation. Additionally, they've developed post-spinning surface modification techniques using plasma treatment and chemical vapor deposition to introduce functional coatings onto fiber surfaces for applications in filtration, energy storage, and biomedical devices[10].

Strengths: Exceptional throughput capabilities for industrial-scale production; superior control over fiber internal structure and crystallinity; versatile post-processing options for enhanced functionality. Weaknesses: High initial investment and operational costs; complex maintenance requirements; challenges in process parameter optimization for new material systems.

Southeast University

Technical Solution: Southeast University has developed a sophisticated electrospinning-plus platform that extends beyond conventional electrospinning capabilities. Their system incorporates a multi-axial electrospinning setup capable of producing tri-layer and quad-layer nanofibers with distinct compartmentalization of different functional materials. A key innovation is their integration of controlled electrical field modulation that dynamically adjusts field strength and direction during spinning, resulting in fibers with programmable internal structures and orientation[6]. The university's research team has also pioneered a hybrid technique combining electrospinning with in-situ polymerization, where monomers in the spinning solution undergo controlled polymerization during the fiber formation process, creating nanofibers with enhanced mechanical properties and molecular weight distribution. Their platform features an automated collection system with precise movement control in three dimensions, enabling the fabrication of complex fiber architectures with predetermined spatial arrangements. Additionally, they've developed post-spinning surface modification protocols using plasma treatment and chemical grafting to introduce functional groups onto fiber surfaces for specific applications in tissue engineering and environmental remediation[8].

Strengths: Advanced capability for multi-component fiber production; precise control over internal fiber structure; versatile post-processing options for surface functionalization. Weaknesses: Complex operation requiring specialized training; higher energy consumption compared to conventional methods; challenges in maintaining consistent quality across large production volumes.

Key Patents and Scientific Breakthroughs in Nanofiber Production

Hierarchical organic-inorganic composites synthesized by electrospinning fibers within a non-conductive and a conductive pre-ceramic gel

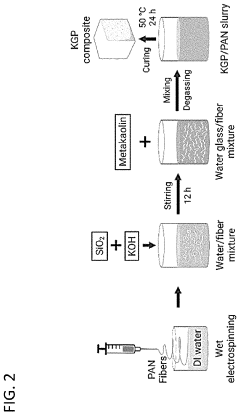

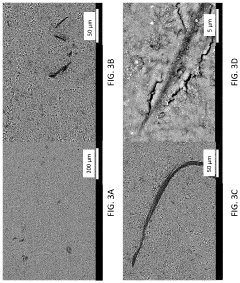

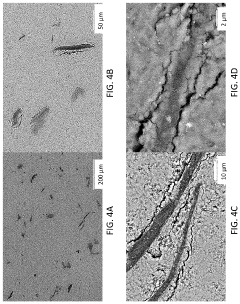

PatentActiveUS20220089496A1

Innovation

- The method involves electrospinning organic polymer fibers in a liquid or gel collector, where ceramic precursors are added before, during, or after fiber collection, and an inorganic curing agent is introduced to form a ceramic matrix, allowing for high dispersion and curing of fibers to create fiber-reinforced ceramic composites with improved mechanical properties.

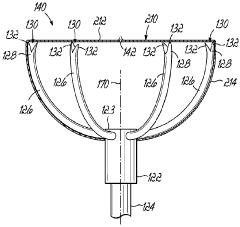

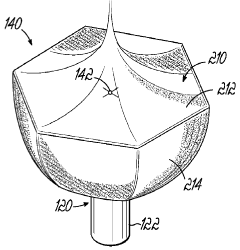

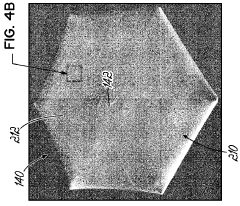

Electro-spinning methods and uses thereof

PatentWO2023133286A1

Innovation

- A method involving a rotating collector with multiple spindles and tines is used to collect fibers, allowing for both aligned and randomly oriented fibers to be produced, with a spinneret capable of receiving an electrical charge and a precursor liquid that includes a polymer and solvent mixture, which is processed to form single crystal fibers with diameters ranging from 1 nm to 5 pm, and subsequent thermal treatments to modify the fibers for specific applications.

Material Compatibility and Process Parameters Optimization

Material compatibility is a critical factor in determining the success of both traditional electrospinning and electrospinning-plus techniques. Different polymers exhibit varying behaviors under electric fields, affecting fiber formation and quality. Natural polymers such as collagen, chitosan, and gelatin typically require specific solvent systems and often benefit from the enhanced control offered by electrospinning-plus methods. Synthetic polymers like polycaprolactone (PCL), poly(lactic-co-glycolic acid) (PLGA), and polyvinyl alcohol (PVA) generally demonstrate better processability in conventional electrospinning but can achieve improved morphological characteristics through electrospinning-plus techniques.

The viscosity of polymer solutions significantly impacts the electrospinning process, with optimal ranges varying between 1-20 Pa·s depending on the specific polymer. Solutions with viscosities outside this range often result in beaded fibers or process instability. Electrospinning-plus techniques, particularly those incorporating auxiliary electric fields, can expand this workable viscosity range by providing additional control mechanisms over the jet formation and elongation.

Solvent selection represents another crucial parameter requiring optimization. Ideal solvents must balance volatility, conductivity, and surface tension while maintaining polymer solubility. For electrospinning-plus techniques, particularly coaxial configurations, solvent compatibility between core and shell solutions becomes essential to prevent premature mixing or phase separation.

Applied voltage optimization differs significantly between conventional and enhanced techniques. While traditional electrospinning typically operates in the 10-30 kV range, electrospinning-plus methods may require modified voltage profiles or multiple power supplies with precisely coordinated settings. The distance between the needle tip and collector (typically 10-20 cm) requires adjustment based on the specific technique employed, with near-field electrospinning demanding much shorter distances (1-3 mm) for direct-write capabilities.

Environmental parameters including temperature (optimal range 20-25°C) and humidity (30-50%) significantly impact fiber formation and solvent evaporation rates. Electrospinning-plus techniques often demonstrate greater sensitivity to these environmental factors, necessitating more stringent control systems to ensure reproducibility.

Flow rate optimization presents unique challenges across different techniques, with conventional electrospinning typically operating at 0.5-3 mL/h, while techniques like melt electrospinning or high-throughput methods may require substantially different flow regimes. The interrelationship between flow rate and other parameters becomes more complex in electrospinning-plus configurations, often requiring multivariate optimization approaches.

The viscosity of polymer solutions significantly impacts the electrospinning process, with optimal ranges varying between 1-20 Pa·s depending on the specific polymer. Solutions with viscosities outside this range often result in beaded fibers or process instability. Electrospinning-plus techniques, particularly those incorporating auxiliary electric fields, can expand this workable viscosity range by providing additional control mechanisms over the jet formation and elongation.

Solvent selection represents another crucial parameter requiring optimization. Ideal solvents must balance volatility, conductivity, and surface tension while maintaining polymer solubility. For electrospinning-plus techniques, particularly coaxial configurations, solvent compatibility between core and shell solutions becomes essential to prevent premature mixing or phase separation.

Applied voltage optimization differs significantly between conventional and enhanced techniques. While traditional electrospinning typically operates in the 10-30 kV range, electrospinning-plus methods may require modified voltage profiles or multiple power supplies with precisely coordinated settings. The distance between the needle tip and collector (typically 10-20 cm) requires adjustment based on the specific technique employed, with near-field electrospinning demanding much shorter distances (1-3 mm) for direct-write capabilities.

Environmental parameters including temperature (optimal range 20-25°C) and humidity (30-50%) significantly impact fiber formation and solvent evaporation rates. Electrospinning-plus techniques often demonstrate greater sensitivity to these environmental factors, necessitating more stringent control systems to ensure reproducibility.

Flow rate optimization presents unique challenges across different techniques, with conventional electrospinning typically operating at 0.5-3 mL/h, while techniques like melt electrospinning or high-throughput methods may require substantially different flow regimes. The interrelationship between flow rate and other parameters becomes more complex in electrospinning-plus configurations, often requiring multivariate optimization approaches.

Scalability and Industrial Implementation Considerations

The scalability of electrospinning and electrospinning-plus techniques represents a critical factor in their industrial adoption. Traditional electrospinning faces significant throughput limitations, typically producing only 0.1-1 g/h per spinneret, which severely restricts large-scale manufacturing capabilities. This bottleneck has historically confined electrospinning applications primarily to laboratory settings and specialized small-batch production.

Electrospinning-plus techniques offer promising advancements in production capacity through various modifications. Multiple-needle systems can increase output by 10-15 times compared to single-needle setups, while needleless systems utilizing rotating drums or disks demonstrate even greater scalability potential, with some commercial systems achieving 50-100 g/h production rates. These improvements directly address one of the most significant barriers to industrial implementation.

Capital investment requirements differ substantially between the techniques. Conventional electrospinning equipment requires relatively modest initial investment ($50,000-200,000 for basic industrial systems), whereas electrospinning-plus technologies often demand significantly higher capital expenditure ($200,000-1,000,000) due to their technical complexity and specialized components. This cost differential creates a notable adoption threshold for smaller manufacturers.

Energy consumption patterns also vary considerably. Standard electrospinning operates at 10-30 kV with minimal current draw, resulting in relatively low power requirements. In contrast, electrospinning-plus methods incorporating auxiliary technologies such as air-assistance or melt processing typically consume 2-5 times more energy, necessitating more robust power infrastructure and increasing operational costs.

Space utilization efficiency represents another important consideration. Modern needleless electrospinning systems demonstrate superior spatial efficiency, with production footprints approximately 60-70% smaller than equivalent-output multi-needle arrays. This advantage becomes particularly significant in high-cost manufacturing environments where facility space carries premium value.

Quality control and process consistency present distinct challenges across techniques. Conventional electrospinning offers well-established process parameters but struggles with jet instability at higher production rates. Electrospinning-plus methods generally provide more robust production stability but introduce additional process variables that require sophisticated monitoring systems, potentially increasing validation complexity and regulatory compliance costs in regulated industries such as medical device manufacturing.

Electrospinning-plus techniques offer promising advancements in production capacity through various modifications. Multiple-needle systems can increase output by 10-15 times compared to single-needle setups, while needleless systems utilizing rotating drums or disks demonstrate even greater scalability potential, with some commercial systems achieving 50-100 g/h production rates. These improvements directly address one of the most significant barriers to industrial implementation.

Capital investment requirements differ substantially between the techniques. Conventional electrospinning equipment requires relatively modest initial investment ($50,000-200,000 for basic industrial systems), whereas electrospinning-plus technologies often demand significantly higher capital expenditure ($200,000-1,000,000) due to their technical complexity and specialized components. This cost differential creates a notable adoption threshold for smaller manufacturers.

Energy consumption patterns also vary considerably. Standard electrospinning operates at 10-30 kV with minimal current draw, resulting in relatively low power requirements. In contrast, electrospinning-plus methods incorporating auxiliary technologies such as air-assistance or melt processing typically consume 2-5 times more energy, necessitating more robust power infrastructure and increasing operational costs.

Space utilization efficiency represents another important consideration. Modern needleless electrospinning systems demonstrate superior spatial efficiency, with production footprints approximately 60-70% smaller than equivalent-output multi-needle arrays. This advantage becomes particularly significant in high-cost manufacturing environments where facility space carries premium value.

Quality control and process consistency present distinct challenges across techniques. Conventional electrospinning offers well-established process parameters but struggles with jet instability at higher production rates. Electrospinning-plus methods generally provide more robust production stability but introduce additional process variables that require sophisticated monitoring systems, potentially increasing validation complexity and regulatory compliance costs in regulated industries such as medical device manufacturing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!