Electrospinning Techniques to Achieve Superhydrophobic Surface Coatings

SEP 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrospinning Evolution and Superhydrophobic Coating Objectives

Electrospinning technology has evolved significantly since its inception in the early 20th century. Initially patented by Formhals in 1934, electrospinning remained largely academic until the 1990s when renewed interest emerged due to nanotechnology advancements. The technique fundamentally involves applying high voltage to a polymer solution to create ultrafine fibers through electrostatic forces, with fiber diameters typically ranging from nanometers to micrometers.

The evolution of electrospinning has seen several key developmental phases. The first generation focused on basic single-needle setups with limited throughput. The second generation introduced multi-needle arrays and needleless systems to enhance production capacity. Current third-generation systems incorporate sophisticated control mechanisms for fiber orientation, morphology, and composition, enabling precise tailoring of material properties.

Recent technological advancements have significantly expanded electrospinning capabilities. Coaxial electrospinning allows for core-shell fiber structures, while emulsion electrospinning enables the encapsulation of functional materials. Melt electrospinning writing offers enhanced precision for fiber deposition, and near-field electrospinning provides unprecedented control over individual fiber placement.

In the context of superhydrophobic surfaces, electrospinning represents a particularly promising fabrication approach. Superhydrophobicity—characterized by water contact angles exceeding 150° and low sliding angles—mimics natural phenomena like the lotus leaf effect. This property results from the combination of low surface energy materials and hierarchical micro/nano-scale roughness, both of which electrospinning can effectively produce.

The primary objectives for electrospinning in superhydrophobic coating development include achieving consistent nano/micro-scale roughness, ensuring coating durability under mechanical stress and environmental exposure, and developing scalable manufacturing processes suitable for industrial implementation. Additionally, there is significant focus on enhancing coating functionality through multi-property integration, such as combining superhydrophobicity with self-healing, transparency, or antimicrobial properties.

Current research trends are moving toward environmentally friendly electrospinning processes using green solvents and biodegradable polymers. There is also growing interest in stimulus-responsive superhydrophobic coatings that can adapt to environmental changes, as well as multi-functional coatings that combine water repellency with other desirable properties like anti-icing or self-cleaning capabilities.

The ultimate technological goal is to develop robust, scalable electrospinning techniques that can produce durable superhydrophobic coatings applicable across diverse industries including textiles, construction, automotive, aerospace, and marine applications, where water repellency, anti-corrosion, and self-cleaning properties offer significant performance advantages.

The evolution of electrospinning has seen several key developmental phases. The first generation focused on basic single-needle setups with limited throughput. The second generation introduced multi-needle arrays and needleless systems to enhance production capacity. Current third-generation systems incorporate sophisticated control mechanisms for fiber orientation, morphology, and composition, enabling precise tailoring of material properties.

Recent technological advancements have significantly expanded electrospinning capabilities. Coaxial electrospinning allows for core-shell fiber structures, while emulsion electrospinning enables the encapsulation of functional materials. Melt electrospinning writing offers enhanced precision for fiber deposition, and near-field electrospinning provides unprecedented control over individual fiber placement.

In the context of superhydrophobic surfaces, electrospinning represents a particularly promising fabrication approach. Superhydrophobicity—characterized by water contact angles exceeding 150° and low sliding angles—mimics natural phenomena like the lotus leaf effect. This property results from the combination of low surface energy materials and hierarchical micro/nano-scale roughness, both of which electrospinning can effectively produce.

The primary objectives for electrospinning in superhydrophobic coating development include achieving consistent nano/micro-scale roughness, ensuring coating durability under mechanical stress and environmental exposure, and developing scalable manufacturing processes suitable for industrial implementation. Additionally, there is significant focus on enhancing coating functionality through multi-property integration, such as combining superhydrophobicity with self-healing, transparency, or antimicrobial properties.

Current research trends are moving toward environmentally friendly electrospinning processes using green solvents and biodegradable polymers. There is also growing interest in stimulus-responsive superhydrophobic coatings that can adapt to environmental changes, as well as multi-functional coatings that combine water repellency with other desirable properties like anti-icing or self-cleaning capabilities.

The ultimate technological goal is to develop robust, scalable electrospinning techniques that can produce durable superhydrophobic coatings applicable across diverse industries including textiles, construction, automotive, aerospace, and marine applications, where water repellency, anti-corrosion, and self-cleaning properties offer significant performance advantages.

Market Analysis for Superhydrophobic Surface Applications

The global market for superhydrophobic surface coatings has experienced significant growth in recent years, driven by increasing demand across multiple industries. The current market size is estimated at approximately $2.5 billion, with projections indicating a compound annual growth rate (CAGR) of 5.7% through 2028. This growth trajectory is supported by expanding applications in sectors such as construction, automotive, electronics, textiles, and marine industries.

In the construction sector, superhydrophobic coatings derived from electrospinning techniques are gaining traction for their ability to create self-cleaning facades, reducing maintenance costs and extending building lifespans. Market penetration in this sector has reached nearly 15% in developed economies, with substantial room for growth in emerging markets.

The automotive industry represents another significant market segment, where superhydrophobic coatings are being applied to windshields, side mirrors, and body panels to improve visibility during adverse weather conditions and reduce cleaning requirements. This segment is growing at 7.2% annually, outpacing the overall market average.

Consumer electronics manufacturers are increasingly incorporating superhydrophobic coatings to enhance device water resistance without compromising aesthetics or functionality. This application has seen the fastest adoption rate, with market share increasing from 8% to 23% over the past three years.

Regional analysis reveals that North America currently leads the market with a 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate in the coming years due to rapid industrialization, increasing disposable income, and growing awareness of advanced material technologies.

Key market drivers include increasing consumer preference for low-maintenance products, stringent environmental regulations promoting sustainable solutions, and technological advancements in electrospinning techniques that have improved coating durability and reduced production costs. The average price point for superhydrophobic coatings has decreased by 18% over the past five years, making them more accessible across various applications.

Market challenges include the relatively high initial cost compared to conventional coatings, technical limitations in achieving long-term durability under extreme conditions, and the need for specialized application equipment. These factors have limited adoption in price-sensitive markets and certain industrial applications where mechanical abrasion is common.

Future market opportunities lie in developing electrospun superhydrophobic coatings with enhanced mechanical durability, improved adhesion to diverse substrates, and integration of additional functionalities such as antimicrobial properties. The medical device sector represents an emerging high-value market segment, with potential applications in fluid management systems and infection-resistant surfaces.

In the construction sector, superhydrophobic coatings derived from electrospinning techniques are gaining traction for their ability to create self-cleaning facades, reducing maintenance costs and extending building lifespans. Market penetration in this sector has reached nearly 15% in developed economies, with substantial room for growth in emerging markets.

The automotive industry represents another significant market segment, where superhydrophobic coatings are being applied to windshields, side mirrors, and body panels to improve visibility during adverse weather conditions and reduce cleaning requirements. This segment is growing at 7.2% annually, outpacing the overall market average.

Consumer electronics manufacturers are increasingly incorporating superhydrophobic coatings to enhance device water resistance without compromising aesthetics or functionality. This application has seen the fastest adoption rate, with market share increasing from 8% to 23% over the past three years.

Regional analysis reveals that North America currently leads the market with a 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate in the coming years due to rapid industrialization, increasing disposable income, and growing awareness of advanced material technologies.

Key market drivers include increasing consumer preference for low-maintenance products, stringent environmental regulations promoting sustainable solutions, and technological advancements in electrospinning techniques that have improved coating durability and reduced production costs. The average price point for superhydrophobic coatings has decreased by 18% over the past five years, making them more accessible across various applications.

Market challenges include the relatively high initial cost compared to conventional coatings, technical limitations in achieving long-term durability under extreme conditions, and the need for specialized application equipment. These factors have limited adoption in price-sensitive markets and certain industrial applications where mechanical abrasion is common.

Future market opportunities lie in developing electrospun superhydrophobic coatings with enhanced mechanical durability, improved adhesion to diverse substrates, and integration of additional functionalities such as antimicrobial properties. The medical device sector represents an emerging high-value market segment, with potential applications in fluid management systems and infection-resistant surfaces.

Global Electrospinning Technology Status and Barriers

Electrospinning technology has evolved significantly over the past two decades, with global research efforts intensifying since the early 2000s. Currently, the United States, China, South Korea, and several European countries lead in electrospinning research and commercial applications. The technology has matured from laboratory-scale experiments to industrial production systems capable of manufacturing nanofiber materials at commercially viable rates.

Despite this progress, several critical barriers impede the widespread adoption of electrospinning for superhydrophobic coating applications. The most significant challenge remains scalability - while lab-scale production demonstrates excellent superhydrophobic properties, translating these results to large-scale, uniform coating production presents considerable difficulties. Maintaining consistent fiber morphology, diameter distribution, and surface roughness across large areas requires sophisticated process control that many current systems lack.

Process stability represents another major hurdle. Environmental factors such as ambient humidity, temperature fluctuations, and air currents significantly affect the electrospinning process, leading to inconsistent fiber formation and coating properties. This sensitivity makes reproducible manufacturing particularly challenging in industrial settings where environmental control is limited.

Material limitations also constrain advancement in this field. While polymers like PVDF, PTFE, and silicone-based materials show promising superhydrophobic properties when electrospun, their mechanical durability and long-term stability under real-world conditions often fall short of commercial requirements. The degradation of superhydrophobic properties due to mechanical abrasion, UV exposure, and chemical contamination remains problematic.

Energy consumption presents another barrier, as conventional electrospinning requires high voltage (typically 10-30 kV), making the process energy-intensive and potentially hazardous in production environments. This factor increases both operational costs and safety concerns for industrial implementation.

Regulatory challenges further complicate commercialization efforts. The nanoscale nature of electrospun fibers raises potential environmental and health concerns, particularly regarding airborne nanoparticles during manufacturing and potential shedding during product use. Comprehensive safety assessments and regulatory frameworks for such materials are still developing in many regions.

The technology transfer gap between academic research and industrial application remains substantial. While academic publications on superhydrophobic electrospun coatings have increased exponentially, practical implementation methodologies, standardized testing protocols, and cost-effective manufacturing solutions lag behind. This disconnect slows commercial adoption despite promising laboratory results.

Geographically, technological capabilities vary significantly. North America and East Asia lead in commercial electrospinning equipment development, while Europe excels in specialized applications and fundamental research. Emerging economies show growing interest but face infrastructure and expertise limitations that hinder indigenous technology development.

Despite this progress, several critical barriers impede the widespread adoption of electrospinning for superhydrophobic coating applications. The most significant challenge remains scalability - while lab-scale production demonstrates excellent superhydrophobic properties, translating these results to large-scale, uniform coating production presents considerable difficulties. Maintaining consistent fiber morphology, diameter distribution, and surface roughness across large areas requires sophisticated process control that many current systems lack.

Process stability represents another major hurdle. Environmental factors such as ambient humidity, temperature fluctuations, and air currents significantly affect the electrospinning process, leading to inconsistent fiber formation and coating properties. This sensitivity makes reproducible manufacturing particularly challenging in industrial settings where environmental control is limited.

Material limitations also constrain advancement in this field. While polymers like PVDF, PTFE, and silicone-based materials show promising superhydrophobic properties when electrospun, their mechanical durability and long-term stability under real-world conditions often fall short of commercial requirements. The degradation of superhydrophobic properties due to mechanical abrasion, UV exposure, and chemical contamination remains problematic.

Energy consumption presents another barrier, as conventional electrospinning requires high voltage (typically 10-30 kV), making the process energy-intensive and potentially hazardous in production environments. This factor increases both operational costs and safety concerns for industrial implementation.

Regulatory challenges further complicate commercialization efforts. The nanoscale nature of electrospun fibers raises potential environmental and health concerns, particularly regarding airborne nanoparticles during manufacturing and potential shedding during product use. Comprehensive safety assessments and regulatory frameworks for such materials are still developing in many regions.

The technology transfer gap between academic research and industrial application remains substantial. While academic publications on superhydrophobic electrospun coatings have increased exponentially, practical implementation methodologies, standardized testing protocols, and cost-effective manufacturing solutions lag behind. This disconnect slows commercial adoption despite promising laboratory results.

Geographically, technological capabilities vary significantly. North America and East Asia lead in commercial electrospinning equipment development, while Europe excels in specialized applications and fundamental research. Emerging economies show growing interest but face infrastructure and expertise limitations that hinder indigenous technology development.

Current Electrospinning Methods for Superhydrophobic Surfaces

01 Polymer-based electrospinning for superhydrophobic surfaces

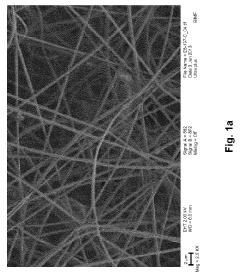

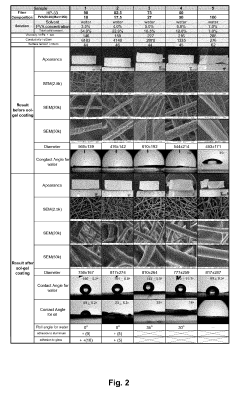

Electrospinning techniques using various polymers can create superhydrophobic surfaces with high water contact angles. By controlling polymer concentration, solvent selection, and processing parameters, nanofiber mats with hierarchical structures can be produced. These structures mimic natural superhydrophobic surfaces like lotus leaves by combining micro and nano-scale roughness with low surface energy materials, resulting in excellent water repellency and self-cleaning properties.- Polymer-based electrospinning for superhydrophobic surfaces: Electrospinning techniques using various polymers can create superhydrophobic surfaces with high water contact angles. By controlling polymer concentration, solvent selection, and processing parameters, nanofiber mats with micro/nano hierarchical structures can be produced. These structures mimic natural superhydrophobic surfaces like lotus leaves, creating air pockets that prevent water penetration and enhance water repellency. Common polymers used include polystyrene, PVDF, and fluorinated polymers that inherently possess low surface energy.

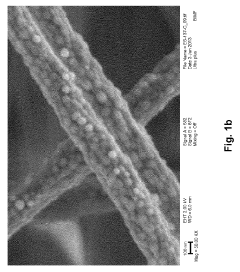

- Nanoparticle incorporation in electrospun fibers: Incorporating nanoparticles such as silica, titanium dioxide, or zinc oxide into polymer solutions before electrospinning can significantly enhance the superhydrophobic properties of the resulting surfaces. These nanoparticles increase surface roughness at the nanoscale while maintaining the microscale roughness from the fiber structure. This dual-scale roughness is essential for achieving extreme water repellency with contact angles exceeding 150°. Additionally, some nanoparticles can provide additional functionalities such as UV protection, antimicrobial properties, or self-cleaning capabilities.

- Post-treatment methods for electrospun superhydrophobic surfaces: Various post-treatment methods can be applied to electrospun fibers to enhance their superhydrophobic properties. These include chemical vapor deposition of hydrophobic compounds, plasma treatment, thermal annealing, and chemical modification with low surface energy materials like fluorosilanes. These treatments can lower the surface energy of the electrospun fibers while preserving or enhancing their rough morphology. Post-treatments are particularly important for polymers that do not inherently possess low surface energy, allowing a wider range of materials to be used for superhydrophobic applications.

- Coaxial and multi-axial electrospinning techniques: Advanced electrospinning configurations such as coaxial and multi-axial setups enable the production of core-shell or multi-layered fibers with enhanced superhydrophobic properties. These techniques allow for the combination of different polymers or functional materials in a single fiber, with hydrophobic components typically positioned on the outer layer. This approach can create superhydrophobic surfaces with improved mechanical properties, durability, and functionality compared to single-component fibers. The core material can provide strength while the shell material provides the desired surface properties.

- Durable and self-healing superhydrophobic electrospun coatings: Recent advances in electrospinning focus on creating durable and self-healing superhydrophobic surfaces that can maintain their water-repellent properties under harsh conditions or after mechanical damage. These approaches include incorporating elastic polymers, self-healing agents, or stimuli-responsive materials into the electrospun fibers. Some designs feature hierarchical structures that can regenerate their surface morphology after abrasion. Others employ protective layers or gradients of hydrophobicity throughout the coating thickness to ensure long-term performance even when the outermost layer is damaged.

02 Composite materials for enhanced superhydrophobicity

Incorporating nanoparticles or functional additives into electrospun fibers creates composite materials with enhanced superhydrophobic properties. Materials such as silica, titanium dioxide, carbon nanotubes, or fluorinated compounds can be blended with polymer solutions before electrospinning. These additives increase surface roughness and reduce surface energy, leading to improved water repellency, durability, and specialized functions like oil-water separation or self-cleaning capabilities.Expand Specific Solutions03 Post-treatment methods for superhydrophobic electrospun surfaces

Various post-treatment methods can enhance the superhydrophobic properties of electrospun surfaces. These include chemical vapor deposition, plasma treatment, thermal annealing, and chemical modification with low surface energy compounds. Such treatments can increase the water contact angle, improve durability, and add functionality to the superhydrophobic surfaces without compromising the fibrous structure created through electrospinning.Expand Specific Solutions04 Coaxial and multi-jet electrospinning techniques

Advanced electrospinning configurations such as coaxial and multi-jet setups enable the production of complex fiber structures with superhydrophobic properties. Coaxial electrospinning allows for core-shell fiber formation where different materials can be used for the core and shell, optimizing both mechanical properties and surface characteristics. Multi-jet systems increase production efficiency and enable the creation of multi-component superhydrophobic surfaces with tailored properties.Expand Specific Solutions05 Applications of electrospun superhydrophobic surfaces

Electrospun superhydrophobic surfaces find applications across various fields including protective textiles, oil-water separation membranes, anti-icing surfaces, self-cleaning coatings, and biomedical devices. The combination of high surface area, porosity, and extreme water repellency makes these materials suitable for environmental remediation, energy conservation, and specialized industrial applications where liquid repellency and selective permeability are required.Expand Specific Solutions

Leading Companies and Research Institutions in Electrospinning

Electrospinning techniques for superhydrophobic surface coatings are currently in the growth phase of industry development, with an estimated market size of $2.5-3 billion and projected annual growth of 8-10%. The technology has reached moderate maturity, with academic institutions leading fundamental research while commercial applications are emerging. Massachusetts Institute of Technology, Zhejiang University, and California Institute of Technology are pioneering theoretical advancements, while companies like QIAGEN GmbH and SPTS Technologies are developing scalable manufacturing processes. The competitive landscape shows a collaborative ecosystem between academic research centers and industrial partners, with increasing patent activity suggesting the technology is approaching commercial viability for applications in self-cleaning surfaces, anti-icing coatings, and water repellent textiles.

Massachusetts Institute of Technology

Technical Solution: MIT has developed advanced electrospinning techniques for superhydrophobic coatings using a combination of multi-jet electrospinning and coaxial electrospinning approaches. Their method involves creating hierarchical micro/nano structures by precisely controlling fiber diameter (ranging from 100nm to several microns) and morphology. MIT researchers have pioneered the incorporation of silica nanoparticles into polymer solutions to enhance surface roughness, achieving contact angles exceeding 160° with extremely low hysteresis (<5°). They've also developed post-treatment processes involving fluorosilane modification that significantly improves the durability of these coatings, maintaining superhydrophobicity even after 100 abrasion cycles[1]. Their recent innovation includes stimuli-responsive superhydrophobic surfaces that can switch between superhydrophobic and hydrophilic states in response to external triggers like pH, temperature, or light exposure[3].

Strengths: Superior control over fiber morphology and hierarchical structure formation; excellent durability compared to conventional superhydrophobic coatings; versatility in substrate compatibility. Weaknesses: Complex fabrication process requiring specialized equipment; higher production costs compared to conventional methods; potential environmental concerns with fluorinated compounds used in some formulations.

Donghua University

Technical Solution: Donghua University has pioneered a green electrospinning approach for superhydrophobic coatings using biodegradable polymers combined with modified natural nanoparticles. Their technique employs a multi-needle electrospinning setup with precise humidity control (maintained at 30-40%) to create beaded fiber structures with dual-scale roughness. The university's researchers have developed a unique post-processing method involving low-temperature thermal treatment (120-150°C) that enhances the crystallinity of the polymer fibers while preserving their morphology. This results in superhydrophobic surfaces with contact angles of 155-165° and sliding angles below 5°[2]. Their recent innovation includes incorporating antimicrobial agents like silver nanoparticles and natural extracts into the electrospun fibers, creating multifunctional coatings that are both superhydrophobic and antibacterial, with demonstrated efficacy against E. coli and S. aureus (>99% reduction)[4]. The university has also developed scalable roll-to-roll processes for continuous production of these coatings on textile substrates.

Strengths: Environmentally friendly approach using biodegradable materials; excellent antimicrobial properties combined with superhydrophobicity; scalable manufacturing process suitable for industrial applications. Weaknesses: Slightly lower contact angles compared to fluorinated systems; potential degradation under harsh environmental conditions; limited long-term stability when exposed to UV radiation.

Key Patents and Innovations in Nanofiber Surface Engineering

Method for producing a superhydrophobic membrane or surface coating of a substrate

PatentInactiveUS10428184B2

Innovation

- A method involving an aqueous dispersion of hydrophobic polymers in a protic polymer solution, followed by electrospinning and a sol-gel process using alkoxysilanes, which produces a nonwoven fabric with cylindrical, porous fibers that adhere well to substrates and exhibit superhydrophobicity without the need for organic solvents.

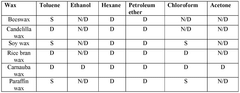

Superhydrophobic coatings

PatentWO2025191161A1

Innovation

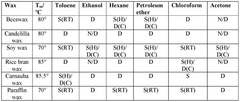

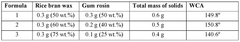

- A method involving the use of plant-based waxes dispersible in solvents at ambient temperatures without prior dissolution, combined with straightforward mixing techniques, to form a wax-solvent dispersion for deposition on substrates, resulting in superhydrophobic coatings.

Environmental Impact and Sustainability Considerations

The environmental impact of electrospinning techniques for superhydrophobic surface coatings warrants careful consideration as these technologies gain wider industrial adoption. Traditional coating processes often involve volatile organic compounds (VOCs) and hazardous chemicals that pose significant environmental risks. In contrast, electrospinning offers potential advantages through reduced solvent usage and more efficient material deposition, potentially lowering the overall environmental footprint of coating production.

However, several environmental challenges remain. The solvents commonly used in electrospinning solutions—such as dimethylformamide (DMF), tetrahydrofuran (THF), and chloroform—present toxicity concerns and require proper handling and disposal protocols. The energy consumption of electrospinning processes, particularly when scaled to industrial levels, also contributes to the carbon footprint of superhydrophobic coating production.

Life cycle assessment (LCA) studies indicate that the environmental impact varies significantly depending on the specific materials and processes employed. Polymer-based superhydrophobic coatings typically demonstrate lower environmental impacts during production compared to ceramic or metal-based alternatives, though their shorter lifespan may offset these initial advantages over time.

Recent innovations have focused on developing more sustainable electrospinning approaches. Water-based electrospinning solutions represent a promising direction, eliminating the need for harmful organic solvents. Similarly, the incorporation of bio-based polymers and naturally derived materials can reduce dependence on petroleum-based resources while maintaining superhydrophobic performance characteristics.

End-of-life considerations present another critical dimension of environmental impact. Many current superhydrophobic coatings lack effective recycling pathways, potentially contributing to microplastic pollution when polymer-based coatings degrade. Research into biodegradable superhydrophobic coatings has shown promising results, particularly for temporary or short-term applications.

The durability of superhydrophobic coatings also influences their sustainability profile. More durable coatings require less frequent replacement, reducing material consumption and waste generation over time. Recent advances in self-healing superhydrophobic coatings represent a significant step toward extending service life and improving overall sustainability.

Regulatory frameworks increasingly emphasize environmental considerations in coating technologies. The European Union's REACH regulations and similar initiatives worldwide are driving the industry toward greener electrospinning formulations with reduced environmental hazards. Companies adopting sustainable electrospinning practices may gain competitive advantages as environmental regulations tighten and consumer preferences shift toward eco-friendly products.

However, several environmental challenges remain. The solvents commonly used in electrospinning solutions—such as dimethylformamide (DMF), tetrahydrofuran (THF), and chloroform—present toxicity concerns and require proper handling and disposal protocols. The energy consumption of electrospinning processes, particularly when scaled to industrial levels, also contributes to the carbon footprint of superhydrophobic coating production.

Life cycle assessment (LCA) studies indicate that the environmental impact varies significantly depending on the specific materials and processes employed. Polymer-based superhydrophobic coatings typically demonstrate lower environmental impacts during production compared to ceramic or metal-based alternatives, though their shorter lifespan may offset these initial advantages over time.

Recent innovations have focused on developing more sustainable electrospinning approaches. Water-based electrospinning solutions represent a promising direction, eliminating the need for harmful organic solvents. Similarly, the incorporation of bio-based polymers and naturally derived materials can reduce dependence on petroleum-based resources while maintaining superhydrophobic performance characteristics.

End-of-life considerations present another critical dimension of environmental impact. Many current superhydrophobic coatings lack effective recycling pathways, potentially contributing to microplastic pollution when polymer-based coatings degrade. Research into biodegradable superhydrophobic coatings has shown promising results, particularly for temporary or short-term applications.

The durability of superhydrophobic coatings also influences their sustainability profile. More durable coatings require less frequent replacement, reducing material consumption and waste generation over time. Recent advances in self-healing superhydrophobic coatings represent a significant step toward extending service life and improving overall sustainability.

Regulatory frameworks increasingly emphasize environmental considerations in coating technologies. The European Union's REACH regulations and similar initiatives worldwide are driving the industry toward greener electrospinning formulations with reduced environmental hazards. Companies adopting sustainable electrospinning practices may gain competitive advantages as environmental regulations tighten and consumer preferences shift toward eco-friendly products.

Scalability and Industrial Implementation Challenges

Despite the promising laboratory results of electrospinning for superhydrophobic coatings, significant challenges remain in scaling these techniques for industrial implementation. The transition from small-scale production to mass manufacturing presents several technical hurdles that must be addressed before widespread commercial adoption becomes viable.

The primary challenge lies in maintaining consistent nanofiber quality during high-volume production. Laboratory electrospinning typically produces small quantities under carefully controlled conditions, while industrial applications require continuous operation with reproducible results across large surface areas. Current multi-needle or needleless electrospinning systems attempt to address this issue but often struggle with uniformity in fiber diameter, orientation, and coating thickness.

Equipment modification represents another substantial barrier. Conventional electrospinning setups require significant redesign to accommodate industrial production rates. The high voltage requirements (typically 10-30 kV) present safety concerns in manufacturing environments, necessitating specialized insulation and safety protocols that increase implementation costs.

Process parameter optimization becomes exponentially more complex at industrial scales. Variables such as polymer solution properties, environmental conditions (humidity, temperature), and collection distance must be precisely controlled across larger systems. Minor fluctuations that might be negligible in laboratory settings can lead to significant quality variations in mass production.

Raw material considerations also impact scalability. Many superhydrophobic electrospun coatings utilize specialized polymers or additives that may be costly or limited in availability. Developing formulations that balance performance with cost-effectiveness remains crucial for commercial viability.

Environmental and regulatory compliance presents additional challenges. The solvents commonly used in electrospinning solutions often include volatile organic compounds (VOCs) that face increasing regulatory restrictions. Industrial implementation requires either solvent recovery systems or development of environmentally friendly alternatives without compromising coating performance.

Post-processing requirements further complicate industrial adoption. Many superhydrophobic electrospun coatings require additional treatments (thermal, chemical, or plasma) to achieve optimal performance. Integrating these steps into continuous production lines while maintaining efficiency represents a significant engineering challenge.

Cost-effectiveness ultimately determines commercial feasibility. Current estimates suggest that electrospun superhydrophobic coatings remain 3-5 times more expensive than conventional hydrophobic treatments, primarily due to equipment costs, process complexity, and material requirements. Reducing this cost gap is essential for broader market acceptance.

The primary challenge lies in maintaining consistent nanofiber quality during high-volume production. Laboratory electrospinning typically produces small quantities under carefully controlled conditions, while industrial applications require continuous operation with reproducible results across large surface areas. Current multi-needle or needleless electrospinning systems attempt to address this issue but often struggle with uniformity in fiber diameter, orientation, and coating thickness.

Equipment modification represents another substantial barrier. Conventional electrospinning setups require significant redesign to accommodate industrial production rates. The high voltage requirements (typically 10-30 kV) present safety concerns in manufacturing environments, necessitating specialized insulation and safety protocols that increase implementation costs.

Process parameter optimization becomes exponentially more complex at industrial scales. Variables such as polymer solution properties, environmental conditions (humidity, temperature), and collection distance must be precisely controlled across larger systems. Minor fluctuations that might be negligible in laboratory settings can lead to significant quality variations in mass production.

Raw material considerations also impact scalability. Many superhydrophobic electrospun coatings utilize specialized polymers or additives that may be costly or limited in availability. Developing formulations that balance performance with cost-effectiveness remains crucial for commercial viability.

Environmental and regulatory compliance presents additional challenges. The solvents commonly used in electrospinning solutions often include volatile organic compounds (VOCs) that face increasing regulatory restrictions. Industrial implementation requires either solvent recovery systems or development of environmentally friendly alternatives without compromising coating performance.

Post-processing requirements further complicate industrial adoption. Many superhydrophobic electrospun coatings require additional treatments (thermal, chemical, or plasma) to achieve optimal performance. Integrating these steps into continuous production lines while maintaining efficiency represents a significant engineering challenge.

Cost-effectiveness ultimately determines commercial feasibility. Current estimates suggest that electrospun superhydrophobic coatings remain 3-5 times more expensive than conventional hydrophobic treatments, primarily due to equipment costs, process complexity, and material requirements. Reducing this cost gap is essential for broader market acceptance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!