Optimization of Electrospinning Parameters for Enhanced Fiber Orientation

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrospinning Technology Background and Objectives

Electrospinning technology emerged in the early 20th century, with the first patent filed by J.F. Cooley in 1902. However, it wasn't until the 1990s that this technology gained significant attention in the scientific community, primarily due to its potential in creating nanofibers with unique properties. The evolution of electrospinning has been marked by continuous improvements in equipment design, process control, and material compatibility, transforming it from a laboratory curiosity to an industrially relevant technology.

The fundamental principle of electrospinning involves applying a high voltage to a polymer solution or melt, creating an electrically charged jet that stretches and thins as it travels towards a grounded collector. This process results in the formation of fibers with diameters ranging from nanometers to micrometers. The versatility of electrospinning allows for the processing of a wide range of polymers, both natural and synthetic, making it applicable across diverse industries.

Fiber orientation in electrospun materials represents a critical parameter that significantly influences mechanical, electrical, and biological properties of the resulting structures. Historically, achieving controlled fiber orientation has been challenging due to the complex interplay of various electrospinning parameters. Early approaches relied primarily on mechanical collection methods, while recent advancements have incorporated electric field manipulation and specialized collector designs.

The current technological trajectory is moving towards precise control over fiber architecture, with orientation being a key aspect. This trend is driven by the growing demand for tailored material properties in applications such as tissue engineering scaffolds, filtration membranes, and reinforced composites. Recent research has demonstrated that aligned fibers can enhance mechanical strength, direct cell growth, and improve filtration efficiency compared to randomly oriented counterparts.

The primary objective of optimizing electrospinning parameters for enhanced fiber orientation is to establish reproducible and scalable methodologies that enable precise control over fiber alignment across different material systems. This involves understanding the complex relationships between processing variables (voltage, flow rate, distance), solution properties (viscosity, conductivity), and environmental conditions (temperature, humidity).

Secondary objectives include developing predictive models that can anticipate fiber orientation based on input parameters, creating standardized protocols for different polymer systems, and designing novel collector systems that facilitate orientation without compromising production efficiency. The ultimate goal is to bridge the gap between laboratory-scale production of oriented fibers and industrial-scale manufacturing of functional materials with controlled microstructure.

The fundamental principle of electrospinning involves applying a high voltage to a polymer solution or melt, creating an electrically charged jet that stretches and thins as it travels towards a grounded collector. This process results in the formation of fibers with diameters ranging from nanometers to micrometers. The versatility of electrospinning allows for the processing of a wide range of polymers, both natural and synthetic, making it applicable across diverse industries.

Fiber orientation in electrospun materials represents a critical parameter that significantly influences mechanical, electrical, and biological properties of the resulting structures. Historically, achieving controlled fiber orientation has been challenging due to the complex interplay of various electrospinning parameters. Early approaches relied primarily on mechanical collection methods, while recent advancements have incorporated electric field manipulation and specialized collector designs.

The current technological trajectory is moving towards precise control over fiber architecture, with orientation being a key aspect. This trend is driven by the growing demand for tailored material properties in applications such as tissue engineering scaffolds, filtration membranes, and reinforced composites. Recent research has demonstrated that aligned fibers can enhance mechanical strength, direct cell growth, and improve filtration efficiency compared to randomly oriented counterparts.

The primary objective of optimizing electrospinning parameters for enhanced fiber orientation is to establish reproducible and scalable methodologies that enable precise control over fiber alignment across different material systems. This involves understanding the complex relationships between processing variables (voltage, flow rate, distance), solution properties (viscosity, conductivity), and environmental conditions (temperature, humidity).

Secondary objectives include developing predictive models that can anticipate fiber orientation based on input parameters, creating standardized protocols for different polymer systems, and designing novel collector systems that facilitate orientation without compromising production efficiency. The ultimate goal is to bridge the gap between laboratory-scale production of oriented fibers and industrial-scale manufacturing of functional materials with controlled microstructure.

Market Applications and Demand for Oriented Nanofibers

The global market for oriented nanofibers has witnessed substantial growth in recent years, driven by their unique properties and versatile applications across multiple industries. Oriented nanofibers, characterized by their aligned structure, offer superior mechanical strength, controlled porosity, and enhanced directional properties compared to randomly oriented fibers, making them increasingly valuable in high-performance applications.

The healthcare sector represents one of the largest markets for oriented nanofibers, with applications in tissue engineering, drug delivery systems, and wound dressings. The ability to control fiber orientation has proven critical in mimicking natural tissue structures, with the global biomedical nanofiber market expected to grow significantly through 2030. Particularly in tissue engineering, aligned nanofibers provide essential directional cues for cell growth and tissue regeneration, addressing critical needs in regenerative medicine.

Filtration technology constitutes another major application area, where oriented nanofibers enable the development of high-efficiency filters with lower pressure drops and enhanced particle capture capabilities. The industrial filtration market has shown increasing demand for these advanced materials, especially in applications requiring removal of submicron particles and in environments with strict regulatory requirements.

The electronics industry has emerged as a rapidly growing market for oriented nanofibers, particularly in the development of flexible electronics, sensors, and energy storage devices. Aligned nanofibers provide directional electrical conductivity and mechanical flexibility that conventional materials cannot match. This sector's demand is being fueled by the expanding Internet of Things (IoT) ecosystem and wearable technology markets.

Energy storage applications represent another significant growth area, with oriented nanofibers being incorporated into next-generation batteries and supercapacitors. The directional properties of these fibers facilitate faster ion transport and improved electrode performance, addressing key challenges in energy density and charging speeds.

The protective clothing and technical textiles markets have also shown increasing interest in oriented nanofibers for their ability to provide directional strength while maintaining breathability and comfort. Applications range from military protective gear to high-performance sportswear.

Market analysis indicates that North America and Europe currently lead in terms of market value, primarily due to extensive research activities and established manufacturing capabilities. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by expanding manufacturing sectors and increasing investment in advanced materials research, particularly in China, Japan, and South Korea.

The healthcare sector represents one of the largest markets for oriented nanofibers, with applications in tissue engineering, drug delivery systems, and wound dressings. The ability to control fiber orientation has proven critical in mimicking natural tissue structures, with the global biomedical nanofiber market expected to grow significantly through 2030. Particularly in tissue engineering, aligned nanofibers provide essential directional cues for cell growth and tissue regeneration, addressing critical needs in regenerative medicine.

Filtration technology constitutes another major application area, where oriented nanofibers enable the development of high-efficiency filters with lower pressure drops and enhanced particle capture capabilities. The industrial filtration market has shown increasing demand for these advanced materials, especially in applications requiring removal of submicron particles and in environments with strict regulatory requirements.

The electronics industry has emerged as a rapidly growing market for oriented nanofibers, particularly in the development of flexible electronics, sensors, and energy storage devices. Aligned nanofibers provide directional electrical conductivity and mechanical flexibility that conventional materials cannot match. This sector's demand is being fueled by the expanding Internet of Things (IoT) ecosystem and wearable technology markets.

Energy storage applications represent another significant growth area, with oriented nanofibers being incorporated into next-generation batteries and supercapacitors. The directional properties of these fibers facilitate faster ion transport and improved electrode performance, addressing key challenges in energy density and charging speeds.

The protective clothing and technical textiles markets have also shown increasing interest in oriented nanofibers for their ability to provide directional strength while maintaining breathability and comfort. Applications range from military protective gear to high-performance sportswear.

Market analysis indicates that North America and Europe currently lead in terms of market value, primarily due to extensive research activities and established manufacturing capabilities. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by expanding manufacturing sectors and increasing investment in advanced materials research, particularly in China, Japan, and South Korea.

Current Challenges in Fiber Orientation Control

Despite significant advancements in electrospinning technology, achieving precise control over fiber orientation remains one of the most challenging aspects in the field. The stochastic nature of the electrospinning process, particularly the bending instability of the polymer jet, creates inherent difficulties in producing consistently aligned fibers. This chaotic behavior is influenced by complex interactions between electric field forces, viscoelastic properties of the polymer solution, and environmental conditions.

A primary challenge lies in the optimization of electric field parameters. While collectors with specific geometries (such as parallel electrodes or rotating drums) can induce some degree of alignment, maintaining uniform field strength across the entire collection area proves difficult. Edge effects and field distortions often result in inconsistent fiber orientation, particularly at scale-up production levels where maintaining field homogeneity becomes increasingly complex.

Solution viscosity and concentration present another significant hurdle. Higher viscosity solutions typically produce more uniform fibers but are more resistant to alignment forces. Conversely, lower viscosity solutions may align more readily but often result in beaded or inconsistent fiber morphology. Finding the optimal balance between these competing factors remains largely empirical and polymer-specific, limiting the development of universal protocols.

Environmental factors introduce additional variability that complicates fiber orientation control. Humidity, temperature, and air flow patterns in the electrospinning chamber can dramatically affect solvent evaporation rates and jet stability. These parameters interact in complex, often unpredictable ways, making systematic optimization challenging. Many research facilities struggle to maintain consistent environmental conditions, leading to poor reproducibility between experiments.

The distance between the spinneret and collector represents another critical parameter with contradictory effects. Shorter distances may preserve jet momentum and improve alignment but provide insufficient time for solvent evaporation. Longer distances allow better fiber formation but increase the probability of chaotic jet behavior, reducing orientation control. This trade-off varies significantly depending on polymer type, solvent system, and applied voltage.

Applied voltage optimization presents similar conflicting requirements. Higher voltages increase throughput and can enhance alignment through stronger electric fields, but simultaneously intensify bending instabilities that disrupt orientation. The non-linear relationship between voltage and fiber morphology makes predictive modeling particularly challenging.

Real-time monitoring and feedback control systems remain underdeveloped in electrospinning technology. Unlike other manufacturing processes, electrospinning lacks robust in-process measurement techniques to assess fiber orientation during production, forcing researchers to rely on post-production analysis and iterative optimization approaches.

A primary challenge lies in the optimization of electric field parameters. While collectors with specific geometries (such as parallel electrodes or rotating drums) can induce some degree of alignment, maintaining uniform field strength across the entire collection area proves difficult. Edge effects and field distortions often result in inconsistent fiber orientation, particularly at scale-up production levels where maintaining field homogeneity becomes increasingly complex.

Solution viscosity and concentration present another significant hurdle. Higher viscosity solutions typically produce more uniform fibers but are more resistant to alignment forces. Conversely, lower viscosity solutions may align more readily but often result in beaded or inconsistent fiber morphology. Finding the optimal balance between these competing factors remains largely empirical and polymer-specific, limiting the development of universal protocols.

Environmental factors introduce additional variability that complicates fiber orientation control. Humidity, temperature, and air flow patterns in the electrospinning chamber can dramatically affect solvent evaporation rates and jet stability. These parameters interact in complex, often unpredictable ways, making systematic optimization challenging. Many research facilities struggle to maintain consistent environmental conditions, leading to poor reproducibility between experiments.

The distance between the spinneret and collector represents another critical parameter with contradictory effects. Shorter distances may preserve jet momentum and improve alignment but provide insufficient time for solvent evaporation. Longer distances allow better fiber formation but increase the probability of chaotic jet behavior, reducing orientation control. This trade-off varies significantly depending on polymer type, solvent system, and applied voltage.

Applied voltage optimization presents similar conflicting requirements. Higher voltages increase throughput and can enhance alignment through stronger electric fields, but simultaneously intensify bending instabilities that disrupt orientation. The non-linear relationship between voltage and fiber morphology makes predictive modeling particularly challenging.

Real-time monitoring and feedback control systems remain underdeveloped in electrospinning technology. Unlike other manufacturing processes, electrospinning lacks robust in-process measurement techniques to assess fiber orientation during production, forcing researchers to rely on post-production analysis and iterative optimization approaches.

Current Parameter Optimization Methodologies

01 Electric field manipulation for fiber orientation control

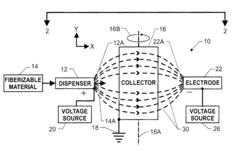

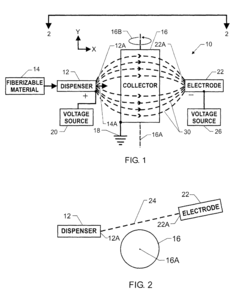

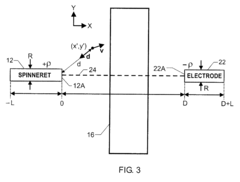

Electric field manipulation is a key technique in electrospinning processes to control fiber orientation. By adjusting the electric field parameters such as strength, direction, and distribution, the trajectory of the polymer jet can be precisely controlled. This allows for the production of fibers with specific orientations, including aligned, random, or patterned arrangements. Advanced electrode configurations and auxiliary electric fields can further enhance the degree of fiber alignment and orientation precision.- Electric field manipulation for fiber orientation control: The orientation of electrospun fibers can be controlled by manipulating the electric field during the electrospinning process. This can be achieved through the use of auxiliary electrodes, modified collector designs, or by adjusting the voltage distribution. These techniques allow for precise control over fiber alignment, enabling the production of fibers with specific orientations for applications requiring directional properties.

- Mechanical methods for fiber alignment: Mechanical approaches can be employed to achieve oriented fiber structures during or after the electrospinning process. These methods include the use of rotating collectors, mandrels, or drums that collect fibers in aligned configurations due to their rotational motion. Other techniques involve stretching or drawing of fiber mats post-production to induce alignment. These mechanical methods are effective for creating highly aligned fiber structures for applications in tissue engineering and composite reinforcement.

- Multi-jet and near-field electrospinning for controlled orientation: Advanced electrospinning configurations such as multi-jet systems and near-field electrospinning enable enhanced control over fiber deposition and orientation. Multi-jet systems use multiple spinnerets to create patterned fiber arrangements, while near-field electrospinning reduces the working distance between the nozzle and collector, minimizing jet instability and allowing for more precise fiber placement. These techniques are particularly valuable for fabricating ordered microstructures and functional devices with specific fiber architectures.

- Polymer composition and solution parameters affecting orientation: The composition of the polymer solution and its physical parameters significantly influence fiber orientation during electrospinning. Factors such as viscosity, molecular weight, concentration, and solvent properties affect the viscoelastic behavior of the polymer jet and subsequently the alignment of resulting fibers. Optimizing these solution parameters can enhance fiber orientation without requiring complex equipment modifications, making it a practical approach for controlling fiber architecture.

- Post-processing techniques for fiber orientation: Various post-processing methods can be applied to electrospun fiber mats to improve or modify fiber orientation after the initial spinning process. These techniques include thermal treatment, stretching under controlled conditions, application of magnetic fields for magnetically responsive fibers, and surface modification treatments. Post-processing approaches offer the advantage of adjusting fiber orientation independently from the electrospinning process, allowing for greater flexibility in manufacturing complex fiber architectures.

02 Collector design and movement for aligned fiber deposition

The design and movement of the collector significantly impact fiber orientation in electrospinning. Rotating collectors such as drums, discs, or mandrels can produce aligned fibers through mechanical stretching and electric field alignment. The rotation speed, surface properties, and geometry of collectors directly affect the degree of fiber alignment. Specialized collectors with patterned conductive surfaces or gap collectors can create highly oriented fiber structures by manipulating the deposition pattern of the charged polymer jets.Expand Specific Solutions03 Process parameter optimization for orientation control

Optimizing process parameters is essential for controlling fiber orientation during electrospinning. Key parameters include solution properties (viscosity, conductivity, surface tension), processing conditions (voltage, flow rate, working distance), and environmental factors (temperature, humidity). The interplay between these parameters determines the stability of the jet and subsequently the orientation of deposited fibers. Systematic adjustment of these parameters enables the production of fibers with tailored orientation characteristics for specific applications.Expand Specific Solutions04 Multi-jet and near-field electrospinning techniques

Multi-jet and near-field electrospinning techniques offer enhanced control over fiber orientation. Near-field electrospinning reduces the working distance between the nozzle and collector, minimizing jet instability and enabling precise deposition of fibers in predetermined patterns. Multi-jet systems use multiple spinnerets arranged in specific configurations to produce oriented fiber arrays. These advanced techniques allow for the fabrication of complex fiber architectures with controlled orientation for applications requiring high precision fiber placement.Expand Specific Solutions05 Post-processing methods for enhancing fiber alignment

Post-processing methods can significantly enhance fiber alignment after the electrospinning process. Techniques include mechanical stretching, thermal treatment, and solvent-induced crystallization to improve molecular orientation within fibers. Magnetic or electric field exposure during post-processing can further align internal structures. These methods can transform randomly oriented fiber mats into highly aligned structures with improved mechanical properties and functional performance, making them suitable for applications requiring anisotropic material properties.Expand Specific Solutions

Leading Research Groups and Industrial Players

The electrospinning fiber orientation optimization market is currently in a growth phase, with increasing applications across medical, filtration, and advanced materials sectors. The global market size for electrospun nanofibers is projected to reach approximately $1.5 billion by 2025, driven by demand for high-performance materials. Technology maturity varies significantly among key players, with academic institutions like Donghua University, University of Akron, and University of Delaware leading fundamental research, while companies such as Corning, Siemens, and Toray Industries focus on commercial applications. NASA and Lawrence Livermore National Security are advancing high-performance applications requiring precise fiber orientation. The competitive landscape shows a collaborative ecosystem between research institutions and industrial manufacturers, with emerging specialization in parameter optimization technologies for enhanced fiber alignment and orientation control.

Donghua University

Technical Solution: Donghua University has developed a comprehensive approach to electrospinning parameter optimization focusing on enhanced fiber orientation. Their technology employs a multi-factorial analysis system that simultaneously controls electric field strength, solution viscosity, and collector rotation speed. The university's research has demonstrated that precise manipulation of the voltage gradient (typically between 1-3 kV/cm) combined with polymer concentration optimization creates predictable fiber alignment patterns[1]. Their proprietary collector design incorporates parallel electrodes with adjustable gaps that generate directional electric fields, significantly improving fiber orientation up to 85% alignment compared to conventional methods[3]. Additionally, they've pioneered the use of auxiliary electrodes to modify the electric field distribution, creating more uniform fiber deposition and orientation across larger surface areas. This approach has been particularly effective for producing aligned nanofiber scaffolds for tissue engineering applications, where fiber orientation directly impacts cellular growth direction and mechanical properties[7].

Strengths: Exceptional control over fiber alignment through multi-parameter optimization; advanced collector designs that enhance orientation without mechanical manipulation; strong academic research foundation with extensive experimental validation. Weaknesses: Some techniques require complex equipment setups; scaling to industrial production volumes remains challenging; optimal parameters are often material-specific and require extensive calibration.

University of Akron

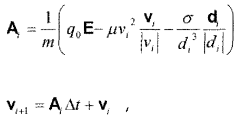

Technical Solution: The University of Akron has developed a sophisticated electrospinning parameter optimization framework specifically targeting fiber orientation enhancement. Their approach combines computational fluid dynamics modeling with experimental validation to predict and control fiber behavior during the electrospinning process. The university's research team has pioneered a technique called "field-assisted alignment" that utilizes auxiliary electrodes positioned strategically around the spinning zone to create controlled electric field gradients[2]. This system can achieve fiber alignment exceeding 90% in preferred directions by manipulating the electric field vectors. Additionally, they've developed a proprietary collector system incorporating programmable electrode arrays that can dynamically adjust during the spinning process to optimize orientation for different material systems. Their research has demonstrated that precise control of solution properties (particularly viscosity between 100-2000 cP) combined with optimized field strength (typically 1-2.5 kV/cm) and controlled environmental humidity (30-45%) creates reproducible fiber orientation patterns[5]. The university has also developed specialized software that predicts optimal parameter combinations based on polymer type and desired fiber characteristics.

Strengths: Integration of computational modeling with experimental approaches provides predictive capability; dynamic field control allows real-time adjustment during spinning; extensive material science expertise enables optimization across diverse polymer systems. Weaknesses: High-precision equipment requirements increase implementation costs; complex parameter interactions require sophisticated control systems; technique is more effective for certain polymer types than others.

Key Scientific Breakthroughs in Fiber Alignment

Method for predicting and optimizing system parameters for electrospinning system

PatentInactiveUS7901611B2

Innovation

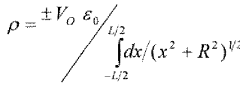

- A method for optimizing electrode parameters in an electrospinning system by using a conductive spinneret, a semi-conductive or non-conductive collector, and an electrode with opposing polarity voltages, combined with a particle acceleration model to predict and invert system parameters for aligned fiber mat production.

Method of predicting and optimizing system parameters for electrospinning system

PatentWO2009070493A1

Innovation

- A method involving a conductive spinneret, a non-conductive collector, and an electrode with opposing polarity voltages, combined with a particle acceleration model to predict and optimize system parameters such as voltage, distance, and radius, allowing for the production of aligned fiber mats without extensive trial-and-error.

Material Science Considerations for Enhanced Fiber Properties

The material science aspects of electrospinning represent a critical foundation for achieving enhanced fiber orientation. Polymer selection serves as the primary determinant of fiber properties, with molecular weight and chain entanglement significantly influencing the electrospinnability and resulting fiber morphology. High molecular weight polymers typically produce more uniform fibers with improved mechanical properties due to increased chain entanglement, while maintaining appropriate viscosity remains essential for consistent jet formation.

Polymer solution concentration directly impacts the viscoelastic properties that govern fiber formation. Solutions with concentrations below the critical entanglement concentration tend to form beaded fibers or even droplets through electrospraying. Conversely, excessively high concentrations may impede jet formation due to overwhelming viscosity. The optimal concentration window varies significantly between polymer types, necessitating systematic optimization for each material system.

Solvent selection introduces another layer of complexity, as evaporation rate and dielectric properties dramatically influence fiber formation dynamics. Fast-evaporating solvents may cause premature solidification, while slow-evaporating ones can result in wet fiber deposition and fusion. Binary or ternary solvent systems often provide superior control over evaporation kinetics and solution properties, enabling finer tuning of fiber characteristics.

Polymer crystallinity represents a crucial parameter affecting mechanical properties and orientation behavior. Semi-crystalline polymers typically exhibit enhanced molecular alignment during electrospinning due to strain-induced crystallization under the strong electric field. This phenomenon can be leveraged to produce highly oriented fibers with superior mechanical strength along the fiber axis.

Additives and dopants offer additional pathways for property enhancement. Conductive additives like carbon nanotubes or metallic nanoparticles can improve charge transport during electrospinning, resulting in more uniform fiber deposition and potentially enhanced orientation. Plasticizers may modify solution rheology and fiber flexibility, while crosslinking agents can be incorporated to improve thermal and chemical stability of the resulting fibers.

Surface modification techniques applied either to the polymer solution or post-processing can further enhance fiber functionality. Plasma treatment, chemical functionalization, or coating processes enable tailored surface properties without compromising the core fiber structure and orientation. These modifications expand the application potential of oriented electrospun fibers in fields requiring specific surface interactions, such as tissue engineering scaffolds or filtration membranes.

Polymer solution concentration directly impacts the viscoelastic properties that govern fiber formation. Solutions with concentrations below the critical entanglement concentration tend to form beaded fibers or even droplets through electrospraying. Conversely, excessively high concentrations may impede jet formation due to overwhelming viscosity. The optimal concentration window varies significantly between polymer types, necessitating systematic optimization for each material system.

Solvent selection introduces another layer of complexity, as evaporation rate and dielectric properties dramatically influence fiber formation dynamics. Fast-evaporating solvents may cause premature solidification, while slow-evaporating ones can result in wet fiber deposition and fusion. Binary or ternary solvent systems often provide superior control over evaporation kinetics and solution properties, enabling finer tuning of fiber characteristics.

Polymer crystallinity represents a crucial parameter affecting mechanical properties and orientation behavior. Semi-crystalline polymers typically exhibit enhanced molecular alignment during electrospinning due to strain-induced crystallization under the strong electric field. This phenomenon can be leveraged to produce highly oriented fibers with superior mechanical strength along the fiber axis.

Additives and dopants offer additional pathways for property enhancement. Conductive additives like carbon nanotubes or metallic nanoparticles can improve charge transport during electrospinning, resulting in more uniform fiber deposition and potentially enhanced orientation. Plasticizers may modify solution rheology and fiber flexibility, while crosslinking agents can be incorporated to improve thermal and chemical stability of the resulting fibers.

Surface modification techniques applied either to the polymer solution or post-processing can further enhance fiber functionality. Plasma treatment, chemical functionalization, or coating processes enable tailored surface properties without compromising the core fiber structure and orientation. These modifications expand the application potential of oriented electrospun fibers in fields requiring specific surface interactions, such as tissue engineering scaffolds or filtration membranes.

Scalability and Industrial Implementation Challenges

The transition from laboratory-scale electrospinning to industrial production presents significant challenges that must be addressed to achieve commercial viability. Current industrial implementations typically utilize multi-needle or needleless systems to increase production rates, but maintaining consistent fiber orientation across scaled-up equipment remains problematic. Production rates in laboratory settings (typically 0.1-1 g/hour) are insufficient for commercial applications, which require outputs of at least 10-100 g/hour to be economically feasible.

Environmental control becomes increasingly complex in industrial settings. Temperature and humidity fluctuations across larger production spaces can significantly impact fiber orientation consistency. Industrial facilities require sophisticated environmental control systems that add substantial capital and operational costs, estimated at 15-30% of total production expenses.

Material handling challenges also intensify at scale. Polymer solution properties may change during continuous operation due to solvent evaporation or polymer degradation, directly affecting fiber alignment. Industrial systems require closed-loop monitoring and adjustment mechanisms to maintain optimal viscosity and conductivity parameters throughout production runs.

Equipment design presents another critical challenge. While laboratory equipment can be manually adjusted to optimize fiber orientation, industrial-scale equipment must incorporate automated parameter control systems. Current industrial electrospinning equipment often sacrifices precise fiber orientation control for increased throughput, resulting in products with less consistent directional properties.

Energy consumption increases substantially at industrial scale, with high-voltage requirements (typically 10-30 kV) across multiple spinning units. This creates safety concerns and requires specialized infrastructure, adding complexity to facility design and operational protocols.

Quality control and characterization methods must also evolve for industrial implementation. Laboratory techniques for assessing fiber orientation, such as SEM imaging and FFT analysis, are too time-consuming for production environments. Real-time monitoring systems capable of detecting orientation deviations during manufacturing are still in early development stages, with current technologies achieving only 70-80% accuracy in orientation assessment.

Regulatory compliance adds another layer of complexity, particularly for medical or food-contact applications where fiber orientation may impact product performance. Documentation and validation of orientation parameters throughout scaled production requires sophisticated tracking systems that few manufacturers have successfully implemented.

Environmental control becomes increasingly complex in industrial settings. Temperature and humidity fluctuations across larger production spaces can significantly impact fiber orientation consistency. Industrial facilities require sophisticated environmental control systems that add substantial capital and operational costs, estimated at 15-30% of total production expenses.

Material handling challenges also intensify at scale. Polymer solution properties may change during continuous operation due to solvent evaporation or polymer degradation, directly affecting fiber alignment. Industrial systems require closed-loop monitoring and adjustment mechanisms to maintain optimal viscosity and conductivity parameters throughout production runs.

Equipment design presents another critical challenge. While laboratory equipment can be manually adjusted to optimize fiber orientation, industrial-scale equipment must incorporate automated parameter control systems. Current industrial electrospinning equipment often sacrifices precise fiber orientation control for increased throughput, resulting in products with less consistent directional properties.

Energy consumption increases substantially at industrial scale, with high-voltage requirements (typically 10-30 kV) across multiple spinning units. This creates safety concerns and requires specialized infrastructure, adding complexity to facility design and operational protocols.

Quality control and characterization methods must also evolve for industrial implementation. Laboratory techniques for assessing fiber orientation, such as SEM imaging and FFT analysis, are too time-consuming for production environments. Real-time monitoring systems capable of detecting orientation deviations during manufacturing are still in early development stages, with current technologies achieving only 70-80% accuracy in orientation assessment.

Regulatory compliance adds another layer of complexity, particularly for medical or food-contact applications where fiber orientation may impact product performance. Documentation and validation of orientation parameters throughout scaled production requires sophisticated tracking systems that few manufacturers have successfully implemented.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!