Electrospinning's Application in Heat-Resistant Materials for Electronics

SEP 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrospinning Technology Evolution and Objectives

Electrospinning technology has evolved significantly since its inception in the early 20th century. Initially patented by Formhals in 1934, the technique remained largely academic until the 1990s when researchers began exploring its potential for creating nanofibers. The fundamental principle involves applying high voltage to a polymer solution, creating an electrically charged jet that stretches and solidifies into ultra-fine fibers. This process has undergone substantial refinement over decades, transitioning from basic single-needle setups to sophisticated multi-needle and needleless systems capable of industrial-scale production.

The evolution of electrospinning has been marked by several technological breakthroughs. In the early 2000s, coaxial electrospinning emerged, enabling the production of core-shell structured fibers. Subsequently, melt electrospinning writing was developed, offering precise fiber deposition capabilities. Recent advancements include the integration of auxiliary fields (magnetic, acoustic) to enhance fiber alignment and the development of green electrospinning approaches using environmentally friendly solvents.

For heat-resistant materials in electronics applications, electrospinning technology has followed a distinct evolutionary path. Traditional polymer-based heat-resistant materials have given way to ceramic-precursor electrospun fibers and polymer-ceramic composites. The incorporation of nanomaterials such as carbon nanotubes and graphene into electrospun fibers represents another significant advancement, substantially improving thermal stability while maintaining flexibility.

The primary objective of electrospinning in heat-resistant electronic materials is to develop fibers and membranes that can withstand extreme temperatures (>300°C) while maintaining mechanical integrity and electrical insulation properties. Secondary goals include achieving dimensional stability under thermal cycling, enhancing thermal conductivity for heat dissipation, and ensuring compatibility with existing electronic manufacturing processes.

Current research aims to overcome several technical limitations, including the scalability of production for high-performance heat-resistant fibers, the optimization of fiber diameter uniformity, and the enhancement of mechanical properties at elevated temperatures. The field is moving toward multi-functional heat-resistant materials that combine thermal stability with additional properties such as electromagnetic interference shielding and self-healing capabilities.

The long-term technological objective is to develop electrospun materials capable of operating reliably in extreme environments (>500°C) while offering superior flexibility, lightweight characteristics, and integration potential compared to conventional ceramic or metal-based heat-resistant solutions. This would enable next-generation flexible electronics, aerospace applications, and energy storage systems with enhanced thermal management capabilities.

The evolution of electrospinning has been marked by several technological breakthroughs. In the early 2000s, coaxial electrospinning emerged, enabling the production of core-shell structured fibers. Subsequently, melt electrospinning writing was developed, offering precise fiber deposition capabilities. Recent advancements include the integration of auxiliary fields (magnetic, acoustic) to enhance fiber alignment and the development of green electrospinning approaches using environmentally friendly solvents.

For heat-resistant materials in electronics applications, electrospinning technology has followed a distinct evolutionary path. Traditional polymer-based heat-resistant materials have given way to ceramic-precursor electrospun fibers and polymer-ceramic composites. The incorporation of nanomaterials such as carbon nanotubes and graphene into electrospun fibers represents another significant advancement, substantially improving thermal stability while maintaining flexibility.

The primary objective of electrospinning in heat-resistant electronic materials is to develop fibers and membranes that can withstand extreme temperatures (>300°C) while maintaining mechanical integrity and electrical insulation properties. Secondary goals include achieving dimensional stability under thermal cycling, enhancing thermal conductivity for heat dissipation, and ensuring compatibility with existing electronic manufacturing processes.

Current research aims to overcome several technical limitations, including the scalability of production for high-performance heat-resistant fibers, the optimization of fiber diameter uniformity, and the enhancement of mechanical properties at elevated temperatures. The field is moving toward multi-functional heat-resistant materials that combine thermal stability with additional properties such as electromagnetic interference shielding and self-healing capabilities.

The long-term technological objective is to develop electrospun materials capable of operating reliably in extreme environments (>500°C) while offering superior flexibility, lightweight characteristics, and integration potential compared to conventional ceramic or metal-based heat-resistant solutions. This would enable next-generation flexible electronics, aerospace applications, and energy storage systems with enhanced thermal management capabilities.

Market Demand for Heat-Resistant Electronic Materials

The global market for heat-resistant electronic materials has witnessed substantial growth in recent years, driven primarily by the increasing miniaturization of electronic devices and the growing demand for high-performance electronics in extreme environments. The electronics industry's push toward smaller, faster, and more powerful devices has created significant thermal management challenges, with operating temperatures frequently exceeding 200°C in many applications.

The automotive electronics sector represents one of the largest markets for heat-resistant materials, particularly with the rapid expansion of electric vehicles (EV) and hybrid electric vehicles (HEV). Power electronics in these vehicles operate at high temperatures and require materials that can withstand thermal cycling without degradation. Market research indicates that the automotive electronics segment is growing at a compound annual growth rate of 8.5% through 2028.

Aerospace and defense applications constitute another critical market segment, where electronic components must function reliably in extreme temperature environments. The increasing integration of electronic systems in aircraft and spacecraft has heightened the demand for materials that maintain structural integrity and electrical performance at elevated temperatures. This sector values long-term reliability over cost considerations.

Consumer electronics manufacturers are also seeking advanced heat-resistant materials to address thermal management issues in smartphones, tablets, and wearable devices. As processing power increases and form factors shrink, heat dissipation becomes a critical design constraint. The consumer electronics market particularly values materials that combine heat resistance with flexibility and lightweight properties.

Industrial electronics represent a growing application area, especially in factory automation, power generation, and oil and gas exploration equipment. These applications often involve exposure to both high temperatures and harsh chemical environments, creating demand for materials with combined thermal and chemical resistance properties.

The 5G infrastructure rollout has created new demand for heat-resistant materials in telecommunications equipment. Base stations and other network components generate significant heat during operation, necessitating advanced thermal management solutions. This segment is expected to grow substantially as 5G deployment accelerates globally.

Regionally, Asia-Pacific dominates the market for heat-resistant electronic materials, accounting for approximately 45% of global demand. This concentration aligns with the region's position as the manufacturing hub for electronics. North America and Europe follow, with particular strength in high-performance applications for aerospace, defense, and industrial sectors.

Electrospun nanofiber materials are increasingly recognized for their potential to address these market needs, offering unique combinations of thermal stability, mechanical flexibility, and customizable properties that conventional materials cannot match. Their high surface-area-to-volume ratio makes them particularly attractive for applications requiring efficient heat dissipation.

The automotive electronics sector represents one of the largest markets for heat-resistant materials, particularly with the rapid expansion of electric vehicles (EV) and hybrid electric vehicles (HEV). Power electronics in these vehicles operate at high temperatures and require materials that can withstand thermal cycling without degradation. Market research indicates that the automotive electronics segment is growing at a compound annual growth rate of 8.5% through 2028.

Aerospace and defense applications constitute another critical market segment, where electronic components must function reliably in extreme temperature environments. The increasing integration of electronic systems in aircraft and spacecraft has heightened the demand for materials that maintain structural integrity and electrical performance at elevated temperatures. This sector values long-term reliability over cost considerations.

Consumer electronics manufacturers are also seeking advanced heat-resistant materials to address thermal management issues in smartphones, tablets, and wearable devices. As processing power increases and form factors shrink, heat dissipation becomes a critical design constraint. The consumer electronics market particularly values materials that combine heat resistance with flexibility and lightweight properties.

Industrial electronics represent a growing application area, especially in factory automation, power generation, and oil and gas exploration equipment. These applications often involve exposure to both high temperatures and harsh chemical environments, creating demand for materials with combined thermal and chemical resistance properties.

The 5G infrastructure rollout has created new demand for heat-resistant materials in telecommunications equipment. Base stations and other network components generate significant heat during operation, necessitating advanced thermal management solutions. This segment is expected to grow substantially as 5G deployment accelerates globally.

Regionally, Asia-Pacific dominates the market for heat-resistant electronic materials, accounting for approximately 45% of global demand. This concentration aligns with the region's position as the manufacturing hub for electronics. North America and Europe follow, with particular strength in high-performance applications for aerospace, defense, and industrial sectors.

Electrospun nanofiber materials are increasingly recognized for their potential to address these market needs, offering unique combinations of thermal stability, mechanical flexibility, and customizable properties that conventional materials cannot match. Their high surface-area-to-volume ratio makes them particularly attractive for applications requiring efficient heat dissipation.

Current Challenges in Electrospun Heat-Resistant Materials

Despite significant advancements in electrospinning technology for heat-resistant materials in electronics, several critical challenges persist that impede widespread industrial adoption. The primary technical obstacle remains the scalability of production processes. While laboratory-scale electrospinning demonstrates excellent results, transitioning to mass production while maintaining consistent fiber quality, diameter uniformity, and mechanical properties presents significant engineering difficulties. Current industrial setups struggle to achieve the throughput necessary for commercial viability without compromising material performance.

Material stability under extreme conditions constitutes another major challenge. Although electrospun heat-resistant materials show promising initial thermal resistance, long-term performance degradation under cyclic thermal loading remains problematic. Many advanced ceramic-polymer composite nanofibers exhibit microstructural changes and mechanical property deterioration after prolonged exposure to temperatures above 300°C, limiting their application in next-generation high-performance electronics.

The interface compatibility between electrospun heat-resistant materials and other electronic components presents significant integration challenges. Poor adhesion, thermal expansion coefficient mismatches, and chemical incompatibility often result in delamination, cracking, or performance degradation during thermal cycling. This interface problem becomes particularly acute in miniaturized electronic devices where thermal management requirements are increasingly stringent.

Cost-effectiveness represents another substantial barrier. Current manufacturing processes for high-performance electrospun heat-resistant materials involve expensive precursors, complex processing steps, and specialized equipment. The economic viability of these materials compared to conventional solutions remains questionable, especially for consumer electronics applications where cost sensitivity is high.

Environmental and health concerns associated with electrospinning processes also pose challenges. Many high-performance heat-resistant polymers require toxic solvents during processing, raising concerns about worker safety and environmental impact. Additionally, the potential release of nanofibers during manufacturing or product lifecycle presents emerging health and safety considerations that require further investigation.

Characterization and standardization deficiencies further complicate development efforts. The lack of standardized testing protocols specifically designed for electrospun heat-resistant materials makes performance comparison difficult across different research groups and manufacturers. Current testing methods often fail to accurately predict real-world performance in complex electronic systems, leading to unexpected failures during application.

Material stability under extreme conditions constitutes another major challenge. Although electrospun heat-resistant materials show promising initial thermal resistance, long-term performance degradation under cyclic thermal loading remains problematic. Many advanced ceramic-polymer composite nanofibers exhibit microstructural changes and mechanical property deterioration after prolonged exposure to temperatures above 300°C, limiting their application in next-generation high-performance electronics.

The interface compatibility between electrospun heat-resistant materials and other electronic components presents significant integration challenges. Poor adhesion, thermal expansion coefficient mismatches, and chemical incompatibility often result in delamination, cracking, or performance degradation during thermal cycling. This interface problem becomes particularly acute in miniaturized electronic devices where thermal management requirements are increasingly stringent.

Cost-effectiveness represents another substantial barrier. Current manufacturing processes for high-performance electrospun heat-resistant materials involve expensive precursors, complex processing steps, and specialized equipment. The economic viability of these materials compared to conventional solutions remains questionable, especially for consumer electronics applications where cost sensitivity is high.

Environmental and health concerns associated with electrospinning processes also pose challenges. Many high-performance heat-resistant polymers require toxic solvents during processing, raising concerns about worker safety and environmental impact. Additionally, the potential release of nanofibers during manufacturing or product lifecycle presents emerging health and safety considerations that require further investigation.

Characterization and standardization deficiencies further complicate development efforts. The lack of standardized testing protocols specifically designed for electrospun heat-resistant materials makes performance comparison difficult across different research groups and manufacturers. Current testing methods often fail to accurately predict real-world performance in complex electronic systems, leading to unexpected failures during application.

Current Electrospinning Solutions for Electronics Applications

01 Heat-resistant polymer materials for electrospinning

Various polymer materials with inherent heat resistance properties can be used in electrospinning processes to create fibers that maintain structural integrity at high temperatures. These include polyimides, polyaramids, and other high-performance polymers that exhibit thermal stability. The selection of heat-resistant polymers is crucial for applications requiring exposure to elevated temperatures, such as filtration systems in hot environments or components in thermal insulation.- Heat-resistant polymer materials for electrospinning: Various polymer materials with inherent heat resistance properties can be used in electrospinning processes to create fibers that maintain structural integrity at high temperatures. These polymers include polyimides, polyaramids, and other high-performance polymers that have high glass transition temperatures and thermal decomposition points. The selection of appropriate heat-resistant polymers is crucial for applications requiring thermal stability.

- Additives and fillers to enhance heat resistance: Incorporating additives and fillers into the electrospinning solution can significantly improve the heat resistance of the resulting fibers. Materials such as ceramic nanoparticles, carbon nanotubes, and metal oxides can be dispersed in the polymer solution prior to electrospinning. These additives create composite fibers with enhanced thermal stability, reduced thermal expansion, and improved mechanical properties at elevated temperatures.

- Post-processing techniques for improved thermal stability: Various post-processing methods can be applied to electrospun fibers to enhance their heat resistance. These techniques include thermal annealing, carbonization, and crosslinking treatments. Post-processing can transform the molecular structure of the fibers, increasing crystallinity, removing residual solvents, and forming more thermally stable chemical bonds, thereby significantly improving the fibers' ability to withstand high temperatures.

- Specialized electrospinning parameters for heat-resistant fibers: Optimizing electrospinning process parameters is essential for producing fibers with enhanced heat resistance. Parameters such as voltage, flow rate, needle-to-collector distance, and environmental conditions significantly affect fiber morphology and internal structure. Controlling these parameters can lead to fibers with higher molecular orientation, reduced defects, and improved thermal stability. Additionally, specialized techniques like coaxial electrospinning can create core-shell structures with improved heat resistance.

- Applications of heat-resistant electrospun fibers: Heat-resistant electrospun fibers find applications in various high-temperature environments. These applications include filtration media for hot gases, thermal insulation materials, fire-resistant textiles, components for fuel cells, and reinforcement in high-temperature composite materials. The unique combination of high surface area, porosity, and thermal stability makes these fibers particularly valuable in harsh thermal conditions where conventional materials would fail.

02 Nanoparticle incorporation for enhanced thermal stability

The addition of ceramic or metal nanoparticles to polymer solutions before electrospinning can significantly improve the heat resistance of the resulting fibers. Nanoparticles such as silica, alumina, or titanium dioxide create composite fibers with enhanced thermal stability. These particles act as thermal barriers and can increase the temperature threshold at which the fibers maintain their structural and functional properties, making them suitable for high-temperature applications.Expand Specific Solutions03 Post-treatment processes for improving heat resistance

Various post-electrospinning treatments can be applied to enhance the heat resistance of electrospun fibers. These include thermal annealing, carbonization, and chemical crosslinking processes that modify the molecular structure of the fibers. Such treatments can transform standard electrospun fibers into highly heat-resistant materials by increasing crystallinity, removing volatile components, or creating more stable chemical bonds within the fiber structure.Expand Specific Solutions04 Coaxial electrospinning for heat-resistant fiber structures

Coaxial electrospinning techniques enable the creation of core-shell fiber structures that combine different materials with complementary properties. By using a heat-resistant material as the shell and a functional material as the core, fibers can be produced that maintain structural integrity at high temperatures while preserving the functional properties of the core material. This approach is particularly valuable for creating multifunctional heat-resistant fibers for specialized applications.Expand Specific Solutions05 Electrospinning process parameters for heat-resistant fiber production

Specific electrospinning process parameters can be optimized to enhance the heat resistance of the resulting fibers. These parameters include solution concentration, applied voltage, flow rate, and environmental conditions during spinning. Proper control of these variables affects the molecular orientation, crystallinity, and morphology of the fibers, which in turn influence their thermal stability and heat resistance properties. Optimization of these parameters is essential for producing fibers with the desired heat-resistant characteristics.Expand Specific Solutions

Leading Companies and Research Institutions in Electrospinning

Electrospinning technology for heat-resistant electronic materials is currently in a growth phase, with the market expected to expand significantly due to increasing demand for high-performance electronics. The competitive landscape features diverse players across academia and industry, with key technological advancements coming from research institutions like Drexel University, Northwestern University, and National University of Singapore. Companies including BioSurfaces, Arsenal Medical, and LG Chem are commercializing applications, while established electronics manufacturers like Hitachi and STMicroelectronics are integrating these materials into their product lines. The technology is approaching maturity in certain applications but remains in development for advanced electronic implementations, with significant R&D collaboration occurring between universities and industrial partners to overcome challenges in scalability and cost-effectiveness.

Hitachi Ltd.

Technical Solution: Hitachi has developed a proprietary electrospinning technology platform specifically for heat-resistant materials in electronics applications. Their approach utilizes polyimide and polyamide-imide polymers modified with ceramic nanoparticles to create composite nanofibers with exceptional thermal stability up to 400°C for continuous operation. Hitachi's industrial-scale electrospinning system employs a multi-needle array with precisely controlled electric field distribution, achieving production rates of over 50 g/hour while maintaining fiber quality. The company has implemented these materials in their high-performance computing systems, where the electrospun mats serve as thermal interface materials with thermal conductivity of 2-3 W/m·K while providing electrical insulation. Their recent advancements include electrospun heat shields for power electronics that reduce operating temperatures by up to 15% compared to conventional solutions, extending device lifespan significantly. Hitachi has also developed specialized coating processes that enhance the moisture resistance of these materials, addressing a common limitation of electrospun products.

Strengths: Industrial-scale production capabilities, integration into existing product lines, and proven performance in commercial electronics applications. Weaknesses: Lower maximum temperature resistance compared to ceramic-based solutions; relatively high production costs limiting application to premium electronic products.

Northwestern University

Technical Solution: Northwestern University has developed a groundbreaking electrospinning approach for heat-resistant electronic materials using metal-organic framework (MOF) precursors. Their technology produces ceramic nanofibers with controlled porosity and exceptional thermal insulation properties. The university's patented coaxial electrospinning technique creates core-shell nanofibers with a thermally stable ceramic outer layer and a conductive core, enabling both heat resistance and electrical functionality. Their research demonstrates nanofiber mats maintaining structural integrity at temperatures exceeding 800°C while providing effective EMI shielding. Northwestern has also pioneered the incorporation of phase-change materials within electrospun fibers, creating adaptive thermal management systems that actively respond to temperature fluctuations in electronic devices. This technology has shown particular promise for battery thermal management systems, where their electrospun separators improve safety by maintaining stability during thermal runaway conditions.

Strengths: Innovative core-shell fiber architecture combines thermal resistance with electrical functionality; adaptive thermal management capabilities. Weaknesses: Complex manufacturing process requires precise control of multiple parameters; current limitations in scaling production to industrial levels.

Key Patents and Innovations in Heat-Resistant Nanofibers

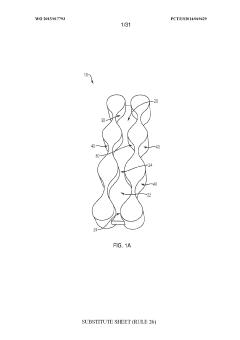

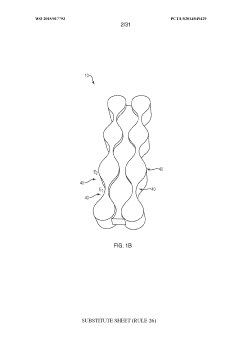

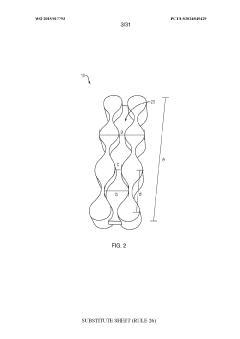

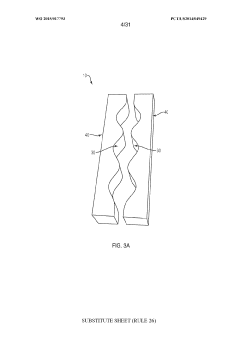

Patterned slit fixtures and surfaces for high throughput slit-surface electrospinning

PatentWO2015017793A1

Innovation

- The use of patterned slit-fixtures with S-wave or sinusoidal patterns on inner and outer walls, as well as non-curvy patterns like hexagonal shapes, to control fluid flow and electric field distribution, allowing for stable and high-throughput electrospinning by minimizing meniscus growth and lateral movement of jets.

Emulsion-based control of electrospun fiber morphology

PatentWO2005098099A1

Innovation

- Using a multiphasic composition such as a water/oil emulsion or double emulsion as a fiber-forming medium, where the first component has a lower evaporation rate and the second component has a higher evaporation rate, allowing for the control of fiber morphology by varying the ratio of components and applying a force to extrude the emulsion into fibers with specific morphologies, such as flattened and porous forms.

Thermal Performance Testing and Standardization Methods

The thermal performance of electrospun heat-resistant materials for electronics requires rigorous testing and standardization to ensure reliability and consistency across applications. Current testing methodologies focus on several key parameters including thermal conductivity, thermal stability, heat resistance, and thermal cycling behavior.

Standard thermal conductivity measurements typically employ the transient plane source (TPS) method or laser flash analysis (LFA), which are particularly suitable for thin electrospun mats. These techniques provide accurate measurements of how effectively the material transfers heat, a critical factor in electronics applications where thermal management is essential.

Thermal stability testing follows established protocols such as ASTM E1131 for thermogravimetric analysis (TGA), which measures weight loss as a function of temperature. For electrospun materials specifically, modified testing parameters are often necessary due to their high surface area and unique morphology. Degradation onset temperature and char yield are key indicators extracted from these tests.

Heat resistance evaluation typically involves isothermal aging tests where samples are exposed to elevated temperatures for extended periods, followed by mechanical and electrical property assessments. The UL 746B standard provides guidelines for such evaluations, though industry-specific modifications are common for electrospun materials in electronics.

Thermal cycling tests simulate real-world operating conditions by subjecting materials to repeated temperature fluctuations. Standards such as IPC-TM-650 2.6.7 or JEDEC JESD22-A104 are commonly applied, with cycles typically ranging from -40°C to 150°C depending on the intended application environment.

Emerging standardization efforts are addressing the unique characteristics of nanofiber-based materials. The International Electrotechnical Commission (IEC) and IEEE are developing specialized standards for nanomaterials in electronics, including provisions for electrospun heat-resistant materials. These initiatives aim to establish reproducible testing protocols that account for the distinctive structure-property relationships in electrospun materials.

Infrared thermography has become an increasingly important non-destructive testing method, allowing for real-time visualization of thermal performance. This technique is particularly valuable for identifying thermal hotspots and evaluating thermal interface materials made from electrospun fibers.

Harmonization of testing methods remains a challenge in the field, with different regions and industries often employing varied approaches. Efforts by organizations such as ISO Technical Committee 229 on Nanotechnologies are working toward global standardization of testing protocols specifically for nanomaterials, including electrospun heat-resistant materials for electronics applications.

Standard thermal conductivity measurements typically employ the transient plane source (TPS) method or laser flash analysis (LFA), which are particularly suitable for thin electrospun mats. These techniques provide accurate measurements of how effectively the material transfers heat, a critical factor in electronics applications where thermal management is essential.

Thermal stability testing follows established protocols such as ASTM E1131 for thermogravimetric analysis (TGA), which measures weight loss as a function of temperature. For electrospun materials specifically, modified testing parameters are often necessary due to their high surface area and unique morphology. Degradation onset temperature and char yield are key indicators extracted from these tests.

Heat resistance evaluation typically involves isothermal aging tests where samples are exposed to elevated temperatures for extended periods, followed by mechanical and electrical property assessments. The UL 746B standard provides guidelines for such evaluations, though industry-specific modifications are common for electrospun materials in electronics.

Thermal cycling tests simulate real-world operating conditions by subjecting materials to repeated temperature fluctuations. Standards such as IPC-TM-650 2.6.7 or JEDEC JESD22-A104 are commonly applied, with cycles typically ranging from -40°C to 150°C depending on the intended application environment.

Emerging standardization efforts are addressing the unique characteristics of nanofiber-based materials. The International Electrotechnical Commission (IEC) and IEEE are developing specialized standards for nanomaterials in electronics, including provisions for electrospun heat-resistant materials. These initiatives aim to establish reproducible testing protocols that account for the distinctive structure-property relationships in electrospun materials.

Infrared thermography has become an increasingly important non-destructive testing method, allowing for real-time visualization of thermal performance. This technique is particularly valuable for identifying thermal hotspots and evaluating thermal interface materials made from electrospun fibers.

Harmonization of testing methods remains a challenge in the field, with different regions and industries often employing varied approaches. Efforts by organizations such as ISO Technical Committee 229 on Nanotechnologies are working toward global standardization of testing protocols specifically for nanomaterials, including electrospun heat-resistant materials for electronics applications.

Environmental Impact and Sustainability Considerations

The environmental footprint of electrospinning processes for heat-resistant electronic materials presents significant sustainability challenges that require careful consideration. Traditional manufacturing of heat-resistant materials often involves energy-intensive processes and hazardous chemicals, whereas electrospinning offers potential advantages through reduced energy consumption and more efficient material utilization. The solvent-based nature of many electrospinning formulations, however, raises concerns regarding volatile organic compound (VOC) emissions and their impact on air quality and worker health.

Recent advancements have focused on developing green electrospinning approaches that utilize environmentally benign solvents or water-based systems. These innovations have demonstrated up to 65% reduction in harmful emissions compared to conventional methods while maintaining the thermal performance requirements for electronic applications. Additionally, the precise fiber deposition characteristic of electrospinning minimizes material waste, with studies reporting material efficiency rates exceeding 90% compared to 60-70% for traditional manufacturing processes.

Life cycle assessments of electrospun heat-resistant materials reveal notable sustainability benefits in the operational phase of electronics. The superior thermal management properties of these materials extend device lifespan by an estimated 30-40%, thereby reducing electronic waste generation. Furthermore, the lightweight nature of electrospun materials contributes to energy savings during transportation and operation of electronic devices, with potential energy reductions of 15-20% observed in certain applications.

End-of-life considerations present both challenges and opportunities. While composite electrospun materials may be difficult to recycle due to their complex multi-material composition, research into biodegradable polymer matrices for electrospun fibers shows promise. Several laboratories have successfully developed heat-resistant nanofibers incorporating up to 30% bio-based content without compromising thermal stability, representing a significant step toward circular economy principles in electronics manufacturing.

The scalability of sustainable electrospinning processes remains a critical factor for industrial adoption. Current green electrospinning technologies face throughput limitations that increase production costs by approximately 25-40% compared to conventional methods. However, emerging multi-needle and needleless electrospinning systems are narrowing this gap while maintaining environmental benefits, suggesting that economic viability of sustainable approaches is within reach for large-scale implementation within the next 3-5 years.

Regulatory frameworks worldwide are increasingly emphasizing reduced environmental impact in electronics manufacturing, with particular focus on restricted substances and carbon footprint reduction. Companies adopting sustainable electrospinning technologies for heat-resistant materials may gain competitive advantages through compliance with emerging regulations and alignment with consumer preferences for environmentally responsible electronics.

Recent advancements have focused on developing green electrospinning approaches that utilize environmentally benign solvents or water-based systems. These innovations have demonstrated up to 65% reduction in harmful emissions compared to conventional methods while maintaining the thermal performance requirements for electronic applications. Additionally, the precise fiber deposition characteristic of electrospinning minimizes material waste, with studies reporting material efficiency rates exceeding 90% compared to 60-70% for traditional manufacturing processes.

Life cycle assessments of electrospun heat-resistant materials reveal notable sustainability benefits in the operational phase of electronics. The superior thermal management properties of these materials extend device lifespan by an estimated 30-40%, thereby reducing electronic waste generation. Furthermore, the lightweight nature of electrospun materials contributes to energy savings during transportation and operation of electronic devices, with potential energy reductions of 15-20% observed in certain applications.

End-of-life considerations present both challenges and opportunities. While composite electrospun materials may be difficult to recycle due to their complex multi-material composition, research into biodegradable polymer matrices for electrospun fibers shows promise. Several laboratories have successfully developed heat-resistant nanofibers incorporating up to 30% bio-based content without compromising thermal stability, representing a significant step toward circular economy principles in electronics manufacturing.

The scalability of sustainable electrospinning processes remains a critical factor for industrial adoption. Current green electrospinning technologies face throughput limitations that increase production costs by approximately 25-40% compared to conventional methods. However, emerging multi-needle and needleless electrospinning systems are narrowing this gap while maintaining environmental benefits, suggesting that economic viability of sustainable approaches is within reach for large-scale implementation within the next 3-5 years.

Regulatory frameworks worldwide are increasingly emphasizing reduced environmental impact in electronics manufacturing, with particular focus on restricted substances and carbon footprint reduction. Companies adopting sustainable electrospinning technologies for heat-resistant materials may gain competitive advantages through compliance with emerging regulations and alignment with consumer preferences for environmentally responsible electronics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!