Exploring Conductive Fiber Development through Electrospinning

SEP 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrospinning Conductive Fiber Background and Objectives

Conductive fibers represent a significant advancement in materials science, bridging the gap between traditional textiles and electronic functionality. The evolution of conductive fiber technology can be traced back to the early 2000s when researchers began exploring methods to incorporate electrical conductivity into flexible fiber structures. This technological progression has been driven by increasing demands for wearable electronics, smart textiles, and flexible sensors across various industries.

Electrospinning has emerged as a particularly promising fabrication technique for conductive fibers due to its versatility and ability to produce ultra-fine fibers with controlled morphology. The process, which utilizes electrostatic forces to draw charged threads of polymer solutions into fibers with diameters ranging from nanometers to micrometers, was first patented in 1934 but has seen significant refinement and application expansion in recent decades.

The current technological trajectory indicates a shift toward multi-functional conductive fibers that not only conduct electricity but also possess additional properties such as antimicrobial activity, UV protection, or self-healing capabilities. This evolution is supported by advancements in nanomaterials, particularly carbon-based materials like graphene and carbon nanotubes, which have demonstrated exceptional electrical conductivity when incorporated into fiber structures.

The primary technical objectives in conductive fiber development through electrospinning include enhancing electrical conductivity while maintaining mechanical flexibility, improving durability under repeated mechanical stress, and developing scalable manufacturing processes suitable for industrial production. Additionally, researchers aim to reduce production costs and environmental impact by exploring sustainable materials and green processing methods.

Another critical objective is the standardization of testing protocols for conductive fibers, as current methods vary widely across research institutions, making direct comparisons between different studies challenging. Establishing uniform testing standards would accelerate technological progress by enabling more effective knowledge sharing and collaboration within the scientific community.

Recent breakthroughs in polymer science and nanotechnology have opened new avenues for conductive fiber development, particularly in creating hybrid structures that combine organic and inorganic materials to achieve optimal performance characteristics. These advances suggest that the field is moving toward increasingly sophisticated fiber architectures designed for specific applications rather than general-purpose conductive materials.

The ultimate goal of this technological pursuit is to develop conductive fibers that seamlessly integrate into everyday textiles, enabling a new generation of smart fabrics that can monitor health parameters, communicate with digital devices, or adapt to environmental conditions while maintaining the comfort and aesthetic qualities expected from traditional textiles.

Electrospinning has emerged as a particularly promising fabrication technique for conductive fibers due to its versatility and ability to produce ultra-fine fibers with controlled morphology. The process, which utilizes electrostatic forces to draw charged threads of polymer solutions into fibers with diameters ranging from nanometers to micrometers, was first patented in 1934 but has seen significant refinement and application expansion in recent decades.

The current technological trajectory indicates a shift toward multi-functional conductive fibers that not only conduct electricity but also possess additional properties such as antimicrobial activity, UV protection, or self-healing capabilities. This evolution is supported by advancements in nanomaterials, particularly carbon-based materials like graphene and carbon nanotubes, which have demonstrated exceptional electrical conductivity when incorporated into fiber structures.

The primary technical objectives in conductive fiber development through electrospinning include enhancing electrical conductivity while maintaining mechanical flexibility, improving durability under repeated mechanical stress, and developing scalable manufacturing processes suitable for industrial production. Additionally, researchers aim to reduce production costs and environmental impact by exploring sustainable materials and green processing methods.

Another critical objective is the standardization of testing protocols for conductive fibers, as current methods vary widely across research institutions, making direct comparisons between different studies challenging. Establishing uniform testing standards would accelerate technological progress by enabling more effective knowledge sharing and collaboration within the scientific community.

Recent breakthroughs in polymer science and nanotechnology have opened new avenues for conductive fiber development, particularly in creating hybrid structures that combine organic and inorganic materials to achieve optimal performance characteristics. These advances suggest that the field is moving toward increasingly sophisticated fiber architectures designed for specific applications rather than general-purpose conductive materials.

The ultimate goal of this technological pursuit is to develop conductive fibers that seamlessly integrate into everyday textiles, enabling a new generation of smart fabrics that can monitor health parameters, communicate with digital devices, or adapt to environmental conditions while maintaining the comfort and aesthetic qualities expected from traditional textiles.

Market Analysis for Conductive Fiber Applications

The global market for conductive fibers is experiencing robust growth, driven by increasing demand across multiple industries. Current market valuations place the conductive fiber sector at approximately $2.5 billion as of 2023, with projections indicating a compound annual growth rate (CAGR) of 11.2% through 2028. This growth trajectory is significantly outpacing traditional textile markets, which typically see 3-4% annual growth rates.

Electrospun conductive fibers represent a particularly promising segment within this market, with specialized applications commanding premium pricing. These advanced fibers typically sell for $150-300 per kilogram, compared to $20-50 for conventional conductive yarns, reflecting their enhanced performance characteristics and specialized manufacturing requirements.

The wearable electronics sector constitutes the largest application market for electrospun conductive fibers, accounting for approximately 35% of current demand. Smart textiles for health monitoring, athletic performance tracking, and consumer electronics integration are driving significant market pull. Major sportswear brands including Nike, Adidas, and Under Armour have all launched product lines incorporating conductive fiber technology, signaling mainstream market acceptance.

Healthcare applications represent the fastest-growing segment, with 16.8% annual growth projected through 2028. Medical devices utilizing electrospun conductive fibers for patient monitoring, drug delivery systems, and tissue engineering applications are gaining regulatory approvals across North America, Europe, and Asia. The aging global population and increasing focus on remote patient monitoring are accelerating adoption in this sector.

Defense and aerospace applications, while smaller in volume, generate substantial revenue due to high performance requirements and specialized certifications. Military applications for communication systems, protective gear, and environmental monitoring represent approximately 18% of the current market value, with government contracts providing stable demand channels.

Regionally, North America leads market consumption at 38%, followed by Europe (29%) and Asia-Pacific (26%). However, the most rapid growth is occurring in emerging Asian markets, particularly China and India, where manufacturing capacity for both raw materials and finished products is expanding rapidly. These regions are projected to account for over 40% of global demand by 2028.

Supply chain considerations remain significant, with raw material availability and processing capabilities representing potential constraints to market growth. The specialized polymers, conductive nanomaterials, and precision manufacturing equipment required for electrospinning create barriers to entry but also provide competitive advantages for established producers with technical expertise and intellectual property portfolios.

Electrospun conductive fibers represent a particularly promising segment within this market, with specialized applications commanding premium pricing. These advanced fibers typically sell for $150-300 per kilogram, compared to $20-50 for conventional conductive yarns, reflecting their enhanced performance characteristics and specialized manufacturing requirements.

The wearable electronics sector constitutes the largest application market for electrospun conductive fibers, accounting for approximately 35% of current demand. Smart textiles for health monitoring, athletic performance tracking, and consumer electronics integration are driving significant market pull. Major sportswear brands including Nike, Adidas, and Under Armour have all launched product lines incorporating conductive fiber technology, signaling mainstream market acceptance.

Healthcare applications represent the fastest-growing segment, with 16.8% annual growth projected through 2028. Medical devices utilizing electrospun conductive fibers for patient monitoring, drug delivery systems, and tissue engineering applications are gaining regulatory approvals across North America, Europe, and Asia. The aging global population and increasing focus on remote patient monitoring are accelerating adoption in this sector.

Defense and aerospace applications, while smaller in volume, generate substantial revenue due to high performance requirements and specialized certifications. Military applications for communication systems, protective gear, and environmental monitoring represent approximately 18% of the current market value, with government contracts providing stable demand channels.

Regionally, North America leads market consumption at 38%, followed by Europe (29%) and Asia-Pacific (26%). However, the most rapid growth is occurring in emerging Asian markets, particularly China and India, where manufacturing capacity for both raw materials and finished products is expanding rapidly. These regions are projected to account for over 40% of global demand by 2028.

Supply chain considerations remain significant, with raw material availability and processing capabilities representing potential constraints to market growth. The specialized polymers, conductive nanomaterials, and precision manufacturing equipment required for electrospinning create barriers to entry but also provide competitive advantages for established producers with technical expertise and intellectual property portfolios.

Current Challenges in Electrospun Conductive Fiber Technology

Despite significant advancements in electrospun conductive fiber technology, several critical challenges continue to impede its widespread industrial application and commercialization. The primary technical obstacle remains the trade-off between electrical conductivity and mechanical properties. When conductive materials such as carbon nanotubes, graphene, or metallic nanoparticles are incorporated into polymer solutions for electrospinning, they often aggregate, creating structural defects that compromise the fiber's mechanical integrity while simultaneously reducing conductivity due to poor dispersion.

The scalability of production presents another significant hurdle. Laboratory-scale electrospinning setups demonstrate promising results, but transitioning to industrial-scale manufacturing introduces complications in maintaining consistent fiber quality, diameter uniformity, and conductivity profiles across large production volumes. Current industrial electrospinning equipment struggles to achieve the precision required for high-performance conductive fibers at economically viable production rates.

Durability under real-world conditions represents a persistent challenge. Electrospun conductive fibers frequently exhibit degradation in electrical performance when subjected to repeated mechanical stress, washing cycles, or environmental factors such as humidity and temperature fluctuations. This limitation severely restricts their application in wearable electronics and smart textiles, where long-term reliability is essential.

The interface between the conductive components and the polymer matrix often suffers from poor adhesion, leading to phase separation during the electrospinning process or subsequent use. This incompatibility results in conductivity loss over time as the conductive network within the fiber deteriorates. Current surface modification techniques and compatibilizers provide only partial solutions to this fundamental materials science challenge.

Cost factors significantly impact commercial viability. High-quality conductive nanomaterials such as single-walled carbon nanotubes or silver nanowires remain expensive, while the electrospinning process itself has relatively low throughput compared to conventional fiber production methods. This combination creates unfavorable economics for mass-market applications, limiting adoption to high-value, specialized applications.

Standardization issues further complicate development efforts. The field lacks universally accepted testing protocols for electrical, mechanical, and durability properties of electrospun conductive fibers. This absence of standardization makes it difficult to compare results across research groups and establish reliable benchmarks for industrial quality control, slowing technological progress and commercial adoption.

Environmental and health concerns also present challenges, particularly regarding the potential release of nanomaterials during production, use, or disposal. Regulatory frameworks for such materials remain underdeveloped in many regions, creating uncertainty for commercial development and potential market barriers.

The scalability of production presents another significant hurdle. Laboratory-scale electrospinning setups demonstrate promising results, but transitioning to industrial-scale manufacturing introduces complications in maintaining consistent fiber quality, diameter uniformity, and conductivity profiles across large production volumes. Current industrial electrospinning equipment struggles to achieve the precision required for high-performance conductive fibers at economically viable production rates.

Durability under real-world conditions represents a persistent challenge. Electrospun conductive fibers frequently exhibit degradation in electrical performance when subjected to repeated mechanical stress, washing cycles, or environmental factors such as humidity and temperature fluctuations. This limitation severely restricts their application in wearable electronics and smart textiles, where long-term reliability is essential.

The interface between the conductive components and the polymer matrix often suffers from poor adhesion, leading to phase separation during the electrospinning process or subsequent use. This incompatibility results in conductivity loss over time as the conductive network within the fiber deteriorates. Current surface modification techniques and compatibilizers provide only partial solutions to this fundamental materials science challenge.

Cost factors significantly impact commercial viability. High-quality conductive nanomaterials such as single-walled carbon nanotubes or silver nanowires remain expensive, while the electrospinning process itself has relatively low throughput compared to conventional fiber production methods. This combination creates unfavorable economics for mass-market applications, limiting adoption to high-value, specialized applications.

Standardization issues further complicate development efforts. The field lacks universally accepted testing protocols for electrical, mechanical, and durability properties of electrospun conductive fibers. This absence of standardization makes it difficult to compare results across research groups and establish reliable benchmarks for industrial quality control, slowing technological progress and commercial adoption.

Environmental and health concerns also present challenges, particularly regarding the potential release of nanomaterials during production, use, or disposal. Regulatory frameworks for such materials remain underdeveloped in many regions, creating uncertainty for commercial development and potential market barriers.

Current Electrospinning Techniques for Conductive Fiber Production

01 Metal-coated fibers for enhanced conductivity

Fibers coated with conductive metals such as silver, copper, or nickel can significantly enhance electrical conductivity. These coatings can be applied through various methods including electroless plating, vapor deposition, or sputtering. The thickness and uniformity of the metal coating directly affects the conductivity level, with thicker coatings generally providing better conductivity. These metal-coated fibers maintain flexibility while offering excellent electrical performance for applications in smart textiles and wearable electronics.- Metal-coated fibers for enhanced conductivity: Fibers coated with conductive metals such as silver, copper, or nickel can significantly enhance electrical conductivity. These coatings can be applied through various methods including electroless plating, vapor deposition, or sputtering. The thickness and uniformity of the metal coating directly affects the conductivity level, with thicker coatings generally providing better conductivity. These metal-coated fibers maintain flexibility while offering excellent electrical performance for applications in smart textiles and wearable electronics.

- Carbon-based conductive fibers: Carbon-based materials including carbon nanotubes (CNTs), graphene, and carbon black can be incorporated into fibers to create highly conductive textiles. These materials can be either blended with polymer solutions before fiber formation or applied as coatings on existing fibers. Carbon-based conductive fibers offer advantages such as lightweight properties, chemical stability, and tunable conductivity levels. The concentration and dispersion quality of carbon materials within the fiber matrix significantly impact the overall conductivity performance.

- Conductive polymer composites for flexible fibers: Conductive polymers such as polyaniline, polypyrrole, and PEDOT:PSS can be used to create electrically conductive fibers with excellent flexibility. These polymers can be either directly spun into fibers or used to coat conventional textile fibers. The conductivity of these polymer-based fibers can be enhanced by adding dopants or by controlling the polymer chain alignment during processing. These fibers maintain their conductivity even under mechanical deformation, making them suitable for wearable electronics and strain sensors.

- Hybrid conductive fiber structures: Hybrid structures combining multiple conductive materials can achieve enhanced electrical properties while maintaining desirable mechanical characteristics. These structures may include core-sheath configurations where a conventional fiber core is surrounded by a conductive outer layer, or blended systems incorporating multiple conductive elements. Synergistic effects between different conductive materials can lead to improved overall performance. These hybrid approaches allow for customization of conductivity levels while addressing challenges related to durability and processability.

- Processing techniques to enhance fiber conductivity: Various processing techniques can significantly improve the conductivity of fibers. These include specialized spinning methods like wet spinning or electrospinning, post-treatment processes such as annealing or stretching, and surface modification techniques. The orientation of conductive particles or polymer chains within the fiber structure can be controlled through these processes to create more efficient electron pathways. Additionally, treatments to remove insulating components or to create interconnected conductive networks within the fiber structure can substantially enhance overall conductivity performance.

02 Carbon-based conductive fibers

Carbon-based materials including carbon nanotubes (CNTs), graphene, and carbon black can be incorporated into fibers to create highly conductive textiles. These materials can be either blended with polymer solutions before fiber formation or applied as coatings on existing fibers. Carbon-based conductive fibers offer advantages such as lightweight properties, good flexibility, and chemical stability. The conductivity can be controlled by adjusting the carbon content and dispersion quality within the fiber structure.Expand Specific Solutions03 Conductive polymer composites for flexible fibers

Conductive polymers such as polyaniline, polypyrrole, and PEDOT:PSS can be used to create electrically conductive fibers with excellent flexibility. These polymers can be either directly spun into fibers or used to coat conventional textile fibers. The conductivity of these polymer-based fibers can be enhanced by incorporating metallic nanoparticles or carbon materials. These composite fibers maintain textile-like properties while providing tunable electrical conductivity suitable for wearable electronics and smart textile applications.Expand Specific Solutions04 Processing techniques to improve fiber conductivity

Various processing techniques can significantly enhance the conductivity of fibers. These include specialized spinning methods like wet spinning and electrospinning, post-treatment processes such as annealing and stretching, and surface modification techniques. The alignment of conductive components within the fiber structure during processing can dramatically improve electron pathways. Additionally, controlling environmental factors during manufacturing such as temperature, humidity, and solvent systems can optimize the conductivity of the resulting fibers.Expand Specific Solutions05 Hybrid conductive fiber structures

Hybrid structures combining different conductive materials can achieve enhanced electrical properties while maintaining mechanical performance. These structures include core-sheath configurations where a conductive core is surrounded by a protective sheath, twisted or braided conductive yarns, and multilayer composite fibers. By strategically combining metals, carbon materials, and conductive polymers in these hybrid structures, the conductivity can be optimized while addressing challenges related to durability, washability, and comfort for practical applications in smart textiles and wearable technology.Expand Specific Solutions

Leading Companies and Research Institutions in Conductive Fiber Development

The electrospinning conductive fiber development market is currently in a growth phase, with increasing applications across wearable electronics, smart textiles, and biomedical devices. The global market is projected to expand significantly, driven by demand for flexible electronics and healthcare innovations. Leading academic institutions like MIT, Donghua University, and Tufts University are advancing fundamental research, while companies such as SINOPEC Beijing Research Institute and Arsenal Medical are focusing on commercial applications. The technology maturity varies across sectors, with established players like Parker-Hannifin and Kimberly Clark investing in industrial-scale production, while research institutions like Taiwan Textile Research Institute and University of Akron are developing next-generation conductive fiber technologies with enhanced conductivity, durability, and manufacturing scalability.

Massachusetts Institute of Technology

Technical Solution: MIT has pioneered advanced electrospinning techniques for conductive fiber development, focusing on scalable manufacturing processes. Their approach combines traditional electrospinning with novel material formulations, including carbon nanotube (CNT) and graphene-based polymer composites. MIT researchers have developed a coaxial electrospinning method that creates fibers with conductive cores and protective polymer sheaths, achieving conductivity values up to 2000 S/cm while maintaining mechanical flexibility. Their process innovation includes controlled alignment of nanomaterials within the fiber structure through electric field manipulation during spinning, resulting in enhanced directional conductivity. MIT has also developed post-processing techniques including thermal annealing and chemical reduction methods that significantly improve the conductivity of electrospun fibers without compromising their structural integrity. Recent work has focused on creating self-healing conductive fibers by incorporating dynamic chemical bonds within the polymer matrix.

Strengths: Superior conductivity-to-weight ratio compared to conventional metal wires; excellent integration with flexible electronics; highly customizable electrical properties through precise material formulation. Weaknesses: Higher production costs compared to conventional textile manufacturing; challenges in achieving uniform conductivity across large-scale production; potential durability issues in harsh environmental conditions.

Donghua University

Technical Solution: Donghua University has developed a multi-component electrospinning system specifically designed for conductive fiber production at industrial scales. Their technology utilizes a combination of intrinsically conductive polymers (ICPs) like polyaniline (PANI) and polypyrrole (PPy) with traditional textile polymers to create composite fibers with tunable electrical properties. A key innovation is their in-situ polymerization technique that allows conductive polymers to form directly within the fiber structure during the electrospinning process, achieving conductivity values of 150-300 S/cm. Their research has demonstrated successful integration of metal nanoparticles (silver, copper) into polymer solutions before electrospinning, creating hybrid fibers with enhanced conductivity and antimicrobial properties. Donghua has also pioneered environmentally friendly approaches using water-based polymer systems rather than toxic organic solvents, making the production process more sustainable while maintaining performance characteristics. Recent developments include temperature-responsive conductive fibers that can modulate their electrical properties based on environmental conditions.

Strengths: Cost-effective scalable production methods suitable for commercial applications; excellent integration with existing textile manufacturing infrastructure; environmentally sustainable production processes. Weaknesses: Lower maximum conductivity compared to carbon nanotube-based alternatives; potential conductivity degradation after repeated mechanical stress; challenges in achieving consistent fiber diameter in mass production.

Key Patents and Research Breakthroughs in Conductive Fiber Materials

Electrospinning polymer fibers and fiber arrays using DC biased ac potential

PatentWO2008106381A3

Innovation

- Development of DC biased AC electrospinning technique to produce aligned fiber arrays with controlled fiber diameters, overcoming the inherent instability of traditional DC electrospinning.

- Creation of a versatile electrospinning method capable of processing polymer solutions containing multiple polymers and secondary materials to impart various functional properties (chemical, physical, optical, magnetic).

- Enhanced control over fiber morphology through the combined effects of AC and DC potentials, enabling more precise fabrication of functional nanofiber arrays.

Emulsion-based control of electrospun fiber morphology

PatentWO2005098099A1

Innovation

- Using a multiphasic composition such as a water/oil emulsion or double emulsion as a fiber-forming medium, where the first component has a lower evaporation rate and the second component has a higher evaporation rate, allowing for the control of fiber morphology by varying the ratio of components and applying a force to extrude the emulsion into fibers with specific morphologies, such as flattened and porous forms.

Sustainability Aspects of Conductive Fiber Manufacturing

The sustainability of conductive fiber manufacturing through electrospinning represents a critical dimension in the advancement of this technology. Traditional manufacturing processes for conductive materials often involve significant environmental impacts, including high energy consumption, toxic chemical usage, and substantial waste generation. Electrospinning, while offering precision and versatility, must be evaluated through a comprehensive sustainability lens to ensure its viability as a long-term manufacturing solution.

Energy efficiency presents both challenges and opportunities in electrospinning processes. The high voltage requirements (typically 10-30 kV) contribute to considerable energy consumption during production. However, recent innovations have demonstrated potential for optimization through ambient temperature processing and reduced operational durations compared to conventional fiber production methods, potentially lowering the overall carbon footprint.

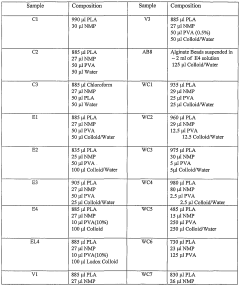

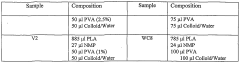

Material selection significantly influences the sustainability profile of conductive fiber manufacturing. The incorporation of biodegradable polymers such as polylactic acid (PLA) and cellulose derivatives as carrier materials represents a promising direction. These materials can be combined with conductive elements like carbon nanotubes or metallic nanoparticles to create fibers with reduced end-of-life environmental impact. Additionally, research into bio-based conductive additives derived from renewable resources is gaining momentum.

Solvent usage remains a substantial environmental concern in electrospinning. Many processes rely on toxic organic solvents like dimethylformamide (DMF) and chloroform, which pose health and environmental hazards. Green chemistry approaches are emerging, including water-based systems and ionic liquids as environmentally benign alternatives. These developments align with circular economy principles and increasingly stringent regulatory frameworks worldwide.

Waste minimization strategies are being implemented through precise control of electrospinning parameters, reducing material loss during production. Closed-loop systems that capture and recycle solvents demonstrate potential for significantly reducing environmental impact. Furthermore, the inherent precision of electrospinning allows for material-efficient production of high-performance fibers with minimal waste generation.

Life cycle assessment (LCA) studies indicate that while electrospinning may have higher initial energy inputs compared to some conventional methods, the enhanced performance and longevity of resulting conductive fibers can offset these impacts through extended product lifecycles. This highlights the importance of considering sustainability across the entire value chain rather than focusing solely on manufacturing processes.

Industry-academia collaborations are accelerating the development of sustainable electrospinning approaches, with several research institutions focusing on green electrospinning techniques that maintain or enhance the functional properties of conductive fibers while reducing environmental impact. These collaborative efforts represent a promising pathway toward environmentally responsible manufacturing of next-generation conductive materials.

Energy efficiency presents both challenges and opportunities in electrospinning processes. The high voltage requirements (typically 10-30 kV) contribute to considerable energy consumption during production. However, recent innovations have demonstrated potential for optimization through ambient temperature processing and reduced operational durations compared to conventional fiber production methods, potentially lowering the overall carbon footprint.

Material selection significantly influences the sustainability profile of conductive fiber manufacturing. The incorporation of biodegradable polymers such as polylactic acid (PLA) and cellulose derivatives as carrier materials represents a promising direction. These materials can be combined with conductive elements like carbon nanotubes or metallic nanoparticles to create fibers with reduced end-of-life environmental impact. Additionally, research into bio-based conductive additives derived from renewable resources is gaining momentum.

Solvent usage remains a substantial environmental concern in electrospinning. Many processes rely on toxic organic solvents like dimethylformamide (DMF) and chloroform, which pose health and environmental hazards. Green chemistry approaches are emerging, including water-based systems and ionic liquids as environmentally benign alternatives. These developments align with circular economy principles and increasingly stringent regulatory frameworks worldwide.

Waste minimization strategies are being implemented through precise control of electrospinning parameters, reducing material loss during production. Closed-loop systems that capture and recycle solvents demonstrate potential for significantly reducing environmental impact. Furthermore, the inherent precision of electrospinning allows for material-efficient production of high-performance fibers with minimal waste generation.

Life cycle assessment (LCA) studies indicate that while electrospinning may have higher initial energy inputs compared to some conventional methods, the enhanced performance and longevity of resulting conductive fibers can offset these impacts through extended product lifecycles. This highlights the importance of considering sustainability across the entire value chain rather than focusing solely on manufacturing processes.

Industry-academia collaborations are accelerating the development of sustainable electrospinning approaches, with several research institutions focusing on green electrospinning techniques that maintain or enhance the functional properties of conductive fibers while reducing environmental impact. These collaborative efforts represent a promising pathway toward environmentally responsible manufacturing of next-generation conductive materials.

Standardization and Quality Control in Conductive Fiber Production

The standardization and quality control of conductive fiber production through electrospinning represents a critical challenge in advancing this technology from laboratory settings to industrial applications. Current quality control methods vary significantly across research institutions and manufacturing facilities, creating inconsistencies in fiber properties and performance characteristics.

Establishing standardized testing protocols is essential for ensuring reproducible electrical conductivity measurements. These protocols must account for environmental factors such as humidity and temperature, which can significantly impact the electrical properties of electrospun conductive fibers. Leading organizations including ASTM International and ISO have begun developing specific standards for conductive textile materials, though comprehensive frameworks specifically for electrospun conductive fibers remain underdeveloped.

In-line monitoring systems represent a promising approach to quality control during production. Advanced techniques including real-time impedance spectroscopy and optical monitoring can detect variations in fiber diameter, alignment, and conductive particle distribution during the electrospinning process. These systems enable immediate process adjustments to maintain consistent quality parameters.

Statistical process control (SPC) methodologies are increasingly being adapted for conductive fiber production. Implementation of Six Sigma principles has demonstrated significant improvements in reducing variability in key performance indicators such as conductivity consistency and mechanical strength. Companies that have adopted these approaches report up to 40% reduction in batch-to-batch variation.

Material certification standards present another critical aspect of quality control. Establishing clear specifications for conductive additives such as carbon nanotubes, silver nanoparticles, and conductive polymers ensures consistent starting materials. Leading manufacturers have developed proprietary testing regimes to verify the purity, dispersion characteristics, and electrical properties of these materials before incorporation into the electrospinning process.

Automated defect detection systems utilizing machine learning algorithms have shown promise in identifying structural abnormalities in conductive fibers. These systems can detect issues such as beading, inconsistent diameter, and conductive particle agglomeration with greater sensitivity than traditional visual inspection methods. Implementation of these technologies has been shown to reduce defect rates by up to 30% in pilot production environments.

The development of reference materials and calibration standards specifically for conductive fibers represents an emerging focus area. These standards would provide benchmarks against which manufacturers could validate their measurement systems and product specifications, further enhancing consistency across the industry.

Establishing standardized testing protocols is essential for ensuring reproducible electrical conductivity measurements. These protocols must account for environmental factors such as humidity and temperature, which can significantly impact the electrical properties of electrospun conductive fibers. Leading organizations including ASTM International and ISO have begun developing specific standards for conductive textile materials, though comprehensive frameworks specifically for electrospun conductive fibers remain underdeveloped.

In-line monitoring systems represent a promising approach to quality control during production. Advanced techniques including real-time impedance spectroscopy and optical monitoring can detect variations in fiber diameter, alignment, and conductive particle distribution during the electrospinning process. These systems enable immediate process adjustments to maintain consistent quality parameters.

Statistical process control (SPC) methodologies are increasingly being adapted for conductive fiber production. Implementation of Six Sigma principles has demonstrated significant improvements in reducing variability in key performance indicators such as conductivity consistency and mechanical strength. Companies that have adopted these approaches report up to 40% reduction in batch-to-batch variation.

Material certification standards present another critical aspect of quality control. Establishing clear specifications for conductive additives such as carbon nanotubes, silver nanoparticles, and conductive polymers ensures consistent starting materials. Leading manufacturers have developed proprietary testing regimes to verify the purity, dispersion characteristics, and electrical properties of these materials before incorporation into the electrospinning process.

Automated defect detection systems utilizing machine learning algorithms have shown promise in identifying structural abnormalities in conductive fibers. These systems can detect issues such as beading, inconsistent diameter, and conductive particle agglomeration with greater sensitivity than traditional visual inspection methods. Implementation of these technologies has been shown to reduce defect rates by up to 30% in pilot production environments.

The development of reference materials and calibration standards specifically for conductive fibers represents an emerging focus area. These standards would provide benchmarks against which manufacturers could validate their measurement systems and product specifications, further enhancing consistency across the industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!