Electrospinning: Engineering Nano-Sized Fiber Networks

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrospinning Technology Evolution and Objectives

Electrospinning technology has evolved significantly since its inception in the early 20th century. The fundamental principle, first patented by J.F. Cooley and W.J. Morton in 1902, involves applying a high voltage to a polymer solution to create electrically charged jets that solidify into fibers. However, it wasn't until the 1990s that this technique gained substantial research attention, primarily due to advancements in nanotechnology and increased demand for nanoscale materials.

The evolution of electrospinning can be traced through several key developmental phases. Initially, the process was limited to simple single-needle setups with minimal control over fiber morphology. By the early 2000s, researchers had begun developing modified techniques such as coaxial electrospinning, allowing for the creation of core-shell nanofibers with enhanced functionality. The mid-2000s saw the emergence of multi-jet electrospinning systems, significantly improving production efficiency and addressing scalability concerns.

Recent technological advancements have focused on precision control of fiber properties, including diameter, orientation, and surface characteristics. Modern electrospinning systems incorporate sophisticated parameter control mechanisms, allowing researchers to manipulate electric field strength, solution viscosity, and environmental conditions with unprecedented accuracy. This has enabled the production of highly specialized nanofiber structures with tailored properties for specific applications.

The primary objectives of current electrospinning research and development are multifaceted. First, there is a strong focus on scalability and industrial viability, as traditional electrospinning methods often suffer from low production rates. Innovations such as needleless electrospinning and rotary jet spinning aim to overcome these limitations. Second, researchers are working to expand the range of spinnable materials beyond conventional polymers to include ceramics, metals, and composite materials.

Another critical objective is enhancing the functionality of electrospun nanofibers through surface modification, incorporation of active agents, and development of smart responsive materials. This includes creating nanofibers with controlled drug release capabilities, antimicrobial properties, and stimuli-responsive behaviors. Additionally, there is growing interest in developing sustainable electrospinning processes using green solvents and biodegradable polymers.

Looking forward, the field is trending toward integrated manufacturing approaches that combine electrospinning with complementary technologies such as 3D printing and microfluidics. The ultimate goal is to establish electrospinning as a versatile, scalable platform technology capable of producing highly engineered nanofibrous materials that can address complex challenges in healthcare, environmental remediation, energy storage, and advanced textiles.

The evolution of electrospinning can be traced through several key developmental phases. Initially, the process was limited to simple single-needle setups with minimal control over fiber morphology. By the early 2000s, researchers had begun developing modified techniques such as coaxial electrospinning, allowing for the creation of core-shell nanofibers with enhanced functionality. The mid-2000s saw the emergence of multi-jet electrospinning systems, significantly improving production efficiency and addressing scalability concerns.

Recent technological advancements have focused on precision control of fiber properties, including diameter, orientation, and surface characteristics. Modern electrospinning systems incorporate sophisticated parameter control mechanisms, allowing researchers to manipulate electric field strength, solution viscosity, and environmental conditions with unprecedented accuracy. This has enabled the production of highly specialized nanofiber structures with tailored properties for specific applications.

The primary objectives of current electrospinning research and development are multifaceted. First, there is a strong focus on scalability and industrial viability, as traditional electrospinning methods often suffer from low production rates. Innovations such as needleless electrospinning and rotary jet spinning aim to overcome these limitations. Second, researchers are working to expand the range of spinnable materials beyond conventional polymers to include ceramics, metals, and composite materials.

Another critical objective is enhancing the functionality of electrospun nanofibers through surface modification, incorporation of active agents, and development of smart responsive materials. This includes creating nanofibers with controlled drug release capabilities, antimicrobial properties, and stimuli-responsive behaviors. Additionally, there is growing interest in developing sustainable electrospinning processes using green solvents and biodegradable polymers.

Looking forward, the field is trending toward integrated manufacturing approaches that combine electrospinning with complementary technologies such as 3D printing and microfluidics. The ultimate goal is to establish electrospinning as a versatile, scalable platform technology capable of producing highly engineered nanofibrous materials that can address complex challenges in healthcare, environmental remediation, energy storage, and advanced textiles.

Market Applications and Demand for Nanofiber Networks

The global market for nanofiber networks has experienced significant growth in recent years, driven by their unique properties and versatile applications across multiple industries. The current market value for nanofiber-based products is estimated to reach $2.5 billion by 2025, with a compound annual growth rate exceeding 20% according to recent market research reports. This remarkable growth trajectory reflects the increasing recognition of nanofibers' exceptional characteristics, including high surface-to-volume ratio, controllable porosity, and superior mechanical properties.

Healthcare and biomedical applications represent the largest market segment for electrospun nanofibers, accounting for approximately 40% of the total market share. Within this sector, tissue engineering scaffolds, drug delivery systems, and wound dressings are experiencing particularly strong demand. The ability of nanofiber networks to mimic extracellular matrices makes them ideal candidates for regenerative medicine applications, while their controlled release capabilities enhance pharmaceutical efficacy.

Filtration and separation technologies constitute another rapidly expanding application area, driven by growing environmental concerns and stringent regulations regarding air and water quality. Nanofiber-enhanced filtration systems demonstrate superior performance in capturing submicron particles and contaminants compared to conventional filtration media. Industries ranging from automotive to semiconductor manufacturing are increasingly adopting these advanced filtration solutions to meet higher efficiency standards.

The energy sector presents substantial growth opportunities for nanofiber networks, particularly in battery separators, fuel cells, and solar cell components. The enhanced electrochemical properties and structural integrity of nanofiber-based materials contribute to improved energy storage and conversion efficiencies. Market analysts project this segment to grow at over 25% annually through 2025, fueled by the global transition toward renewable energy sources.

Protective clothing and smart textiles represent emerging application areas with significant market potential. Nanofiber-enhanced fabrics offer superior protection against chemical and biological agents while maintaining breathability and comfort. The defense industry has shown particular interest in these materials, with several major procurement programs underway in developed economies.

Regional analysis indicates that North America and Europe currently dominate the nanofiber market, collectively accounting for approximately 60% of global demand. However, Asia-Pacific is emerging as the fastest-growing region, with China, Japan, and South Korea making substantial investments in nanofiber research and manufacturing infrastructure. This regional shift reflects broader trends in advanced materials manufacturing and increasing technological sophistication in emerging economies.

Consumer awareness and acceptance of nanofiber-based products remain challenges to broader market penetration, particularly in consumer goods sectors. Additionally, cost considerations continue to limit applications in price-sensitive markets, though economies of scale and manufacturing innovations are gradually addressing this barrier.

Healthcare and biomedical applications represent the largest market segment for electrospun nanofibers, accounting for approximately 40% of the total market share. Within this sector, tissue engineering scaffolds, drug delivery systems, and wound dressings are experiencing particularly strong demand. The ability of nanofiber networks to mimic extracellular matrices makes them ideal candidates for regenerative medicine applications, while their controlled release capabilities enhance pharmaceutical efficacy.

Filtration and separation technologies constitute another rapidly expanding application area, driven by growing environmental concerns and stringent regulations regarding air and water quality. Nanofiber-enhanced filtration systems demonstrate superior performance in capturing submicron particles and contaminants compared to conventional filtration media. Industries ranging from automotive to semiconductor manufacturing are increasingly adopting these advanced filtration solutions to meet higher efficiency standards.

The energy sector presents substantial growth opportunities for nanofiber networks, particularly in battery separators, fuel cells, and solar cell components. The enhanced electrochemical properties and structural integrity of nanofiber-based materials contribute to improved energy storage and conversion efficiencies. Market analysts project this segment to grow at over 25% annually through 2025, fueled by the global transition toward renewable energy sources.

Protective clothing and smart textiles represent emerging application areas with significant market potential. Nanofiber-enhanced fabrics offer superior protection against chemical and biological agents while maintaining breathability and comfort. The defense industry has shown particular interest in these materials, with several major procurement programs underway in developed economies.

Regional analysis indicates that North America and Europe currently dominate the nanofiber market, collectively accounting for approximately 60% of global demand. However, Asia-Pacific is emerging as the fastest-growing region, with China, Japan, and South Korea making substantial investments in nanofiber research and manufacturing infrastructure. This regional shift reflects broader trends in advanced materials manufacturing and increasing technological sophistication in emerging economies.

Consumer awareness and acceptance of nanofiber-based products remain challenges to broader market penetration, particularly in consumer goods sectors. Additionally, cost considerations continue to limit applications in price-sensitive markets, though economies of scale and manufacturing innovations are gradually addressing this barrier.

Current Electrospinning Techniques and Barriers

Electrospinning technology has evolved significantly over the past few decades, with several distinct techniques now established in both research and industrial applications. Conventional needle-based electrospinning remains the most widely used approach, where a polymer solution is ejected through a metallic needle under high voltage. This method offers precise control over fiber diameter but suffers from low production rates, typically 0.1-1 g/h, limiting industrial scalability.

To address throughput limitations, needleless electrospinning techniques have emerged, utilizing rotating drums, disks, or wire electrodes to generate multiple polymer jets simultaneously. These methods can increase production rates by 10-100 times compared to conventional approaches. Melt electrospinning, another variant, processes polymer melts rather than solutions, eliminating solvent-related environmental concerns but requiring higher operating temperatures and voltages.

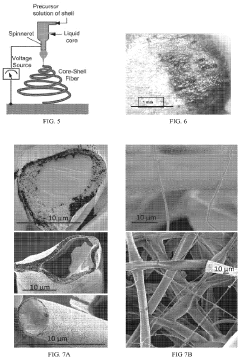

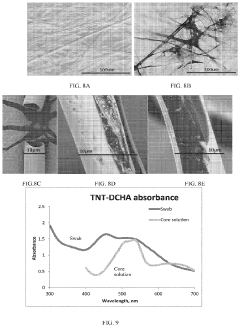

Coaxial electrospinning represents a significant advancement, enabling the production of core-shell structured nanofibers through concentric needle arrangements. This technique allows for encapsulation of bioactive compounds or creation of hollow fibers, expanding potential applications in drug delivery and tissue engineering. Similarly, emulsion electrospinning achieves comparable structures using emulsified solutions, though with less precise control.

Despite these innovations, electrospinning faces several persistent technical barriers. Process stability remains challenging, with environmental factors like temperature and humidity significantly affecting fiber formation. Minor fluctuations in these parameters can lead to inconsistent fiber morphology and mechanical properties. The limited range of spinnable polymers also restricts application scope, as many polymers lack suitable viscoelastic properties for stable jet formation.

Scalability presents another major hurdle, particularly for high-precision applications requiring uniform fiber characteristics. While needleless systems improve throughput, they often compromise on fiber diameter consistency and morphological control. The trade-off between production rate and quality control continues to challenge industrial implementation.

Energy consumption poses additional concerns, with conventional setups requiring high voltages (10-30 kV) and specialized safety infrastructure. This increases operational costs and complicates integration into existing manufacturing environments. For biomedical applications, sterilization compatibility presents further complications, as many electrospun materials cannot withstand conventional sterilization methods without structural degradation.

Regulatory compliance represents a significant non-technical barrier, particularly for medical and pharmaceutical applications. The complex nature of electrospun materials, often involving multiple components and novel structures, complicates regulatory approval pathways and extends time-to-market for innovative products.

To address throughput limitations, needleless electrospinning techniques have emerged, utilizing rotating drums, disks, or wire electrodes to generate multiple polymer jets simultaneously. These methods can increase production rates by 10-100 times compared to conventional approaches. Melt electrospinning, another variant, processes polymer melts rather than solutions, eliminating solvent-related environmental concerns but requiring higher operating temperatures and voltages.

Coaxial electrospinning represents a significant advancement, enabling the production of core-shell structured nanofibers through concentric needle arrangements. This technique allows for encapsulation of bioactive compounds or creation of hollow fibers, expanding potential applications in drug delivery and tissue engineering. Similarly, emulsion electrospinning achieves comparable structures using emulsified solutions, though with less precise control.

Despite these innovations, electrospinning faces several persistent technical barriers. Process stability remains challenging, with environmental factors like temperature and humidity significantly affecting fiber formation. Minor fluctuations in these parameters can lead to inconsistent fiber morphology and mechanical properties. The limited range of spinnable polymers also restricts application scope, as many polymers lack suitable viscoelastic properties for stable jet formation.

Scalability presents another major hurdle, particularly for high-precision applications requiring uniform fiber characteristics. While needleless systems improve throughput, they often compromise on fiber diameter consistency and morphological control. The trade-off between production rate and quality control continues to challenge industrial implementation.

Energy consumption poses additional concerns, with conventional setups requiring high voltages (10-30 kV) and specialized safety infrastructure. This increases operational costs and complicates integration into existing manufacturing environments. For biomedical applications, sterilization compatibility presents further complications, as many electrospun materials cannot withstand conventional sterilization methods without structural degradation.

Regulatory compliance represents a significant non-technical barrier, particularly for medical and pharmaceutical applications. The complex nature of electrospun materials, often involving multiple components and novel structures, complicates regulatory approval pathways and extends time-to-market for innovative products.

Contemporary Electrospinning Process Solutions

01 Electrospinning process parameters for nano-fiber production

Various process parameters can be optimized in electrospinning to control the morphology and properties of nano-sized fiber networks. These parameters include voltage, flow rate, distance between the needle and collector, and environmental conditions such as temperature and humidity. By adjusting these parameters, researchers can produce nano-fibers with desired diameters, orientations, and surface characteristics for specific applications.- Electrospinning process parameters for nano-fiber production: The electrospinning process involves controlling various parameters to produce nano-sized fiber networks with desired properties. These parameters include voltage, flow rate, distance between the needle and collector, and solution properties. By optimizing these parameters, it is possible to control the diameter, morphology, and alignment of the resulting nanofibers. The process typically involves applying a high voltage to a polymer solution, which creates an electrically charged jet that stretches and thins as it travels to a grounded collector.

- Polymer selection and solution preparation for electrospinning: The selection of appropriate polymers and preparation of spinning solutions are critical factors in electrospinning nano-sized fiber networks. Various natural and synthetic polymers can be used, including polyvinyl alcohol (PVA), polylactic acid (PLA), polyacrylonitrile (PAN), and biopolymers. The concentration, molecular weight, and solvent system significantly affect the spinnability and resulting fiber properties. Additives can be incorporated to modify fiber characteristics or introduce functionality. Proper solution preparation ensures consistent fiber formation and prevents issues like beading or irregular fiber diameters.

- Functional applications of electrospun nanofiber networks: Electrospun nano-sized fiber networks have diverse applications across multiple fields due to their high surface area-to-volume ratio and customizable properties. These applications include filtration membranes, tissue engineering scaffolds, drug delivery systems, protective clothing, sensors, and energy storage devices. The nanofiber networks can be functionalized with various compounds to enhance their performance for specific applications. Their porous structure and interconnected network make them particularly suitable for applications requiring controlled permeability, cell attachment, or molecular interactions.

- Advanced electrospinning techniques for controlled nanofiber architecture: Advanced electrospinning techniques have been developed to create more complex and controlled nanofiber architectures. These include coaxial electrospinning for core-shell fibers, near-field electrospinning for precise fiber deposition, multi-jet electrospinning for increased production, and rotating collector systems for aligned fibers. Other innovations include melt electrospinning, emulsion electrospinning, and gas-assisted electrospinning. These techniques allow for the fabrication of nanofiber networks with specific orientations, layered structures, or integrated functionalities that enhance their performance in various applications.

- Composite and hybrid nanofiber systems: Composite and hybrid nanofiber systems combine different materials to create electrospun networks with enhanced properties. These systems may incorporate nanoparticles, carbon nanotubes, graphene, or other nanomaterials within the fiber structure. Alternatively, they may combine different polymers or include inorganic components to create organic-inorganic hybrid fibers. Such composite approaches can significantly improve mechanical strength, electrical conductivity, thermal stability, or bioactivity of the nanofiber networks. The resulting materials often exhibit synergistic properties that exceed those of the individual components.

02 Polymer selection and solution preparation for electrospinning

The selection of polymers and preparation of polymer solutions significantly influence the electrospinning process and resulting nano-fiber networks. Various natural and synthetic polymers can be used, including polyvinyl alcohol (PVA), polycaprolactone (PCL), and polyacrylonitrile (PAN). The concentration, molecular weight, and solvent system affect solution viscosity, conductivity, and surface tension, which in turn determine fiber formation, diameter, and structural integrity of the nano-fiber networks.Expand Specific Solutions03 Functionalization and modification of electrospun nano-fibers

Electrospun nano-fibers can be functionalized or modified to enhance their properties for specific applications. Techniques include incorporating functional additives into the spinning solution, post-spinning surface treatments, and coating processes. These modifications can impart properties such as antimicrobial activity, improved biocompatibility, enhanced mechanical strength, or specific chemical reactivity to the nano-fiber networks, expanding their potential applications in various fields.Expand Specific Solutions04 Applications of electrospun nano-fiber networks in filtration and separation

Electrospun nano-fiber networks offer excellent potential for filtration and separation applications due to their high surface area-to-volume ratio, interconnected porous structure, and customizable fiber diameter. These networks can be designed to filter particulates, bacteria, viruses, and other contaminants from air or liquids. The high porosity combined with small pore size enables high flux rates while maintaining excellent filtration efficiency, making them suitable for applications ranging from air purification to water treatment and biomedical separations.Expand Specific Solutions05 Electrospun nano-fibers for tissue engineering and biomedical applications

Electrospun nano-fiber networks closely mimic the extracellular matrix structure, making them excellent scaffolds for tissue engineering and various biomedical applications. These scaffolds provide structural support for cell attachment, proliferation, and differentiation. The high porosity facilitates nutrient transport and waste removal, while the fiber architecture can be tailored to guide cell growth in specific directions. Additionally, these nano-fiber networks can be used for controlled drug delivery systems, wound dressings, and implantable medical devices.Expand Specific Solutions

Leading Electrospinning Equipment Manufacturers and Research Institutions

Electrospinning technology for nano-sized fiber networks is currently in a growth phase, with the market expanding rapidly due to increasing applications in filtration, healthcare, and textiles. The global market size is estimated to reach several billion dollars by 2025, driven by demand for high-performance materials. Technologically, the field shows varying maturity levels across applications, with filtration being more established while medical applications remain emerging. Leading academic institutions (MIT, Cornell, Northwestern University) are advancing fundamental research, while companies like Matregenix, Verdex Technology, and CorNeat Vision are commercializing applications. Research organizations such as RTI International and corporate players including Parker-Hannifin and Corning are investing in proprietary electrospinning technologies, indicating the field's competitive potential and industrial relevance.

Donghua University

Technical Solution: Donghua University has established itself as a leader in electrospinning technology with their innovative multi-functional nanofiber production systems. Their research team has developed a high-throughput needleless electrospinning technology that increases production rates by over 300% compared to conventional methods while maintaining fiber quality and uniformity. Their patented solution involves specialized electrode designs and electric field manipulation techniques that enable the formation of multiple jets from free liquid surfaces. Donghua has also pioneered the development of stimuli-responsive electrospun fibers that can change properties in response to environmental triggers such as pH, temperature, or light exposure. Their technology incorporates in-line monitoring systems using spectroscopic techniques to ensure real-time quality control during production. Additionally, they've developed specialized post-processing treatments to enhance the mechanical properties and functionality of electrospun materials for applications ranging from filtration to smart textiles[4][7].

Strengths: Industry-leading production throughput; advanced stimuli-responsive fiber capabilities; comprehensive quality control systems integrated into production. Weaknesses: Higher energy consumption compared to conventional methods; complex parameter optimization required for new material systems; specialized equipment needs for implementation.

Matregenix, Inc.

Technical Solution: Matregenix has commercialized proprietary electrospinning technology focused on biomaterial applications, particularly for wound healing and tissue regeneration. Their platform technology enables the production of nanofiber scaffolds with precisely controlled fiber diameter distribution (ranging from 50-500nm) and porosity profiles optimized for cellular infiltration. Matregenix's innovation includes a patented multi-layer electrospinning process that creates gradient structures mimicking the hierarchical organization of natural tissues. Their technology incorporates specialized polymer blending techniques that allow for the incorporation of multiple bioactive components with different release kinetics from a single fiber system. The company has developed a scalable manufacturing process that maintains consistent quality while increasing production capacity to commercial levels, addressing one of the key challenges in electrospinning commercialization. Additionally, their proprietary surface modification techniques enhance cell attachment and proliferation on electrospun scaffolds[6][8].

Strengths: Commercially validated technology with proven scalability; advanced multi-component fiber capabilities; specialized expertise in biomaterial applications. Weaknesses: Relatively narrow application focus compared to academic institutions; higher production costs than traditional materials; complex regulatory pathway for medical applications.

Critical Patents and Innovations in Nanofiber Engineering

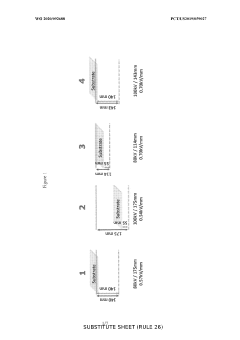

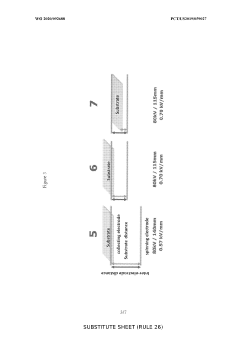

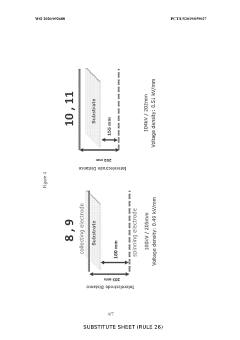

Efficient production of nanofiber structures

PatentWO2020092688A1

Innovation

- The development of electrospinning apparatuses with a substrate positioned between the spinning and collecting electrodes, allowing for adjustable ratios of substrate distance to interelectrode distance, enabling independent control and optimization of these parameters to enhance productivity.

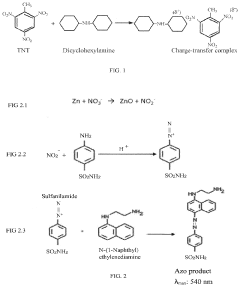

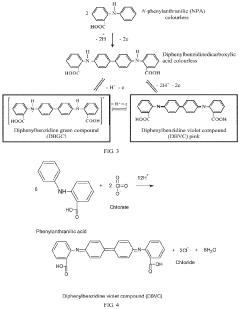

Composition and method for detection of molecules of interest

PatentActiveUS20210109077A1

Innovation

- Development of compositions comprising electrospun nanofibers with encapsulated colorimetric reactants that break upon stress, allowing for immediate and sensitive detection of explosive compounds through a colorimetric change, eliminating the need for additional detection devices.

Scalability and Mass Production Challenges

Despite the promising applications of electrospinning technology in various fields, scaling up from laboratory-scale production to industrial mass production remains one of the most significant challenges. Traditional single-needle electrospinning setups typically produce only 0.01-0.1 g/h of nanofibers, which is inadequate for commercial applications requiring kilograms or tons of material. This production bottleneck has severely limited the widespread industrial adoption of electrospun nanofibers.

Several approaches have emerged to address these scalability issues. Multi-needle systems increase throughput by operating multiple spinnerets simultaneously, but they introduce new complications such as needle clogging, uneven electric field distribution, and maintenance challenges. Needleless electrospinning technologies, including rotating drums, disks, and wire electrodes, offer higher productivity by generating multiple jets from free liquid surfaces, potentially increasing production rates to 10-50 g/h per unit.

Solution electrospinning represents another promising approach, where polymer solutions are directly electrospun without needles, significantly reducing clogging issues. However, this method faces challenges in maintaining consistent fiber quality across large production volumes. The precise control of environmental parameters—humidity, temperature, and air flow—becomes increasingly difficult at industrial scales, leading to potential variations in fiber morphology and properties.

Energy consumption presents another substantial hurdle for mass production. Industrial-scale electrospinning requires high voltages (typically 10-30 kV) maintained over extended periods, resulting in significant electricity costs. Additionally, the solvent recovery systems necessary for environmentally responsible production add further complexity and expense to the manufacturing process.

Quality control mechanisms must also evolve to accommodate mass production. Current laboratory inspection methods, often relying on microscopy and manual assessment, are impractical for continuous high-volume production. Automated in-line quality monitoring systems using optical sensors, laser diffraction, or AI-powered image analysis are being developed but remain in early stages of implementation.

The economic viability of scaled electrospinning operations depends heavily on reducing production costs while maintaining fiber quality. Current estimates suggest that production costs need to decrease by 30-50% to make electrospun materials competitive with conventional alternatives in many applications. This necessitates not only technological innovations in the electrospinning process itself but also advancements in supporting technologies such as polymer preparation, solvent recovery, and post-processing techniques.

Several approaches have emerged to address these scalability issues. Multi-needle systems increase throughput by operating multiple spinnerets simultaneously, but they introduce new complications such as needle clogging, uneven electric field distribution, and maintenance challenges. Needleless electrospinning technologies, including rotating drums, disks, and wire electrodes, offer higher productivity by generating multiple jets from free liquid surfaces, potentially increasing production rates to 10-50 g/h per unit.

Solution electrospinning represents another promising approach, where polymer solutions are directly electrospun without needles, significantly reducing clogging issues. However, this method faces challenges in maintaining consistent fiber quality across large production volumes. The precise control of environmental parameters—humidity, temperature, and air flow—becomes increasingly difficult at industrial scales, leading to potential variations in fiber morphology and properties.

Energy consumption presents another substantial hurdle for mass production. Industrial-scale electrospinning requires high voltages (typically 10-30 kV) maintained over extended periods, resulting in significant electricity costs. Additionally, the solvent recovery systems necessary for environmentally responsible production add further complexity and expense to the manufacturing process.

Quality control mechanisms must also evolve to accommodate mass production. Current laboratory inspection methods, often relying on microscopy and manual assessment, are impractical for continuous high-volume production. Automated in-line quality monitoring systems using optical sensors, laser diffraction, or AI-powered image analysis are being developed but remain in early stages of implementation.

The economic viability of scaled electrospinning operations depends heavily on reducing production costs while maintaining fiber quality. Current estimates suggest that production costs need to decrease by 30-50% to make electrospun materials competitive with conventional alternatives in many applications. This necessitates not only technological innovations in the electrospinning process itself but also advancements in supporting technologies such as polymer preparation, solvent recovery, and post-processing techniques.

Environmental Impact and Sustainability Considerations

Electrospinning technology, while offering significant advantages in various applications, presents several environmental challenges that must be addressed for sustainable implementation. The process typically involves organic solvents such as dimethylformamide (DMF), tetrahydrofuran (THF), and chloroform, which are known for their toxicity and environmental persistence. These solvents can contribute to air pollution through volatile organic compound (VOC) emissions during the electrospinning process, potentially affecting both worker health and surrounding ecosystems.

Water consumption represents another significant environmental concern, particularly in solution preparation and equipment cleaning phases. In industrial-scale operations, this can amount to substantial water usage, contributing to resource depletion in water-stressed regions. Additionally, the energy requirements for maintaining high voltage differentials and precise environmental controls in electrospinning facilities result in considerable carbon footprints, especially when powered by non-renewable energy sources.

Polymer waste management presents ongoing challenges, as electrospinning inevitably generates material waste through process optimization, equipment calibration, and rejected products. Many synthetic polymers used in electrospinning are petroleum-derived and non-biodegradable, potentially contributing to microplastic pollution if improperly disposed of or when products reach end-of-life stages.

Recent sustainability innovations are addressing these environmental concerns through several approaches. Green electrospinning techniques utilize water-based systems and bio-derived solvents like ethanol and acetic acid, significantly reducing toxic emissions. Researchers have successfully developed closed-loop solvent recovery systems that can recapture up to 95% of solvents for reuse, dramatically reducing both waste and raw material requirements.

The incorporation of biodegradable and bio-based polymers represents a promising direction, with materials such as polylactic acid (PLA), polyhydroxyalkanoates (PHA), and cellulose derivatives gaining traction. These materials offer comparable performance to synthetic alternatives while providing improved end-of-life characteristics. Life cycle assessment (LCA) studies indicate that electrospun products using these sustainable materials can reduce environmental impact by 30-60% compared to conventional approaches.

Energy efficiency improvements through optimized equipment design and process parameters have demonstrated potential energy savings of 25-40%. Some manufacturers have implemented renewable energy sources to power electrospinning operations, further reducing the carbon footprint. Additionally, precision manufacturing techniques have minimized material waste, with advanced systems achieving material utilization rates exceeding 90%, compared to 60-70% in conventional setups.

Water consumption represents another significant environmental concern, particularly in solution preparation and equipment cleaning phases. In industrial-scale operations, this can amount to substantial water usage, contributing to resource depletion in water-stressed regions. Additionally, the energy requirements for maintaining high voltage differentials and precise environmental controls in electrospinning facilities result in considerable carbon footprints, especially when powered by non-renewable energy sources.

Polymer waste management presents ongoing challenges, as electrospinning inevitably generates material waste through process optimization, equipment calibration, and rejected products. Many synthetic polymers used in electrospinning are petroleum-derived and non-biodegradable, potentially contributing to microplastic pollution if improperly disposed of or when products reach end-of-life stages.

Recent sustainability innovations are addressing these environmental concerns through several approaches. Green electrospinning techniques utilize water-based systems and bio-derived solvents like ethanol and acetic acid, significantly reducing toxic emissions. Researchers have successfully developed closed-loop solvent recovery systems that can recapture up to 95% of solvents for reuse, dramatically reducing both waste and raw material requirements.

The incorporation of biodegradable and bio-based polymers represents a promising direction, with materials such as polylactic acid (PLA), polyhydroxyalkanoates (PHA), and cellulose derivatives gaining traction. These materials offer comparable performance to synthetic alternatives while providing improved end-of-life characteristics. Life cycle assessment (LCA) studies indicate that electrospun products using these sustainable materials can reduce environmental impact by 30-60% compared to conventional approaches.

Energy efficiency improvements through optimized equipment design and process parameters have demonstrated potential energy savings of 25-40%. Some manufacturers have implemented renewable energy sources to power electrospinning operations, further reducing the carbon footprint. Additionally, precision manufacturing techniques have minimized material waste, with advanced systems achieving material utilization rates exceeding 90%, compared to 60-70% in conventional setups.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!