Electrospinning: Bridging the Gap in Nanotechnology and Textile Engineering

SEP 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrospinning Evolution and Research Objectives

Electrospinning technology has evolved significantly since its inception in the early 20th century. The fundamental concept was first patented by J.F. Cooley and W.J. Morton in 1902, but it was Anton Formhals who made substantial contributions through a series of patents from 1934 to 1944, establishing the foundation for modern electrospinning processes. The technology remained relatively dormant until the 1990s when nanotechnology emerged as a prominent field, catalyzing renewed interest in electrospinning as a viable method for nanofiber production.

The evolution of electrospinning has been characterized by progressive refinements in equipment design, process parameters, and material compatibility. Early systems were rudimentary, utilizing simple needle-based setups with limited control over fiber morphology. Contemporary electrospinning apparatus incorporates sophisticated features such as climate-controlled chambers, multi-axial collectors, and automated parameter adjustment systems, enabling unprecedented precision in nanofiber fabrication.

Material science advancements have expanded the range of polymers and composite materials compatible with electrospinning. Initial applications primarily utilized synthetic polymers like polyvinyl alcohol (PVA) and polycaprolactone (PCL). Current research encompasses natural polymers, conductive materials, ceramics, and complex composite systems, significantly broadening the application landscape for electrospun nanofibers.

The technical trajectory of electrospinning has been marked by several pivotal innovations, including coaxial electrospinning (early 2000s), which enabled the production of core-shell nanofibers, and near-field electrospinning (2006), which provided enhanced control over fiber deposition. More recent developments include melt electrospinning writing and centrifugal electrospinning, addressing scalability challenges inherent in traditional methods.

Research objectives in the electrospinning domain are increasingly focused on bridging fundamental scientific understanding with practical industrial implementation. Primary goals include enhancing production efficiency to transition from laboratory-scale to industrial-scale manufacturing, developing standardized methodologies for quality control, and optimizing process parameters for specific applications in medical textiles, filtration systems, and energy storage devices.

The convergence of electrospinning with other emerging technologies represents a significant research frontier. Integration with 3D printing technologies, incorporation of stimuli-responsive materials, and development of smart textile platforms capable of sensing and responding to environmental changes are areas of intense investigation. Additionally, sustainability considerations are driving research into green electrospinning processes utilizing bio-derived polymers and environmentally benign solvents.

As nanotechnology and textile engineering continue to evolve, electrospinning stands at a critical juncture, poised to bridge theoretical nanoscience with practical applications across multiple industries. The research trajectory suggests a future where electrospun nanofibers become integral components in next-generation materials and devices, fundamentally transforming traditional textile paradigms.

The evolution of electrospinning has been characterized by progressive refinements in equipment design, process parameters, and material compatibility. Early systems were rudimentary, utilizing simple needle-based setups with limited control over fiber morphology. Contemporary electrospinning apparatus incorporates sophisticated features such as climate-controlled chambers, multi-axial collectors, and automated parameter adjustment systems, enabling unprecedented precision in nanofiber fabrication.

Material science advancements have expanded the range of polymers and composite materials compatible with electrospinning. Initial applications primarily utilized synthetic polymers like polyvinyl alcohol (PVA) and polycaprolactone (PCL). Current research encompasses natural polymers, conductive materials, ceramics, and complex composite systems, significantly broadening the application landscape for electrospun nanofibers.

The technical trajectory of electrospinning has been marked by several pivotal innovations, including coaxial electrospinning (early 2000s), which enabled the production of core-shell nanofibers, and near-field electrospinning (2006), which provided enhanced control over fiber deposition. More recent developments include melt electrospinning writing and centrifugal electrospinning, addressing scalability challenges inherent in traditional methods.

Research objectives in the electrospinning domain are increasingly focused on bridging fundamental scientific understanding with practical industrial implementation. Primary goals include enhancing production efficiency to transition from laboratory-scale to industrial-scale manufacturing, developing standardized methodologies for quality control, and optimizing process parameters for specific applications in medical textiles, filtration systems, and energy storage devices.

The convergence of electrospinning with other emerging technologies represents a significant research frontier. Integration with 3D printing technologies, incorporation of stimuli-responsive materials, and development of smart textile platforms capable of sensing and responding to environmental changes are areas of intense investigation. Additionally, sustainability considerations are driving research into green electrospinning processes utilizing bio-derived polymers and environmentally benign solvents.

As nanotechnology and textile engineering continue to evolve, electrospinning stands at a critical juncture, poised to bridge theoretical nanoscience with practical applications across multiple industries. The research trajectory suggests a future where electrospun nanofibers become integral components in next-generation materials and devices, fundamentally transforming traditional textile paradigms.

Market Applications and Demand Analysis for Nanofibers

The global nanofiber market has experienced significant growth in recent years, driven by the unique properties that nanofibers offer across multiple industries. Current market valuations place the global nanofiber market at approximately 3.1 billion USD in 2023, with projections indicating a compound annual growth rate (CAGR) of 25.8% through 2030, potentially reaching 12.7 billion USD by the end of the forecast period.

Healthcare and medical applications represent the largest market segment for nanofibers, accounting for roughly 32% of the total market share. Within this sector, wound dressings, tissue engineering scaffolds, and drug delivery systems demonstrate particularly strong demand. The superior absorption capabilities, controlled release mechanisms, and biocompatibility of electrospun nanofibers make them ideal for these applications, with wound care products alone growing at 28% annually.

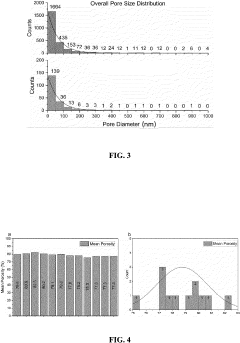

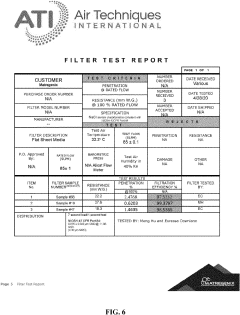

The filtration industry constitutes the second-largest application area, representing approximately 27% of market demand. As environmental regulations become increasingly stringent worldwide, the demand for high-efficiency filtration systems utilizing nanofiber membranes continues to rise. Air filtration systems, water purification membranes, and industrial filtration solutions benefit from the high surface area-to-volume ratio and controllable pore size of electrospun nanofibers, delivering filtration efficiency improvements of 30-40% compared to conventional materials.

The textile and apparel sector has emerged as a rapidly growing application area, currently accounting for 18% of the market but expanding at a CAGR of 29%. Smart textiles, protective clothing, and high-performance sportswear increasingly incorporate nanofibers to enhance properties such as moisture management, thermal regulation, and antimicrobial protection. Major sportswear brands have begun integrating electrospun nanofiber layers into premium product lines, commanding price premiums of 15-25%.

Energy storage applications, particularly in battery separators and components for fuel cells, represent approximately 12% of current market demand but are projected to grow at over 30% annually through 2030. The automotive and electronics industries are driving this growth as they seek more efficient and lightweight energy storage solutions.

Regionally, North America and Europe currently dominate the nanofiber market with combined market share of 58%, though Asia-Pacific is experiencing the fastest growth rate at 32% annually, led by China, Japan, and South Korea. This regional growth is fueled by increasing industrial applications, government investments in nanotechnology research, and expanding healthcare infrastructure.

Consumer awareness of nanotechnology benefits remains relatively low at 37%, indicating significant untapped market potential as education and product visibility increase. Industry surveys suggest that over 65% of potential industrial users cite cost as the primary barrier to adoption, highlighting the need for more economical electrospinning processes and equipment.

Healthcare and medical applications represent the largest market segment for nanofibers, accounting for roughly 32% of the total market share. Within this sector, wound dressings, tissue engineering scaffolds, and drug delivery systems demonstrate particularly strong demand. The superior absorption capabilities, controlled release mechanisms, and biocompatibility of electrospun nanofibers make them ideal for these applications, with wound care products alone growing at 28% annually.

The filtration industry constitutes the second-largest application area, representing approximately 27% of market demand. As environmental regulations become increasingly stringent worldwide, the demand for high-efficiency filtration systems utilizing nanofiber membranes continues to rise. Air filtration systems, water purification membranes, and industrial filtration solutions benefit from the high surface area-to-volume ratio and controllable pore size of electrospun nanofibers, delivering filtration efficiency improvements of 30-40% compared to conventional materials.

The textile and apparel sector has emerged as a rapidly growing application area, currently accounting for 18% of the market but expanding at a CAGR of 29%. Smart textiles, protective clothing, and high-performance sportswear increasingly incorporate nanofibers to enhance properties such as moisture management, thermal regulation, and antimicrobial protection. Major sportswear brands have begun integrating electrospun nanofiber layers into premium product lines, commanding price premiums of 15-25%.

Energy storage applications, particularly in battery separators and components for fuel cells, represent approximately 12% of current market demand but are projected to grow at over 30% annually through 2030. The automotive and electronics industries are driving this growth as they seek more efficient and lightweight energy storage solutions.

Regionally, North America and Europe currently dominate the nanofiber market with combined market share of 58%, though Asia-Pacific is experiencing the fastest growth rate at 32% annually, led by China, Japan, and South Korea. This regional growth is fueled by increasing industrial applications, government investments in nanotechnology research, and expanding healthcare infrastructure.

Consumer awareness of nanotechnology benefits remains relatively low at 37%, indicating significant untapped market potential as education and product visibility increase. Industry surveys suggest that over 65% of potential industrial users cite cost as the primary barrier to adoption, highlighting the need for more economical electrospinning processes and equipment.

Global Electrospinning Technology Landscape and Barriers

Electrospinning technology has witnessed significant global development over the past two decades, with research centers and commercial applications emerging across North America, Europe, and Asia. The United States leads in fundamental research and patent filings, with institutions like MIT, Harvard, and Stanford pioneering novel applications in biomedical engineering and advanced materials. European countries, particularly Germany and the United Kingdom, have focused on industrial-scale implementations and precision control systems for electrospinning processes.

In Asia, China has rapidly expanded its electrospinning research capacity, now producing the highest volume of academic publications in the field, while Japan and South Korea excel in specialized applications for electronics and filtration technologies. This geographical distribution reflects different strategic priorities and industrial strengths across regions.

Despite widespread research, significant barriers impede broader commercialization of electrospinning technology. The foremost challenge remains scalability - laboratory success often fails to translate to industrial production due to throughput limitations. Conventional electrospinning setups typically produce only 0.1-0.5 grams of nanofibers per hour, insufficient for mass-market applications. Multiple-needle and needleless systems have improved output but introduce consistency issues.

Process control presents another substantial hurdle. Environmental factors such as humidity and temperature significantly impact fiber formation, requiring sophisticated control systems that increase production costs. The high voltage requirements (typically 10-30 kV) also introduce safety concerns and regulatory complications for industrial implementation.

Material limitations further constrain applications. While over 100 polymers have been successfully electrospun in laboratory settings, many commercially relevant polymers remain difficult to process due to solubility issues or molecular weight constraints. Additionally, the reliance on organic solvents in many electrospinning formulations raises environmental and workplace safety concerns.

Economic barriers also persist. The capital investment for industrial-scale electrospinning equipment remains high relative to conventional fiber production methods, with specialized systems costing between $500,000 and $2 million. This creates a significant entry barrier for smaller manufacturers and limits adoption in cost-sensitive markets.

Regulatory frameworks present varying challenges across regions. Medical applications face particularly stringent requirements, with FDA approval processes in the US requiring extensive validation of both the electrospinning process and resulting materials. In Europe, REACH regulations impact solvent selection and waste management protocols for electrospinning operations.

In Asia, China has rapidly expanded its electrospinning research capacity, now producing the highest volume of academic publications in the field, while Japan and South Korea excel in specialized applications for electronics and filtration technologies. This geographical distribution reflects different strategic priorities and industrial strengths across regions.

Despite widespread research, significant barriers impede broader commercialization of electrospinning technology. The foremost challenge remains scalability - laboratory success often fails to translate to industrial production due to throughput limitations. Conventional electrospinning setups typically produce only 0.1-0.5 grams of nanofibers per hour, insufficient for mass-market applications. Multiple-needle and needleless systems have improved output but introduce consistency issues.

Process control presents another substantial hurdle. Environmental factors such as humidity and temperature significantly impact fiber formation, requiring sophisticated control systems that increase production costs. The high voltage requirements (typically 10-30 kV) also introduce safety concerns and regulatory complications for industrial implementation.

Material limitations further constrain applications. While over 100 polymers have been successfully electrospun in laboratory settings, many commercially relevant polymers remain difficult to process due to solubility issues or molecular weight constraints. Additionally, the reliance on organic solvents in many electrospinning formulations raises environmental and workplace safety concerns.

Economic barriers also persist. The capital investment for industrial-scale electrospinning equipment remains high relative to conventional fiber production methods, with specialized systems costing between $500,000 and $2 million. This creates a significant entry barrier for smaller manufacturers and limits adoption in cost-sensitive markets.

Regulatory frameworks present varying challenges across regions. Medical applications face particularly stringent requirements, with FDA approval processes in the US requiring extensive validation of both the electrospinning process and resulting materials. In Europe, REACH regulations impact solvent selection and waste management protocols for electrospinning operations.

Current Electrospinning Methods and Parameters

01 Electrospinning process parameters and optimization

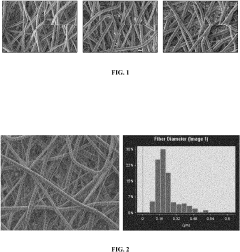

The electrospinning process involves various parameters that can be optimized to control fiber formation. These parameters include voltage, flow rate, distance between the needle and collector, and solution properties. Optimization of these parameters is crucial for producing uniform fibers with desired characteristics. The process typically involves applying a high voltage to a polymer solution, which creates an electric field that draws the solution into fibers as the solvent evaporates.- Electrospinning process parameters and optimization: Electrospinning processes can be optimized by controlling various parameters such as voltage, flow rate, distance between collector and nozzle, and solution properties. These parameters significantly affect the morphology, diameter, and alignment of the resulting nanofibers. Optimization techniques can improve fiber quality, reduce defects, and enhance production efficiency for various applications.

- Nanofiber materials and compositions: Various polymeric materials and compositions can be used in electrospinning to create functional nanofibers with specific properties. These include synthetic polymers, natural polymers, polymer blends, and composite materials incorporating nanoparticles or active ingredients. The selection of materials affects the mechanical properties, biocompatibility, degradation rate, and functionality of the resulting nanofiber structures.

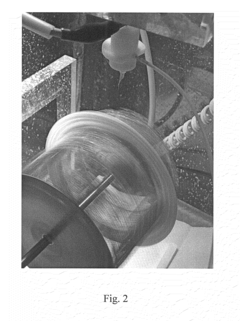

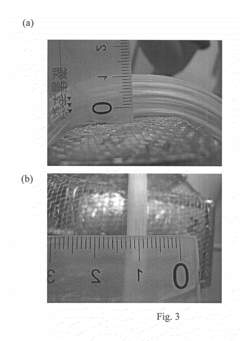

- Electrospinning equipment and apparatus design: Advanced electrospinning equipment designs incorporate specialized components such as multi-nozzle systems, rotating collectors, and environmental control chambers. These design innovations enable the production of aligned fibers, core-shell structures, and 3D scaffolds. Modified apparatus configurations can improve production scale, fiber uniformity, and enable the creation of complex nanofiber architectures.

- Applications of electrospun nanofibers: Electrospun nanofibers find applications across multiple fields including tissue engineering, filtration, drug delivery, wound dressing, and energy storage. The high surface area-to-volume ratio, porosity, and customizable properties of these fibers make them suitable for various industrial and biomedical applications. Specific functionalization techniques can enhance their performance for targeted uses.

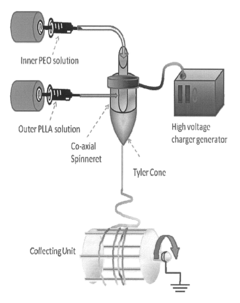

- Coaxial and multi-component electrospinning: Coaxial and multi-component electrospinning techniques enable the production of nanofibers with complex structures such as core-shell fibers, hollow fibers, and fibers with multiple compartments. These advanced methods allow for the incorporation of multiple functional materials within a single fiber structure, enabling controlled release of active ingredients, improved mechanical properties, and multi-functional capabilities.

02 Nanofiber materials and compositions

Electrospinning can be used to produce nanofibers from various materials including polymers, composites, and biomaterials. The composition of the spinning solution significantly affects the properties of the resulting fibers. Different polymers such as PVA, PCL, PLA, and natural polymers can be used to create fibers with specific characteristics. Additionally, composite nanofibers can be created by incorporating functional materials like nanoparticles, drugs, or bioactive compounds into the polymer solution before spinning.Expand Specific Solutions03 Electrospinning equipment and apparatus design

Various designs of electrospinning equipment have been developed to enhance the process efficiency and fiber quality. These include modifications to the spinneret design, collector configurations, and environmental control systems. Advanced setups may incorporate multiple spinnerets for increased production, rotating collectors for aligned fibers, or climate-controlled chambers to maintain consistent humidity and temperature. Innovations in apparatus design aim to overcome limitations of traditional electrospinning and enable industrial-scale production.Expand Specific Solutions04 Applications of electrospun nanofibers

Electrospun nanofibers have diverse applications across multiple fields due to their high surface area-to-volume ratio and tunable properties. They are used in filtration systems, tissue engineering scaffolds, wound dressings, drug delivery systems, and energy storage devices. In biomedical applications, the fibers can mimic extracellular matrix structures, supporting cell growth and tissue regeneration. For environmental applications, nanofiber membranes offer efficient filtration of contaminants from air and water.Expand Specific Solutions05 Coaxial and multi-axial electrospinning techniques

Advanced electrospinning techniques include coaxial and multi-axial approaches that allow for the creation of core-shell or multi-layered nanofibers. These techniques use specialized nozzles with concentric or multiple channels to simultaneously spin different solutions. The resulting fibers can have distinct core and shell compositions, enabling controlled release of encapsulated substances or combining materials with different properties. These complex fiber structures expand the functional capabilities of electrospun materials for specialized applications.Expand Specific Solutions

Leading Institutions and Companies in Nanofiber Production

Electrospinning technology is currently in a growth phase, bridging nanotechnology and textile engineering with expanding applications across medical, filtration, and smart textile sectors. The global market is projected to reach significant scale, driven by increasing demand for nanofiber-based products. In terms of technical maturity, the field shows varied development levels with academic institutions like Donghua University, MIT, and Nanyang Technological University leading fundamental research, while companies such as BioSurfaces, Matregenix, and Poly-Med have commercialized specific applications. Research Triangle Institute and Taiwan Textile Research Institute represent the important bridge between academic innovation and industrial implementation. The competitive landscape features collaboration between specialized startups and established institutions, with increasing focus on scalability and cost-effectiveness to enable broader market adoption.

Poly-Med, Inc.

Technical Solution: Poly-Med has developed an advanced electrospinning platform called "AbsorbSpin" that focuses on creating absorbable and biodegradable nanofiber structures for medical textiles and tissue engineering. Their proprietary technology combines electrospinning with precise polymer chemistry to create fibers with controlled degradation profiles ranging from weeks to years. Poly-Med's approach involves custom-synthesized polymers specifically designed for electrospinning, including novel copolymers of lactide, glycolide, caprolactone, and dioxanone that offer tunable mechanical and degradation properties. Their patented process incorporates in-line plasma treatment capabilities that modify fiber surface properties during fabrication, enhancing cell attachment without compromising bulk material properties[3]. The AbsorbSpin platform can produce aligned fiber arrays with over 90% orientation in a specified direction, creating anisotropic materials that mimic the structural organization of natural tissues like tendons and ligaments[8]. Poly-Med has also developed techniques for incorporating therapeutic agents into nanofibers with encapsulation efficiencies exceeding 85% and controlled release profiles extending from hours to months.

Strengths: Poly-Med's specialized focus on absorbable materials creates unique advantages for medical applications requiring controlled degradation. Their integration of polymer synthesis with electrospinning enables customized materials with precise property profiles. Weaknesses: The narrow focus on biodegradable medical applications limits versatility for permanent textile applications. The complex polymer chemistry and processing parameters require specialized expertise and equipment, potentially limiting accessibility.

Matregenix, Inc.

Technical Solution: Matregenix has developed a proprietary electrospinning platform called "MatreSpun" specifically designed for biomedical applications bridging nanotechnology and textile engineering. Their technology focuses on creating biomimetic scaffolds that replicate the native extracellular matrix (ECM) structure for tissue engineering applications. The MatreSpun platform utilizes a multi-jet electrospinning system capable of simultaneously processing multiple polymers to create composite nanofiber structures with controlled fiber orientation and porosity. Their patented process can produce nanofibers with diameters ranging from 50-500 nm with a narrow size distribution (±15%), achieving production rates up to 5 g/hour while maintaining structural consistency[4]. Matregenix has pioneered techniques for surface functionalization of electrospun fibers, incorporating bioactive molecules that enhance cell adhesion and proliferation, with demonstrated improvements in cell attachment rates of over 200% compared to unmodified scaffolds[6]. Their technology enables the creation of gradient structures that mimic tissue interfaces, such as the tendon-bone junction, with mechanical properties that transition smoothly between different tissue types.

Strengths: Matregenix's technology excels in creating biomimetic structures with precise control over biological and mechanical properties, making it ideal for medical applications. Their multi-polymer approach enables complex composite materials with tailored functionality. Weaknesses: The focus on biomedical applications may limit versatility for broader industrial textile applications. The complex processing and stringent quality requirements for medical-grade materials result in higher production costs compared to conventional textile manufacturing.

Critical Patents and Breakthroughs in Nanofiber Engineering

Electrostatic-assisted fiber spinning method and production of highly aligned and packed hollow fiber assembly and membrane

PatentActiveUS20110264235A1

Innovation

- The development of a method that uses coaxial electrospinning with a rotating drum collector to produce fibers with an orientation angle of no larger than ±5° and a packing density of at least 5 fibers per layer, maintaining a significant portion of the fiber weight during the electrospinning process to achieve highly aligned and closely packed hollow or solid fibers.

Electrospun nanofibrous polymer membrane for use in air filtration applications

PatentPendingUS20230167591A1

Innovation

- An electrospun polymer nanofibrous membrane with integrated antimicrobial or antiviral agents, metal-organic frameworks, and photocatalytic agents, offering high filtering efficiency, breathability, and transparency, suitable for use in facemasks, respirators, and HVAC systems, while potentially combining with carbon nanofiber membranes for CO2 removal.

Sustainability Aspects of Electrospinning Processes

Sustainability has emerged as a critical consideration in the development and application of electrospinning technologies. The environmental impact of electrospinning processes encompasses multiple dimensions that require careful assessment and mitigation strategies. Traditional electrospinning often relies on toxic solvents such as dimethylformamide (DMF), dichloromethane, and chloroform, which pose significant environmental and health risks through volatile organic compound (VOC) emissions during processing.

Recent advancements have focused on transitioning to green electrospinning approaches that utilize environmentally benign solvents. Water-based systems, ionic liquids, and supercritical CO2 have demonstrated promising results as sustainable alternatives. These green solvents significantly reduce the carbon footprint of electrospinning operations while maintaining comparable fiber quality and production efficiency.

Energy consumption represents another sustainability challenge in electrospinning processes. The high voltage requirements (typically 10-30 kV) contribute to substantial energy usage during continuous production. Innovative approaches such as solar-powered electrospinning units and energy recovery systems have been developed to address this concern, reducing the overall energy intensity by up to 40% compared to conventional setups.

Polymer selection plays a crucial role in the sustainability profile of electrospun products. Bio-based polymers derived from renewable resources—including polylactic acid (PLA), cellulose derivatives, and chitosan—are increasingly replacing petroleum-based polymers. These materials offer biodegradability and reduced environmental persistence while maintaining the functional properties required for advanced applications in medical textiles and filtration systems.

Waste management in electrospinning operations presents both challenges and opportunities. The process generates minimal solid waste compared to conventional textile manufacturing, but the nanoscale fibers produced may pose unique environmental risks if improperly disposed of. Closed-loop recycling systems for solvent recovery have been implemented in industrial settings, achieving recovery rates exceeding 85% and substantially reducing waste streams.

Life cycle assessment (LCA) studies of electrospun products reveal significant sustainability advantages in specific applications. For instance, electrospun nanofiber filters demonstrate extended service life and reduced material consumption compared to conventional filters, resulting in a 30-50% reduction in overall environmental impact despite the energy-intensive production process.

The integration of sustainability principles into electrospinning research has accelerated in recent years, with approximately 25% of current publications addressing environmental aspects. This trend reflects growing recognition of sustainability as not merely a regulatory compliance issue but a fundamental design parameter that influences material selection, process optimization, and application development in the evolving landscape of nanotechnology and textile engineering.

Recent advancements have focused on transitioning to green electrospinning approaches that utilize environmentally benign solvents. Water-based systems, ionic liquids, and supercritical CO2 have demonstrated promising results as sustainable alternatives. These green solvents significantly reduce the carbon footprint of electrospinning operations while maintaining comparable fiber quality and production efficiency.

Energy consumption represents another sustainability challenge in electrospinning processes. The high voltage requirements (typically 10-30 kV) contribute to substantial energy usage during continuous production. Innovative approaches such as solar-powered electrospinning units and energy recovery systems have been developed to address this concern, reducing the overall energy intensity by up to 40% compared to conventional setups.

Polymer selection plays a crucial role in the sustainability profile of electrospun products. Bio-based polymers derived from renewable resources—including polylactic acid (PLA), cellulose derivatives, and chitosan—are increasingly replacing petroleum-based polymers. These materials offer biodegradability and reduced environmental persistence while maintaining the functional properties required for advanced applications in medical textiles and filtration systems.

Waste management in electrospinning operations presents both challenges and opportunities. The process generates minimal solid waste compared to conventional textile manufacturing, but the nanoscale fibers produced may pose unique environmental risks if improperly disposed of. Closed-loop recycling systems for solvent recovery have been implemented in industrial settings, achieving recovery rates exceeding 85% and substantially reducing waste streams.

Life cycle assessment (LCA) studies of electrospun products reveal significant sustainability advantages in specific applications. For instance, electrospun nanofiber filters demonstrate extended service life and reduced material consumption compared to conventional filters, resulting in a 30-50% reduction in overall environmental impact despite the energy-intensive production process.

The integration of sustainability principles into electrospinning research has accelerated in recent years, with approximately 25% of current publications addressing environmental aspects. This trend reflects growing recognition of sustainability as not merely a regulatory compliance issue but a fundamental design parameter that influences material selection, process optimization, and application development in the evolving landscape of nanotechnology and textile engineering.

Scalability Challenges for Industrial Implementation

Despite the promising potential of electrospinning technology in nanotechnology and textile engineering, significant scalability challenges persist for industrial implementation. Current laboratory-scale electrospinning setups typically produce only a few grams of nanofibers per hour, which falls far short of industrial requirements that often demand production rates in kilograms per hour. This throughput limitation represents one of the most critical barriers to widespread commercial adoption.

The transition from single-needle systems to multi-needle or needleless systems has partially addressed this challenge, with some advanced setups achieving production rates of 10-50 grams per hour. However, these solutions introduce new complications, including maintaining consistent fiber quality across multiple spinning sites and preventing jet interference between adjacent spinning points. Variations in fiber diameter, morphology, and mechanical properties can significantly compromise product performance in high-value applications.

Energy consumption presents another substantial hurdle for industrial scaling. Conventional electrospinning requires high voltage (typically 10-30 kV), which translates to considerable energy costs when scaled to industrial production volumes. Additionally, the process exhibits relatively low energy efficiency, with significant power losses occurring during operation. Innovative approaches such as alternating current electrospinning show promise for reducing energy requirements but remain in early development stages.

Process control and automation represent critical challenges for continuous manufacturing operations. Current industrial implementations struggle with real-time monitoring and adjustment capabilities, leading to quality inconsistencies during extended production runs. The complex interplay between environmental factors (humidity, temperature), solution properties, and equipment parameters necessitates sophisticated control systems that can maintain optimal processing conditions over time.

Solvent recovery and environmental considerations further complicate industrial implementation. Many electrospinning processes utilize organic solvents that require proper handling and recovery systems to meet environmental regulations and reduce operational costs. The development of green electrospinning approaches using water-based systems or environmentally friendly solvents remains an active research area but faces challenges in achieving comparable fiber quality and production efficiency.

Standardization issues also impede widespread industrial adoption. The lack of universally accepted quality standards, testing protocols, and process parameters makes it difficult for manufacturers to establish consistent production specifications across different equipment and facilities. This standardization gap creates barriers for supply chain integration and quality assurance in commercial applications.

The transition from single-needle systems to multi-needle or needleless systems has partially addressed this challenge, with some advanced setups achieving production rates of 10-50 grams per hour. However, these solutions introduce new complications, including maintaining consistent fiber quality across multiple spinning sites and preventing jet interference between adjacent spinning points. Variations in fiber diameter, morphology, and mechanical properties can significantly compromise product performance in high-value applications.

Energy consumption presents another substantial hurdle for industrial scaling. Conventional electrospinning requires high voltage (typically 10-30 kV), which translates to considerable energy costs when scaled to industrial production volumes. Additionally, the process exhibits relatively low energy efficiency, with significant power losses occurring during operation. Innovative approaches such as alternating current electrospinning show promise for reducing energy requirements but remain in early development stages.

Process control and automation represent critical challenges for continuous manufacturing operations. Current industrial implementations struggle with real-time monitoring and adjustment capabilities, leading to quality inconsistencies during extended production runs. The complex interplay between environmental factors (humidity, temperature), solution properties, and equipment parameters necessitates sophisticated control systems that can maintain optimal processing conditions over time.

Solvent recovery and environmental considerations further complicate industrial implementation. Many electrospinning processes utilize organic solvents that require proper handling and recovery systems to meet environmental regulations and reduce operational costs. The development of green electrospinning approaches using water-based systems or environmentally friendly solvents remains an active research area but faces challenges in achieving comparable fiber quality and production efficiency.

Standardization issues also impede widespread industrial adoption. The lack of universally accepted quality standards, testing protocols, and process parameters makes it difficult for manufacturers to establish consistent production specifications across different equipment and facilities. This standardization gap creates barriers for supply chain integration and quality assurance in commercial applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!