The Impact of Electrospinning on Flexibility and Stretchability in Smart Fabrics

SEP 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrospinning Technology Evolution and Objectives

Electrospinning technology emerged in the early 20th century when Anton Formhals patented the process in 1934. However, it wasn't until the 1990s that this technology gained significant attention in the scientific community, primarily due to advancements in nanomaterial characterization techniques. The fundamental principle involves applying a high voltage to a polymer solution or melt, creating an electrically charged jet that stretches and thins as it travels toward a collector, resulting in ultra-fine fibers with diameters ranging from nanometers to micrometers.

The evolution of electrospinning has been marked by several key technological breakthroughs. Initially limited to laboratory-scale production, the early 2000s saw the development of multi-needle and needleless electrospinning systems, significantly enhancing production capacity. Coaxial electrospinning, introduced around 2003, enabled the creation of core-shell structured nanofibers, expanding the functional possibilities of electrospun materials.

In the context of smart fabrics, electrospinning technology has undergone a remarkable transformation over the past decade. Traditional electrospun fibers were primarily valued for their high surface-to-volume ratio and porosity. However, recent innovations have focused on enhancing the mechanical properties of these fibers, particularly flexibility and stretchability, which are crucial for wearable applications.

The integration of conductive materials into electrospun fibers represents another significant milestone. By incorporating conductive polymers, carbon nanomaterials, or metallic nanoparticles, researchers have developed electrospun fibers with electrical conductivity while maintaining their inherent flexibility. This advancement has been pivotal for the development of sensors, actuators, and energy storage components in smart textiles.

Recent years have witnessed the emergence of stimuli-responsive electrospun fibers, capable of changing their properties in response to external stimuli such as temperature, pH, or electrical signals. These "smart" fibers form the foundation of advanced functionalities in modern smart fabrics, enabling applications ranging from health monitoring to adaptive thermal regulation.

The primary objectives of current electrospinning research in smart fabrics include enhancing the mechanical durability of electrospun materials under repeated deformation, improving the washability and environmental stability of functional fibers, and developing scalable production methods for commercial viability. Additionally, there is a growing focus on creating multi-functional fibers that can simultaneously sense multiple parameters while maintaining comfort and wearability.

Another critical objective is reducing the environmental impact of electrospinning processes by developing green solvents and biodegradable polymers. This aligns with the broader sustainability goals in the textile industry and addresses concerns about microplastic pollution from synthetic fibers.

The evolution of electrospinning has been marked by several key technological breakthroughs. Initially limited to laboratory-scale production, the early 2000s saw the development of multi-needle and needleless electrospinning systems, significantly enhancing production capacity. Coaxial electrospinning, introduced around 2003, enabled the creation of core-shell structured nanofibers, expanding the functional possibilities of electrospun materials.

In the context of smart fabrics, electrospinning technology has undergone a remarkable transformation over the past decade. Traditional electrospun fibers were primarily valued for their high surface-to-volume ratio and porosity. However, recent innovations have focused on enhancing the mechanical properties of these fibers, particularly flexibility and stretchability, which are crucial for wearable applications.

The integration of conductive materials into electrospun fibers represents another significant milestone. By incorporating conductive polymers, carbon nanomaterials, or metallic nanoparticles, researchers have developed electrospun fibers with electrical conductivity while maintaining their inherent flexibility. This advancement has been pivotal for the development of sensors, actuators, and energy storage components in smart textiles.

Recent years have witnessed the emergence of stimuli-responsive electrospun fibers, capable of changing their properties in response to external stimuli such as temperature, pH, or electrical signals. These "smart" fibers form the foundation of advanced functionalities in modern smart fabrics, enabling applications ranging from health monitoring to adaptive thermal regulation.

The primary objectives of current electrospinning research in smart fabrics include enhancing the mechanical durability of electrospun materials under repeated deformation, improving the washability and environmental stability of functional fibers, and developing scalable production methods for commercial viability. Additionally, there is a growing focus on creating multi-functional fibers that can simultaneously sense multiple parameters while maintaining comfort and wearability.

Another critical objective is reducing the environmental impact of electrospinning processes by developing green solvents and biodegradable polymers. This aligns with the broader sustainability goals in the textile industry and addresses concerns about microplastic pollution from synthetic fibers.

Market Analysis for Flexible Smart Textile Applications

The global market for flexible smart textiles is experiencing unprecedented growth, driven by increasing consumer demand for wearable technology that seamlessly integrates into daily life. Current market valuations place the smart textile sector at approximately 3.6 billion USD in 2023, with projections indicating a compound annual growth rate (CAGR) of 26.2% through 2030. Flexible and stretchable smart fabrics, particularly those enhanced through electrospinning technology, represent one of the fastest-growing segments within this market.

Healthcare applications currently dominate the flexible smart textile market, accounting for roughly 32% of total market share. The integration of electrospun fibers into medical monitoring devices has created significant opportunities for continuous health monitoring solutions that conform to body contours while maintaining accuracy. This segment is expected to maintain strong growth as aging populations in developed economies drive demand for remote patient monitoring systems.

The sports and fitness sector represents the second-largest application area, comprising approximately 28% of the market. Consumers increasingly seek performance-enhancing apparel that can monitor biometric data while providing comfort during physical activity. Electrospun fabrics offer superior breathability and flexibility compared to conventional e-textiles, creating a competitive advantage for manufacturers who have mastered this technology.

Military and defense applications, though smaller in overall market share at 17%, demonstrate the highest willingness to adopt premium-priced solutions. The extreme durability requirements and need for multifunctional capabilities make electrospun smart fabrics particularly valuable in this sector, with significant government funding supporting continued research and development.

Consumer electronics integration represents an emerging application with substantial growth potential. As the boundaries between traditional textiles and electronic devices continue to blur, market analysts predict this segment could grow at 34% annually, potentially overtaking other applications by 2028. The ability of electrospun fabrics to accommodate stretchable circuits while maintaining textile-like properties positions them ideally for this convergence.

Regional analysis reveals Asia-Pacific as the fastest-growing market for flexible smart textiles, with China and South Korea leading manufacturing innovation. North America maintains the largest market share currently, driven by strong research institutions and venture capital investment in smart textile startups. European markets demonstrate particular strength in high-end applications, especially in automotive and luxury fashion sectors where electrospun smart fabrics command premium pricing.

Consumer willingness to pay for flexible smart textiles varies significantly by application, with healthcare users demonstrating the highest price tolerance, followed by professional athletes and military procurement. Mass-market adoption hinges on manufacturers achieving economies of scale that can bring production costs down while maintaining the enhanced performance characteristics that electrospinning technology enables.

Healthcare applications currently dominate the flexible smart textile market, accounting for roughly 32% of total market share. The integration of electrospun fibers into medical monitoring devices has created significant opportunities for continuous health monitoring solutions that conform to body contours while maintaining accuracy. This segment is expected to maintain strong growth as aging populations in developed economies drive demand for remote patient monitoring systems.

The sports and fitness sector represents the second-largest application area, comprising approximately 28% of the market. Consumers increasingly seek performance-enhancing apparel that can monitor biometric data while providing comfort during physical activity. Electrospun fabrics offer superior breathability and flexibility compared to conventional e-textiles, creating a competitive advantage for manufacturers who have mastered this technology.

Military and defense applications, though smaller in overall market share at 17%, demonstrate the highest willingness to adopt premium-priced solutions. The extreme durability requirements and need for multifunctional capabilities make electrospun smart fabrics particularly valuable in this sector, with significant government funding supporting continued research and development.

Consumer electronics integration represents an emerging application with substantial growth potential. As the boundaries between traditional textiles and electronic devices continue to blur, market analysts predict this segment could grow at 34% annually, potentially overtaking other applications by 2028. The ability of electrospun fabrics to accommodate stretchable circuits while maintaining textile-like properties positions them ideally for this convergence.

Regional analysis reveals Asia-Pacific as the fastest-growing market for flexible smart textiles, with China and South Korea leading manufacturing innovation. North America maintains the largest market share currently, driven by strong research institutions and venture capital investment in smart textile startups. European markets demonstrate particular strength in high-end applications, especially in automotive and luxury fashion sectors where electrospun smart fabrics command premium pricing.

Consumer willingness to pay for flexible smart textiles varies significantly by application, with healthcare users demonstrating the highest price tolerance, followed by professional athletes and military procurement. Mass-market adoption hinges on manufacturers achieving economies of scale that can bring production costs down while maintaining the enhanced performance characteristics that electrospinning technology enables.

Current Challenges in Electrospun Smart Fabric Development

Despite significant advancements in electrospinning technology for smart fabrics, several critical challenges continue to impede the full realization of flexible and stretchable electronic textiles. The primary technical obstacle remains the inherent trade-off between electrical conductivity and mechanical properties. When conductive materials are incorporated into electrospun fibers, they often compromise the fabric's flexibility and stretchability, creating a fundamental engineering dilemma that researchers are still working to resolve.

The scalability of electrospinning processes presents another significant hurdle. While laboratory-scale production of electrospun smart fabrics has demonstrated promising results, transitioning to industrial-scale manufacturing while maintaining consistent fiber quality, uniform distribution of functional components, and reproducible performance metrics remains problematic. Current industrial electrospinning setups struggle with throughput limitations and process parameter control across larger production volumes.

Durability under real-world conditions continues to challenge developers. Electrospun smart fabrics frequently exhibit performance degradation after repeated mechanical deformation, washing cycles, or exposure to environmental factors such as humidity and temperature fluctuations. The interface between the electrospun fibers and embedded electronic components often represents a weak point, with delamination and connection failures occurring during normal wear and use.

Material compatibility issues further complicate development efforts. Many high-performance conductive materials and functional additives are difficult to incorporate into the electrospinning process due to solubility limitations, viscosity requirements, or chemical incompatibilities with polymer solutions. This restricts the range of available materials and potentially limits the performance ceiling of resulting smart fabrics.

Power management remains an unresolved challenge, as many smart fabric applications require integrated energy storage or harvesting capabilities. Incorporating batteries or energy harvesting components while maintaining the fabric's flexibility, comfort, and washability presents significant design and manufacturing difficulties that current electrospinning approaches have not fully addressed.

Standardization and testing methodologies specific to electrospun smart fabrics are notably underdeveloped. The industry lacks consensus on performance metrics, testing protocols, and quality standards, making it difficult to compare different solutions or establish benchmarks for commercial viability. This absence of standardization slows adoption and commercialization efforts.

Cost considerations also present barriers to widespread implementation. Current manufacturing processes for high-performance electrospun smart fabrics involve expensive materials, complex processing steps, and specialized equipment, resulting in products that are prohibitively expensive for mass-market applications. Finding cost-effective approaches without sacrificing performance remains a critical challenge for researchers and manufacturers alike.

The scalability of electrospinning processes presents another significant hurdle. While laboratory-scale production of electrospun smart fabrics has demonstrated promising results, transitioning to industrial-scale manufacturing while maintaining consistent fiber quality, uniform distribution of functional components, and reproducible performance metrics remains problematic. Current industrial electrospinning setups struggle with throughput limitations and process parameter control across larger production volumes.

Durability under real-world conditions continues to challenge developers. Electrospun smart fabrics frequently exhibit performance degradation after repeated mechanical deformation, washing cycles, or exposure to environmental factors such as humidity and temperature fluctuations. The interface between the electrospun fibers and embedded electronic components often represents a weak point, with delamination and connection failures occurring during normal wear and use.

Material compatibility issues further complicate development efforts. Many high-performance conductive materials and functional additives are difficult to incorporate into the electrospinning process due to solubility limitations, viscosity requirements, or chemical incompatibilities with polymer solutions. This restricts the range of available materials and potentially limits the performance ceiling of resulting smart fabrics.

Power management remains an unresolved challenge, as many smart fabric applications require integrated energy storage or harvesting capabilities. Incorporating batteries or energy harvesting components while maintaining the fabric's flexibility, comfort, and washability presents significant design and manufacturing difficulties that current electrospinning approaches have not fully addressed.

Standardization and testing methodologies specific to electrospun smart fabrics are notably underdeveloped. The industry lacks consensus on performance metrics, testing protocols, and quality standards, making it difficult to compare different solutions or establish benchmarks for commercial viability. This absence of standardization slows adoption and commercialization efforts.

Cost considerations also present barriers to widespread implementation. Current manufacturing processes for high-performance electrospun smart fabrics involve expensive materials, complex processing steps, and specialized equipment, resulting in products that are prohibitively expensive for mass-market applications. Finding cost-effective approaches without sacrificing performance remains a critical challenge for researchers and manufacturers alike.

Existing Electrospinning Methods for Enhanced Flexibility

01 Polymer composition for flexible electrospun fibers

Specific polymer compositions can be used in electrospinning to enhance the flexibility and stretchability of the resulting fibers. These compositions include elastomeric polymers, polymer blends, and copolymers that maintain their structural integrity while allowing for significant deformation. The addition of plasticizers or the use of polymers with inherently low glass transition temperatures contributes to improved flexibility in the electrospun materials.- Material selection for flexible electrospun fibers: The choice of polymers and additives significantly impacts the flexibility and stretchability of electrospun fibers. Elastomeric polymers such as polyurethane, thermoplastic polyurethane (TPU), and polycaprolactone (PCL) are commonly used to create stretchable nanofibers. Incorporating elastomeric components into polymer blends can enhance the mechanical properties of the resulting fibers, allowing them to withstand repeated stretching and bending without permanent deformation.

- Fiber alignment and structural design: The arrangement and structural design of electrospun fibers play a crucial role in determining the flexibility and stretchability of the resulting materials. Techniques such as controlled deposition, patterning, and creating hierarchical structures can be employed to enhance mechanical properties. Aligned fibers can provide directional stretchability, while randomly oriented fibers often offer omnidirectional flexibility. Creating wavy, coiled, or helical fiber structures allows for greater extensibility by providing structural mechanisms for accommodating strain.

- Composite and hybrid electrospun materials: Combining electrospun fibers with other materials or creating hybrid structures can significantly enhance flexibility and stretchability. Incorporating conductive materials like carbon nanotubes or silver nanowires into electrospun fibers creates stretchable electronics that maintain conductivity under deformation. Layered structures with alternating rigid and flexible components can provide both strength and stretchability. Fiber-reinforced composites using electrospun nanofibers as the reinforcing phase can improve the mechanical properties of the matrix material.

- Processing parameters optimization: The electrospinning process parameters significantly influence the flexibility and stretchability of the resulting fibers. Factors such as solution concentration, applied voltage, flow rate, and collector distance can be optimized to control fiber diameter, morphology, and internal structure. Post-processing treatments like thermal annealing, crosslinking, or mechanical conditioning can further enhance the stretchability of electrospun materials. Controlling the solvent evaporation rate and environmental conditions during spinning affects the crystallinity and molecular orientation within fibers, which directly impacts their mechanical properties.

- Applications of flexible electrospun materials: Flexible and stretchable electrospun materials find applications across various fields. In wearable technology, these materials serve as comfortable, conformable substrates for sensors and electronic components that can adapt to body movements. Medical applications include tissue engineering scaffolds that mimic the mechanical properties of natural tissues, wound dressings that conform to irregular surfaces, and drug delivery systems with controlled release properties. Stretchable electrospun materials are also used in energy storage devices like flexible batteries and supercapacitors, as well as in smart textiles that respond to environmental stimuli or user input.

02 Fiber alignment and structural design for stretchability

The arrangement and alignment of electrospun fibers significantly impact the stretchability of the resulting material. Techniques such as controlled deposition, collector modification, and post-processing treatments can create structures with fibers aligned in specific patterns or directions. These structural designs, including wavy, coiled, or helical fiber arrangements, allow for greater extension without fiber breakage, enhancing the overall stretchability of the material.Expand Specific Solutions03 Composite and hybrid materials for enhanced mechanical properties

Incorporating multiple materials into electrospun fibers creates composite structures with enhanced flexibility and stretchability. These composites may combine rigid and elastic components, incorporate nanoparticles, or feature core-shell structures. The synergistic interaction between different materials allows for improved mechanical properties, including better recovery after stretching and increased durability during repeated deformation cycles.Expand Specific Solutions04 Processing parameters affecting flexibility

Various electrospinning process parameters directly influence the flexibility and stretchability of the resulting fibers. These parameters include solution concentration, applied voltage, flow rate, and environmental conditions such as humidity and temperature. Optimizing these parameters can control fiber diameter, crystallinity, and molecular orientation, which in turn affect the mechanical properties of the electrospun material.Expand Specific Solutions05 Post-treatment methods for improving stretchability

Post-electrospinning treatments can significantly enhance the flexibility and stretchability of fiber mats. These treatments include thermal annealing, chemical crosslinking, mechanical stretching, and surface modifications. Such processes can alter the molecular structure, reduce internal stress, create additional bonds between fibers, or modify the surface properties to achieve desired mechanical characteristics in the final product.Expand Specific Solutions

Leading Companies and Research Institutions in Smart Textiles

The electrospinning technology for smart fabrics is currently in a growth phase, with the market expanding rapidly due to increasing demand for wearable technology and functional textiles. The global smart fabric market is projected to reach significant scale as applications diversify across healthcare, sports, and defense sectors. From a technological maturity perspective, academic institutions lead fundamental research, with MIT, University of Delaware, and Johns Hopkins University pioneering innovative approaches to enhance flexibility and stretchability. Commercial entities like Kolon Glotech, Gentex, and Nicast are advancing practical applications, while specialized companies such as Poly-Med focus on biomedical implementations. Government agencies like NASA contribute to high-performance applications, creating a competitive landscape where collaboration between research institutions and industry partners drives innovation toward market-ready solutions.

Massachusetts Institute of Technology

Technical Solution: MIT has pioneered advanced electrospinning techniques for creating highly flexible and stretchable smart fabrics. Their approach involves using core-shell electrospinning to create fibers with conductive cores and elastic polymer shells. This structure allows for maintaining electrical conductivity even under significant mechanical deformation (up to 300% strain) while preserving sensing capabilities. MIT researchers have developed a specialized coaxial electrospinning setup that enables precise control over the fiber morphology and composition, resulting in fabrics that can withstand repeated stretching cycles (>10,000) without significant performance degradation. Their technology incorporates thermoplastic elastomers with conductive nanomaterials (carbon nanotubes, silver nanowires) to achieve both stretchability and functionality. MIT has also implemented a post-processing technique involving controlled thermal treatment to enhance the interface between the conductive elements and polymer matrix, significantly improving durability.

Strengths: Superior stretchability while maintaining electrical conductivity; excellent durability under repeated mechanical stress; precise control over fiber architecture. Weaknesses: Complex manufacturing process requiring specialized equipment; higher production costs compared to conventional methods; challenges in scaling up for mass production.

University of Akron

Technical Solution: The University of Akron has developed a proprietary electrospinning technique focused on creating multi-functional smart fabrics with enhanced flexibility. Their approach utilizes a combination of solution and melt electrospinning to create hierarchical fiber structures with controlled porosity. The university's researchers have pioneered the incorporation of liquid crystalline elastomers into electrospun fibers, creating materials that respond to multiple stimuli (temperature, light, and electrical signals) while maintaining excellent mechanical properties. Their technology employs a modified electrospinning setup with controlled environmental parameters (humidity, temperature) to achieve precise fiber alignment and consistent mechanical properties. The resulting fabrics demonstrate reversible shape-memory behavior, with the ability to return to their original dimensions after stretching up to 200%. Additionally, they've developed a post-electrospinning treatment involving controlled crosslinking reactions to enhance the durability and wash resistance of the smart fabrics.

Strengths: Multi-stimuli responsive capabilities; excellent shape recovery properties; controlled fiber architecture for optimized mechanical performance. Weaknesses: Complex material formulations requiring precise processing conditions; potential challenges in maintaining uniform properties across large fabric areas; limited long-term stability under extreme environmental conditions.

Key Patents and Innovations in Stretchable Electrospun Fibers

Fibrous materials incorporating amyloid proteins and process for manufacturing same

PatentWO2016203166A1

Innovation

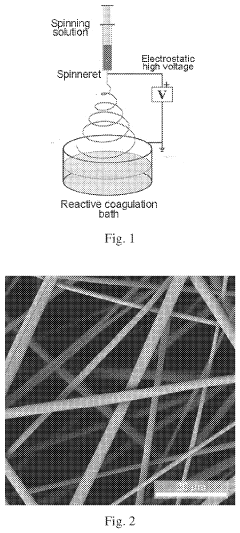

- A solvent-based spinning process, specifically electrospinning, is used to produce fibrous composite materials incorporating amyloid proteins, which preserves the functional properties of the proteins and enhances the rheological properties of the resulting fibers, allowing for the creation of materials with improved elasticity and functionality such as nickel chelation.

Magnetic fiber material, preparation method for same, and applications thereof

PatentActiveUS20230011363A1

Innovation

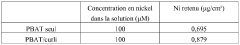

- A method involving in-situ synthesis of magnetic materials through electrospinning using a reactive coagulation bath to prevent agglomeration, where a polymer and magnetic load raw material are dissolved in a solvent, and the solute component in the coagulation bath reacts with the magnetic material to maintain dispersion and enhance magnetic properties.

Sustainability Aspects of Electrospun Smart Textile Production

The sustainability of electrospun smart textile production represents a critical dimension in the evolution of wearable technology. Current manufacturing processes for electrospun smart fabrics involve significant environmental challenges, including high energy consumption during the electrospinning process and the use of potentially harmful solvents. These factors contribute to a considerable carbon footprint that must be addressed as production scales increase to meet growing market demand.

Material selection plays a pivotal role in sustainability considerations. Traditional electrospinning often relies on petroleum-based polymers that present end-of-life disposal challenges. Recent research has demonstrated promising results with biodegradable alternatives such as polylactic acid (PLA), cellulose derivatives, and chitosan. These bio-based materials can reduce environmental impact while maintaining the flexibility and stretchability characteristics essential for smart fabric functionality.

Water consumption represents another significant sustainability concern in electrospun textile production. Conventional wet-spinning techniques require substantial water resources for polymer dissolution and fiber collection. Innovative dry electrospinning methods are emerging as water-conserving alternatives, reducing resource utilization by up to 60% compared to traditional approaches while preserving mechanical properties crucial for wearable applications.

Energy efficiency improvements present substantial opportunities for sustainability enhancement. Current electrospinning setups typically operate at high voltages (10-30 kV) for extended periods, resulting in considerable energy consumption. Research indicates that optimized field configurations and ambient condition controls can reduce energy requirements by 25-40% without compromising fiber quality or the resulting fabric's flexibility characteristics.

Lifecycle assessment (LCA) studies reveal that the environmental impact of electrospun smart textiles extends beyond production to include use phase and disposal considerations. Smart fabrics designed with modular components facilitate easier separation of electronic elements from textile substrates, enhancing recyclability. Additionally, emerging design approaches incorporate disassembly considerations from inception, allowing for component recovery and reducing landfill contributions.

Regulatory frameworks are increasingly influencing sustainable production practices in smart textiles. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar global initiatives are driving manufacturers toward greener chemistry approaches in electrospinning. This includes the development of non-toxic solvent systems and water-based polymer solutions that maintain the mechanical performance required for stretchable smart fabrics while reducing environmental and health hazards.

Material selection plays a pivotal role in sustainability considerations. Traditional electrospinning often relies on petroleum-based polymers that present end-of-life disposal challenges. Recent research has demonstrated promising results with biodegradable alternatives such as polylactic acid (PLA), cellulose derivatives, and chitosan. These bio-based materials can reduce environmental impact while maintaining the flexibility and stretchability characteristics essential for smart fabric functionality.

Water consumption represents another significant sustainability concern in electrospun textile production. Conventional wet-spinning techniques require substantial water resources for polymer dissolution and fiber collection. Innovative dry electrospinning methods are emerging as water-conserving alternatives, reducing resource utilization by up to 60% compared to traditional approaches while preserving mechanical properties crucial for wearable applications.

Energy efficiency improvements present substantial opportunities for sustainability enhancement. Current electrospinning setups typically operate at high voltages (10-30 kV) for extended periods, resulting in considerable energy consumption. Research indicates that optimized field configurations and ambient condition controls can reduce energy requirements by 25-40% without compromising fiber quality or the resulting fabric's flexibility characteristics.

Lifecycle assessment (LCA) studies reveal that the environmental impact of electrospun smart textiles extends beyond production to include use phase and disposal considerations. Smart fabrics designed with modular components facilitate easier separation of electronic elements from textile substrates, enhancing recyclability. Additionally, emerging design approaches incorporate disassembly considerations from inception, allowing for component recovery and reducing landfill contributions.

Regulatory frameworks are increasingly influencing sustainable production practices in smart textiles. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar global initiatives are driving manufacturers toward greener chemistry approaches in electrospinning. This includes the development of non-toxic solvent systems and water-based polymer solutions that maintain the mechanical performance required for stretchable smart fabrics while reducing environmental and health hazards.

Standards and Testing Protocols for Flexible Smart Fabrics

The development of standardized testing protocols for flexible smart fabrics represents a critical challenge in the electrospinning domain. Currently, the industry lacks unified standards specifically designed to evaluate the unique properties of electrospun smart textiles, particularly regarding their flexibility and stretchability performance under various conditions.

International organizations such as ASTM International, ISO, and AATCC have established general textile testing methods, but these often fail to address the distinctive characteristics of electrospun smart fabrics. For instance, ASTM D1388 measures fabric stiffness, while ASTM D5034 evaluates tensile strength, yet neither adequately captures the complex interplay between electronic functionality and mechanical properties in smart textiles.

Testing protocols for electrospun smart fabrics must evaluate multiple parameters simultaneously. Key metrics include electrical conductivity retention during stretching, sensor accuracy under deformation, washability while maintaining electronic functions, and long-term reliability under repeated mechanical stress. The IPC-9204 standard for stretchable electronics provides some guidance but requires adaptation for textile-specific applications.

Emerging testing methodologies focus on cyclic loading tests that measure conductivity changes during repeated stretching, environmental testing for performance under varying humidity and temperature conditions, and abrasion resistance testing while monitoring electronic functionality. These protocols typically employ specialized equipment such as dynamic mechanical analyzers modified to measure electrical properties simultaneously with mechanical deformation.

Wearable technology companies and research institutions have developed proprietary testing protocols, creating inconsistencies in performance reporting across the industry. This fragmentation hinders meaningful comparison between different electrospun smart fabric technologies and slows market adoption.

Recent collaborative efforts between academia and industry stakeholders aim to establish standardized testing frameworks. The IEEE P2731 working group is developing standards for wearable electronic devices, while the Smart Textile Alliance has initiated a project to create testing guidelines specifically for electronically enhanced textiles. These initiatives recognize the need for test methods that evaluate both the textile and electronic aspects of smart fabrics.

For electrospun materials specifically, testing protocols must address unique challenges such as fiber alignment under strain, nanofiber junction stability during stretching, and the impact of fiber diameter distribution on overall fabric performance. Standardized sample preparation methods are equally important, as variations in electrospinning parameters can significantly affect the final material properties.

International organizations such as ASTM International, ISO, and AATCC have established general textile testing methods, but these often fail to address the distinctive characteristics of electrospun smart fabrics. For instance, ASTM D1388 measures fabric stiffness, while ASTM D5034 evaluates tensile strength, yet neither adequately captures the complex interplay between electronic functionality and mechanical properties in smart textiles.

Testing protocols for electrospun smart fabrics must evaluate multiple parameters simultaneously. Key metrics include electrical conductivity retention during stretching, sensor accuracy under deformation, washability while maintaining electronic functions, and long-term reliability under repeated mechanical stress. The IPC-9204 standard for stretchable electronics provides some guidance but requires adaptation for textile-specific applications.

Emerging testing methodologies focus on cyclic loading tests that measure conductivity changes during repeated stretching, environmental testing for performance under varying humidity and temperature conditions, and abrasion resistance testing while monitoring electronic functionality. These protocols typically employ specialized equipment such as dynamic mechanical analyzers modified to measure electrical properties simultaneously with mechanical deformation.

Wearable technology companies and research institutions have developed proprietary testing protocols, creating inconsistencies in performance reporting across the industry. This fragmentation hinders meaningful comparison between different electrospun smart fabric technologies and slows market adoption.

Recent collaborative efforts between academia and industry stakeholders aim to establish standardized testing frameworks. The IEEE P2731 working group is developing standards for wearable electronic devices, while the Smart Textile Alliance has initiated a project to create testing guidelines specifically for electronically enhanced textiles. These initiatives recognize the need for test methods that evaluate both the textile and electronic aspects of smart fabrics.

For electrospun materials specifically, testing protocols must address unique challenges such as fiber alignment under strain, nanofiber junction stability during stretching, and the impact of fiber diameter distribution on overall fabric performance. Standardized sample preparation methods are equally important, as variations in electrospinning parameters can significantly affect the final material properties.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!