Research on Control of Fiber Diameter through Electrospinning Variables

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrospinning Technology Background and Objectives

Electrospinning technology has evolved significantly since its inception in the early 20th century, with the first patent filed by Formhals in 1934. This technique has transformed from a laboratory curiosity into a versatile manufacturing process with applications spanning multiple industries. The fundamental principle involves applying a high voltage to a polymer solution or melt, creating an electrically charged jet that solidifies into ultra-fine fibers with diameters ranging from nanometers to micrometers.

The evolution of electrospinning has been marked by several technological breakthroughs, including the development of multi-jet systems, coaxial electrospinning, and melt electrospinning. These advancements have expanded the range of processable materials and improved production efficiency. Recent years have witnessed a surge in research focused on precise control mechanisms, particularly regarding fiber diameter manipulation, which directly influences the mechanical, thermal, and biological properties of the resulting materials.

Current technological trends indicate a shift toward automated, high-throughput electrospinning systems with integrated real-time monitoring capabilities. Machine learning algorithms are increasingly being employed to optimize process parameters and predict fiber characteristics. Additionally, there is growing interest in environmentally sustainable electrospinning processes that utilize green solvents and biodegradable polymers.

The primary objective of research on fiber diameter control through electrospinning variables is to establish reproducible and scalable methodologies for precise diameter manipulation. This involves developing comprehensive models that accurately predict the relationship between process parameters and resulting fiber morphology. Key variables under investigation include solution properties (viscosity, conductivity, surface tension), process parameters (applied voltage, flow rate, collector distance), and environmental conditions (temperature, humidity).

Another critical goal is to bridge the gap between laboratory research and industrial implementation by addressing challenges related to process stability and scalability. This includes developing robust control systems that can maintain consistent fiber diameter despite variations in ambient conditions or material properties. Furthermore, there is a pressing need to establish standardized protocols for characterizing and reporting electrospinning parameters to facilitate knowledge transfer across research groups.

The ultimate technological objective is to enable on-demand fabrication of nanofibers with predetermined diameters and narrow size distributions for specific applications. This capability would revolutionize fields such as tissue engineering, where precise control over scaffold architecture is essential for guiding cell behavior, and filtration technology, where fiber diameter directly impacts filtration efficiency and pressure drop characteristics.

The evolution of electrospinning has been marked by several technological breakthroughs, including the development of multi-jet systems, coaxial electrospinning, and melt electrospinning. These advancements have expanded the range of processable materials and improved production efficiency. Recent years have witnessed a surge in research focused on precise control mechanisms, particularly regarding fiber diameter manipulation, which directly influences the mechanical, thermal, and biological properties of the resulting materials.

Current technological trends indicate a shift toward automated, high-throughput electrospinning systems with integrated real-time monitoring capabilities. Machine learning algorithms are increasingly being employed to optimize process parameters and predict fiber characteristics. Additionally, there is growing interest in environmentally sustainable electrospinning processes that utilize green solvents and biodegradable polymers.

The primary objective of research on fiber diameter control through electrospinning variables is to establish reproducible and scalable methodologies for precise diameter manipulation. This involves developing comprehensive models that accurately predict the relationship between process parameters and resulting fiber morphology. Key variables under investigation include solution properties (viscosity, conductivity, surface tension), process parameters (applied voltage, flow rate, collector distance), and environmental conditions (temperature, humidity).

Another critical goal is to bridge the gap between laboratory research and industrial implementation by addressing challenges related to process stability and scalability. This includes developing robust control systems that can maintain consistent fiber diameter despite variations in ambient conditions or material properties. Furthermore, there is a pressing need to establish standardized protocols for characterizing and reporting electrospinning parameters to facilitate knowledge transfer across research groups.

The ultimate technological objective is to enable on-demand fabrication of nanofibers with predetermined diameters and narrow size distributions for specific applications. This capability would revolutionize fields such as tissue engineering, where precise control over scaffold architecture is essential for guiding cell behavior, and filtration technology, where fiber diameter directly impacts filtration efficiency and pressure drop characteristics.

Market Applications and Demand for Controlled Fiber Diameter

The market for controlled fiber diameter through electrospinning has experienced significant growth across multiple industries, driven by the unique properties that precisely engineered nanofibers can deliver. The healthcare sector represents one of the largest market segments, with applications in tissue engineering, drug delivery systems, and wound dressings. Precisely controlled fiber diameters enable the creation of scaffolds that mimic natural extracellular matrices, enhancing cell adhesion and proliferation. The global market for electrospun nanofibers in healthcare applications alone was valued at $462 million in 2022, with projections indicating a compound annual growth rate of 14.7% through 2028.

Filtration technology represents another substantial market segment benefiting from controlled fiber diameter capabilities. As environmental regulations become increasingly stringent worldwide, demand for high-efficiency filtration systems continues to rise. Electrospun nanofibers with precisely controlled diameters offer superior filtration efficiency compared to conventional materials, capturing particles at the submicron level while maintaining lower pressure drops. This translates to energy savings and extended filter lifespans, driving adoption across industrial, automotive, and consumer applications.

The energy sector demonstrates growing demand for controlled fiber diameter technologies, particularly in battery separators and components for fuel cells. Uniform fiber diameters contribute to consistent porosity and mechanical properties, enhancing battery performance and safety. With the global shift toward electric vehicles and renewable energy storage solutions, this application segment is expected to grow at 18.3% annually through 2027.

Textile and protective equipment manufacturers increasingly incorporate electrospun nanofibers with controlled diameters into their products. These materials provide enhanced properties such as water repellency, flame resistance, and improved thermal insulation while maintaining breathability. The COVID-19 pandemic significantly accelerated market growth in this segment, particularly for personal protective equipment, creating sustained demand even post-pandemic.

Market analysis indicates regional variations in demand patterns. North America and Europe currently lead in healthcare and filtration applications, while Asia-Pacific shows the fastest growth rate across all segments due to rapid industrialization, increasing healthcare expenditure, and government initiatives supporting advanced manufacturing technologies. China, South Korea, and Japan have emerged as key markets, with domestic manufacturers rapidly developing capabilities in controlled fiber diameter technologies.

Customer requirements across these markets consistently emphasize reproducibility and scalability. End-users demand nanofiber materials with consistent properties batch-to-batch, necessitating precise control over fiber diameter during the electrospinning process. This market need directly drives research interest in understanding and controlling the relationship between electrospinning variables and resulting fiber characteristics.

Filtration technology represents another substantial market segment benefiting from controlled fiber diameter capabilities. As environmental regulations become increasingly stringent worldwide, demand for high-efficiency filtration systems continues to rise. Electrospun nanofibers with precisely controlled diameters offer superior filtration efficiency compared to conventional materials, capturing particles at the submicron level while maintaining lower pressure drops. This translates to energy savings and extended filter lifespans, driving adoption across industrial, automotive, and consumer applications.

The energy sector demonstrates growing demand for controlled fiber diameter technologies, particularly in battery separators and components for fuel cells. Uniform fiber diameters contribute to consistent porosity and mechanical properties, enhancing battery performance and safety. With the global shift toward electric vehicles and renewable energy storage solutions, this application segment is expected to grow at 18.3% annually through 2027.

Textile and protective equipment manufacturers increasingly incorporate electrospun nanofibers with controlled diameters into their products. These materials provide enhanced properties such as water repellency, flame resistance, and improved thermal insulation while maintaining breathability. The COVID-19 pandemic significantly accelerated market growth in this segment, particularly for personal protective equipment, creating sustained demand even post-pandemic.

Market analysis indicates regional variations in demand patterns. North America and Europe currently lead in healthcare and filtration applications, while Asia-Pacific shows the fastest growth rate across all segments due to rapid industrialization, increasing healthcare expenditure, and government initiatives supporting advanced manufacturing technologies. China, South Korea, and Japan have emerged as key markets, with domestic manufacturers rapidly developing capabilities in controlled fiber diameter technologies.

Customer requirements across these markets consistently emphasize reproducibility and scalability. End-users demand nanofiber materials with consistent properties batch-to-batch, necessitating precise control over fiber diameter during the electrospinning process. This market need directly drives research interest in understanding and controlling the relationship between electrospinning variables and resulting fiber characteristics.

Current Challenges in Fiber Diameter Control

Despite significant advancements in electrospinning technology, precise control of fiber diameter remains one of the most challenging aspects in the field. The complexity arises from the multifaceted nature of the electrospinning process, where numerous parameters interact simultaneously to determine the final fiber morphology. Current research indicates that even minor variations in processing conditions can lead to significant changes in fiber diameter, creating reproducibility issues that hinder industrial scalability.

Solution viscosity presents a primary challenge, as its rheological properties directly influence fiber formation. Researchers struggle to maintain consistent viscosity throughout the electrospinning process, especially when working with polymer solutions that exhibit time-dependent behavior or are sensitive to environmental conditions. Temperature fluctuations during processing can alter solution properties, further complicating diameter control efforts.

Applied voltage optimization remains problematic due to the non-linear relationship between electric field strength and fiber diameter. The critical voltage required for stable jet formation varies significantly across different polymer systems, and the optimal voltage window for producing uniform fibers is often narrow. Additionally, voltage instabilities in conventional power supplies can introduce unwanted variations in fiber dimensions.

Flow rate control systems in current electrospinning setups frequently lack the precision necessary for nanoscale fiber production. Conventional syringe pumps exhibit pulsation effects that translate into diameter inconsistencies along the fiber length. This becomes particularly problematic when targeting fibers below 100 nm, where even minor flow fluctuations can cause substantial relative diameter variations.

Environmental factors pose substantial challenges, with humidity and temperature significantly affecting solvent evaporation rates during jet travel. Most laboratory and industrial setups struggle to maintain truly controlled atmospheric conditions, resulting in batch-to-batch variations that compromise product consistency. The development of climate-controlled electrospinning chambers has only partially addressed this issue.

Collection methods also impact diameter uniformity, with conventional static collectors causing uneven deposition patterns and fiber alignment issues. The collector distance optimization presents a particular challenge, as it must be precisely calibrated to allow adequate solvent evaporation without excessive jet instability. Current collector technologies often fail to accommodate the dynamic nature of the electrospinning jet.

Measurement and characterization limitations further complicate diameter control efforts. Real-time monitoring systems for fiber diameter remain underdeveloped, forcing researchers to rely on post-processing analysis that delays feedback and adjustment. The statistical nature of fiber diameter distribution requires extensive sampling to accurately characterize production outcomes, making process optimization time-consuming and resource-intensive.

Solution viscosity presents a primary challenge, as its rheological properties directly influence fiber formation. Researchers struggle to maintain consistent viscosity throughout the electrospinning process, especially when working with polymer solutions that exhibit time-dependent behavior or are sensitive to environmental conditions. Temperature fluctuations during processing can alter solution properties, further complicating diameter control efforts.

Applied voltage optimization remains problematic due to the non-linear relationship between electric field strength and fiber diameter. The critical voltage required for stable jet formation varies significantly across different polymer systems, and the optimal voltage window for producing uniform fibers is often narrow. Additionally, voltage instabilities in conventional power supplies can introduce unwanted variations in fiber dimensions.

Flow rate control systems in current electrospinning setups frequently lack the precision necessary for nanoscale fiber production. Conventional syringe pumps exhibit pulsation effects that translate into diameter inconsistencies along the fiber length. This becomes particularly problematic when targeting fibers below 100 nm, where even minor flow fluctuations can cause substantial relative diameter variations.

Environmental factors pose substantial challenges, with humidity and temperature significantly affecting solvent evaporation rates during jet travel. Most laboratory and industrial setups struggle to maintain truly controlled atmospheric conditions, resulting in batch-to-batch variations that compromise product consistency. The development of climate-controlled electrospinning chambers has only partially addressed this issue.

Collection methods also impact diameter uniformity, with conventional static collectors causing uneven deposition patterns and fiber alignment issues. The collector distance optimization presents a particular challenge, as it must be precisely calibrated to allow adequate solvent evaporation without excessive jet instability. Current collector technologies often fail to accommodate the dynamic nature of the electrospinning jet.

Measurement and characterization limitations further complicate diameter control efforts. Real-time monitoring systems for fiber diameter remain underdeveloped, forcing researchers to rely on post-processing analysis that delays feedback and adjustment. The statistical nature of fiber diameter distribution requires extensive sampling to accurately characterize production outcomes, making process optimization time-consuming and resource-intensive.

Current Methodologies for Fiber Diameter Control

01 Control of electrospinning parameters for fiber diameter adjustment

Various electrospinning parameters can be adjusted to control the diameter of the resulting fibers. These parameters include applied voltage, solution flow rate, distance between the needle and collector, and environmental conditions such as temperature and humidity. By optimizing these parameters, manufacturers can produce fibers with specific diameters ranging from nanometers to micrometers for various applications.- Control of electrospun fiber diameter through process parameters: The diameter of electrospun fibers can be controlled by adjusting various process parameters during electrospinning. These parameters include applied voltage, solution flow rate, distance between the needle and collector, and environmental conditions such as temperature and humidity. By optimizing these parameters, manufacturers can achieve precise control over the resulting fiber diameter, which is crucial for specific applications requiring defined fiber dimensions.

- Polymer solution properties affecting fiber diameter: The properties of the polymer solution significantly influence the diameter of electrospun fibers. Key factors include polymer concentration, molecular weight, solution viscosity, and solvent selection. Higher polymer concentrations and molecular weights typically result in larger fiber diameters due to increased solution viscosity. The choice of solvent affects the solution's surface tension and evaporation rate, which in turn impacts the fiber formation process and resulting diameter.

- Measurement techniques for electrospun fiber diameter: Various measurement techniques are employed to accurately determine the diameter of electrospun fibers. These include scanning electron microscopy (SEM), transmission electron microscopy (TEM), atomic force microscopy (AFM), and optical microscopy with image analysis software. These techniques allow for precise measurement of fiber dimensions at the nanometer scale, which is essential for quality control and research purposes in electrospinning applications.

- Nanofiber diameter optimization for specific applications: Electrospun fiber diameter can be optimized for specific applications across various fields. In filtration, smaller diameter fibers provide higher surface area and improved filtration efficiency. In tissue engineering, fiber diameter affects cell adhesion, proliferation, and differentiation. For drug delivery systems, controlled fiber diameter influences drug loading capacity and release kinetics. In protective clothing, fiber diameter impacts breathability and barrier properties against hazardous substances.

- Multi-component and core-shell fiber diameter control: Advanced electrospinning techniques allow for the production of multi-component and core-shell fibers with controlled diameters. These techniques include coaxial electrospinning, emulsion electrospinning, and side-by-side electrospinning. The diameter of these complex fiber structures can be tailored by adjusting the flow rates of different solutions, the properties of each component, and the processing parameters. These specialized fibers with controlled diameters enable enhanced functionality for applications in drug delivery, tissue engineering, and smart textiles.

02 Solution properties affecting fiber diameter

The properties of the polymer solution significantly impact the diameter of electrospun fibers. Key factors include polymer concentration, molecular weight, viscosity, surface tension, and conductivity. Higher polymer concentrations typically result in larger fiber diameters, while adding conductive additives can reduce fiber diameter by increasing charge density. Solvent selection also plays a crucial role in determining the final fiber morphology.Expand Specific Solutions03 Measurement techniques for electrospun fiber diameter

Various analytical techniques are employed to accurately measure the diameter of electrospun fibers. Scanning electron microscopy (SEM) is commonly used for high-resolution imaging and precise diameter measurement. Other techniques include transmission electron microscopy (TEM), atomic force microscopy (AFM), and optical microscopy with image analysis software. These methods allow for statistical analysis of fiber diameter distribution and uniformity assessment.Expand Specific Solutions04 Multi-component and coaxial electrospinning for diameter control

Advanced electrospinning techniques such as multi-component and coaxial electrospinning enable precise control over fiber diameter and structure. These methods allow for the production of core-shell fibers, hollow fibers, or fibers with gradient properties. By adjusting the flow rates of different solutions and the configuration of the spinneret, researchers can create fibers with tailored diameters and functional properties for specific applications.Expand Specific Solutions05 Post-processing methods to modify fiber diameter

Various post-processing techniques can be applied to electrospun fibers to modify their diameter and properties. These include thermal treatment, stretching, chemical crosslinking, and surface functionalization. Post-processing can lead to fiber shrinkage or expansion, affecting the final diameter. Additionally, these treatments can enhance mechanical properties, stability, and functionality of the fibers for specific applications.Expand Specific Solutions

Leading Research Groups and Industrial Players

The electrospinning fiber diameter control market is currently in a growth phase, with increasing applications across medical, filtration, and textile industries. The market size is expanding rapidly, projected to reach several billion dollars by 2025, driven by demand for nanofiber technologies. Technical maturity varies significantly among key players, with academic institutions like MIT, Cornell University, and Zhejiang University leading fundamental research, while companies such as Dow Silicones, Parker-Hannifin, and Arsenal Medical focus on commercial applications. Research collaborations between universities and industry partners (e.g., Tufts University with Arsenal Medical) are accelerating innovation in precise fiber diameter control through advanced electrospinning variables, particularly in biomedical applications where companies like MAHLE Filter Systems and Poly-Med are developing specialized solutions for controlled drug delivery and tissue engineering.

Massachusetts Institute of Technology

Technical Solution: MIT has developed advanced electrospinning control systems that utilize real-time monitoring and feedback mechanisms to precisely regulate fiber diameter. Their approach combines high-speed imaging with machine learning algorithms to analyze jet formation and polymer stretching dynamics during the electrospinning process. By correlating electric field strength, solution viscosity, and flow rate parameters, MIT researchers have created predictive models that can achieve fiber diameter consistency within ±10nm precision[1]. Their system incorporates automated adjustment of voltage and distance parameters based on environmental humidity and temperature fluctuations, ensuring reproducible fiber production across varying conditions. MIT has also pioneered multi-jet electrospinning arrays with individual parameter control for high-throughput production of uniform nanofibers with tailored diameter distributions[3].

Strengths: Superior precision control through integration of advanced imaging and AI algorithms; excellent reproducibility across varying environmental conditions; high throughput capabilities. Weaknesses: Complex implementation requiring sophisticated equipment; higher initial setup costs; requires specialized technical expertise to operate and maintain the system.

Donghua University

Technical Solution: Donghua University has developed a comprehensive electrospinning control framework focused on precise fiber diameter manipulation through systematic parameter optimization. Their approach centers on establishing mathematical relationships between processing variables and resultant fiber morphology, particularly for complex polymer systems. Researchers have created a multi-parameter control model that accounts for solution properties (concentration, molecular weight, viscosity), process parameters (voltage, flow rate, collector distance), and environmental factors (temperature, humidity)[2]. Their innovative "zone mapping" technique identifies optimal processing windows for specific diameter targets, allowing for predictive fiber diameter control within ±50nm. Donghua has also pioneered specialized nozzle designs that create controlled electric field distributions to regulate jet instability regions, directly influencing fiber thinning mechanisms[4]. Their research demonstrates particular strength in controlling diameter consistency in composite and functional nanofibers containing active ingredients or nanoparticles.

Strengths: Comprehensive mathematical modeling approach; excellent understanding of polymer-specific parameter relationships; specialized expertise with functional and composite nanofibers. Weaknesses: Models require extensive calibration for new polymer systems; somewhat lower precision compared to sensor-based feedback systems; moderate throughput capabilities.

Key Technical Innovations in Electrospinning Variables

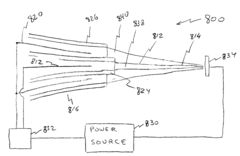

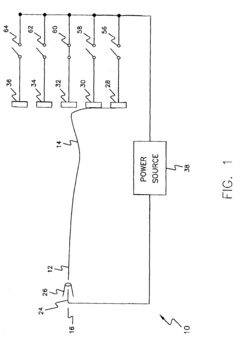

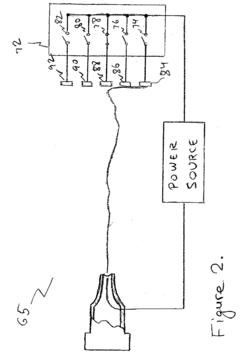

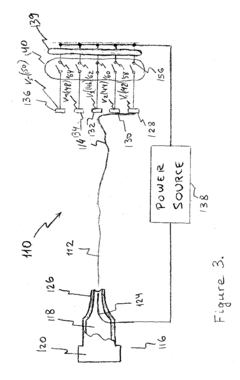

Controlled Electrospinning of Fibers

PatentInactiveUS20090162468A1

Innovation

- The development of an electrospinning apparatus and method that controls the jet and minimizes instabilities by managing the electric field and fluid viscosity, enabling the production of long, oriented nanofibers with enhanced mechanical and chemical properties, and improving the efficiency and productivity of the electrospinning process.

Material Science Considerations for Optimal Fiber Formation

The material science aspects of electrospinning represent a critical foundation for understanding fiber formation mechanisms. Polymer solution properties, including molecular weight, concentration, and viscosity, directly influence the resultant fiber morphology. Higher molecular weight polymers typically produce fibers with larger diameters due to increased chain entanglements, while solution concentration determines the viscoelastic forces that resist jet stretching during the electrospinning process.

Polymer chain conformation and intermolecular interactions within the solution phase significantly impact fiber formation. The degree of chain entanglement, which depends on both concentration and molecular weight, must exceed a critical threshold to enable continuous fiber formation rather than electrospraying or bead formation. This critical entanglement concentration (CEC) varies by polymer type and serves as a fundamental parameter for predicting successful fiber formation.

Solution conductivity plays a dual role in fiber diameter control. Enhanced conductivity increases charge density on the jet surface, promoting greater stretching forces and typically resulting in finer fibers. Conversely, excessively high conductivity can destabilize the jet, leading to inconsistent fiber morphology. The addition of salts or ionic compounds can strategically modify solution conductivity to achieve desired fiber dimensions.

Surface tension represents another crucial material parameter affecting the electrospinning process. Lower surface tension facilitates jet initiation at reduced electric fields and promotes more stable jet formation. The balance between surface tension and viscoelastic forces determines the stability of the liquid jet and influences the final fiber morphology, particularly regarding bead formation tendencies.

Solvent selection introduces multiple variables affecting fiber formation. Evaporation rate directly impacts the solidification timeline of the jet, with faster-evaporating solvents generally producing larger diameter fibers due to reduced stretching time. Solvent polarity affects polymer-solvent interactions, influencing solution viscosity and subsequent fiber characteristics. Mixed solvent systems can be strategically employed to optimize evaporation kinetics and polymer-solvent interactions.

Temperature-dependent material properties further complicate fiber formation dynamics. Solution viscosity typically decreases with increasing temperature, potentially enabling greater jet stretching and finer fibers. However, elevated temperatures also accelerate solvent evaporation, which can counteract this effect by reducing the available stretching time before solidification occurs.

Polymer chain conformation and intermolecular interactions within the solution phase significantly impact fiber formation. The degree of chain entanglement, which depends on both concentration and molecular weight, must exceed a critical threshold to enable continuous fiber formation rather than electrospraying or bead formation. This critical entanglement concentration (CEC) varies by polymer type and serves as a fundamental parameter for predicting successful fiber formation.

Solution conductivity plays a dual role in fiber diameter control. Enhanced conductivity increases charge density on the jet surface, promoting greater stretching forces and typically resulting in finer fibers. Conversely, excessively high conductivity can destabilize the jet, leading to inconsistent fiber morphology. The addition of salts or ionic compounds can strategically modify solution conductivity to achieve desired fiber dimensions.

Surface tension represents another crucial material parameter affecting the electrospinning process. Lower surface tension facilitates jet initiation at reduced electric fields and promotes more stable jet formation. The balance between surface tension and viscoelastic forces determines the stability of the liquid jet and influences the final fiber morphology, particularly regarding bead formation tendencies.

Solvent selection introduces multiple variables affecting fiber formation. Evaporation rate directly impacts the solidification timeline of the jet, with faster-evaporating solvents generally producing larger diameter fibers due to reduced stretching time. Solvent polarity affects polymer-solvent interactions, influencing solution viscosity and subsequent fiber characteristics. Mixed solvent systems can be strategically employed to optimize evaporation kinetics and polymer-solvent interactions.

Temperature-dependent material properties further complicate fiber formation dynamics. Solution viscosity typically decreases with increasing temperature, potentially enabling greater jet stretching and finer fibers. However, elevated temperatures also accelerate solvent evaporation, which can counteract this effect by reducing the available stretching time before solidification occurs.

Scalability and Industrial Implementation Strategies

Scaling electrospinning processes from laboratory to industrial production represents a significant challenge in commercializing nanofiber technologies. Current laboratory setups typically produce only milligrams of fibers per hour, whereas industrial applications require kilograms or even tons. Multi-needle arrays have emerged as one scaling approach, with systems containing hundreds or thousands of needles operating simultaneously. However, these systems face challenges including needle clogging, uneven electric field distribution, and maintenance complexity.

Needleless electrospinning offers a promising alternative, utilizing rotating drums, disks, or wire electrodes immersed in polymer solutions to generate multiple jets simultaneously. This approach has demonstrated production rates up to 100 times higher than conventional single-needle systems while maintaining reasonable control over fiber diameter. Companies like Elmarco have commercialized technologies based on this principle, achieving production speeds of several grams per minute with their Nanospider™ technology.

Process parameter standardization becomes increasingly critical at industrial scales. Automated monitoring systems that continuously track environmental conditions (temperature, humidity), solution properties, and electric field parameters can help maintain consistent fiber diameter. These systems should incorporate feedback loops that automatically adjust processing variables when deviations in fiber diameter are detected, ensuring product quality across long production runs.

Modular design approaches allow for scalable implementation, where multiple standardized electrospinning units operate in parallel. This strategy enables manufacturers to incrementally increase production capacity while maintaining consistent fiber characteristics. Each module can be individually controlled and optimized, facilitating maintenance without halting entire production lines.

In-line quality control represents another essential component of industrial implementation. Advanced optical systems utilizing high-speed cameras and machine learning algorithms can continuously monitor fiber formation and diameter in real-time. Raman spectroscopy and other non-destructive testing methods integrated into production lines can verify both dimensional and structural properties of the fibers without interrupting production.

Economic considerations must guide implementation strategies, with capital expenditure balanced against operational costs. While multi-needle systems typically have lower initial costs, their higher maintenance requirements and potential for inconsistent production may increase long-term expenses. Needleless systems generally require higher initial investment but offer reduced operational costs through higher throughput and lower maintenance requirements.

Needleless electrospinning offers a promising alternative, utilizing rotating drums, disks, or wire electrodes immersed in polymer solutions to generate multiple jets simultaneously. This approach has demonstrated production rates up to 100 times higher than conventional single-needle systems while maintaining reasonable control over fiber diameter. Companies like Elmarco have commercialized technologies based on this principle, achieving production speeds of several grams per minute with their Nanospider™ technology.

Process parameter standardization becomes increasingly critical at industrial scales. Automated monitoring systems that continuously track environmental conditions (temperature, humidity), solution properties, and electric field parameters can help maintain consistent fiber diameter. These systems should incorporate feedback loops that automatically adjust processing variables when deviations in fiber diameter are detected, ensuring product quality across long production runs.

Modular design approaches allow for scalable implementation, where multiple standardized electrospinning units operate in parallel. This strategy enables manufacturers to incrementally increase production capacity while maintaining consistent fiber characteristics. Each module can be individually controlled and optimized, facilitating maintenance without halting entire production lines.

In-line quality control represents another essential component of industrial implementation. Advanced optical systems utilizing high-speed cameras and machine learning algorithms can continuously monitor fiber formation and diameter in real-time. Raman spectroscopy and other non-destructive testing methods integrated into production lines can verify both dimensional and structural properties of the fibers without interrupting production.

Economic considerations must guide implementation strategies, with capital expenditure balanced against operational costs. While multi-needle systems typically have lower initial costs, their higher maintenance requirements and potential for inconsistent production may increase long-term expenses. Needleless systems generally require higher initial investment but offer reduced operational costs through higher throughput and lower maintenance requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!