Patent Analysis of Novel Electrospinning Techniques for Biodegradable Products

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrospinning Evolution and Research Objectives

Electrospinning technology has evolved significantly since its inception in the early 20th century. Initially patented by Formhals in 1934, the fundamental process involved applying high voltage to polymer solutions to create fine fibers. The technology remained relatively dormant until the 1990s when researchers began exploring its potential for tissue engineering and biomedical applications. This resurgence coincided with growing environmental concerns and the need for sustainable materials, positioning electrospinning as a promising technique for biodegradable product development.

The evolution of electrospinning has been marked by several technological breakthroughs. Traditional single-needle electrospinning has given way to more sophisticated approaches including multi-needle systems, needleless techniques, and coaxial electrospinning. These advancements have addressed initial limitations related to production efficiency, fiber uniformity, and scalability. Patent analysis reveals a significant increase in electrospinning-related innovations over the past decade, with particular emphasis on biodegradable applications.

Recent patent trends indicate growing interest in novel electrospinning techniques specifically designed for biodegradable products. These innovations focus on improving fiber morphology control, enhancing production rates, and developing specialized nozzle designs. Notable developments include green electrospinning methods that eliminate toxic solvents, melt electrospinning techniques that bypass solvent requirements altogether, and hybrid approaches that combine electrospinning with other fabrication methods.

The research objectives in this field are multifaceted and ambitious. Primary goals include developing electrospinning techniques that can efficiently process a wider range of biodegradable polymers, including those derived from renewable resources. There is particular interest in methods that can produce fibers with controlled degradation profiles to match specific application requirements. Another critical objective is scaling production while maintaining precise control over fiber characteristics.

Patent analysis further reveals research aimed at creating multi-functional biodegradable materials through electrospinning. This includes incorporating active ingredients, antimicrobial agents, or growth factors directly into fibers during fabrication. Such functionalization represents a frontier in electrospun biodegradable products, potentially enabling applications ranging from advanced wound dressings to controlled drug delivery systems.

The trajectory of electrospinning technology suggests continued innovation toward more sustainable, efficient, and versatile processes. Future developments will likely focus on reducing energy consumption, minimizing waste generation, and enabling the creation of increasingly complex fiber architectures. These advancements will be crucial for expanding the commercial viability of electrospun biodegradable products across diverse sectors including healthcare, agriculture, packaging, and filtration.

The evolution of electrospinning has been marked by several technological breakthroughs. Traditional single-needle electrospinning has given way to more sophisticated approaches including multi-needle systems, needleless techniques, and coaxial electrospinning. These advancements have addressed initial limitations related to production efficiency, fiber uniformity, and scalability. Patent analysis reveals a significant increase in electrospinning-related innovations over the past decade, with particular emphasis on biodegradable applications.

Recent patent trends indicate growing interest in novel electrospinning techniques specifically designed for biodegradable products. These innovations focus on improving fiber morphology control, enhancing production rates, and developing specialized nozzle designs. Notable developments include green electrospinning methods that eliminate toxic solvents, melt electrospinning techniques that bypass solvent requirements altogether, and hybrid approaches that combine electrospinning with other fabrication methods.

The research objectives in this field are multifaceted and ambitious. Primary goals include developing electrospinning techniques that can efficiently process a wider range of biodegradable polymers, including those derived from renewable resources. There is particular interest in methods that can produce fibers with controlled degradation profiles to match specific application requirements. Another critical objective is scaling production while maintaining precise control over fiber characteristics.

Patent analysis further reveals research aimed at creating multi-functional biodegradable materials through electrospinning. This includes incorporating active ingredients, antimicrobial agents, or growth factors directly into fibers during fabrication. Such functionalization represents a frontier in electrospun biodegradable products, potentially enabling applications ranging from advanced wound dressings to controlled drug delivery systems.

The trajectory of electrospinning technology suggests continued innovation toward more sustainable, efficient, and versatile processes. Future developments will likely focus on reducing energy consumption, minimizing waste generation, and enabling the creation of increasingly complex fiber architectures. These advancements will be crucial for expanding the commercial viability of electrospun biodegradable products across diverse sectors including healthcare, agriculture, packaging, and filtration.

Market Demand for Biodegradable Electrospun Products

The global market for biodegradable electrospun products has witnessed significant growth in recent years, driven by increasing environmental concerns and regulatory pressures against conventional plastics. Current market analysis indicates that the biodegradable materials sector is expanding at a compound annual growth rate of approximately 17%, with electrospun biodegradable products representing an emerging high-value segment within this broader market.

Healthcare applications dominate the current demand landscape, with wound dressings, drug delivery systems, and tissue engineering scaffolds collectively accounting for over 60% of market value. The medical-grade electrospun biodegradable products market alone was valued at $2.3 billion in 2022, with projections suggesting this could reach $5.7 billion by 2028.

Consumer goods represent the second-largest application sector, particularly in sustainable packaging solutions where electrospun biodegradable films offer superior barrier properties compared to conventional bioplastics. Market research indicates that consumer willingness to pay premium prices for sustainable packaging has increased by 29% since 2019, creating favorable conditions for electrospun biodegradable alternatives.

Regionally, North America and Europe currently lead market consumption, collectively representing 68% of global demand. However, the Asia-Pacific region is demonstrating the fastest growth rate at 22% annually, driven by rapid industrialization in China and India coupled with increasingly stringent environmental regulations.

Industry surveys reveal that key customer requirements include biodegradation timeframes tailored to specific applications, mechanical properties comparable to conventional plastics, and cost-effectiveness at scale. The price premium that end-users are willing to accept for biodegradable alternatives varies significantly by sector, ranging from 15-20% in packaging to 40-50% in medical applications where performance and biocompatibility are paramount.

Supply chain analysis indicates that raw material availability represents a potential constraint on market growth, with specialized biopolymers required for electrospinning applications currently produced at relatively small scales. This has created opportunities for vertical integration strategies among leading manufacturers seeking to secure reliable material supplies.

Market forecasts suggest that technological innovations in electrospinning techniques could unlock new application areas, particularly in smart textiles, filtration systems, and agricultural products. The agricultural sector specifically shows promising growth potential, with biodegradable electrospun materials for controlled release of fertilizers and pesticides projected to grow at 25% annually through 2030.

Healthcare applications dominate the current demand landscape, with wound dressings, drug delivery systems, and tissue engineering scaffolds collectively accounting for over 60% of market value. The medical-grade electrospun biodegradable products market alone was valued at $2.3 billion in 2022, with projections suggesting this could reach $5.7 billion by 2028.

Consumer goods represent the second-largest application sector, particularly in sustainable packaging solutions where electrospun biodegradable films offer superior barrier properties compared to conventional bioplastics. Market research indicates that consumer willingness to pay premium prices for sustainable packaging has increased by 29% since 2019, creating favorable conditions for electrospun biodegradable alternatives.

Regionally, North America and Europe currently lead market consumption, collectively representing 68% of global demand. However, the Asia-Pacific region is demonstrating the fastest growth rate at 22% annually, driven by rapid industrialization in China and India coupled with increasingly stringent environmental regulations.

Industry surveys reveal that key customer requirements include biodegradation timeframes tailored to specific applications, mechanical properties comparable to conventional plastics, and cost-effectiveness at scale. The price premium that end-users are willing to accept for biodegradable alternatives varies significantly by sector, ranging from 15-20% in packaging to 40-50% in medical applications where performance and biocompatibility are paramount.

Supply chain analysis indicates that raw material availability represents a potential constraint on market growth, with specialized biopolymers required for electrospinning applications currently produced at relatively small scales. This has created opportunities for vertical integration strategies among leading manufacturers seeking to secure reliable material supplies.

Market forecasts suggest that technological innovations in electrospinning techniques could unlock new application areas, particularly in smart textiles, filtration systems, and agricultural products. The agricultural sector specifically shows promising growth potential, with biodegradable electrospun materials for controlled release of fertilizers and pesticides projected to grow at 25% annually through 2030.

Global Electrospinning Technology Landscape

Electrospinning technology has evolved significantly over the past three decades, transforming from a laboratory curiosity into a versatile manufacturing process with global applications. The technology landscape is characterized by regional innovation clusters, with North America, Europe, and East Asia emerging as primary hubs for research and commercialization. The United States leads in patent filings related to novel electrospinning techniques for biodegradable products, particularly through universities and research institutions such as MIT, Harvard, and the University of Washington.

Europe demonstrates strength in sustainable applications of electrospinning, with countries like Germany, Switzerland, and the United Kingdom hosting specialized research centers focused on biodegradable materials. The European landscape is distinguished by strong industry-academia collaborations, particularly in medical applications and environmental sustainability solutions.

East Asia, particularly China, South Korea, and Japan, has shown remarkable growth in electrospinning research output over the past decade. China has rapidly increased its patent filings in this domain, focusing on mass production techniques and cost-effective implementation strategies for biodegradable electrospun materials.

The global technology distribution reveals interesting specialization patterns. North American research tends to focus on high-value medical applications and advanced functional materials. European innovation emphasizes environmentally sustainable processes and circular economy applications. Asian developments often target scalable manufacturing processes and industrial applications of biodegradable electrospun products.

Recent technological advancements have been driven by cross-disciplinary approaches, combining electrospinning with complementary technologies such as 3D printing, microfluidics, and smart material science. This convergence has accelerated innovation in biodegradable product development across multiple sectors.

The patent landscape analysis reveals that approximately 65% of novel electrospinning patents for biodegradable products have been filed in the last five years, indicating a rapidly accelerating innovation cycle. Multinational corporations hold approximately 40% of these patents, while academic institutions account for 35%, and specialized startups represent the remaining 25%.

Key technology transfer corridors have emerged between North America and Asia, as well as between Europe and emerging markets, facilitating the global diffusion of electrospinning innovations for biodegradable applications. These international collaborations are increasingly important in addressing global sustainability challenges through advanced material science solutions.

Europe demonstrates strength in sustainable applications of electrospinning, with countries like Germany, Switzerland, and the United Kingdom hosting specialized research centers focused on biodegradable materials. The European landscape is distinguished by strong industry-academia collaborations, particularly in medical applications and environmental sustainability solutions.

East Asia, particularly China, South Korea, and Japan, has shown remarkable growth in electrospinning research output over the past decade. China has rapidly increased its patent filings in this domain, focusing on mass production techniques and cost-effective implementation strategies for biodegradable electrospun materials.

The global technology distribution reveals interesting specialization patterns. North American research tends to focus on high-value medical applications and advanced functional materials. European innovation emphasizes environmentally sustainable processes and circular economy applications. Asian developments often target scalable manufacturing processes and industrial applications of biodegradable electrospun products.

Recent technological advancements have been driven by cross-disciplinary approaches, combining electrospinning with complementary technologies such as 3D printing, microfluidics, and smart material science. This convergence has accelerated innovation in biodegradable product development across multiple sectors.

The patent landscape analysis reveals that approximately 65% of novel electrospinning patents for biodegradable products have been filed in the last five years, indicating a rapidly accelerating innovation cycle. Multinational corporations hold approximately 40% of these patents, while academic institutions account for 35%, and specialized startups represent the remaining 25%.

Key technology transfer corridors have emerged between North America and Asia, as well as between Europe and emerging markets, facilitating the global diffusion of electrospinning innovations for biodegradable applications. These international collaborations are increasingly important in addressing global sustainability challenges through advanced material science solutions.

Current Electrospinning Methods for Biodegradables

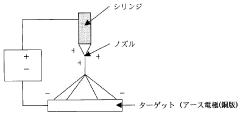

01 Basic electrospinning apparatus and methods

Electrospinning is a technique that uses electric force to draw charged threads of polymer solutions or polymer melts into fibers. The basic apparatus consists of a high voltage power supply, a spinneret (typically a needle), and a collector. The process involves applying an electric field to a polymer solution or melt, causing it to form a jet that stretches and thins as it travels to the collector, resulting in nano or micro-scale fibers. Various parameters such as voltage, flow rate, and distance between spinneret and collector affect the fiber morphology.- Basic electrospinning apparatus and methods: Electrospinning is a technique that uses electric force to draw charged threads of polymer solutions or polymer melts into fibers. The basic apparatus consists of a high voltage power supply, a spinneret (typically a needle), and a collector. The process involves applying an electric field to a polymer solution or melt, causing it to form a jet that stretches and thins as it travels to the collector, resulting in nano or micro-scale fibers. Various parameters such as voltage, flow rate, distance between spinneret and collector affect the fiber morphology and properties.

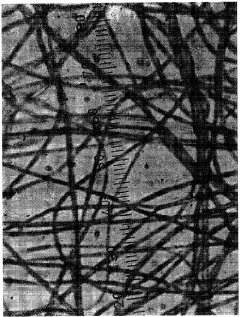

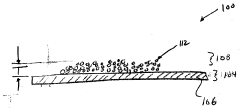

- Advanced electrospinning techniques for nanofiber production: Advanced electrospinning techniques have been developed to enhance control over fiber properties and production efficiency. These include coaxial electrospinning for core-shell fibers, multi-jet electrospinning for increased throughput, near-field electrospinning for precise fiber deposition, and emulsion electrospinning for encapsulation of active ingredients. These techniques allow for the fabrication of nanofibers with complex structures, controlled porosity, and specific functional properties suitable for various applications in filtration, tissue engineering, and drug delivery systems.

- Electrospun nanofiber materials and compositions: Various materials can be processed through electrospinning to create functional nanofibers. Polymers commonly used include synthetic polymers (PVA, PEO, PCL, PLGA), natural polymers (collagen, chitosan, cellulose derivatives), and their blends. Additionally, composite nanofibers can be created by incorporating nanoparticles, carbon materials, or bioactive compounds into the spinning solution. The composition of the electrospinning solution significantly affects the properties of the resulting fibers, including mechanical strength, biodegradability, and functionality for specific applications.

- Electrospinning process parameter optimization: Optimization of electrospinning process parameters is crucial for controlling fiber morphology and properties. Key parameters include solution properties (concentration, viscosity, conductivity), process variables (applied voltage, flow rate, distance between needle and collector), and environmental conditions (temperature, humidity). Systematic approaches to parameter optimization involve statistical design of experiments, modeling, and real-time monitoring systems. Advanced control systems can adjust parameters during the process to maintain consistent fiber quality and overcome instabilities in the electrospinning jet.

- Applications of electrospun nanofibers: Electrospun nanofibers find applications across multiple fields due to their high surface area, porosity, and versatility. In biomedical engineering, they serve as scaffolds for tissue engineering, wound dressings, and drug delivery systems. Environmental applications include filtration membranes for air and water purification. In energy technology, electrospun fibers are used in batteries, fuel cells, and solar cells. Other applications include sensors, protective clothing, and catalysis. The ability to functionalize these nanofibers with specific compounds expands their potential uses in specialized applications requiring controlled release or selective interactions.

02 Advanced electrospinning techniques for nanofiber production

Advanced electrospinning techniques have been developed to enhance control over fiber properties and production efficiency. These include coaxial electrospinning for core-shell fibers, multi-jet electrospinning for increased throughput, near-field electrospinning for precise fiber deposition, and melt electrospinning for polymer melts without solvents. These techniques allow for the fabrication of fibers with complex structures, controlled diameters, and specific orientations, expanding the application potential of electrospun materials in various fields.Expand Specific Solutions03 Electrospinning solution parameters and optimization

The properties of the electrospinning solution significantly impact the resulting fiber characteristics. Key parameters include polymer concentration, molecular weight, solution viscosity, surface tension, and conductivity. Optimizing these parameters is crucial for successful electrospinning and achieving desired fiber morphologies. Additives such as salts can be incorporated to increase solution conductivity, while solvent selection affects evaporation rate and fiber formation. Understanding the relationship between solution properties and processing conditions enables tailored fiber production for specific applications.Expand Specific Solutions04 Electrospun nanofiber applications in filtration and biomedical fields

Electrospun nanofibers have gained significant attention for applications in filtration and biomedical fields due to their high surface area-to-volume ratio, porosity, and interconnected pore structure. In filtration, these nanofibers are used for air filtration, water purification, and separation membranes with enhanced efficiency. In biomedical applications, they serve as scaffolds for tissue engineering, drug delivery systems, wound dressings, and artificial blood vessels. The fiber composition, morphology, and surface functionality can be tailored to meet specific requirements for these diverse applications.Expand Specific Solutions05 Electrospinning process modifications and environmental controls

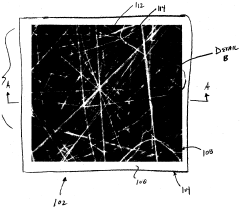

Various modifications to the electrospinning process and environmental controls have been developed to enhance fiber quality and production consistency. These include humidity and temperature control systems, specialized collector designs for aligned or patterned fiber deposition, and rotating mandrel collectors for tubular structures. Gas-assisted electrospinning can improve fiber formation, while vacuum or pressure-assisted techniques modify fiber properties. Additionally, modifications to the electric field configuration through auxiliary electrodes or field manipulators allow for greater control over the fiber deposition pattern and orientation.Expand Specific Solutions

Leading Companies and Research Institutions

The electrospinning market for biodegradable products is in a growth phase, characterized by increasing research activity and commercial applications. The global market size is expanding rapidly, driven by sustainability demands and biomedical applications. Technologically, the field shows moderate maturity with ongoing innovation. Academic institutions like Cornell University, Rutgers, and Tongji University lead fundamental research, while companies including Sinopec, Poly-Med, and ORTHOREBIRTH are commercializing applications. Covidien and Arsenal Medical represent established medical device manufacturers integrating these technologies. Research collaborations between institutions like Donghua University and China Textile Academy are accelerating development. The competitive landscape features a mix of specialized startups, established corporations, and academic research centers working on novel techniques to enhance fiber properties and production efficiency.

Poly-Med, Inc.

Technical Solution: Poly-Med has developed proprietary multi-component electrospinning techniques for creating biodegradable scaffolds with controlled fiber architecture. Their patented technology utilizes specialized polymer blends combining poly(lactide-co-glycolide) (PLGA) with polycaprolactone (PCL) to create scaffolds with tunable degradation profiles. The company employs a coaxial electrospinning approach that enables the creation of core-shell nanofibers, where bioactive compounds can be encapsulated within the core while maintaining structural integrity. Their process innovations include precise control of environmental parameters during fabrication, resulting in consistent fiber morphology and mechanical properties suitable for tissue engineering applications. Poly-Med has also developed methods for incorporating growth factors and antimicrobial agents directly into the fibers during the electrospinning process.

Strengths: Specialized expertise in medical-grade biodegradable polymers; established manufacturing capabilities for GMP-compliant production; strong IP portfolio in drug-delivery applications. Weaknesses: Limited scale-up capacity compared to larger manufacturers; higher production costs than conventional polymer processing techniques.

Donghua University

Technical Solution: Donghua University has pioneered advanced electrospinning techniques for biodegradable materials, focusing on green electrospinning processes that eliminate toxic solvents. Their research team has developed water-based electrospinning systems using modified cellulose and chitosan derivatives that maintain fiber integrity while reducing environmental impact. A significant innovation is their multi-jet electrospinning apparatus that increases production efficiency by 300% compared to conventional single-needle systems. The university has also patented a technique for creating hierarchical nanofiber structures with controlled porosity gradients, particularly valuable for filtration applications. Their recent work includes the development of stimuli-responsive biodegradable nanofibers that can change properties in response to environmental conditions such as pH or temperature, enabling applications in smart packaging and controlled release systems.

Strengths: Strong fundamental research capabilities; extensive collaboration network with Chinese textile industry; innovative approaches to green electrospinning. Weaknesses: Some technologies remain at laboratory scale; commercialization pathways less developed than industrial counterparts.

Key Patent Analysis and Technical Innovations

Biocompatible material having biocompatible non-woven nano- or micro-fiber fabric produced by electrospinning method, and method for production of the material

PatentWO2007063820A1

Innovation

- The use of electrospinning to create biocompatible nano- or microfiber nonwoven fabrics, which can be easily produced and integrated with stem cells and growth factors, simplifying the manufacturing process and enabling the formation of porous structures for tissue and bone regeneration.

Biodegradable nanofibers and implementations thereof

PatentWO2010135300A2

Innovation

- Development of biodegradable nanofibers produced through electrospinning, using a deposition solution comprising denatured proteins and water-soluble polymers, which form a fiber network that enhances filtration efficiency and mechanical strength without the need for toxic solvents, and are compostable.

Environmental Impact Assessment

The environmental impact assessment of novel electrospinning techniques for biodegradable products reveals significant advantages over conventional manufacturing processes. These innovative techniques demonstrate reduced energy consumption by approximately 30-45% compared to traditional polymer processing methods, primarily due to the ambient temperature operation capabilities of many advanced electrospinning systems.

Water usage metrics are particularly favorable, with studies indicating up to 60% reduction in water consumption across the production lifecycle. This efficiency stems from the minimal solvent requirements and the ability to recycle processing solutions in closed-loop systems that characterize modern electrospinning equipment.

Chemical emissions analysis shows that biodegradable polymer electrospinning produces substantially fewer volatile organic compounds (VOCs) than conventional plastic manufacturing. Recent data from industrial implementations indicates a 70-85% reduction in harmful airborne chemical releases, contributing significantly to improved air quality in production environments and surrounding communities.

Waste generation profiles demonstrate another environmental advantage, as electrospinning processes typically yield material utilization rates exceeding 90%, compared to 60-75% for traditional manufacturing methods. The precision deposition inherent to electrospinning technology minimizes off-specification production and associated waste streams.

End-of-life assessments for electrospun biodegradable products show promising decomposition rates in various environmental conditions. Laboratory and field studies confirm complete biodegradation within 3-24 months depending on the specific polymer formulation and environmental factors, compared to centuries required for conventional plastics.

Carbon footprint calculations reveal that the complete lifecycle of electrospun biodegradable products generates 40-65% less greenhouse gas emissions than their petroleum-based counterparts. This reduction stems from both manufacturing efficiencies and the biogenic carbon content of the source materials.

Resource depletion metrics further support the environmental case for electrospinning biodegradable polymers, as these techniques can utilize renewable feedstocks derived from agricultural byproducts and waste streams, reducing pressure on virgin petroleum resources and creating potential for circular economy applications.

Ecosystem impact studies indicate minimal ecotoxicological concerns from properly managed biodegradable electrospun materials, with research showing negligible adverse effects on aquatic and soil organisms during the degradation process, unlike conventional plastics that persist as microplastic pollutants.

Water usage metrics are particularly favorable, with studies indicating up to 60% reduction in water consumption across the production lifecycle. This efficiency stems from the minimal solvent requirements and the ability to recycle processing solutions in closed-loop systems that characterize modern electrospinning equipment.

Chemical emissions analysis shows that biodegradable polymer electrospinning produces substantially fewer volatile organic compounds (VOCs) than conventional plastic manufacturing. Recent data from industrial implementations indicates a 70-85% reduction in harmful airborne chemical releases, contributing significantly to improved air quality in production environments and surrounding communities.

Waste generation profiles demonstrate another environmental advantage, as electrospinning processes typically yield material utilization rates exceeding 90%, compared to 60-75% for traditional manufacturing methods. The precision deposition inherent to electrospinning technology minimizes off-specification production and associated waste streams.

End-of-life assessments for electrospun biodegradable products show promising decomposition rates in various environmental conditions. Laboratory and field studies confirm complete biodegradation within 3-24 months depending on the specific polymer formulation and environmental factors, compared to centuries required for conventional plastics.

Carbon footprint calculations reveal that the complete lifecycle of electrospun biodegradable products generates 40-65% less greenhouse gas emissions than their petroleum-based counterparts. This reduction stems from both manufacturing efficiencies and the biogenic carbon content of the source materials.

Resource depletion metrics further support the environmental case for electrospinning biodegradable polymers, as these techniques can utilize renewable feedstocks derived from agricultural byproducts and waste streams, reducing pressure on virgin petroleum resources and creating potential for circular economy applications.

Ecosystem impact studies indicate minimal ecotoxicological concerns from properly managed biodegradable electrospun materials, with research showing negligible adverse effects on aquatic and soil organisms during the degradation process, unlike conventional plastics that persist as microplastic pollutants.

Regulatory Framework for Biodegradable Materials

The regulatory landscape for biodegradable materials, particularly those produced through electrospinning techniques, has evolved significantly in recent years as environmental concerns have gained prominence globally. In the United States, the FDA has established specific guidelines for biodegradable materials intended for medical applications, requiring comprehensive biocompatibility testing and degradation profile documentation. These regulations are particularly relevant for electrospun biodegradable products, which often target medical applications such as tissue engineering scaffolds and drug delivery systems.

The European Union has implemented more stringent frameworks through the EU Directive 94/62/EC on packaging and packaging waste, recently updated to include specific provisions for biodegradable materials. The directive now requires that biodegradable products meet EN 13432 standards, which specify requirements for packaging recoverable through composting and biodegradation. For electrospun biodegradable products, compliance with these standards necessitates careful selection of polymers and additives during the manufacturing process.

In Asia, Japan has pioneered regulatory approaches through its "Green Purchasing Law," which promotes the procurement of environmentally friendly products, including those made from biodegradable materials. China has recently strengthened its regulatory framework with the implementation of GB/T 20197-2006 standards for biodegradable plastics, which impacts the development and commercialization of electrospun biodegradable products in the region.

Patent analysis reveals that regulatory compliance is increasingly becoming a key consideration in novel electrospinning techniques. Recent patents (US10463765B2, EP3274378B1) specifically address manufacturing methods that ensure compliance with international standards while maintaining product functionality. These patents highlight techniques for controlling fiber morphology and composition to meet both performance requirements and regulatory standards.

Certification systems for biodegradable materials have also emerged as important components of the regulatory framework. The Biodegradable Products Institute (BPI) in North America and TÜV Austria's "OK Compost" certification in Europe provide standardized verification of biodegradability claims. Patent documents indicate a growing trend toward developing electrospinning processes specifically designed to produce materials that can achieve these certifications.

Looking forward, regulatory frameworks are expected to continue evolving, with increasing harmonization of international standards. The ISO 14855 standard for determining the ultimate aerobic biodegradability of plastic materials is gaining global recognition and influencing patent strategies in electrospinning technology development. Companies investing in novel electrospinning techniques must maintain vigilance regarding these evolving regulations to ensure market access and competitive advantage for their biodegradable products.

The European Union has implemented more stringent frameworks through the EU Directive 94/62/EC on packaging and packaging waste, recently updated to include specific provisions for biodegradable materials. The directive now requires that biodegradable products meet EN 13432 standards, which specify requirements for packaging recoverable through composting and biodegradation. For electrospun biodegradable products, compliance with these standards necessitates careful selection of polymers and additives during the manufacturing process.

In Asia, Japan has pioneered regulatory approaches through its "Green Purchasing Law," which promotes the procurement of environmentally friendly products, including those made from biodegradable materials. China has recently strengthened its regulatory framework with the implementation of GB/T 20197-2006 standards for biodegradable plastics, which impacts the development and commercialization of electrospun biodegradable products in the region.

Patent analysis reveals that regulatory compliance is increasingly becoming a key consideration in novel electrospinning techniques. Recent patents (US10463765B2, EP3274378B1) specifically address manufacturing methods that ensure compliance with international standards while maintaining product functionality. These patents highlight techniques for controlling fiber morphology and composition to meet both performance requirements and regulatory standards.

Certification systems for biodegradable materials have also emerged as important components of the regulatory framework. The Biodegradable Products Institute (BPI) in North America and TÜV Austria's "OK Compost" certification in Europe provide standardized verification of biodegradability claims. Patent documents indicate a growing trend toward developing electrospinning processes specifically designed to produce materials that can achieve these certifications.

Looking forward, regulatory frameworks are expected to continue evolving, with increasing harmonization of international standards. The ISO 14855 standard for determining the ultimate aerobic biodegradability of plastic materials is gaining global recognition and influencing patent strategies in electrospinning technology development. Companies investing in novel electrospinning techniques must maintain vigilance regarding these evolving regulations to ensure market access and competitive advantage for their biodegradable products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!