Emerging Opportunities in the Electrospinning Equipment Market

SEP 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrospinning Technology Evolution and Objectives

Electrospinning technology has evolved significantly since its inception in the early 20th century. The fundamental principle, discovered by Formhals in 1934, involves applying high voltage to a polymer solution to create ultrafine fibers. This technology remained largely academic until the 1990s when researchers began exploring its potential for advanced material applications. The evolution accelerated in the early 2000s with the development of more sophisticated equipment capable of controlling fiber diameter, orientation, and morphology with greater precision.

The technological trajectory has been marked by several key innovations, including the transition from single-needle to multi-needle and needleless systems, enabling industrial-scale production. Coaxial electrospinning emerged in the mid-2000s, allowing the creation of core-shell nanofibers with enhanced functionality. Recent advancements include the integration of environmental control systems, real-time monitoring capabilities, and automation features that significantly improve reproducibility and quality control.

Current electrospinning equipment ranges from laboratory-scale devices to industrial production systems. The market has witnessed a shift from basic manual setups to sophisticated computer-controlled platforms with multiple functionalities. Modern systems incorporate features such as climate control chambers, multi-axis collectors, and programmable deposition patterns, expanding the versatility and application scope of electrospun materials.

The primary objective of electrospinning technology development is to bridge the gap between laboratory research and commercial production. This involves addressing challenges related to scalability, process control, and cost-effectiveness. Specific technical goals include enhancing throughput rates while maintaining fiber quality, developing more energy-efficient systems, and creating versatile platforms capable of processing a wider range of polymers and composite materials.

Another critical objective is the standardization of electrospinning processes and equipment specifications to ensure consistency across different manufacturing environments. This standardization is essential for the technology's adoption in regulated industries such as healthcare and aerospace, where material performance and reliability are paramount.

Looking forward, the technology aims to incorporate smart manufacturing principles, including IoT connectivity, AI-driven process optimization, and predictive maintenance capabilities. These advancements will enable more adaptive production systems that can automatically adjust parameters based on real-time feedback, further enhancing efficiency and product quality. The ultimate goal is to establish electrospinning as a mainstream manufacturing technology for high-value materials across multiple industries.

The technological trajectory has been marked by several key innovations, including the transition from single-needle to multi-needle and needleless systems, enabling industrial-scale production. Coaxial electrospinning emerged in the mid-2000s, allowing the creation of core-shell nanofibers with enhanced functionality. Recent advancements include the integration of environmental control systems, real-time monitoring capabilities, and automation features that significantly improve reproducibility and quality control.

Current electrospinning equipment ranges from laboratory-scale devices to industrial production systems. The market has witnessed a shift from basic manual setups to sophisticated computer-controlled platforms with multiple functionalities. Modern systems incorporate features such as climate control chambers, multi-axis collectors, and programmable deposition patterns, expanding the versatility and application scope of electrospun materials.

The primary objective of electrospinning technology development is to bridge the gap between laboratory research and commercial production. This involves addressing challenges related to scalability, process control, and cost-effectiveness. Specific technical goals include enhancing throughput rates while maintaining fiber quality, developing more energy-efficient systems, and creating versatile platforms capable of processing a wider range of polymers and composite materials.

Another critical objective is the standardization of electrospinning processes and equipment specifications to ensure consistency across different manufacturing environments. This standardization is essential for the technology's adoption in regulated industries such as healthcare and aerospace, where material performance and reliability are paramount.

Looking forward, the technology aims to incorporate smart manufacturing principles, including IoT connectivity, AI-driven process optimization, and predictive maintenance capabilities. These advancements will enable more adaptive production systems that can automatically adjust parameters based on real-time feedback, further enhancing efficiency and product quality. The ultimate goal is to establish electrospinning as a mainstream manufacturing technology for high-value materials across multiple industries.

Market Demand Analysis for Electrospinning Equipment

The electrospinning equipment market has witnessed significant growth in recent years, driven primarily by expanding applications across multiple industries. The global market value reached approximately $2.3 billion in 2022 and is projected to grow at a compound annual growth rate of 7.8% through 2028. This robust growth trajectory reflects the increasing adoption of nanofiber technologies across diverse sectors including healthcare, filtration, energy storage, and textiles.

Healthcare applications represent the largest market segment, accounting for nearly 40% of the total demand. Within this sector, tissue engineering and drug delivery systems are experiencing particularly strong growth due to advancements in regenerative medicine and personalized healthcare approaches. The demand for specialized electrospinning equipment capable of producing biocompatible scaffolds with precise fiber architectures has increased by over 25% in the past three years.

The filtration industry constitutes the second-largest market segment, driven by stringent environmental regulations and growing air and water quality concerns globally. High-efficiency particulate air (HEPA) filters incorporating electrospun nanofibers demonstrate superior filtration efficiency, creating substantial demand for industrial-scale electrospinning systems. This segment is expected to grow at 9.2% annually through 2027.

Energy storage applications, particularly in battery separator membranes and supercapacitor components, represent the fastest-growing segment with a projected growth rate of 12.5% annually. The transition toward renewable energy and electric vehicles has significantly accelerated demand for high-performance energy storage solutions incorporating nanofiber technologies.

Geographically, North America and Europe currently dominate the market with combined market share of 65%, primarily due to extensive research activities and established manufacturing infrastructure. However, the Asia-Pacific region is emerging as the fastest-growing market, with China, South Korea, and India leading regional growth at rates exceeding 10% annually.

Customer segmentation reveals that academic and research institutions account for approximately 35% of current equipment purchases, while industrial end-users represent 55%, with the remainder attributed to government laboratories and specialized service providers. The industrial segment is projected to grow most rapidly as commercialization of nanofiber applications accelerates.

A notable market trend is the increasing demand for modular, scalable electrospinning systems that can transition seamlessly from laboratory research to industrial production. Equipment manufacturers are responding with integrated solutions featuring advanced process control capabilities, in-line quality monitoring, and enhanced automation features to improve production efficiency and consistency.

Healthcare applications represent the largest market segment, accounting for nearly 40% of the total demand. Within this sector, tissue engineering and drug delivery systems are experiencing particularly strong growth due to advancements in regenerative medicine and personalized healthcare approaches. The demand for specialized electrospinning equipment capable of producing biocompatible scaffolds with precise fiber architectures has increased by over 25% in the past three years.

The filtration industry constitutes the second-largest market segment, driven by stringent environmental regulations and growing air and water quality concerns globally. High-efficiency particulate air (HEPA) filters incorporating electrospun nanofibers demonstrate superior filtration efficiency, creating substantial demand for industrial-scale electrospinning systems. This segment is expected to grow at 9.2% annually through 2027.

Energy storage applications, particularly in battery separator membranes and supercapacitor components, represent the fastest-growing segment with a projected growth rate of 12.5% annually. The transition toward renewable energy and electric vehicles has significantly accelerated demand for high-performance energy storage solutions incorporating nanofiber technologies.

Geographically, North America and Europe currently dominate the market with combined market share of 65%, primarily due to extensive research activities and established manufacturing infrastructure. However, the Asia-Pacific region is emerging as the fastest-growing market, with China, South Korea, and India leading regional growth at rates exceeding 10% annually.

Customer segmentation reveals that academic and research institutions account for approximately 35% of current equipment purchases, while industrial end-users represent 55%, with the remainder attributed to government laboratories and specialized service providers. The industrial segment is projected to grow most rapidly as commercialization of nanofiber applications accelerates.

A notable market trend is the increasing demand for modular, scalable electrospinning systems that can transition seamlessly from laboratory research to industrial production. Equipment manufacturers are responding with integrated solutions featuring advanced process control capabilities, in-line quality monitoring, and enhanced automation features to improve production efficiency and consistency.

Current State and Technical Barriers in Electrospinning

Electrospinning technology has evolved significantly over the past two decades, transitioning from laboratory-scale research to commercial applications. Currently, the global electrospinning equipment market is experiencing robust growth, valued at approximately $2.3 billion in 2022 with projections to reach $3.8 billion by 2027, representing a CAGR of 10.6%. This growth is primarily driven by increasing applications in healthcare, filtration, energy storage, and textile industries.

Despite this positive trajectory, the technology faces several critical technical barriers. The most significant challenge remains scalability - traditional electrospinning setups typically produce only 0.1-1 g/h of nanofibers, insufficient for large-scale industrial applications. Multi-needle and needleless systems have emerged as potential solutions, increasing production to 10-50 g/h, but still fall short of industrial demands that often require hundreds of grams per hour.

Process stability represents another major hurdle. Environmental factors such as humidity (optimal range 30-60%) and temperature (ideal range 20-25°C) significantly impact fiber formation. Current systems struggle to maintain consistent fiber morphology during extended production runs, with quality degradation typically occurring after 4-6 hours of continuous operation. This instability necessitates frequent system adjustments and quality control interventions.

Material limitations also constrain market expansion. While PVA, PEO, and PVDF polymers process relatively easily, many high-performance polymers like PEEK and PEI require specialized solvents and processing conditions. The equipment capable of handling these advanced materials remains limited, with only about 15% of commercial systems offering this capability, creating a significant market gap.

Energy efficiency presents another challenge, with conventional systems consuming 0.5-2 kWh per gram of nanofiber produced. This high energy requirement makes electrospinning less economically viable for certain applications compared to alternative manufacturing methods like meltblowing, which typically consumes 0.1-0.3 kWh per gram of material.

Precision control systems remain underdeveloped in many commercial offerings. While high-end research equipment incorporates advanced monitoring for parameters such as electric field strength, solution viscosity, and fiber diameter, most industrial systems lack real-time feedback mechanisms. This results in batch-to-batch variations of 15-30% in fiber properties, unacceptable for applications requiring strict quality standards.

Geographically, North America and Europe dominate equipment manufacturing with approximately 65% market share, while Asia-Pacific represents the fastest-growing market for implementation. This distribution creates challenges in technology transfer and adaptation to different manufacturing environments and regulatory frameworks across regions.

Despite this positive trajectory, the technology faces several critical technical barriers. The most significant challenge remains scalability - traditional electrospinning setups typically produce only 0.1-1 g/h of nanofibers, insufficient for large-scale industrial applications. Multi-needle and needleless systems have emerged as potential solutions, increasing production to 10-50 g/h, but still fall short of industrial demands that often require hundreds of grams per hour.

Process stability represents another major hurdle. Environmental factors such as humidity (optimal range 30-60%) and temperature (ideal range 20-25°C) significantly impact fiber formation. Current systems struggle to maintain consistent fiber morphology during extended production runs, with quality degradation typically occurring after 4-6 hours of continuous operation. This instability necessitates frequent system adjustments and quality control interventions.

Material limitations also constrain market expansion. While PVA, PEO, and PVDF polymers process relatively easily, many high-performance polymers like PEEK and PEI require specialized solvents and processing conditions. The equipment capable of handling these advanced materials remains limited, with only about 15% of commercial systems offering this capability, creating a significant market gap.

Energy efficiency presents another challenge, with conventional systems consuming 0.5-2 kWh per gram of nanofiber produced. This high energy requirement makes electrospinning less economically viable for certain applications compared to alternative manufacturing methods like meltblowing, which typically consumes 0.1-0.3 kWh per gram of material.

Precision control systems remain underdeveloped in many commercial offerings. While high-end research equipment incorporates advanced monitoring for parameters such as electric field strength, solution viscosity, and fiber diameter, most industrial systems lack real-time feedback mechanisms. This results in batch-to-batch variations of 15-30% in fiber properties, unacceptable for applications requiring strict quality standards.

Geographically, North America and Europe dominate equipment manufacturing with approximately 65% market share, while Asia-Pacific represents the fastest-growing market for implementation. This distribution creates challenges in technology transfer and adaptation to different manufacturing environments and regulatory frameworks across regions.

Current Technical Solutions in Electrospinning Equipment

01 Electrospinning apparatus design and components

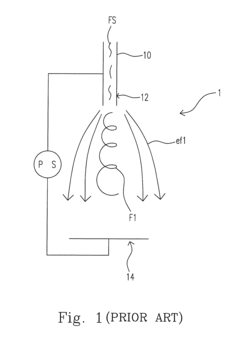

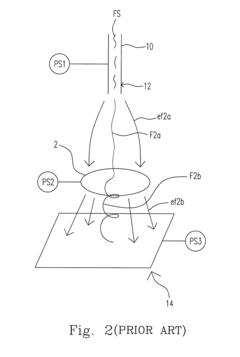

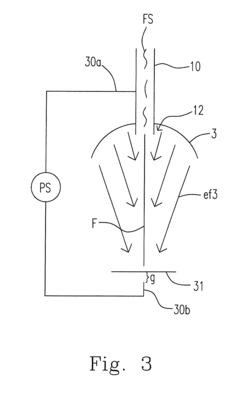

Electrospinning equipment typically consists of several key components including a high voltage power supply, a spinneret (needle or nozzle), a syringe pump for polymer solution delivery, and a collector. The design of these components significantly affects the quality and properties of the resulting nanofibers. Various modifications to the basic setup include multi-needle systems, rotating collectors, and temperature-controlled chambers to enhance production efficiency and fiber quality.- Electrospinning apparatus design and components: Electrospinning equipment typically consists of several key components including a high voltage power supply, a spinneret (needle or nozzle), a syringe pump for polymer solution delivery, and a collector. The design of these components significantly affects the quality and properties of the resulting nanofibers. Various modifications to the basic setup include multiple spinnerets for increased production, rotating collectors for aligned fibers, and temperature control systems for process optimization.

- Multi-nozzle electrospinning systems: Multi-nozzle electrospinning systems have been developed to increase production efficiency and throughput. These systems feature multiple spinnerets arranged in various configurations, allowing for simultaneous production of nanofibers from different solutions or at different parameters. Advanced designs incorporate automated nozzle movement, independent control of each nozzle, and specialized collection systems to prevent interference between adjacent jets, resulting in more uniform fiber production at industrial scales.

- Collector designs for fiber alignment and patterning: Specialized collectors have been developed for controlling fiber deposition patterns and alignment. These include rotating drums or discs for producing aligned fibers, patterned conductive templates for creating structured fiber mats, and gap collectors for suspended fiber arrays. The collector design significantly influences the morphology, orientation, and macroscopic properties of the resulting nanofibrous materials, enabling tailored structures for specific applications in tissue engineering, filtration, and electronics.

- Environmental control systems for electrospinning: Environmental control systems are crucial components of advanced electrospinning equipment. These systems regulate temperature, humidity, and airflow within the spinning chamber to ensure consistent fiber formation. Controlled environments prevent solvent evaporation issues, reduce the effects of ambient conditions on the process, and enable the production of fibers with consistent morphology and properties. Some systems incorporate inert gas atmospheres for processing oxygen-sensitive materials or for safety when using volatile solvents.

- Automated and smart electrospinning systems: Modern electrospinning equipment incorporates automation and smart control features for improved process control and reproducibility. These systems include computerized interfaces for parameter adjustment, real-time monitoring of process variables, feedback control mechanisms, and data logging capabilities. Advanced equipment may feature machine learning algorithms to optimize processing conditions, automatic fault detection, and remote operation capabilities, making the electrospinning process more reliable and suitable for industrial-scale production of nanofibers.

02 Advanced collector systems for fiber alignment

Specialized collector systems are crucial in electrospinning equipment for controlling fiber deposition and alignment. These systems include rotating drums, parallel electrodes, and patterned collectors that enable the production of aligned nanofiber mats with controlled orientation. The collector design influences fiber morphology, diameter uniformity, and spatial arrangement, which are important for applications requiring specific mechanical or functional properties.Expand Specific Solutions03 Multi-jet and needleless electrospinning systems

To overcome the production rate limitations of single-needle electrospinning, multi-jet and needleless systems have been developed. These systems utilize multiple spinnerets arranged in arrays or completely eliminate needles by using rotating cylinders, discs, or balls partially immersed in polymer solution. Such configurations significantly increase throughput while maintaining fiber quality, making them suitable for industrial-scale production of nanofibers.Expand Specific Solutions04 Environmental control systems for electrospinning

Environmental parameters such as temperature, humidity, and air flow significantly affect the electrospinning process. Advanced electrospinning equipment incorporates environmental control systems including humidity regulators, temperature controllers, and laminar flow chambers. These systems help maintain consistent spinning conditions, resulting in more uniform fiber morphology and improved reproducibility of nanofiber properties.Expand Specific Solutions05 Automated and smart electrospinning systems

Modern electrospinning equipment features automation and smart control systems that monitor and adjust process parameters in real-time. These systems incorporate sensors for measuring solution viscosity, electric field strength, and fiber diameter, along with feedback control mechanisms to maintain optimal spinning conditions. Some advanced systems also include computer vision for quality control and machine learning algorithms to optimize process parameters for specific materials and target fiber properties.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The electrospinning equipment market is currently in a growth phase, characterized by increasing adoption across biomedical, filtration, and textile applications. The global market size is projected to expand significantly due to rising demand for nanofiber-based products in healthcare and environmental sectors. Technologically, the field shows varying maturity levels with established players like Corning, Inc. and Toshiba Corp. offering commercial solutions, while research institutions including MIT, Northwestern University, and Korea Advanced Institute of Science & Technology drive innovation. Companies like Arsenal Medical and Innovative Mechanical Engineering Technologies BV are developing specialized applications, while academic-industry partnerships between institutions like Donghua University and Taiwan Textile Research Institute are accelerating commercialization. The market exhibits a balanced ecosystem of commercial equipment manufacturers, specialized application developers, and research-focused organizations.

Taiwan Textile Research Institute

Technical Solution: Taiwan Textile Research Institute (TTRI) has developed advanced electrospinning equipment featuring multi-nozzle arrays that significantly increase production efficiency. Their systems incorporate precise environmental control chambers maintaining optimal temperature (20-30°C) and humidity (30-60%) for consistent fiber formation. TTRI's equipment utilizes proprietary high-voltage power supplies (up to 30kV) with exceptional stability (±0.1kV), enabling the production of nanofibers with diameters ranging from 50-500nm. Their technology includes automated collection systems with programmable movement patterns for creating aligned fiber structures and gradient materials. TTRI has also pioneered hybrid electrospinning systems that combine solution and melt electrospinning capabilities in a single platform, expanding the range of processable polymers and applications in filtration, medical textiles, and energy storage materials.

Strengths: Superior production efficiency through multi-nozzle design; exceptional environmental control for consistent quality; versatility through hybrid spinning capabilities. Weaknesses: Higher initial investment costs compared to basic systems; requires specialized technical expertise for operation and maintenance; system complexity may present challenges for smaller research operations.

Corning, Inc.

Technical Solution: Corning has developed proprietary electrospinning equipment focused on ceramic and glass fiber production, leveraging their materials expertise. Their systems feature specialized high-temperature spinnerets capable of operating at up to 300°C, allowing for processing of high-melting-point materials. Corning's equipment incorporates precision flow control systems that maintain material delivery with ±0.5% accuracy, critical for producing uniform fibers with diameters as small as 100nm. Their technology includes patented collector designs that enable the creation of complex 3D architectures and aligned fiber arrays for applications in filtration, catalysis, and energy storage. Corning's systems also feature integrated in-line characterization tools that monitor fiber formation in real-time, allowing for automated process adjustments to maintain quality. This equipment is particularly valuable for producing specialized ceramic membranes with controlled porosity and surface functionality.

Strengths: Exceptional capability for processing high-temperature materials; precision control systems for uniform fiber production; advanced collector designs for complex structures. Weaknesses: Systems are optimized primarily for ceramic/glass materials with limited polymer processing capabilities; higher cost compared to conventional polymer electrospinning equipment; requires specialized knowledge of ceramic processing.

Core Patents and Technical Literature Analysis

Equipment for electrospinning

PatentInactiveUS8540504B2

Innovation

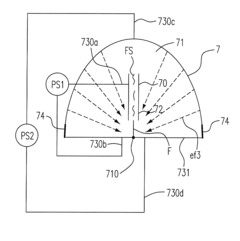

- The electrospinning equipment incorporates a guide unit with a bent structure extending from the spinneret towards the collector, coupled with a power supply featuring a first and second electrode, where the second electrode is positioned under the collector, creating a convergent electric field pattern that stabilizes the thread's path and reduces transverse fluctuations, allowing for stable deposition.

Cold part load and peak fire opportunities

PatentInactiveUS20180293600A1

Innovation

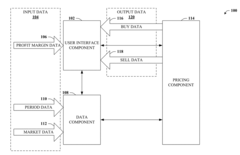

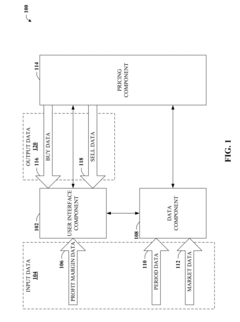

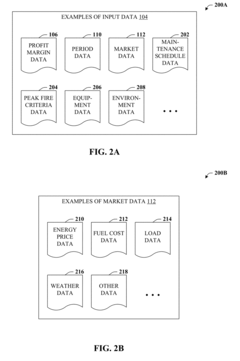

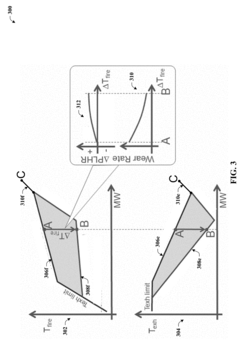

- A system that determines buy and sell data based on market conditions and profit margins to advise operating energy-producing equipment according to cold part load or peak fire protocols, balancing fuel consumption, equipment wear, and financial opportunities.

Material Science Advancements for Electrospinning

Recent advancements in material science have significantly expanded the capabilities and applications of electrospinning technology. The development of novel polymers with enhanced properties has enabled the production of nanofibers with superior mechanical strength, biocompatibility, and functionality. These materials include biodegradable polymers like polycaprolactone (PCL) and poly(lactic-co-glycolic acid) (PLGA), which have revolutionized tissue engineering applications by providing scaffolds that mimic natural extracellular matrices.

Composite materials represent another frontier in electrospinning innovation. By incorporating nanoparticles, carbon nanotubes, or graphene into polymer solutions, researchers have created nanofibers with enhanced electrical conductivity, antimicrobial properties, and sensing capabilities. These composite nanofibers are finding applications in smart textiles, wearable electronics, and advanced filtration systems.

The emergence of stimuli-responsive materials has opened new possibilities for electrospun products. These materials can change their properties in response to environmental factors such as temperature, pH, or light. For instance, thermo-responsive polymers like poly(N-isopropylacrylamide) can be electrospun into fibers that contract or expand with temperature changes, enabling applications in controlled drug delivery systems and smart textiles.

Coaxial electrospinning techniques have enabled the production of core-shell nanofibers, where different materials form the core and shell of each fiber. This advancement allows for encapsulation of active ingredients, controlled release of drugs, or creation of fibers with dual functionality. The technique has been particularly valuable in pharmaceutical applications and advanced filtration systems.

Green chemistry approaches are increasingly influencing electrospinning material development. Researchers are exploring sustainable alternatives to traditional petroleum-based polymers, including cellulose derivatives, chitosan, and other biopolymers. These materials not only reduce environmental impact but often provide unique properties beneficial for biomedical applications due to their inherent biocompatibility.

Surface modification techniques have enhanced the functionality of electrospun fibers. Methods such as plasma treatment, chemical functionalization, and coating processes allow tailoring of surface properties like hydrophilicity, protein adsorption, and cell adhesion. These modifications are crucial for biomedical applications where specific cell-material interactions are desired.

The integration of conductive polymers like polyaniline and polypyrrole into electrospinning has enabled the development of electrically active nanofibers. These materials are finding applications in energy storage devices, sensors, and neural interfaces, where electrical conductivity combined with the high surface area of nanofibers provides unique advantages.

Composite materials represent another frontier in electrospinning innovation. By incorporating nanoparticles, carbon nanotubes, or graphene into polymer solutions, researchers have created nanofibers with enhanced electrical conductivity, antimicrobial properties, and sensing capabilities. These composite nanofibers are finding applications in smart textiles, wearable electronics, and advanced filtration systems.

The emergence of stimuli-responsive materials has opened new possibilities for electrospun products. These materials can change their properties in response to environmental factors such as temperature, pH, or light. For instance, thermo-responsive polymers like poly(N-isopropylacrylamide) can be electrospun into fibers that contract or expand with temperature changes, enabling applications in controlled drug delivery systems and smart textiles.

Coaxial electrospinning techniques have enabled the production of core-shell nanofibers, where different materials form the core and shell of each fiber. This advancement allows for encapsulation of active ingredients, controlled release of drugs, or creation of fibers with dual functionality. The technique has been particularly valuable in pharmaceutical applications and advanced filtration systems.

Green chemistry approaches are increasingly influencing electrospinning material development. Researchers are exploring sustainable alternatives to traditional petroleum-based polymers, including cellulose derivatives, chitosan, and other biopolymers. These materials not only reduce environmental impact but often provide unique properties beneficial for biomedical applications due to their inherent biocompatibility.

Surface modification techniques have enhanced the functionality of electrospun fibers. Methods such as plasma treatment, chemical functionalization, and coating processes allow tailoring of surface properties like hydrophilicity, protein adsorption, and cell adhesion. These modifications are crucial for biomedical applications where specific cell-material interactions are desired.

The integration of conductive polymers like polyaniline and polypyrrole into electrospinning has enabled the development of electrically active nanofibers. These materials are finding applications in energy storage devices, sensors, and neural interfaces, where electrical conductivity combined with the high surface area of nanofibers provides unique advantages.

Sustainability and Green Manufacturing Considerations

The electrospinning equipment market is increasingly embracing sustainability principles as environmental concerns become more prominent across manufacturing sectors. Current electrospinning processes often involve significant solvent usage, creating environmental challenges through volatile organic compound (VOC) emissions and waste generation. Leading manufacturers are responding by developing green electrospinning technologies that utilize water-based polymer solutions and biodegradable solvents, substantially reducing environmental impact while maintaining production efficiency.

Energy consumption represents another critical sustainability concern in electrospinning operations. Traditional equipment typically requires high voltage supplies operating continuously, resulting in considerable energy usage. Recent innovations include energy-efficient power supplies with intelligent power management systems that optimize electricity consumption by up to 40% compared to conventional models. Additionally, several manufacturers have integrated renewable energy compatibility into their equipment designs, allowing operations to be powered by solar or other sustainable energy sources.

Material sustainability is evolving rapidly within the electrospinning sector. Research indicates growing adoption of bio-based polymers derived from renewable resources such as cellulose, chitosan, and polylactic acid (PLA). These materials not only reduce dependence on petroleum-based polymers but also offer enhanced biodegradability characteristics. Market analysis shows that equipment capable of processing these sustainable materials is experiencing 25% faster growth than conventional systems.

Circular economy principles are beginning to influence equipment design philosophy. Next-generation electrospinning systems increasingly feature modular construction that facilitates repair, component replacement, and eventual recycling. Some manufacturers have implemented take-back programs for end-of-life equipment, recovering valuable materials and reducing electronic waste. These initiatives align with extended producer responsibility frameworks being adopted globally.

Manufacturing processes for electrospinning equipment itself are undergoing sustainability transformations. Industry leaders are implementing lean manufacturing techniques that minimize material waste during production. Advanced manufacturing facilities utilize energy-efficient climate control systems and optimize production workflows to reduce carbon footprints. Several prominent manufacturers have published sustainability reports documenting significant reductions in water usage, energy consumption, and waste generation in their production facilities.

Regulatory compliance is becoming a market differentiator as environmental standards tighten worldwide. Equipment designed with built-in emissions control systems and solvent recovery capabilities commands premium pricing and enjoys preferential status in environmentally conscious markets. Forward-thinking manufacturers are proactively designing equipment that exceeds current environmental regulations, anticipating stricter future requirements and positioning their products advantageously for long-term market success.

Energy consumption represents another critical sustainability concern in electrospinning operations. Traditional equipment typically requires high voltage supplies operating continuously, resulting in considerable energy usage. Recent innovations include energy-efficient power supplies with intelligent power management systems that optimize electricity consumption by up to 40% compared to conventional models. Additionally, several manufacturers have integrated renewable energy compatibility into their equipment designs, allowing operations to be powered by solar or other sustainable energy sources.

Material sustainability is evolving rapidly within the electrospinning sector. Research indicates growing adoption of bio-based polymers derived from renewable resources such as cellulose, chitosan, and polylactic acid (PLA). These materials not only reduce dependence on petroleum-based polymers but also offer enhanced biodegradability characteristics. Market analysis shows that equipment capable of processing these sustainable materials is experiencing 25% faster growth than conventional systems.

Circular economy principles are beginning to influence equipment design philosophy. Next-generation electrospinning systems increasingly feature modular construction that facilitates repair, component replacement, and eventual recycling. Some manufacturers have implemented take-back programs for end-of-life equipment, recovering valuable materials and reducing electronic waste. These initiatives align with extended producer responsibility frameworks being adopted globally.

Manufacturing processes for electrospinning equipment itself are undergoing sustainability transformations. Industry leaders are implementing lean manufacturing techniques that minimize material waste during production. Advanced manufacturing facilities utilize energy-efficient climate control systems and optimize production workflows to reduce carbon footprints. Several prominent manufacturers have published sustainability reports documenting significant reductions in water usage, energy consumption, and waste generation in their production facilities.

Regulatory compliance is becoming a market differentiator as environmental standards tighten worldwide. Equipment designed with built-in emissions control systems and solvent recovery capabilities commands premium pricing and enjoys preferential status in environmentally conscious markets. Forward-thinking manufacturers are proactively designing equipment that exceeds current environmental regulations, anticipating stricter future requirements and positioning their products advantageously for long-term market success.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!