Exploration of Multi-Component Fiber Synthesis via Electrospinning

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrospinning Technology Evolution and Objectives

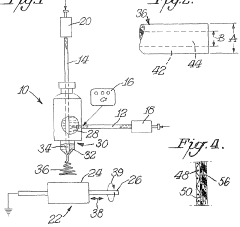

Electrospinning technology has evolved significantly since its inception in the early 20th century. Initially patented by Formhals in 1934, the fundamental process involves applying high voltage to a polymer solution to create ultrafine fibers. The technology remained relatively dormant until the 1990s when renewed interest emerged due to advancements in nanotechnology and materials science, leading to significant improvements in equipment precision and process control.

The evolution of electrospinning can be characterized by three distinct phases. The first phase (1934-1990s) focused on basic process development and understanding the fundamental principles. The second phase (1990s-2010) saw rapid expansion in research applications and equipment refinement, including the development of multi-jet systems and environmental control chambers. The current phase (2010-present) has been marked by sophisticated innovations enabling precise control over fiber morphology, orientation, and composition.

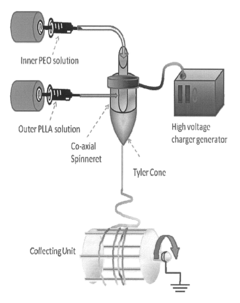

Multi-component fiber synthesis represents a significant advancement in electrospinning technology. Traditional electrospinning typically produced single-component fibers, limiting their functionality. The development of coaxial electrospinning in the early 2000s marked a breakthrough, allowing the creation of core-shell structured fibers. This innovation expanded to include tri-axial and multi-axial configurations, enabling the production of fibers with increasingly complex architectures and compositions.

The primary objectives of current research in multi-component fiber synthesis via electrospinning include achieving precise control over fiber composition gradients, developing scalable manufacturing processes for industrial applications, and creating fibers with programmable release properties for biomedical applications. Researchers aim to overcome challenges related to solution compatibility, process stability, and reproducibility at scale.

Another critical objective is the integration of smart materials into multi-component fibers, enabling responsive behaviors to environmental stimuli such as temperature, pH, or electrical signals. This direction holds promise for applications in wearable technology, tissue engineering, and environmental sensing.

The field is also moving toward sustainable practices, with increasing focus on using biodegradable polymers and environmentally friendly solvents. This trend aligns with global sustainability goals and opens new application areas in green technology and circular economy solutions.

Looking forward, the technology trajectory suggests continued refinement of multi-component electrospinning techniques, with emphasis on precision control, scalability, and integration with complementary technologies such as 3D printing and microfluidics to create hierarchically structured materials with unprecedented functionality.

The evolution of electrospinning can be characterized by three distinct phases. The first phase (1934-1990s) focused on basic process development and understanding the fundamental principles. The second phase (1990s-2010) saw rapid expansion in research applications and equipment refinement, including the development of multi-jet systems and environmental control chambers. The current phase (2010-present) has been marked by sophisticated innovations enabling precise control over fiber morphology, orientation, and composition.

Multi-component fiber synthesis represents a significant advancement in electrospinning technology. Traditional electrospinning typically produced single-component fibers, limiting their functionality. The development of coaxial electrospinning in the early 2000s marked a breakthrough, allowing the creation of core-shell structured fibers. This innovation expanded to include tri-axial and multi-axial configurations, enabling the production of fibers with increasingly complex architectures and compositions.

The primary objectives of current research in multi-component fiber synthesis via electrospinning include achieving precise control over fiber composition gradients, developing scalable manufacturing processes for industrial applications, and creating fibers with programmable release properties for biomedical applications. Researchers aim to overcome challenges related to solution compatibility, process stability, and reproducibility at scale.

Another critical objective is the integration of smart materials into multi-component fibers, enabling responsive behaviors to environmental stimuli such as temperature, pH, or electrical signals. This direction holds promise for applications in wearable technology, tissue engineering, and environmental sensing.

The field is also moving toward sustainable practices, with increasing focus on using biodegradable polymers and environmentally friendly solvents. This trend aligns with global sustainability goals and opens new application areas in green technology and circular economy solutions.

Looking forward, the technology trajectory suggests continued refinement of multi-component electrospinning techniques, with emphasis on precision control, scalability, and integration with complementary technologies such as 3D printing and microfluidics to create hierarchically structured materials with unprecedented functionality.

Market Applications for Multi-Component Fibers

Multi-component fibers produced through electrospinning have emerged as versatile materials with applications spanning numerous industries, driven by their unique structural properties and customizable functionalities. The global market for these advanced materials is experiencing significant growth, with particular momentum in healthcare, environmental remediation, and energy sectors.

In the healthcare domain, multi-component electrospun fibers are revolutionizing tissue engineering and drug delivery systems. These fibers can simultaneously incorporate multiple bioactive compounds with controlled release profiles, enabling targeted therapeutic approaches. The wound care segment particularly benefits from these materials, as they can combine antimicrobial agents with growth factors to promote healing while preventing infection.

Filtration technology represents another substantial market opportunity. Multi-component fibers enable the creation of filtration membranes with hierarchical structures that can simultaneously address multiple contaminants. This capability is driving adoption in both industrial wastewater treatment and consumer water purification systems, where removal of complex pollutant mixtures is increasingly required by regulatory standards.

The energy sector has identified significant applications for these advanced fibers in next-generation battery separators and components for fuel cells. By incorporating multiple functional materials within a single fiber structure, manufacturers can develop energy storage solutions with enhanced performance characteristics including improved ion conductivity, mechanical stability, and thermal resistance.

Smart textiles constitute a rapidly expanding application area, with multi-component fibers enabling the integration of sensing, responsive, and protective functions within wearable products. This market segment is particularly attractive due to growing consumer interest in performance apparel and health monitoring capabilities embedded in everyday clothing.

Agricultural applications are also emerging, with controlled-release fertilizer systems and crop protection products utilizing multi-component fibers to optimize nutrient delivery while minimizing environmental impact. These solutions address the growing demand for sustainable farming practices and precision agriculture technologies.

The construction industry has begun incorporating these advanced fibers into composite materials for enhanced structural properties and multifunctional building elements. Applications include self-healing concrete additives, thermal management systems, and lightweight reinforcement materials that contribute to energy-efficient building designs.

Aerospace and automotive sectors represent premium markets for multi-component fibers, particularly in lightweight composite structures that require combinations of mechanical strength, thermal stability, and electrical conductivity. These high-value applications drive significant research investment despite their relatively smaller volume compared to consumer markets.

In the healthcare domain, multi-component electrospun fibers are revolutionizing tissue engineering and drug delivery systems. These fibers can simultaneously incorporate multiple bioactive compounds with controlled release profiles, enabling targeted therapeutic approaches. The wound care segment particularly benefits from these materials, as they can combine antimicrobial agents with growth factors to promote healing while preventing infection.

Filtration technology represents another substantial market opportunity. Multi-component fibers enable the creation of filtration membranes with hierarchical structures that can simultaneously address multiple contaminants. This capability is driving adoption in both industrial wastewater treatment and consumer water purification systems, where removal of complex pollutant mixtures is increasingly required by regulatory standards.

The energy sector has identified significant applications for these advanced fibers in next-generation battery separators and components for fuel cells. By incorporating multiple functional materials within a single fiber structure, manufacturers can develop energy storage solutions with enhanced performance characteristics including improved ion conductivity, mechanical stability, and thermal resistance.

Smart textiles constitute a rapidly expanding application area, with multi-component fibers enabling the integration of sensing, responsive, and protective functions within wearable products. This market segment is particularly attractive due to growing consumer interest in performance apparel and health monitoring capabilities embedded in everyday clothing.

Agricultural applications are also emerging, with controlled-release fertilizer systems and crop protection products utilizing multi-component fibers to optimize nutrient delivery while minimizing environmental impact. These solutions address the growing demand for sustainable farming practices and precision agriculture technologies.

The construction industry has begun incorporating these advanced fibers into composite materials for enhanced structural properties and multifunctional building elements. Applications include self-healing concrete additives, thermal management systems, and lightweight reinforcement materials that contribute to energy-efficient building designs.

Aerospace and automotive sectors represent premium markets for multi-component fibers, particularly in lightweight composite structures that require combinations of mechanical strength, thermal stability, and electrical conductivity. These high-value applications drive significant research investment despite their relatively smaller volume compared to consumer markets.

Current Limitations in Multi-Component Electrospinning

Despite significant advancements in electrospinning technology, multi-component fiber synthesis faces several critical limitations that impede its broader industrial application and technological advancement. The primary challenge remains the precise control of fiber morphology and component distribution within multi-component systems. When multiple polymers or functional materials are introduced into a single electrospinning process, maintaining consistent fiber diameter, orientation, and internal structure becomes exponentially more complex than with single-component systems.

Material compatibility presents another significant hurdle. Different polymers and functional additives often possess incompatible physicochemical properties, including solubility parameters, viscosity, electrical conductivity, and surface tension. These incompatibilities can lead to phase separation during the electrospinning process, resulting in heterogeneous fiber structures or even process failure. The selection of appropriate solvent systems that can accommodate multiple components without compromising their functional properties remains particularly challenging.

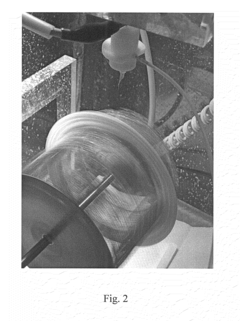

Scalability issues severely restrict industrial implementation of multi-component electrospinning. Current laboratory-scale setups typically produce only small quantities of fibers with limited throughput. When scaling to industrial production, maintaining consistent fiber quality across larger spinning areas while handling multiple polymer solutions simultaneously introduces significant engineering challenges. The complexity of multi-component spinning equipment and the need for precise environmental control further complicate scale-up efforts.

Process parameter optimization represents another major limitation. The interdependence of electrospinning parameters (voltage, flow rate, distance to collector) becomes exponentially more complex in multi-component systems. Each additional component introduces new variables that affect the overall spinning process, creating a vast parameter space that is difficult to optimize systematically. This complexity often necessitates extensive trial-and-error approaches, making process development time-consuming and resource-intensive.

Characterization and quality control of multi-component fibers present unique analytical challenges. Conventional techniques may be insufficient to fully assess the internal structure, component distribution, and interfacial properties of complex fiber systems. Advanced analytical methods often require specialized equipment and expertise, limiting widespread adoption and standardization of quality metrics for multi-component fibers.

Regulatory and standardization frameworks remain underdeveloped for multi-component electrospun materials, particularly for high-value applications in healthcare, filtration, and protective equipment. The lack of established standards for testing, characterization, and performance evaluation creates barriers to commercialization and market acceptance of these advanced materials.

Material compatibility presents another significant hurdle. Different polymers and functional additives often possess incompatible physicochemical properties, including solubility parameters, viscosity, electrical conductivity, and surface tension. These incompatibilities can lead to phase separation during the electrospinning process, resulting in heterogeneous fiber structures or even process failure. The selection of appropriate solvent systems that can accommodate multiple components without compromising their functional properties remains particularly challenging.

Scalability issues severely restrict industrial implementation of multi-component electrospinning. Current laboratory-scale setups typically produce only small quantities of fibers with limited throughput. When scaling to industrial production, maintaining consistent fiber quality across larger spinning areas while handling multiple polymer solutions simultaneously introduces significant engineering challenges. The complexity of multi-component spinning equipment and the need for precise environmental control further complicate scale-up efforts.

Process parameter optimization represents another major limitation. The interdependence of electrospinning parameters (voltage, flow rate, distance to collector) becomes exponentially more complex in multi-component systems. Each additional component introduces new variables that affect the overall spinning process, creating a vast parameter space that is difficult to optimize systematically. This complexity often necessitates extensive trial-and-error approaches, making process development time-consuming and resource-intensive.

Characterization and quality control of multi-component fibers present unique analytical challenges. Conventional techniques may be insufficient to fully assess the internal structure, component distribution, and interfacial properties of complex fiber systems. Advanced analytical methods often require specialized equipment and expertise, limiting widespread adoption and standardization of quality metrics for multi-component fibers.

Regulatory and standardization frameworks remain underdeveloped for multi-component electrospun materials, particularly for high-value applications in healthcare, filtration, and protective equipment. The lack of established standards for testing, characterization, and performance evaluation creates barriers to commercialization and market acceptance of these advanced materials.

Established Multi-Component Fiber Fabrication Methods

01 Polymer blending techniques for multi-component fibers

Various polymer blending techniques are employed in the synthesis of multi-component fibers to achieve specific properties. These techniques involve combining different polymers with complementary characteristics to create fibers with enhanced performance. The blending process can include melt blending, solution blending, or reactive blending methods, which determine the final fiber structure and properties. These methods allow for the creation of fibers with tailored mechanical strength, thermal stability, and chemical resistance.- Polymer blending techniques for multi-component fibers: Various polymer blending techniques are employed in the synthesis of multi-component fibers to achieve specific properties. These techniques involve combining different polymers with complementary characteristics to create fibers with enhanced performance. The blending process can include melt blending, solution blending, or reactive blending methods, which determine the final fiber structure and properties. These methods allow for the creation of fibers with tailored mechanical strength, thermal stability, and chemical resistance.

- Bicomponent fiber extrusion processes: Bicomponent fiber extrusion involves the simultaneous extrusion of two different polymers through specially designed spinnerets to form fibers with distinct cross-sectional configurations. Common configurations include core-sheath, side-by-side, islands-in-sea, and segmented pie structures. The process parameters, such as temperature, pressure, and draw ratio, significantly influence the final fiber properties. This technology enables the production of fibers with combined properties from different polymers, such as strength from one component and elasticity from another.

- Functional additives for enhanced fiber properties: Incorporating functional additives during multi-component fiber synthesis can significantly enhance fiber properties. These additives include flame retardants, antimicrobial agents, UV stabilizers, and conductive materials. The additives can be incorporated into specific components of the fiber structure to achieve targeted functionality while maintaining the overall fiber performance. This approach allows for the development of specialized fibers for applications in protective clothing, medical textiles, and technical textiles with specific performance requirements.

- Sustainable and biodegradable multi-component fibers: The synthesis of sustainable and biodegradable multi-component fibers involves using renewable polymers and environmentally friendly processing methods. Bio-based polymers such as polylactic acid (PLA), polyhydroxyalkanoates (PHA), and cellulose derivatives are combined with other biodegradable components to create fibers with reduced environmental impact. These fibers maintain necessary performance characteristics while offering improved end-of-life options, including biodegradability and compostability, making them suitable for applications in disposable textiles, agricultural products, and eco-friendly consumer goods.

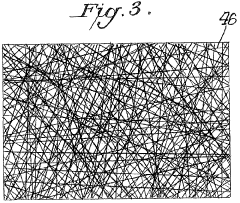

- Advanced spinning technologies for complex fiber structures: Advanced spinning technologies enable the production of complex multi-component fiber structures with precise control over fiber morphology and component distribution. These technologies include electrospinning, melt-electrospinning, centrifugal spinning, and microfluidic spinning. They allow for the creation of ultra-fine fibers, hollow fibers, porous fibers, and fibers with gradient properties. The resulting complex structures offer enhanced functionality for specialized applications in filtration, tissue engineering, energy storage, and smart textiles.

02 Bicomponent fiber extrusion processes

Bicomponent fiber extrusion involves the simultaneous extrusion of two different polymers through specially designed spinnerets to form a single fiber with distinct polymer regions. Common configurations include core-sheath, side-by-side, islands-in-the-sea, and segmented pie structures. The process parameters, such as temperature, pressure, and draw ratio, significantly influence the final fiber properties. This technology enables the production of fibers with combined properties from different polymers, such as strength from one component and elasticity from another.Expand Specific Solutions03 Functional additives for enhanced fiber properties

Incorporating functional additives during multi-component fiber synthesis can significantly enhance fiber properties. These additives include flame retardants, antimicrobial agents, UV stabilizers, antioxidants, and conductive materials. The additives can be incorporated into specific components of the fiber structure to impart targeted functionality while maintaining the base properties of the fiber. This approach allows for the development of specialized fibers for applications in protective clothing, medical textiles, and technical textiles with specific performance requirements.Expand Specific Solutions04 Sustainable and biodegradable multi-component fibers

The synthesis of sustainable and biodegradable multi-component fibers involves using bio-based polymers and environmentally friendly processing methods. These fibers can incorporate natural polymers like cellulose, chitosan, and polylactic acid (PLA), or biodegradable synthetic polymers. The processing techniques are designed to minimize environmental impact while maintaining fiber performance. These sustainable fibers address growing environmental concerns and can be used in applications ranging from disposable textiles to agricultural products with controlled degradation properties.Expand Specific Solutions05 Advanced spinning technologies for complex fiber structures

Advanced spinning technologies enable the creation of complex multi-component fiber structures with specialized properties. These technologies include electrospinning, melt-blowing, centrifugal spinning, and wet spinning methods adapted for multi-component systems. The precise control of processing parameters allows for the development of fibers with nanoscale features, hollow structures, or porous morphologies. These advanced techniques facilitate the production of high-performance fibers for specialized applications in filtration, energy storage, tissue engineering, and smart textiles.Expand Specific Solutions

Leading Research Groups and Industry Manufacturers

The electrospinning multi-component fiber synthesis market is currently in a growth phase, characterized by increasing research activities and emerging commercial applications. The global market size for electrospun fibers is expanding rapidly, driven by applications in healthcare, filtration, and energy storage. From a technological maturity perspective, academic institutions lead fundamental research, with MIT, Tufts University, and Johns Hopkins University pioneering novel fiber compositions and processing techniques. Commercial development is advancing through companies like PPG Industries, Corning, and Arsenal Medical, who are translating academic discoveries into scalable manufacturing processes. Notably, Arda Biomaterials and S2Medical are commercializing biomedical applications, while Poly-Med focuses on biodegradable polymer fibers. The technology shows promising transition from laboratory research to industrial implementation, though challenges in large-scale production and standardization remain.

Massachusetts Institute of Technology

Technical Solution: MIT has pioneered advanced multi-component fiber electrospinning techniques through their Research Laboratory of Electronics and Institute for Soldier Nanotechnologies. Their approach involves thermal drawing processes combined with electrospinning to create fibers with complex architectures and multiple functionalities. MIT researchers have developed a platform technology that enables the integration of multiple materials (polymers, metals, and semiconductors) into a single fiber structure with precise spatial arrangement. Their technology allows for the creation of fibers with electronic, optical, and mechanical functionalities that can be tailored for specific applications. MIT has demonstrated the ability to produce fibers with embedded sensors, actuators, and even microfluidic channels, enabling applications ranging from smart textiles to biomedical devices. Their recent innovations include the development of digital fibers that can sense, store, and process information, representing a significant advancement in multi-component fiber technology[1][3].

Strengths: Exceptional integration of diverse materials (metals, polymers, semiconductors) into single fiber structures; advanced capabilities for creating functional fibers with electronic and sensing properties; strong interdisciplinary approach combining materials science, electrical engineering, and bioengineering. Weaknesses: Complex manufacturing processes may limit scalability; higher production costs compared to conventional electrospinning; requires specialized equipment and expertise for implementation.

Beijing University of Chemical Technology

Technical Solution: Beijing University of Chemical Technology (BUCT) has established a comprehensive research program on multi-component fiber electrospinning through their State Key Laboratory of Chemical Resource Engineering and Advanced Materials Institute. Their approach focuses on developing novel polymer blends and composite systems specifically designed for electrospinning processes. BUCT researchers have pioneered techniques for creating multi-component fibers with hierarchical structures by combining electrospinning with other fabrication methods such as electrospraying and 3D printing. They've developed specialized nozzle designs that enable the production of Janus fibers and multi-layered structures with distinct compartments. Their technology allows for precise control over the spatial distribution of functional components within fiber structures, enabling applications in catalysis, environmental remediation, and energy storage. Recent innovations include stimuli-responsive multi-component fibers for controlled release applications and fibers with self-healing properties achieved through the strategic placement of reactive components within the fiber structure[3][6].

Strengths: Strong expertise in polymer chemistry and materials engineering applied to electrospinning; innovative approaches to creating hierarchical fiber structures; excellent capabilities in developing functional materials for environmental and energy applications. Weaknesses: Some research may face challenges in scaling to industrial production; potential intellectual property restrictions for international commercialization; limited focus on biomedical applications compared to other institutions.

Key Patents in Advanced Electrospinning Technology

Electrostatic-assisted fiber spinning method and production of highly aligned and packed hollow fiber assembly and membrane

PatentActiveUS20110264235A1

Innovation

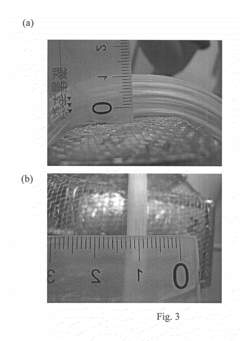

- The development of a method that uses coaxial electrospinning with a rotating drum collector to produce fibers with an orientation angle of no larger than ±5° and a packing density of at least 5 fibers per layer, maintaining a significant portion of the fiber weight during the electrospinning process to achieve highly aligned and closely packed hollow or solid fibers.

Coaxial polycarbonate/polyurethane composite nanofibers

PatentWO2008060675A2

Innovation

- Electrospinning of polycarbonate and polyurethane through coaxial capillaries to form submicron-sized fibers with a polycarbonate shell and polyurethane core, creating a nonwoven fabric that combines filtration efficiency with mechanical properties like elasticity.

Material Compatibility and Processing Parameters

Material compatibility represents a critical factor in multi-component fiber synthesis via electrospinning, directly influencing the structural integrity and functional properties of the resulting fibers. When combining multiple polymers, ceramics, or composite materials within a single fiber system, their chemical compatibility must be carefully evaluated to prevent phase separation or degradation during processing. Solvent selection plays a pivotal role in this context, as all components must dissolve adequately in a common solvent system while maintaining stable rheological properties throughout the electrospinning process.

Processing parameters significantly impact the morphology and performance of multi-component electrospun fibers. Applied voltage typically ranges from 10-30 kV, with higher voltages generally producing finer fibers but potentially causing instabilities in multi-component systems. The feed rate, typically between 0.5-5 mL/h, must be optimized to ensure consistent material delivery while preventing droplet formation or jet instability. The collector distance (10-20 cm) affects solvent evaporation time and fiber stretching, requiring careful calibration for multi-component systems with different evaporation rates.

Environmental conditions, including temperature (20-25°C) and relative humidity (30-50%), substantially influence the electrospinning process. Higher humidity levels may cause slower solvent evaporation in hydrophilic components while accelerating it in hydrophobic ones, potentially leading to structural inconsistencies in multi-component fibers. Temperature variations can alter solution viscosity differentially across components, necessitating precise environmental control.

Solution properties present another critical parameter set, with viscosity (typically 100-3000 cP) requiring particular attention in multi-component systems. The viscosity ratio between different polymer solutions must be carefully balanced to prevent preferential stretching of one component over others. Surface tension (20-50 mN/m) and conductivity variations between components can lead to segregation effects during jet formation, potentially resulting in non-uniform component distribution within the fiber structure.

Advanced processing techniques have emerged to address these compatibility challenges, including coaxial electrospinning for core-shell structures, emulsion electrospinning for encapsulation of incompatible materials, and sequential electrospinning for layered composite structures. These approaches enable the integration of otherwise incompatible materials by creating distinct spatial arrangements within the fiber architecture, expanding the range of possible material combinations while maintaining process stability.

Processing parameters significantly impact the morphology and performance of multi-component electrospun fibers. Applied voltage typically ranges from 10-30 kV, with higher voltages generally producing finer fibers but potentially causing instabilities in multi-component systems. The feed rate, typically between 0.5-5 mL/h, must be optimized to ensure consistent material delivery while preventing droplet formation or jet instability. The collector distance (10-20 cm) affects solvent evaporation time and fiber stretching, requiring careful calibration for multi-component systems with different evaporation rates.

Environmental conditions, including temperature (20-25°C) and relative humidity (30-50%), substantially influence the electrospinning process. Higher humidity levels may cause slower solvent evaporation in hydrophilic components while accelerating it in hydrophobic ones, potentially leading to structural inconsistencies in multi-component fibers. Temperature variations can alter solution viscosity differentially across components, necessitating precise environmental control.

Solution properties present another critical parameter set, with viscosity (typically 100-3000 cP) requiring particular attention in multi-component systems. The viscosity ratio between different polymer solutions must be carefully balanced to prevent preferential stretching of one component over others. Surface tension (20-50 mN/m) and conductivity variations between components can lead to segregation effects during jet formation, potentially resulting in non-uniform component distribution within the fiber structure.

Advanced processing techniques have emerged to address these compatibility challenges, including coaxial electrospinning for core-shell structures, emulsion electrospinning for encapsulation of incompatible materials, and sequential electrospinning for layered composite structures. These approaches enable the integration of otherwise incompatible materials by creating distinct spatial arrangements within the fiber architecture, expanding the range of possible material combinations while maintaining process stability.

Scalability and Commercialization Challenges

Despite the promising potential of multi-component fiber synthesis via electrospinning, significant challenges exist in scaling laboratory successes to commercial production. Current laboratory setups typically produce only milligrams to grams of fibers per hour, whereas industrial applications require kilograms to tons. This throughput gap represents one of the most formidable barriers to commercialization.

The transition from single-spinneret laboratory systems to multi-spinneret arrays introduces complex engineering challenges. Maintaining uniform electric field distribution across multiple spinnerets requires sophisticated design considerations. When scaled up, even minor variations in field strength can lead to significant inconsistencies in fiber morphology and composition across production batches.

Process stability during continuous operation presents another critical challenge. Laboratory demonstrations typically run for minutes to hours, while commercial production requires uninterrupted operation for days or weeks. Ensuring consistent precursor delivery, stable Taylor cone formation, and uniform fiber collection over extended periods demands advanced control systems and robust equipment design.

Quality control becomes increasingly complex with multi-component fibers. The precise ratio of components, their distribution within the fiber structure, and the resulting mechanical and functional properties must be monitored continuously. Current analytical techniques often require destructive testing and are difficult to implement as in-line quality control measures for high-throughput production.

Economic viability represents a significant hurdle. The capital expenditure for specialized electrospinning equipment, coupled with relatively slow production rates compared to conventional fiber manufacturing methods, results in higher production costs. For many potential applications, these costs currently outweigh the performance benefits of multi-component electrospun fibers.

Regulatory considerations further complicate commercialization efforts, particularly for biomedical and food-related applications. The novel nature of multi-component electrospun materials often means that regulatory frameworks are not well-established, requiring extensive safety and efficacy testing before market approval.

Despite these challenges, several companies have made progress in commercializing electrospinning technology, primarily for single-component fibers. Adapting these advances to multi-component systems will require collaborative efforts between academic researchers, equipment manufacturers, and end-users to develop scalable, cost-effective production methods that maintain the unique properties that make these materials valuable.

The transition from single-spinneret laboratory systems to multi-spinneret arrays introduces complex engineering challenges. Maintaining uniform electric field distribution across multiple spinnerets requires sophisticated design considerations. When scaled up, even minor variations in field strength can lead to significant inconsistencies in fiber morphology and composition across production batches.

Process stability during continuous operation presents another critical challenge. Laboratory demonstrations typically run for minutes to hours, while commercial production requires uninterrupted operation for days or weeks. Ensuring consistent precursor delivery, stable Taylor cone formation, and uniform fiber collection over extended periods demands advanced control systems and robust equipment design.

Quality control becomes increasingly complex with multi-component fibers. The precise ratio of components, their distribution within the fiber structure, and the resulting mechanical and functional properties must be monitored continuously. Current analytical techniques often require destructive testing and are difficult to implement as in-line quality control measures for high-throughput production.

Economic viability represents a significant hurdle. The capital expenditure for specialized electrospinning equipment, coupled with relatively slow production rates compared to conventional fiber manufacturing methods, results in higher production costs. For many potential applications, these costs currently outweigh the performance benefits of multi-component electrospun fibers.

Regulatory considerations further complicate commercialization efforts, particularly for biomedical and food-related applications. The novel nature of multi-component electrospun materials often means that regulatory frameworks are not well-established, requiring extensive safety and efficacy testing before market approval.

Despite these challenges, several companies have made progress in commercializing electrospinning technology, primarily for single-component fibers. Adapting these advances to multi-component systems will require collaborative efforts between academic researchers, equipment manufacturers, and end-users to develop scalable, cost-effective production methods that maintain the unique properties that make these materials valuable.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!