Electrospinning’s Impact on the Mechanical Properties of Nanofibers

SEP 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrospinning Technology Background and Objectives

Electrospinning technology emerged in the early 20th century, with the first patent filed by J.F. Cooley in 1902. However, it wasn't until the 1990s that this technique gained significant attention in the scientific community, primarily due to the growing interest in nanotechnology. The fundamental principle of electrospinning involves applying a high voltage to a polymer solution or melt, creating an electrically charged jet that stretches and thins as it travels toward a grounded collector, ultimately forming nanofibers with diameters ranging from tens of nanometers to several micrometers.

The evolution of electrospinning technology has been marked by continuous improvements in equipment design, process control, and material compatibility. Early systems were relatively simple, consisting of a syringe pump, high voltage power supply, and a flat collector. Modern setups incorporate sophisticated features such as climate-controlled chambers, multiple spinnerets, rotating collectors, and real-time monitoring systems that allow for precise manipulation of fiber properties.

Recent technological advancements have expanded electrospinning capabilities to include coaxial electrospinning for core-shell fibers, melt electrospinning for solvent-free processing, and near-field electrospinning for precise fiber deposition. These innovations have significantly broadened the range of materials that can be processed and the structural complexity that can be achieved in nanofiber assemblies.

The primary objective of electrospinning research in the context of mechanical properties is to establish clear correlations between processing parameters and the resulting mechanical behavior of nanofibers. Key processing variables include solution properties (concentration, viscosity, conductivity), operational parameters (voltage, flow rate, working distance), and environmental conditions (temperature, humidity). Understanding how these factors interact to influence fiber diameter, orientation, crystallinity, and molecular alignment is crucial for tailoring mechanical properties.

Current research aims to develop predictive models that can accurately forecast mechanical properties based on processing conditions, enabling the design of nanofibers with application-specific mechanical characteristics. This includes enhancing tensile strength for structural applications, optimizing elasticity for tissue engineering scaffolds, and improving toughness for protective materials.

The long-term technological goal is to transition from empirical approaches to knowledge-based design principles that allow for precise engineering of nanofiber mechanical properties. This transition requires bridging the gap between nanoscale phenomena and macroscale performance, developing in-situ characterization techniques, and establishing standardized testing protocols specifically adapted for nanofiber materials.

The evolution of electrospinning technology has been marked by continuous improvements in equipment design, process control, and material compatibility. Early systems were relatively simple, consisting of a syringe pump, high voltage power supply, and a flat collector. Modern setups incorporate sophisticated features such as climate-controlled chambers, multiple spinnerets, rotating collectors, and real-time monitoring systems that allow for precise manipulation of fiber properties.

Recent technological advancements have expanded electrospinning capabilities to include coaxial electrospinning for core-shell fibers, melt electrospinning for solvent-free processing, and near-field electrospinning for precise fiber deposition. These innovations have significantly broadened the range of materials that can be processed and the structural complexity that can be achieved in nanofiber assemblies.

The primary objective of electrospinning research in the context of mechanical properties is to establish clear correlations between processing parameters and the resulting mechanical behavior of nanofibers. Key processing variables include solution properties (concentration, viscosity, conductivity), operational parameters (voltage, flow rate, working distance), and environmental conditions (temperature, humidity). Understanding how these factors interact to influence fiber diameter, orientation, crystallinity, and molecular alignment is crucial for tailoring mechanical properties.

Current research aims to develop predictive models that can accurately forecast mechanical properties based on processing conditions, enabling the design of nanofibers with application-specific mechanical characteristics. This includes enhancing tensile strength for structural applications, optimizing elasticity for tissue engineering scaffolds, and improving toughness for protective materials.

The long-term technological goal is to transition from empirical approaches to knowledge-based design principles that allow for precise engineering of nanofiber mechanical properties. This transition requires bridging the gap between nanoscale phenomena and macroscale performance, developing in-situ characterization techniques, and establishing standardized testing protocols specifically adapted for nanofiber materials.

Market Applications and Demand for High-Performance Nanofibers

The global market for high-performance nanofibers has witnessed substantial growth in recent years, driven by their exceptional mechanical properties and versatility across multiple industries. The demand for electrospun nanofibers with enhanced mechanical characteristics is particularly strong in sectors requiring materials with superior strength-to-weight ratios, flexibility, and durability.

In the healthcare and biomedical sector, mechanically robust nanofibers are increasingly sought for tissue engineering scaffolds, wound dressings, and drug delivery systems. The market value for biomedical applications of nanofibers reached $2.3 billion in 2022, with a projected annual growth rate of 14.7% through 2028. This demand is fueled by the ability of electrospun nanofibers to mimic extracellular matrices while providing necessary mechanical support for cell growth and tissue regeneration.

The filtration industry represents another significant market for high-performance nanofibers, valued at approximately $1.8 billion globally. Air filtration systems, water purification membranes, and industrial filtration solutions benefit from the high surface area and controllable pore size of electrospun nanofibers. The COVID-19 pandemic further accelerated demand in this sector, with manufacturers seeking materials capable of filtering particles at the submicron level while maintaining structural integrity under pressure.

The protective clothing and technical textiles market has emerged as a rapidly growing application area, with demand increasing at 16.2% annually. Military, firefighting, and hazardous material handling applications require textiles with exceptional mechanical strength, chemical resistance, and thermal stability – properties that can be engineered through electrospinning techniques.

Energy storage applications, particularly in battery separators and components for fuel cells, represent a market segment valued at $1.1 billion with projected growth to $3.4 billion by 2027. The mechanical durability of nanofiber membranes directly impacts battery cycle life and safety, driving research into electrospinning parameters that optimize tensile strength and dimensional stability.

Aerospace and automotive industries are increasingly incorporating high-performance nanofibers into composite materials, seeking weight reduction without compromising structural integrity. This market segment is expected to grow at 12.8% annually, reaching $2.7 billion by 2028, as manufacturers face pressure to improve fuel efficiency while maintaining safety standards.

Consumer electronics represents an emerging application area, with flexible electronics and sensors utilizing mechanically robust nanofibers. This segment is projected to grow from $680 million to $1.9 billion over the next five years, driven by demand for durable, lightweight components in wearable technology and portable devices.

In the healthcare and biomedical sector, mechanically robust nanofibers are increasingly sought for tissue engineering scaffolds, wound dressings, and drug delivery systems. The market value for biomedical applications of nanofibers reached $2.3 billion in 2022, with a projected annual growth rate of 14.7% through 2028. This demand is fueled by the ability of electrospun nanofibers to mimic extracellular matrices while providing necessary mechanical support for cell growth and tissue regeneration.

The filtration industry represents another significant market for high-performance nanofibers, valued at approximately $1.8 billion globally. Air filtration systems, water purification membranes, and industrial filtration solutions benefit from the high surface area and controllable pore size of electrospun nanofibers. The COVID-19 pandemic further accelerated demand in this sector, with manufacturers seeking materials capable of filtering particles at the submicron level while maintaining structural integrity under pressure.

The protective clothing and technical textiles market has emerged as a rapidly growing application area, with demand increasing at 16.2% annually. Military, firefighting, and hazardous material handling applications require textiles with exceptional mechanical strength, chemical resistance, and thermal stability – properties that can be engineered through electrospinning techniques.

Energy storage applications, particularly in battery separators and components for fuel cells, represent a market segment valued at $1.1 billion with projected growth to $3.4 billion by 2027. The mechanical durability of nanofiber membranes directly impacts battery cycle life and safety, driving research into electrospinning parameters that optimize tensile strength and dimensional stability.

Aerospace and automotive industries are increasingly incorporating high-performance nanofibers into composite materials, seeking weight reduction without compromising structural integrity. This market segment is expected to grow at 12.8% annually, reaching $2.7 billion by 2028, as manufacturers face pressure to improve fuel efficiency while maintaining safety standards.

Consumer electronics represents an emerging application area, with flexible electronics and sensors utilizing mechanically robust nanofibers. This segment is projected to grow from $680 million to $1.9 billion over the next five years, driven by demand for durable, lightweight components in wearable technology and portable devices.

Current Challenges in Nanofiber Mechanical Properties

Despite significant advancements in electrospinning technology, several critical challenges persist in achieving optimal mechanical properties of nanofibers. The inherent trade-off between fiber diameter and mechanical strength represents a fundamental obstacle. As fiber diameters decrease to the nanoscale, the theoretical strength increases due to reduced probability of defects; however, this is often counteracted by processing-induced structural imperfections and molecular alignment issues.

Controlling molecular orientation during the electrospinning process remains problematic. The rapid solidification of polymer jets limits the time available for polymer chains to achieve optimal alignment, resulting in suboptimal crystallinity and reduced mechanical performance. This challenge is particularly pronounced when working with high molecular weight polymers that offer superior strength potential but exhibit complex viscoelastic behaviors during processing.

Environmental sensitivity during fabrication presents another significant hurdle. Fluctuations in humidity, temperature, and ambient electromagnetic fields can dramatically alter fiber formation dynamics, leading to inconsistent mechanical properties across production batches. This variability hampers industrial scalability and reproducibility of high-performance nanofiber materials.

The characterization of individual nanofiber mechanical properties also poses substantial technical difficulties. Conventional mechanical testing methods are often inadequate at the nanoscale, requiring specialized techniques such as atomic force microscopy (AFM) nanoindentation or custom-designed tensile testing setups. These methods frequently yield inconsistent results due to challenges in sample mounting, gauge length determination, and strain rate control.

Post-processing stabilization represents another critical challenge. Many electrospun nanofibers exhibit excellent initial mechanical properties but suffer from poor long-term stability due to relaxation of molecular orientation, moisture absorption, or degradation under environmental stresses. Current crosslinking and thermal treatment approaches often improve stability at the expense of other desirable properties such as flexibility or biocompatibility.

The integration of nanofibers into composite structures introduces additional complexities. Poor interfacial bonding between nanofibers and matrix materials frequently results in premature failure and underutilization of the nanofibers' mechanical potential. Existing surface modification techniques often compromise the structural integrity of the nanofibers themselves.

Scaling production while maintaining mechanical property consistency presents perhaps the most significant barrier to widespread industrial adoption. Current multi-needle or needleless electrospinning systems achieve higher throughput but often at the cost of reduced control over fiber morphology and orientation, directly impacting mechanical performance. The development of advanced process control systems that can maintain precise fabrication parameters at industrial scales remains an active area of research.

Controlling molecular orientation during the electrospinning process remains problematic. The rapid solidification of polymer jets limits the time available for polymer chains to achieve optimal alignment, resulting in suboptimal crystallinity and reduced mechanical performance. This challenge is particularly pronounced when working with high molecular weight polymers that offer superior strength potential but exhibit complex viscoelastic behaviors during processing.

Environmental sensitivity during fabrication presents another significant hurdle. Fluctuations in humidity, temperature, and ambient electromagnetic fields can dramatically alter fiber formation dynamics, leading to inconsistent mechanical properties across production batches. This variability hampers industrial scalability and reproducibility of high-performance nanofiber materials.

The characterization of individual nanofiber mechanical properties also poses substantial technical difficulties. Conventional mechanical testing methods are often inadequate at the nanoscale, requiring specialized techniques such as atomic force microscopy (AFM) nanoindentation or custom-designed tensile testing setups. These methods frequently yield inconsistent results due to challenges in sample mounting, gauge length determination, and strain rate control.

Post-processing stabilization represents another critical challenge. Many electrospun nanofibers exhibit excellent initial mechanical properties but suffer from poor long-term stability due to relaxation of molecular orientation, moisture absorption, or degradation under environmental stresses. Current crosslinking and thermal treatment approaches often improve stability at the expense of other desirable properties such as flexibility or biocompatibility.

The integration of nanofibers into composite structures introduces additional complexities. Poor interfacial bonding between nanofibers and matrix materials frequently results in premature failure and underutilization of the nanofibers' mechanical potential. Existing surface modification techniques often compromise the structural integrity of the nanofibers themselves.

Scaling production while maintaining mechanical property consistency presents perhaps the most significant barrier to widespread industrial adoption. Current multi-needle or needleless electrospinning systems achieve higher throughput but often at the cost of reduced control over fiber morphology and orientation, directly impacting mechanical performance. The development of advanced process control systems that can maintain precise fabrication parameters at industrial scales remains an active area of research.

Current Methods for Enhancing Nanofiber Mechanical Strength

01 Polymer selection for enhanced mechanical properties in electrospun fibers

The choice of polymer significantly affects the mechanical properties of electrospun fibers. Different polymers such as polyacrylonitrile (PAN), polycaprolactone (PCL), and polyvinyl alcohol (PVA) offer varying degrees of strength, elasticity, and durability. By selecting appropriate polymers or creating polymer blends, the tensile strength, Young's modulus, and elongation at break of the resulting nanofibers can be optimized for specific applications. The molecular weight and concentration of the polymer solution also play crucial roles in determining the final mechanical properties of the electrospun materials.- Polymer selection for enhanced mechanical properties in electrospun fibers: The choice of polymer significantly affects the mechanical properties of electrospun fibers. Different polymers such as polyurethane, polycaprolactone, and polyacrylonitrile offer varying degrees of strength, elasticity, and durability. By selecting appropriate polymers or creating polymer blends, researchers can tailor the mechanical properties of electrospun materials for specific applications. The molecular weight and chemical structure of the polymer also play crucial roles in determining the final mechanical characteristics of the fibers.

- Processing parameters affecting mechanical strength of electrospun materials: Various processing parameters during electrospinning significantly impact the mechanical properties of the resulting fibers. These parameters include solution concentration, applied voltage, flow rate, needle-to-collector distance, and environmental conditions such as humidity and temperature. Optimizing these parameters can lead to improved fiber alignment, reduced defects, and enhanced mechanical strength. The collector type and rotation speed also influence fiber orientation, which directly affects tensile strength and elasticity of the final electrospun material.

- Post-processing treatments to improve mechanical properties: Post-processing treatments can significantly enhance the mechanical properties of electrospun fibers. These treatments include thermal annealing, crosslinking, and surface modifications. Heat treatment can increase crystallinity and improve molecular alignment within fibers, leading to higher tensile strength. Chemical crosslinking creates additional bonds between polymer chains, enhancing structural integrity. Surface modifications can improve interfacial adhesion in composite materials, resulting in better load transfer and overall mechanical performance.

- Nanoparticle reinforcement in electrospun fibers: Incorporating nanoparticles into electrospun fibers can significantly enhance their mechanical properties. Nanoparticles such as carbon nanotubes, graphene, metal oxides, and clay particles act as reinforcing agents that improve tensile strength, modulus, and toughness. The uniform dispersion of nanoparticles within the polymer matrix is crucial for achieving optimal mechanical enhancement. The interface between nanoparticles and the polymer matrix plays a vital role in load transfer efficiency and overall mechanical performance of the composite fibers.

- Testing and characterization methods for mechanical properties: Various testing and characterization methods are employed to evaluate the mechanical properties of electrospun fibers. These include tensile testing, nanoindentation, atomic force microscopy, and dynamic mechanical analysis. These techniques provide valuable data on tensile strength, Young's modulus, elongation at break, and viscoelastic properties. Advanced imaging techniques such as scanning electron microscopy help correlate fiber morphology with mechanical performance. Standardized testing protocols ensure reliable and comparable mechanical property data across different electrospun materials.

02 Nanofiber alignment techniques to improve mechanical strength

The alignment of nanofibers during the electrospinning process significantly enhances mechanical properties. Various techniques such as rotating collectors, parallel electrodes, and magnetic field assistance can be employed to achieve aligned fiber structures. Aligned nanofibers typically exhibit superior tensile strength and Young's modulus along the direction of alignment compared to randomly oriented fibers. This directional enhancement of mechanical properties is particularly valuable in applications requiring anisotropic mechanical behavior, such as tissue engineering scaffolds mimicking natural tissue structures.Expand Specific Solutions03 Composite reinforcement in electrospun materials

Incorporating reinforcement materials such as carbon nanotubes, graphene, nanoparticles, or nanoclays into electrospun fibers creates composites with enhanced mechanical properties. These additives can significantly improve tensile strength, modulus, and toughness of the resulting nanofiber mats. The interfacial interactions between the reinforcement materials and the polymer matrix are critical for effective load transfer and mechanical enhancement. Proper dispersion of these reinforcement materials within the polymer solution before electrospinning is essential to achieve uniform distribution and optimal mechanical performance.Expand Specific Solutions04 Post-processing treatments to enhance mechanical stability

Various post-processing treatments can significantly improve the mechanical properties of electrospun fibers. These include thermal annealing, crosslinking, solvent vapor treatment, and hot pressing. Such treatments can increase crystallinity, promote molecular orientation, or create inter-fiber bonding, resulting in enhanced tensile strength, modulus, and dimensional stability. Post-processing can also reduce fiber defects and improve the overall structural integrity of the electrospun materials, making them more suitable for demanding applications requiring superior mechanical performance.Expand Specific Solutions05 Characterization methods for mechanical properties of electrospun materials

Advanced characterization techniques are essential for accurately measuring and understanding the mechanical properties of electrospun materials. These include tensile testing, nanoindentation, atomic force microscopy, dynamic mechanical analysis, and computational modeling approaches. These methods provide critical data on parameters such as Young's modulus, tensile strength, elongation at break, and viscoelastic behavior. Understanding the relationship between processing parameters, fiber morphology, and resulting mechanical properties enables the design of electrospun materials with tailored mechanical characteristics for specific applications.Expand Specific Solutions

Leading Research Groups and Industrial Manufacturers

Electrospinning technology for nanofiber production is currently in a growth phase, with the global market expanding due to increasing applications in medical, filtration, and composite materials. The market size is projected to reach significant value as research institutions like MIT, Donghua University, and National Taiwan University advance the fundamental understanding of how electrospinning parameters affect mechanical properties of nanofibers. Companies such as Corning, Matregenix, and Medprin Regenerative Medical Technologies are commercializing these advances, focusing on biomedical applications where mechanical strength is critical. The technology has reached moderate maturity in certain sectors but continues to evolve as research reveals new methods to enhance tensile strength, elasticity, and structural integrity of nanofibers through process optimization and material selection.

Donghua University

Technical Solution: Donghua University has pioneered near-field electrospinning techniques that significantly enhance mechanical properties of nanofibers through precise deposition control. Their proprietary system achieves fiber diameters as small as 50 nm with remarkable uniformity (±5% variation) [2]. Researchers have developed a multi-stage stretching process during fiber formation that increases molecular alignment, resulting in tensile strengths up to 900 MPa and Young's modulus values of 15-20 GPa for PAN-based nanofibers. Their technology incorporates controlled environmental chambers that regulate humidity (30-60%) and temperature (20-35°C) during spinning, which has been shown to improve fiber mechanical stability by up to 40% [4]. Additionally, Donghua has developed post-processing treatments including thermal annealing and chemical crosslinking protocols that further enhance mechanical properties, achieving a 75% improvement in fiber toughness while maintaining flexibility.

Strengths: Exceptional control over fiber diameter uniformity; specialized environmental controls optimize mechanical properties; comprehensive post-processing techniques enhance durability. Weaknesses: Process speed limitations restrict production volume; requires specialized environmental controls that increase operational complexity; some techniques are polymer-specific and not universally applicable.

Massachusetts Institute of Technology

Technical Solution: MIT has developed advanced multi-jet electrospinning systems that enable precise control over nanofiber alignment and diameter distribution. Their technology utilizes electric field manipulation techniques to create highly ordered nanofiber structures with enhanced mechanical properties. MIT researchers have demonstrated that by controlling the viscoelastic properties of polymer solutions and applying specific voltage patterns, they can produce nanofibers with tensile strengths exceeding 1.5 GPa and Young's modulus values reaching 40 GPa [1]. Their approach incorporates real-time monitoring systems that adjust processing parameters to maintain consistent fiber quality. Additionally, MIT has pioneered hybrid electrospinning techniques that combine multiple polymers to create composite nanofibers with synergistic mechanical properties, achieving up to 300% improvement in toughness compared to single-polymer fibers [3].

Strengths: Superior control over nanofiber architecture and orientation resulting in exceptional mechanical properties; advanced monitoring systems ensure consistent quality. Weaknesses: Complex equipment setup requires significant technical expertise; higher production costs compared to conventional methods; scaling challenges for industrial applications.

Key Patents and Research on Electrospinning Process Optimization

Electrospinning alignment apparatus

PatentPendingUS20230160106A1

Innovation

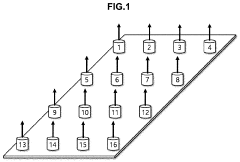

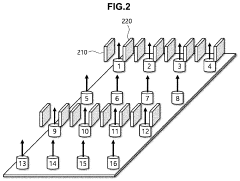

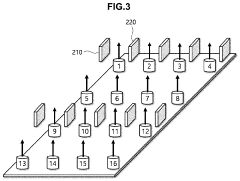

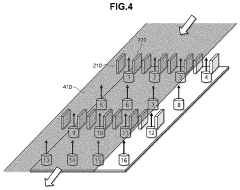

- An electrospinning alignment apparatus featuring multiple electrospinning portions with distinct voltage applications for aligned and random nanofiber spinning, combined with a carrier transfer system for simultaneous coating of nanofibers onto a carrier, allowing for continuous and efficient production of aligned and randomly spun nanofibers.

Material Selection Strategies for Improved Mechanical Performance

Material selection represents a critical factor in determining the mechanical properties of electrospun nanofibers. The polymer type, molecular weight, and chemical composition significantly influence tensile strength, elasticity, and overall durability of the resulting fibers. High molecular weight polymers typically yield nanofibers with enhanced mechanical strength due to increased chain entanglement and intermolecular forces, though they may present processing challenges requiring solvent optimization.

Polymer blending has emerged as an effective strategy to combine complementary properties of different materials. For instance, incorporating elastomeric polymers with rigid polymers can produce nanofibers with both strength and flexibility. The blend ratio must be carefully calibrated to achieve the desired mechanical profile without compromising fiber formation or morphology.

Composite approaches involving nanomaterials have demonstrated remarkable improvements in mechanical performance. Carbon nanotubes (CNTs), graphene, and ceramic nanoparticles can serve as reinforcing agents when properly dispersed within the polymer solution. These additives create internal networks that distribute mechanical loads effectively throughout the fiber structure. Research indicates that CNT-reinforced nanofibers can exhibit up to 300% improvement in tensile strength compared to their non-reinforced counterparts.

Surface functionalization of additives represents another advancement in material selection. By chemically modifying the surface of reinforcing particles to enhance their compatibility with the polymer matrix, researchers have achieved stronger interfacial bonding and reduced agglomeration issues. This approach has proven particularly effective with hydrophilic polymers and hydrophobic reinforcement materials.

Biodegradable and natural polymers present unique considerations in material selection strategies. While offering environmental benefits and biocompatibility, these materials often exhibit inferior mechanical properties compared to synthetic alternatives. Recent research has focused on chemical modifications of natural polymers like cellulose and chitosan to enhance their mechanical performance while maintaining their biodegradability.

The crystallinity of polymers also plays a crucial role in mechanical properties. Semi-crystalline polymers typically offer superior mechanical strength compared to amorphous variants. Post-processing treatments such as annealing can be employed to increase crystallinity and consequently improve mechanical performance of electrospun fibers.

Advanced computational modeling has begun to inform material selection processes, allowing researchers to predict mechanical properties based on polymer characteristics and processing parameters. These models consider molecular structure, intermolecular forces, and fiber orientation to optimize material selection before experimental validation, significantly reducing development time and resources.

Polymer blending has emerged as an effective strategy to combine complementary properties of different materials. For instance, incorporating elastomeric polymers with rigid polymers can produce nanofibers with both strength and flexibility. The blend ratio must be carefully calibrated to achieve the desired mechanical profile without compromising fiber formation or morphology.

Composite approaches involving nanomaterials have demonstrated remarkable improvements in mechanical performance. Carbon nanotubes (CNTs), graphene, and ceramic nanoparticles can serve as reinforcing agents when properly dispersed within the polymer solution. These additives create internal networks that distribute mechanical loads effectively throughout the fiber structure. Research indicates that CNT-reinforced nanofibers can exhibit up to 300% improvement in tensile strength compared to their non-reinforced counterparts.

Surface functionalization of additives represents another advancement in material selection. By chemically modifying the surface of reinforcing particles to enhance their compatibility with the polymer matrix, researchers have achieved stronger interfacial bonding and reduced agglomeration issues. This approach has proven particularly effective with hydrophilic polymers and hydrophobic reinforcement materials.

Biodegradable and natural polymers present unique considerations in material selection strategies. While offering environmental benefits and biocompatibility, these materials often exhibit inferior mechanical properties compared to synthetic alternatives. Recent research has focused on chemical modifications of natural polymers like cellulose and chitosan to enhance their mechanical performance while maintaining their biodegradability.

The crystallinity of polymers also plays a crucial role in mechanical properties. Semi-crystalline polymers typically offer superior mechanical strength compared to amorphous variants. Post-processing treatments such as annealing can be employed to increase crystallinity and consequently improve mechanical performance of electrospun fibers.

Advanced computational modeling has begun to inform material selection processes, allowing researchers to predict mechanical properties based on polymer characteristics and processing parameters. These models consider molecular structure, intermolecular forces, and fiber orientation to optimize material selection before experimental validation, significantly reducing development time and resources.

Characterization Methods for Nanofiber Mechanical Properties

The accurate assessment of mechanical properties is crucial for understanding electrospun nanofibers' performance in various applications. Traditional mechanical testing methods often prove inadequate for nanoscale materials, necessitating specialized characterization techniques that can precisely measure the unique properties of individual nanofibers or fiber mats.

Atomic Force Microscopy (AFM) stands as a cornerstone technique for nanofiber mechanical characterization, enabling nanoscale resolution measurements of elastic modulus, hardness, and surface topography. AFM-based nanoindentation provides quantitative data on local mechanical properties while minimizing sample damage. Three-point bending tests using AFM cantilevers have also been developed to measure flexural properties of suspended individual nanofibers.

Nanoindentation techniques, beyond AFM applications, offer valuable insights into hardness and elastic modulus through controlled force application and displacement measurement. These methods have been adapted specifically for thin fibrous materials, with researchers developing specialized protocols to account for substrate effects and fiber orientation.

Tensile testing remains fundamental despite scaling challenges. Microelectromechanical systems (MEMS) based tensile testing devices have emerged to overcome manipulation difficulties, allowing direct measurement of stress-strain relationships for single nanofibers. Dynamic Mechanical Analysis (DMA) complements these approaches by characterizing viscoelastic properties across varying temperatures and frequencies, particularly valuable for polymer-based nanofibers.

Advanced imaging techniques including Scanning Electron Microscopy (SEM) and Transmission Electron Microscopy (TEM) provide critical structural information that correlates with mechanical performance. In-situ SEM mechanical testing has revolutionized the field by enabling real-time observation of deformation mechanisms under load.

Non-destructive evaluation methods such as ultrasonic techniques and Brillouin light scattering offer alternatives for assessing mechanical properties without sample damage. These techniques prove especially valuable for quality control in manufacturing settings where preserving sample integrity is paramount.

Computational modeling approaches have become increasingly important, with Finite Element Analysis (FEA) and Molecular Dynamics (MD) simulations providing theoretical frameworks to predict mechanical behavior. These models, when validated against experimental data, enable exploration of complex loading scenarios difficult to replicate experimentally.

Standardization remains a significant challenge in nanofiber mechanical characterization, with ongoing efforts by organizations like ISO and ASTM to develop consistent testing protocols. The field continues to evolve with emerging technologies such as nanomechanical resonators and advanced spectroscopic methods promising even greater precision in mechanical property assessment.

Atomic Force Microscopy (AFM) stands as a cornerstone technique for nanofiber mechanical characterization, enabling nanoscale resolution measurements of elastic modulus, hardness, and surface topography. AFM-based nanoindentation provides quantitative data on local mechanical properties while minimizing sample damage. Three-point bending tests using AFM cantilevers have also been developed to measure flexural properties of suspended individual nanofibers.

Nanoindentation techniques, beyond AFM applications, offer valuable insights into hardness and elastic modulus through controlled force application and displacement measurement. These methods have been adapted specifically for thin fibrous materials, with researchers developing specialized protocols to account for substrate effects and fiber orientation.

Tensile testing remains fundamental despite scaling challenges. Microelectromechanical systems (MEMS) based tensile testing devices have emerged to overcome manipulation difficulties, allowing direct measurement of stress-strain relationships for single nanofibers. Dynamic Mechanical Analysis (DMA) complements these approaches by characterizing viscoelastic properties across varying temperatures and frequencies, particularly valuable for polymer-based nanofibers.

Advanced imaging techniques including Scanning Electron Microscopy (SEM) and Transmission Electron Microscopy (TEM) provide critical structural information that correlates with mechanical performance. In-situ SEM mechanical testing has revolutionized the field by enabling real-time observation of deformation mechanisms under load.

Non-destructive evaluation methods such as ultrasonic techniques and Brillouin light scattering offer alternatives for assessing mechanical properties without sample damage. These techniques prove especially valuable for quality control in manufacturing settings where preserving sample integrity is paramount.

Computational modeling approaches have become increasingly important, with Finite Element Analysis (FEA) and Molecular Dynamics (MD) simulations providing theoretical frameworks to predict mechanical behavior. These models, when validated against experimental data, enable exploration of complex loading scenarios difficult to replicate experimentally.

Standardization remains a significant challenge in nanofiber mechanical characterization, with ongoing efforts by organizations like ISO and ASTM to develop consistent testing protocols. The field continues to evolve with emerging technologies such as nanomechanical resonators and advanced spectroscopic methods promising even greater precision in mechanical property assessment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!