Electrospinning in the Creation of Multifunctional Wearables

SEP 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrospinning Technology Evolution and Objectives

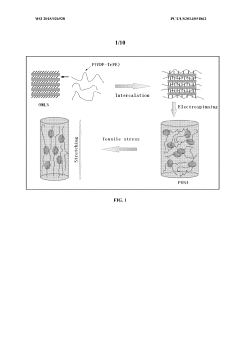

Electrospinning technology has evolved significantly since its inception in the early 20th century, with the first patent filed by J.F. Cooley and W.J. Morton in 1902. However, it wasn't until the 1990s that this technology gained substantial research attention, primarily due to advancements in nanomaterials and the growing demand for specialized functional materials. The fundamental principle of electrospinning involves applying a high voltage to a polymer solution or melt, creating an electrically charged jet that stretches and solidifies into ultra-fine fibers with diameters ranging from nanometers to micrometers.

The evolution of electrospinning has been marked by several key technological improvements. Initially limited to simple setups producing random fiber mats, the technology has progressed to include coaxial electrospinning (early 2000s), which enables the creation of core-shell fibers, and multi-jet electrospinning systems that significantly increase production capacity. Recent innovations include near-field electrospinning for precise fiber deposition and melt electrospinning writing for controlled 3D architectures.

In the context of wearable technology, electrospinning has undergone a transformative journey from producing basic textile materials to creating sophisticated multifunctional fabrics. The integration of conductive polymers, piezoelectric materials, and stimuli-responsive compounds has expanded the application scope dramatically, particularly in the wearables sector where form factor and functionality must coexist harmoniously.

The primary objective of electrospinning in multifunctional wearables is to develop textile-based platforms that seamlessly integrate sensing, actuation, energy harvesting, and storage capabilities while maintaining the comfort, flexibility, and durability expected from conventional garments. This involves overcoming the inherent challenges of maintaining electrical conductivity during mechanical deformation, ensuring biocompatibility for prolonged skin contact, and developing scalable manufacturing processes.

Current research aims to optimize fiber morphology, composition, and arrangement to enhance specific functionalities such as electrical conductivity, mechanical strength, and biocompatibility. The goal is to create wearable systems capable of monitoring physiological parameters, environmental conditions, and physical movements while potentially responding to these inputs through integrated actuators or displays.

Looking forward, the technological trajectory points toward the development of fully integrated wearable systems where electrospun fibers serve as the foundational material platform. This includes the creation of self-powered wearables through triboelectric or piezoelectric energy harvesting, biodegradable electronic textiles for sustainable applications, and adaptive materials that can respond to environmental stimuli or user needs through programmed material properties.

The evolution of electrospinning has been marked by several key technological improvements. Initially limited to simple setups producing random fiber mats, the technology has progressed to include coaxial electrospinning (early 2000s), which enables the creation of core-shell fibers, and multi-jet electrospinning systems that significantly increase production capacity. Recent innovations include near-field electrospinning for precise fiber deposition and melt electrospinning writing for controlled 3D architectures.

In the context of wearable technology, electrospinning has undergone a transformative journey from producing basic textile materials to creating sophisticated multifunctional fabrics. The integration of conductive polymers, piezoelectric materials, and stimuli-responsive compounds has expanded the application scope dramatically, particularly in the wearables sector where form factor and functionality must coexist harmoniously.

The primary objective of electrospinning in multifunctional wearables is to develop textile-based platforms that seamlessly integrate sensing, actuation, energy harvesting, and storage capabilities while maintaining the comfort, flexibility, and durability expected from conventional garments. This involves overcoming the inherent challenges of maintaining electrical conductivity during mechanical deformation, ensuring biocompatibility for prolonged skin contact, and developing scalable manufacturing processes.

Current research aims to optimize fiber morphology, composition, and arrangement to enhance specific functionalities such as electrical conductivity, mechanical strength, and biocompatibility. The goal is to create wearable systems capable of monitoring physiological parameters, environmental conditions, and physical movements while potentially responding to these inputs through integrated actuators or displays.

Looking forward, the technological trajectory points toward the development of fully integrated wearable systems where electrospun fibers serve as the foundational material platform. This includes the creation of self-powered wearables through triboelectric or piezoelectric energy harvesting, biodegradable electronic textiles for sustainable applications, and adaptive materials that can respond to environmental stimuli or user needs through programmed material properties.

Market Analysis for Multifunctional Wearable Textiles

The global market for multifunctional wearable textiles is experiencing unprecedented growth, driven by increasing consumer demand for smart clothing that combines fashion with functionality. The market size for smart textiles was valued at approximately $3.2 billion in 2022 and is projected to reach $16.5 billion by 2030, representing a compound annual growth rate (CAGR) of 22.7% during the forecast period.

Electrospun multifunctional wearables represent a significant segment within this market, with applications spanning healthcare monitoring, sports performance enhancement, military and defense, and fashion technology. The healthcare sector currently dominates the market share, accounting for 38% of the total market value, primarily due to the growing adoption of remote patient monitoring systems and the increasing prevalence of chronic diseases requiring continuous health tracking.

Consumer preferences are shifting toward lightweight, comfortable, and aesthetically pleasing wearable solutions that seamlessly integrate into daily life. This trend has created substantial opportunities for electrospun textiles, which offer superior breathability, flexibility, and customization capabilities compared to conventional manufacturing methods.

Regional analysis reveals North America as the current market leader with 42% market share, followed by Europe (28%) and Asia-Pacific (22%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 26.3% during the forecast period, primarily driven by rapid industrialization, increasing disposable income, and growing technological adoption in countries like China, Japan, and South Korea.

Key market segments for electrospun multifunctional wearables include health monitoring garments (35%), sports performance apparel (27%), protective workwear (18%), and fashion technology (12%), with other applications comprising the remaining 8%. The health monitoring segment is projected to maintain its dominant position due to increasing healthcare costs and the growing emphasis on preventive healthcare.

Demographic trends indicate that millennials and Gen Z consumers represent the largest customer base for multifunctional wearables, with 65% of purchases coming from consumers aged 18-40. This demographic typically values sustainability, technological integration, and personalization—all attributes that electrospun textiles can effectively deliver.

Market challenges include high production costs, technical limitations in scaling electrospinning processes, and consumer concerns regarding data privacy and security in connected wearables. Additionally, regulatory hurdles related to medical-grade wearables present significant market entry barriers for new players.

Despite these challenges, the market outlook remains highly positive, with electrospun multifunctional wearables positioned to revolutionize multiple industries through their unique combination of comfort, functionality, and adaptability to diverse consumer needs.

Electrospun multifunctional wearables represent a significant segment within this market, with applications spanning healthcare monitoring, sports performance enhancement, military and defense, and fashion technology. The healthcare sector currently dominates the market share, accounting for 38% of the total market value, primarily due to the growing adoption of remote patient monitoring systems and the increasing prevalence of chronic diseases requiring continuous health tracking.

Consumer preferences are shifting toward lightweight, comfortable, and aesthetically pleasing wearable solutions that seamlessly integrate into daily life. This trend has created substantial opportunities for electrospun textiles, which offer superior breathability, flexibility, and customization capabilities compared to conventional manufacturing methods.

Regional analysis reveals North America as the current market leader with 42% market share, followed by Europe (28%) and Asia-Pacific (22%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 26.3% during the forecast period, primarily driven by rapid industrialization, increasing disposable income, and growing technological adoption in countries like China, Japan, and South Korea.

Key market segments for electrospun multifunctional wearables include health monitoring garments (35%), sports performance apparel (27%), protective workwear (18%), and fashion technology (12%), with other applications comprising the remaining 8%. The health monitoring segment is projected to maintain its dominant position due to increasing healthcare costs and the growing emphasis on preventive healthcare.

Demographic trends indicate that millennials and Gen Z consumers represent the largest customer base for multifunctional wearables, with 65% of purchases coming from consumers aged 18-40. This demographic typically values sustainability, technological integration, and personalization—all attributes that electrospun textiles can effectively deliver.

Market challenges include high production costs, technical limitations in scaling electrospinning processes, and consumer concerns regarding data privacy and security in connected wearables. Additionally, regulatory hurdles related to medical-grade wearables present significant market entry barriers for new players.

Despite these challenges, the market outlook remains highly positive, with electrospun multifunctional wearables positioned to revolutionize multiple industries through their unique combination of comfort, functionality, and adaptability to diverse consumer needs.

Current Electrospinning Capabilities and Barriers

Electrospinning technology has evolved significantly over the past two decades, enabling the fabrication of nanofibrous materials with exceptional properties suitable for wearable applications. Current capabilities include the production of fibers with diameters ranging from 50 nm to several micrometers, offering high surface-to-volume ratios that enhance functionality in wearable devices. The technique allows for precise control over fiber morphology, orientation, and composition, facilitating the development of materials with tailored mechanical, electrical, and thermal properties.

Modern electrospinning systems can incorporate multiple functional materials within a single fiber structure through coaxial or multi-axial configurations. This capability has been instrumental in creating fibers with core-shell structures that can encapsulate active ingredients, sensors, or phase-change materials for smart textile applications. Additionally, recent advancements have enabled the integration of conductive polymers and nanomaterials, such as carbon nanotubes and graphene, into electrospun fibers, enhancing their electrical conductivity for electronic textile applications.

Despite these capabilities, several barriers limit the widespread adoption of electrospinning in commercial wearable technology. Production scalability remains a significant challenge, as traditional electrospinning setups typically yield only small quantities of material. While some industrial-scale systems have emerged, they often struggle to maintain consistent fiber quality and uniformity across large production volumes, hampering mass manufacturing potential.

Environmental control during the electrospinning process presents another barrier. Parameters such as humidity, temperature, and air flow significantly impact fiber formation and properties. Maintaining these conditions consistently in large-scale production environments proves challenging, leading to variability in the final product quality and performance characteristics.

Material limitations also constrain current applications. Many polymers suitable for electrospinning lack the durability required for everyday wearable applications. Electrospun fibers often exhibit poor mechanical strength and abrasion resistance compared to conventional textiles, limiting their practical use in garments subjected to regular wear and washing cycles.

Integration challenges persist when incorporating electrospun materials into existing textile manufacturing processes. The delicate nature of nanofibrous mats makes them difficult to handle during subsequent processing steps, such as cutting, sewing, or lamination. Furthermore, ensuring robust electrical connections in e-textile applications remains problematic, particularly when devices must withstand repeated mechanical deformation and washing cycles.

Regulatory and safety considerations present additional barriers, particularly for wearables intended for direct skin contact. The potential release of nanoparticles from electrospun materials during use raises concerns about biocompatibility and long-term health effects, necessitating comprehensive testing and certification processes that add time and cost to product development cycles.

Modern electrospinning systems can incorporate multiple functional materials within a single fiber structure through coaxial or multi-axial configurations. This capability has been instrumental in creating fibers with core-shell structures that can encapsulate active ingredients, sensors, or phase-change materials for smart textile applications. Additionally, recent advancements have enabled the integration of conductive polymers and nanomaterials, such as carbon nanotubes and graphene, into electrospun fibers, enhancing their electrical conductivity for electronic textile applications.

Despite these capabilities, several barriers limit the widespread adoption of electrospinning in commercial wearable technology. Production scalability remains a significant challenge, as traditional electrospinning setups typically yield only small quantities of material. While some industrial-scale systems have emerged, they often struggle to maintain consistent fiber quality and uniformity across large production volumes, hampering mass manufacturing potential.

Environmental control during the electrospinning process presents another barrier. Parameters such as humidity, temperature, and air flow significantly impact fiber formation and properties. Maintaining these conditions consistently in large-scale production environments proves challenging, leading to variability in the final product quality and performance characteristics.

Material limitations also constrain current applications. Many polymers suitable for electrospinning lack the durability required for everyday wearable applications. Electrospun fibers often exhibit poor mechanical strength and abrasion resistance compared to conventional textiles, limiting their practical use in garments subjected to regular wear and washing cycles.

Integration challenges persist when incorporating electrospun materials into existing textile manufacturing processes. The delicate nature of nanofibrous mats makes them difficult to handle during subsequent processing steps, such as cutting, sewing, or lamination. Furthermore, ensuring robust electrical connections in e-textile applications remains problematic, particularly when devices must withstand repeated mechanical deformation and washing cycles.

Regulatory and safety considerations present additional barriers, particularly for wearables intended for direct skin contact. The potential release of nanoparticles from electrospun materials during use raises concerns about biocompatibility and long-term health effects, necessitating comprehensive testing and certification processes that add time and cost to product development cycles.

Current Electrospinning Methods for Wearable Applications

01 Multifunctional nanofiber fabrication via electrospinning

Electrospinning techniques can be used to fabricate multifunctional nanofibers with various properties. These nanofibers can be designed with specific characteristics such as high surface area, porosity, and mechanical strength. The process involves applying a high voltage to a polymer solution or melt, which creates an electrically charged jet that solidifies into fibers. This approach allows for the creation of nanofibers with tailored functionalities for applications in filtration, tissue engineering, and protective clothing.- Multifunctional nanofiber fabrication via electrospinning: Electrospinning techniques can be used to fabricate multifunctional nanofibers with various properties. These nanofibers can be engineered to possess specific characteristics such as high surface area, porosity, and mechanical strength. The process involves applying a high voltage to a polymer solution or melt, resulting in the formation of ultrafine fibers. By controlling the electrospinning parameters, nanofibers with tailored functionalities can be produced for applications in filtration, tissue engineering, and drug delivery.

- Composite electrospun materials with enhanced properties: Composite materials can be created through electrospinning by incorporating different functional components into the polymer solution. These components may include nanoparticles, carbon nanotubes, or bioactive agents, which enhance the properties of the resulting nanofibers. The composite electrospun materials exhibit multifunctionality such as antimicrobial activity, electrical conductivity, or improved mechanical properties. This approach allows for the development of advanced materials with combined functionalities for specialized applications.

- Electrospinning for biomedical applications: Electrospun nanofibers have significant potential in biomedical applications due to their multifunctionality. These nanofibers can be designed to mimic the extracellular matrix, promote cell adhesion and proliferation, and deliver therapeutic agents. By controlling the fiber composition and structure, electrospun scaffolds can be tailored for tissue engineering, wound healing, and drug delivery systems. The biocompatibility and biodegradability of these materials make them particularly suitable for medical applications.

- Coaxial and multi-axial electrospinning techniques: Advanced electrospinning techniques such as coaxial and multi-axial electrospinning enable the production of nanofibers with complex structures and enhanced multifunctionality. These techniques involve the simultaneous electrospinning of multiple polymer solutions through concentric or adjacent nozzles, resulting in core-shell or side-by-side fiber structures. Such architectures allow for the incorporation of different functional materials within a single fiber, enabling controlled release of bioactive agents, improved mechanical properties, or the combination of hydrophilic and hydrophobic components.

- Environmental and energy applications of electrospun materials: Electrospun nanofibers with multifunctional properties have significant applications in environmental remediation and energy storage/conversion. These materials can be designed for air and water filtration, pollutant adsorption, catalysis, and as components in energy devices such as batteries, fuel cells, and solar cells. The high surface area, porosity, and ability to incorporate functional additives make electrospun materials effective for capturing contaminants, facilitating chemical reactions, or enhancing energy storage capacity.

02 Incorporation of functional additives in electrospun fibers

Various functional additives can be incorporated into polymer solutions before electrospinning to enhance the properties of the resulting fibers. These additives include antimicrobial agents, drugs, nanoparticles, and other bioactive compounds. The incorporation of these additives enables the development of multifunctional electrospun materials with properties such as antibacterial activity, drug delivery capabilities, and enhanced mechanical strength. The resulting composite fibers can be used in applications ranging from wound dressings to environmental remediation.Expand Specific Solutions03 Coaxial and multi-axial electrospinning for complex fiber structures

Advanced electrospinning techniques such as coaxial and multi-axial electrospinning allow for the creation of complex fiber structures with multiple functionalities. These techniques involve the use of multiple concentric nozzles to produce fibers with core-shell or multi-layered structures. Such structures can encapsulate different materials within a single fiber, enabling controlled release of active ingredients, improved mechanical properties, and the combination of otherwise incompatible materials. These complex fiber structures find applications in drug delivery systems, tissue engineering scaffolds, and smart textiles.Expand Specific Solutions04 Surface modification of electrospun fibers for enhanced functionality

Post-processing techniques can be applied to modify the surface of electrospun fibers, enhancing their functionality. These techniques include plasma treatment, chemical functionalization, and coating processes. Surface modification can improve properties such as hydrophilicity, biocompatibility, and reactivity of the fibers. By tailoring the surface properties, electrospun materials can be optimized for specific applications such as filtration membranes, sensors, and biomedical devices, expanding their multifunctional capabilities.Expand Specific Solutions05 Electrospun nanofibers for environmental and energy applications

Multifunctional electrospun nanofibers can be designed specifically for environmental remediation and energy applications. These fibers can incorporate catalytic materials, adsorbents, or conductive polymers to create materials for water purification, air filtration, and energy storage devices. The high surface area and porosity of electrospun fibers make them particularly effective for these applications. Additionally, the ability to incorporate multiple functional components allows for the development of integrated systems that can simultaneously address multiple environmental or energy-related challenges.Expand Specific Solutions

Leading Companies and Research Institutions in Electrospinning

Electrospinning in wearable technology is currently in a growth phase, transitioning from research to commercialization. The market is expanding rapidly, projected to reach significant scale as multifunctional wearables gain traction across healthcare, fitness, and consumer electronics sectors. Leading academic institutions like MIT, Cornell, and Donghua University are advancing fundamental research, while companies such as BioSurfaces, Poly-Med, and Arsenal Medical are commercializing applications. NASA and Corning represent established players exploring high-performance applications. Chinese universities (Qingdao University of Science & Technology) are emerging as significant contributors, particularly in textile applications. The technology shows varying maturity levels across applications, with medical textiles being more advanced than consumer wearables, creating a competitive landscape balanced between academic innovation and industrial implementation.

Massachusetts Institute of Technology

Technical Solution: MIT has developed groundbreaking electrospinning technologies for multifunctional wearables through their Advanced Functional Fabrics of America (AFFOA) initiative. Their approach combines traditional electrospinning with advanced materials science to create fibers with unprecedented functionality. MIT researchers have pioneered a multi-jet electrospinning system that enables the production of fibers with precisely controlled compositions and structures at industrial scales. Their technology incorporates thermochromic and photochromic materials into nanofibers to create color-changing fabrics that respond to environmental stimuli. MIT has also developed piezoelectric nanofibers that generate electricity from body movement, enabling self-powered wearable electronics. A significant innovation is their integration of microfluidic channels within electrospun fibers to create fabrics capable of controlled drug delivery or chemical sensing. Additionally, MIT has created electrospun membranes with tunable wettability for advanced moisture management in athletic and medical textiles, addressing both comfort and functional requirements.

Strengths: Cutting-edge research combining multiple disciplines (materials science, electrical engineering, bioengineering); strong focus on scalable manufacturing processes; extensive intellectual property portfolio. Weaknesses: Many technologies remain at laboratory scale with significant challenges for mass production; high cost of specialized materials may limit commercial applications in consumer markets.

BioSurfaces, Inc.

Technical Solution: BioSurfaces has developed proprietary electrospinning technologies specifically designed for creating bioactive wearable materials with therapeutic properties. Their platform technology, BioSpun™, uses a modified electrospinning process to incorporate bioactive molecules directly into nanofibers without compromising their biological activity. The company has created electrospun matrices that mimic the extracellular matrix structure, providing an ideal interface between wearable devices and human skin to reduce irritation and improve comfort during extended wear. Their technology enables the controlled release of therapeutic compounds from wearable patches for transdermal drug delivery applications, with release kinetics that can be tailored to specific treatment protocols. BioSurfaces has also developed antimicrobial electrospun fabrics that incorporate natural antimicrobial peptides rather than traditional metal nanoparticles, offering a more sustainable approach to infection prevention in medical textiles. Additionally, they've pioneered electrospun materials with gradient structures that provide different functionalities at different depths, such as moisture management at the skin interface and environmental protection at the outer surface, creating truly multifunctional single-layer materials for advanced wearable applications.

Strengths: Highly specialized in biomedical applications with proven clinical relevance; strong intellectual property position in bioactive fiber production; excellent control over drug release kinetics from electrospun materials. Weaknesses: Narrower focus primarily on healthcare applications rather than consumer wearables; higher production costs compared to conventional textile manufacturing; regulatory approval processes can delay commercialization of medical applications.

Key Patents and Innovations in Electrospun Wearables

Electrospinning to form nanofibers

PatentWO2015026928A1

Innovation

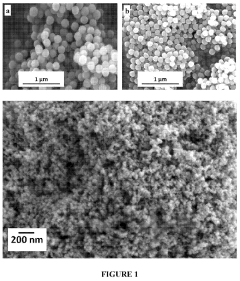

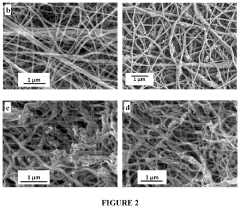

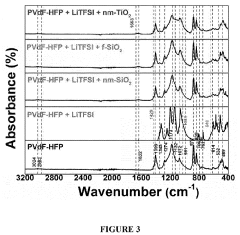

- The development of a P(VDF-TrFE)/organosilicate composite membrane fabricated through electrospinning, which incorporates organosilicate as a reinforcing agent to enhance mechanical properties like strength, modulus, and toughness while maintaining high porosity and piezoelectricity.

Weavable, conformable, wearable and flexible components for advanced battery technology

PatentActiveUS20200274201A1

Innovation

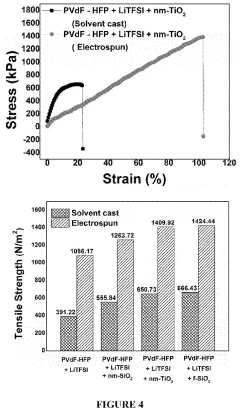

- A flexible energy storage system is created using electrospun, textile-like assemblies with a flexible gel-polymer electrolyte and nanostructured fillers, incorporating electrospun silicon anodes and sulfur cathodes, which provide improved ionic conductivity and mechanical strength, preventing polysulfide dissolution and enhancing cycling stability.

Sustainability Aspects of Electrospun Wearable Materials

The sustainability of electrospun wearable materials represents a critical dimension in the evolution of multifunctional wearable technologies. As environmental concerns increasingly influence consumer choices and regulatory frameworks, the electrospinning industry must address several key sustainability aspects throughout the product lifecycle.

Material selection constitutes the foundation of sustainable electrospun wearables. Traditional electrospinning often relies on petroleum-based polymers like polyurethane and polyacrylonitrile, which present significant end-of-life challenges. Recent research has demonstrated promising results with biodegradable alternatives such as polylactic acid (PLA), polyhydroxyalkanoates (PHAs), and cellulose derivatives. These bio-based polymers can reduce carbon footprints by up to 70% compared to conventional materials while maintaining comparable mechanical properties.

Energy consumption during the electrospinning process presents another sustainability challenge. The high voltage requirements (typically 10-30 kV) and extended operation times contribute to substantial energy usage. Innovations in low-energy electrospinning techniques have emerged, including room temperature electrospinning and solar-powered systems that reduce energy demands by approximately 40-50%. These approaches significantly diminish the environmental impact while maintaining production efficiency.

Water usage and solvent management represent critical environmental considerations. Conventional electrospinning often employs toxic solvents like dimethylformamide (DMF) and chloroform, which pose ecological hazards. Green chemistry approaches have introduced water-based systems and benign solvents such as acetic acid and ethanol, reducing environmental toxicity while improving workplace safety. Additionally, closed-loop solvent recovery systems can recapture up to 85% of solvents, substantially reducing waste generation.

End-of-life considerations for electrospun wearables must address the growing electronic waste crisis. Design for disassembly principles enables the separation of electronic components from textile substrates, facilitating recycling of valuable materials. Biodegradable electrospun matrices can be engineered to decompose under specific conditions while remaining durable during normal use, offering a balanced approach to product longevity and environmental impact.

The economic dimensions of sustainability cannot be overlooked. While sustainable materials and processes may increase initial production costs by 15-30%, lifecycle analyses demonstrate long-term economic benefits through reduced waste management expenses, regulatory compliance, and growing consumer preference for environmentally responsible products. Market research indicates consumers are willing to pay premium prices (10-25% higher) for demonstrably sustainable wearable technologies.

Material selection constitutes the foundation of sustainable electrospun wearables. Traditional electrospinning often relies on petroleum-based polymers like polyurethane and polyacrylonitrile, which present significant end-of-life challenges. Recent research has demonstrated promising results with biodegradable alternatives such as polylactic acid (PLA), polyhydroxyalkanoates (PHAs), and cellulose derivatives. These bio-based polymers can reduce carbon footprints by up to 70% compared to conventional materials while maintaining comparable mechanical properties.

Energy consumption during the electrospinning process presents another sustainability challenge. The high voltage requirements (typically 10-30 kV) and extended operation times contribute to substantial energy usage. Innovations in low-energy electrospinning techniques have emerged, including room temperature electrospinning and solar-powered systems that reduce energy demands by approximately 40-50%. These approaches significantly diminish the environmental impact while maintaining production efficiency.

Water usage and solvent management represent critical environmental considerations. Conventional electrospinning often employs toxic solvents like dimethylformamide (DMF) and chloroform, which pose ecological hazards. Green chemistry approaches have introduced water-based systems and benign solvents such as acetic acid and ethanol, reducing environmental toxicity while improving workplace safety. Additionally, closed-loop solvent recovery systems can recapture up to 85% of solvents, substantially reducing waste generation.

End-of-life considerations for electrospun wearables must address the growing electronic waste crisis. Design for disassembly principles enables the separation of electronic components from textile substrates, facilitating recycling of valuable materials. Biodegradable electrospun matrices can be engineered to decompose under specific conditions while remaining durable during normal use, offering a balanced approach to product longevity and environmental impact.

The economic dimensions of sustainability cannot be overlooked. While sustainable materials and processes may increase initial production costs by 15-30%, lifecycle analyses demonstrate long-term economic benefits through reduced waste management expenses, regulatory compliance, and growing consumer preference for environmentally responsible products. Market research indicates consumers are willing to pay premium prices (10-25% higher) for demonstrably sustainable wearable technologies.

Manufacturing Scalability and Commercialization Challenges

Despite the promising potential of electrospinning technology in wearable applications, significant manufacturing scalability and commercialization challenges persist that hinder widespread market adoption. Traditional electrospinning setups typically operate at laboratory scales, producing only small quantities of nanofiber materials that are insufficient for commercial production demands. The transition from lab-scale to industrial-scale manufacturing represents a critical bottleneck in the commercialization pathway.

Current industrial electrospinning systems face several technical limitations. Productivity rates remain relatively low compared to conventional textile manufacturing processes, with typical production speeds ranging from 0.1-10 g/h depending on the specific setup. This creates a substantial cost barrier, as the production economics do not yet support mass-market pricing structures for electrospun wearable products.

Quality control and consistency present additional manufacturing challenges. Maintaining uniform fiber diameter, orientation, and material properties across large production batches requires sophisticated monitoring systems and process controls that add complexity and cost to manufacturing operations. Environmental factors such as humidity and temperature must be precisely regulated to ensure product consistency.

The integration of electrospun materials with conventional textiles and electronic components presents another significant hurdle. Current assembly processes are largely manual and difficult to automate, creating labor-intensive production workflows that further impact cost structures. Specialized equipment for handling delicate nanofiber structures during integration processes remains underdeveloped.

Regulatory compliance represents a substantial commercialization challenge, particularly for wearables with health monitoring or medical applications. Electrospun materials must undergo rigorous safety testing to address concerns regarding potential nanoparticle shedding, skin irritation, and biocompatibility. The regulatory pathway remains unclear in many jurisdictions, creating market uncertainty.

Investment requirements for establishing commercial-scale electrospinning facilities are substantial, with specialized equipment costs ranging from $500,000 to several million dollars depending on production capacity. This high capital expenditure requirement creates significant barriers to entry for startups and smaller manufacturers, limiting innovation in the sector.

Market education presents another commercialization challenge, as consumers and industry partners have limited understanding of electrospun material benefits compared to conventional textiles. Developing effective value propositions and marketing strategies that clearly communicate the performance advantages of these advanced materials remains critical for market acceptance and premium pricing justification.

Current industrial electrospinning systems face several technical limitations. Productivity rates remain relatively low compared to conventional textile manufacturing processes, with typical production speeds ranging from 0.1-10 g/h depending on the specific setup. This creates a substantial cost barrier, as the production economics do not yet support mass-market pricing structures for electrospun wearable products.

Quality control and consistency present additional manufacturing challenges. Maintaining uniform fiber diameter, orientation, and material properties across large production batches requires sophisticated monitoring systems and process controls that add complexity and cost to manufacturing operations. Environmental factors such as humidity and temperature must be precisely regulated to ensure product consistency.

The integration of electrospun materials with conventional textiles and electronic components presents another significant hurdle. Current assembly processes are largely manual and difficult to automate, creating labor-intensive production workflows that further impact cost structures. Specialized equipment for handling delicate nanofiber structures during integration processes remains underdeveloped.

Regulatory compliance represents a substantial commercialization challenge, particularly for wearables with health monitoring or medical applications. Electrospun materials must undergo rigorous safety testing to address concerns regarding potential nanoparticle shedding, skin irritation, and biocompatibility. The regulatory pathway remains unclear in many jurisdictions, creating market uncertainty.

Investment requirements for establishing commercial-scale electrospinning facilities are substantial, with specialized equipment costs ranging from $500,000 to several million dollars depending on production capacity. This high capital expenditure requirement creates significant barriers to entry for startups and smaller manufacturers, limiting innovation in the sector.

Market education presents another commercialization challenge, as consumers and industry partners have limited understanding of electrospun material benefits compared to conventional textiles. Developing effective value propositions and marketing strategies that clearly communicate the performance advantages of these advanced materials remains critical for market acceptance and premium pricing justification.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!