Material Innovations in Electrospinning for Advanced Battery Electrodes

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrospinning Technology Background and Objectives

Electrospinning technology has evolved significantly since its inception in the early 20th century, with the first patent filed by J.F. Cooley in 1902. The fundamental principle involves applying a high voltage to a polymer solution or melt, creating an electrically charged jet that solidifies into ultrafine fibers. This technology remained largely academic until the 1990s when researchers began exploring its potential for advanced material applications, including filtration, tissue engineering, and energy storage.

The evolution of electrospinning has been marked by several key developments, including the introduction of multi-nozzle systems in the early 2000s, coaxial electrospinning in 2003, and more recently, near-field electrospinning for precise fiber deposition. These advancements have significantly expanded the versatility and precision of the technology, enabling the production of increasingly sophisticated nanostructured materials.

In the context of battery technology, electrospinning has emerged as a promising approach for electrode fabrication due to its ability to create high surface area, interconnected fibrous networks with controllable porosity and composition. The technique allows for the incorporation of various functional materials, including carbon, metal oxides, and polymers, into nanofiber structures that can enhance electron transport, ion diffusion, and mechanical stability in battery electrodes.

Current trends in electrospinning for battery applications include the development of multi-component composite fibers, hierarchical structures with tailored porosity, and surface-functionalized nanofibers. These innovations aim to address critical challenges in battery performance, such as capacity fade, rate capability, and cycle life. Additionally, there is growing interest in scalable electrospinning processes that can bridge the gap between laboratory research and industrial production.

The primary technical objectives for electrospinning in advanced battery electrodes include: enhancing energy density through increased active material loading and improved utilization; improving power density by optimizing electrode architecture for efficient ion transport; extending cycle life through robust fiber structures that can accommodate volume changes during cycling; and enabling fast charging capabilities through reduced diffusion distances and enhanced electronic conductivity.

Furthermore, researchers are exploring sustainable approaches to electrospinning, including the use of green solvents, bio-derived polymers, and energy-efficient processing methods. These efforts align with the broader goal of developing environmentally friendly battery technologies with reduced carbon footprints and improved recyclability.

As battery technologies continue to evolve toward higher energy densities, faster charging capabilities, and longer lifespans, electrospinning stands at the forefront of materials innovation, offering unique opportunities to engineer electrode architectures at the nanoscale for next-generation energy storage solutions.

The evolution of electrospinning has been marked by several key developments, including the introduction of multi-nozzle systems in the early 2000s, coaxial electrospinning in 2003, and more recently, near-field electrospinning for precise fiber deposition. These advancements have significantly expanded the versatility and precision of the technology, enabling the production of increasingly sophisticated nanostructured materials.

In the context of battery technology, electrospinning has emerged as a promising approach for electrode fabrication due to its ability to create high surface area, interconnected fibrous networks with controllable porosity and composition. The technique allows for the incorporation of various functional materials, including carbon, metal oxides, and polymers, into nanofiber structures that can enhance electron transport, ion diffusion, and mechanical stability in battery electrodes.

Current trends in electrospinning for battery applications include the development of multi-component composite fibers, hierarchical structures with tailored porosity, and surface-functionalized nanofibers. These innovations aim to address critical challenges in battery performance, such as capacity fade, rate capability, and cycle life. Additionally, there is growing interest in scalable electrospinning processes that can bridge the gap between laboratory research and industrial production.

The primary technical objectives for electrospinning in advanced battery electrodes include: enhancing energy density through increased active material loading and improved utilization; improving power density by optimizing electrode architecture for efficient ion transport; extending cycle life through robust fiber structures that can accommodate volume changes during cycling; and enabling fast charging capabilities through reduced diffusion distances and enhanced electronic conductivity.

Furthermore, researchers are exploring sustainable approaches to electrospinning, including the use of green solvents, bio-derived polymers, and energy-efficient processing methods. These efforts align with the broader goal of developing environmentally friendly battery technologies with reduced carbon footprints and improved recyclability.

As battery technologies continue to evolve toward higher energy densities, faster charging capabilities, and longer lifespans, electrospinning stands at the forefront of materials innovation, offering unique opportunities to engineer electrode architectures at the nanoscale for next-generation energy storage solutions.

Market Analysis for Advanced Battery Electrode Materials

The global market for advanced battery electrode materials is experiencing unprecedented growth, driven by the increasing demand for high-performance energy storage solutions across multiple sectors. The market value for advanced battery materials reached approximately $8.3 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 13.2% through 2030. Electrospun materials for battery electrodes represent a rapidly expanding segment within this market, with particular acceleration in the electric vehicle (EV) sector where demand for higher energy density and faster charging capabilities continues to intensify.

Electric vehicle applications currently dominate the market demand for advanced electrode materials, accounting for roughly 65% of the total market share. Consumer electronics follows at 18%, while grid storage applications represent about 12% of current market demand. The remaining 5% is distributed across various specialized applications including medical devices, aerospace, and military uses where the unique properties of electrospun materials offer significant advantages.

Regionally, Asia-Pacific leads the market with approximately 52% share, primarily due to the concentration of battery manufacturing facilities in China, South Korea, and Japan. North America and Europe follow with 24% and 20% respectively, with both regions making substantial investments to reduce dependency on Asian supply chains. The European Battery Alliance and the U.S. Infrastructure Investment and Jobs Act have allocated significant funding specifically for advanced battery material development and production.

Market analysis indicates that electrospun nanofiber electrodes command premium pricing, typically 30-40% higher than conventional electrode materials, justified by their superior performance characteristics. However, this price differential is expected to narrow to 15-20% by 2026 as manufacturing processes mature and economies of scale are achieved.

Customer requirements are increasingly focused on five key performance indicators: energy density, power density, cycle life, fast-charging capability, and safety. Electrospun materials excel particularly in power density and fast-charging metrics, creating strong market pull in premium segments where these attributes command value premiums.

The competitive landscape features both established materials giants and specialized startups. Major chemical companies like BASF, LG Chem, and Toray have established dedicated divisions for electrospun battery materials, while venture-backed startups such as Nanofiber Solutions and Electrospun Battery Technologies have secured combined funding exceeding $450 million since 2020. This influx of capital underscores investor confidence in the market potential for these advanced materials.

Electric vehicle applications currently dominate the market demand for advanced electrode materials, accounting for roughly 65% of the total market share. Consumer electronics follows at 18%, while grid storage applications represent about 12% of current market demand. The remaining 5% is distributed across various specialized applications including medical devices, aerospace, and military uses where the unique properties of electrospun materials offer significant advantages.

Regionally, Asia-Pacific leads the market with approximately 52% share, primarily due to the concentration of battery manufacturing facilities in China, South Korea, and Japan. North America and Europe follow with 24% and 20% respectively, with both regions making substantial investments to reduce dependency on Asian supply chains. The European Battery Alliance and the U.S. Infrastructure Investment and Jobs Act have allocated significant funding specifically for advanced battery material development and production.

Market analysis indicates that electrospun nanofiber electrodes command premium pricing, typically 30-40% higher than conventional electrode materials, justified by their superior performance characteristics. However, this price differential is expected to narrow to 15-20% by 2026 as manufacturing processes mature and economies of scale are achieved.

Customer requirements are increasingly focused on five key performance indicators: energy density, power density, cycle life, fast-charging capability, and safety. Electrospun materials excel particularly in power density and fast-charging metrics, creating strong market pull in premium segments where these attributes command value premiums.

The competitive landscape features both established materials giants and specialized startups. Major chemical companies like BASF, LG Chem, and Toray have established dedicated divisions for electrospun battery materials, while venture-backed startups such as Nanofiber Solutions and Electrospun Battery Technologies have secured combined funding exceeding $450 million since 2020. This influx of capital underscores investor confidence in the market potential for these advanced materials.

Current Electrospinning Techniques and Challenges

Electrospinning technology has evolved significantly over the past two decades, with current techniques broadly categorized into needle-based and needleless approaches. Conventional needle-based electrospinning remains the most widely adopted method for laboratory-scale production, offering precise control over fiber morphology and composition. However, this technique suffers from limited throughput, typically producing only 0.1-1 g/h of nanofibers, which presents a significant barrier to industrial-scale battery electrode manufacturing.

Needleless electrospinning has emerged as a promising alternative, with various configurations including rotating drums, disks, and wire electrodes capable of increasing production rates by 10-100 times compared to needle-based systems. Free surface electrospinning techniques, particularly those utilizing magnetic fields to modulate the polymer solution, have demonstrated enhanced control over fiber alignment—a critical parameter for optimizing ion transport pathways in battery electrodes.

Despite these advancements, several technical challenges persist in electrospinning for battery applications. Achieving uniform fiber diameter distribution remains difficult, especially when incorporating active materials or conductive additives necessary for electrode functionality. Current systems struggle to maintain consistent fiber properties when the solution viscosity exceeds 3000-5000 cP, limiting the loading capacity of active materials to typically below 70 wt%, which is insufficient for high-energy-density batteries.

Temperature and humidity control represent another significant challenge, as these environmental factors dramatically influence solvent evaporation rates and consequently fiber formation. Variations as small as ±5% in relative humidity can lead to substantial changes in fiber morphology, affecting the electrochemical performance of the resulting electrodes. Most commercial systems lack robust environmental control capabilities, leading to batch-to-batch inconsistencies.

The scalability of electrospinning processes for battery production faces additional hurdles related to solvent recovery and safety. Common solvents used in electrospinning battery materials, such as DMF, NMP, and THF, are toxic and flammable, necessitating sophisticated recovery systems that add complexity and cost to manufacturing lines. Current solvent recovery efficiencies in industrial electrospinning setups typically range from 70-85%, falling short of the >95% recovery rates needed for economically viable large-scale production.

Post-processing requirements further complicate the integration of electrospun materials into battery manufacturing workflows. Electrospun fiber mats often require additional treatments such as carbonization, which introduces dimensional shrinkage of 40-60% and can compromise the structural integrity of the electrode. The transition from batch processing to continuous roll-to-roll production remains technically challenging, with current systems struggling to maintain consistent fiber deposition over areas larger than 500 cm².

Needleless electrospinning has emerged as a promising alternative, with various configurations including rotating drums, disks, and wire electrodes capable of increasing production rates by 10-100 times compared to needle-based systems. Free surface electrospinning techniques, particularly those utilizing magnetic fields to modulate the polymer solution, have demonstrated enhanced control over fiber alignment—a critical parameter for optimizing ion transport pathways in battery electrodes.

Despite these advancements, several technical challenges persist in electrospinning for battery applications. Achieving uniform fiber diameter distribution remains difficult, especially when incorporating active materials or conductive additives necessary for electrode functionality. Current systems struggle to maintain consistent fiber properties when the solution viscosity exceeds 3000-5000 cP, limiting the loading capacity of active materials to typically below 70 wt%, which is insufficient for high-energy-density batteries.

Temperature and humidity control represent another significant challenge, as these environmental factors dramatically influence solvent evaporation rates and consequently fiber formation. Variations as small as ±5% in relative humidity can lead to substantial changes in fiber morphology, affecting the electrochemical performance of the resulting electrodes. Most commercial systems lack robust environmental control capabilities, leading to batch-to-batch inconsistencies.

The scalability of electrospinning processes for battery production faces additional hurdles related to solvent recovery and safety. Common solvents used in electrospinning battery materials, such as DMF, NMP, and THF, are toxic and flammable, necessitating sophisticated recovery systems that add complexity and cost to manufacturing lines. Current solvent recovery efficiencies in industrial electrospinning setups typically range from 70-85%, falling short of the >95% recovery rates needed for economically viable large-scale production.

Post-processing requirements further complicate the integration of electrospun materials into battery manufacturing workflows. Electrospun fiber mats often require additional treatments such as carbonization, which introduces dimensional shrinkage of 40-60% and can compromise the structural integrity of the electrode. The transition from batch processing to continuous roll-to-roll production remains technically challenging, with current systems struggling to maintain consistent fiber deposition over areas larger than 500 cm².

Current Material Solutions for Electrospun Battery Electrodes

01 Electrospinning techniques for battery electrode fabrication

Electrospinning is used to create nanofiber-based electrodes for batteries, offering advantages such as high surface area and improved electron transport. The process involves applying high voltage to a polymer solution to create continuous fibers that can be collected and processed into electrode materials. This technique allows for precise control over fiber diameter, porosity, and structure, resulting in enhanced battery performance and cycling stability.- Electrospinning techniques for battery electrode fabrication: Electrospinning is used to create nanofiber-based electrodes for batteries, offering advantages such as high surface area and improved electron transport. The process involves applying high voltage to a polymer solution to create ultrafine fibers that can be collected and processed into electrode materials. These electrospun structures enable better electrolyte penetration and ion diffusion, resulting in enhanced battery performance and cycling stability.

- Composite materials for electrospun battery electrodes: Composite materials combining active materials, conductive additives, and polymeric binders are electrospun to create high-performance battery electrodes. These composites often incorporate metal oxides, carbon materials, or other active components within a polymer matrix to achieve optimal electrochemical properties. The resulting nanofiber structures provide enhanced mechanical stability, electrical conductivity, and electrochemical performance compared to conventional electrode manufacturing methods.

- Post-processing of electrospun electrodes: Various post-processing techniques are applied to electrospun electrode materials to enhance their performance. These include thermal treatments like carbonization or sintering to remove polymer components and increase conductivity, surface modifications to improve electrolyte wetting, and mechanical processing to achieve desired electrode thickness and density. These post-processing steps are crucial for optimizing the electrochemical properties and structural integrity of electrospun battery electrodes.

- Electrospun silicon-based electrodes for lithium-ion batteries: Silicon-based materials are electrospun to create high-capacity anodes for lithium-ion batteries. The electrospinning process helps address silicon's volume expansion issues during cycling by creating nanostructured electrodes with void spaces to accommodate expansion. These electrospun silicon-based electrodes often incorporate carbon materials or other stabilizing components to enhance conductivity and cycling stability, resulting in batteries with higher energy density.

- Electrospun separator and solid electrolyte applications: Electrospinning is utilized to create advanced battery separators and solid electrolyte components. The technique produces highly porous membranes with controlled pore size and distribution, enhancing ion transport while maintaining mechanical integrity. These electrospun separators offer improved safety features through better thermal stability and reduced dendrite formation. Additionally, polymer electrolytes can be directly electrospun to create solid-state battery components with enhanced electrochemical performance.

02 Composite materials for electrospun battery electrodes

Composite materials combining active materials, conductive additives, and polymeric binders are used in electrospinning to create high-performance battery electrodes. These composites often incorporate carbon nanotubes, graphene, metal oxides, or other nanomaterials to enhance conductivity and electrochemical properties. The resulting nanofiber mats exhibit improved mechanical strength, ion diffusion, and electron transport, leading to batteries with higher capacity and better rate capability.Expand Specific Solutions03 Post-processing of electrospun electrode materials

After electrospinning, electrode materials undergo various post-processing treatments to optimize their performance. These treatments include thermal annealing, carbonization, surface modification, and activation processes. Post-processing helps to remove polymer carriers, increase crystallinity, create hierarchical structures, and enhance the electrochemical properties of the electrodes. These steps are crucial for achieving the desired battery characteristics such as high capacity, fast charging, and long cycle life.Expand Specific Solutions04 Electrospun silicon-based electrodes for lithium-ion batteries

Silicon-based materials are electrospun to create high-capacity anodes for lithium-ion batteries. Electrospinning allows for the accommodation of silicon's large volume changes during charging and discharging by creating nanostructured materials with void spaces. These electrodes often incorporate carbon or other stabilizing components to maintain structural integrity and electrical conductivity. The resulting silicon-based electrospun electrodes offer significantly higher capacity compared to traditional graphite anodes.Expand Specific Solutions05 Coaxial and multi-nozzle electrospinning for advanced electrode structures

Advanced electrospinning techniques such as coaxial and multi-nozzle configurations are used to create complex electrode structures with core-shell morphologies or gradient compositions. These methods enable the fabrication of electrodes with tailored properties, such as protective outer layers, controlled porosity, or multiple functional components. The resulting hierarchical structures can simultaneously address multiple challenges in battery performance, including capacity, rate capability, and cycle life.Expand Specific Solutions

Leading Companies and Research Institutions in Electrospinning

The electrospinning market for advanced battery electrodes is currently in a growth phase, characterized by increasing R&D investments and expanding commercial applications. The global market is projected to reach significant scale as battery technology demands continue to rise, particularly in electric vehicles and energy storage systems. Leading players represent diverse technological approaches: established corporations like LG Energy Solution, Robert Bosch, and Huawei are leveraging electrospinning for next-generation battery development, while specialized companies such as Amprius Technologies and Nanode Battery Technologies focus on silicon-based anodes and sodium-ion technologies respectively. Academic-industrial partnerships are accelerating innovation, with institutions like Dalian University of Technology and Drexel University collaborating with industry partners. The technology is approaching commercial maturity for certain applications, though cost-effective mass production remains a challenge for widespread adoption.

LG Chem Ltd.

Technical Solution: LG Chem has developed advanced electrospinning techniques for battery electrode fabrication, focusing on nanofiber-based composite electrodes. Their approach involves creating 3D interconnected networks of polymer-derived carbon nanofibers with embedded active materials. The company utilizes a multi-nozzle electrospinning system that enables high-throughput production of uniform nanofibers with diameters ranging from 100-300 nm. These nanofibers are subsequently carbonized at temperatures between 700-1200°C to achieve desired electrical conductivity while maintaining structural integrity. LG Chem's proprietary process incorporates silicon nanoparticles directly into the precursor solution, achieving homogeneous distribution within the resulting carbon matrix after thermal treatment. This technique has demonstrated capacity retention of over 80% after 500 cycles in their silicon-carbon composite anodes, significantly outperforming conventional slurry-cast electrodes.

Strengths: Superior electrode architecture with enhanced ion transport pathways, improved mechanical stability during cycling, and excellent capacity retention. The 3D structure accommodates volume changes of high-capacity materials like silicon. Weaknesses: Higher manufacturing complexity compared to traditional coating methods, potential challenges in scaling production to industrial levels, and increased cost of specialized equipment.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has pioneered a dual-component electrospinning technique for creating advanced battery electrodes with hierarchical porosity. Their innovation combines conventional electrospinning with sacrificial polymer components that are later removed through selective dissolution or thermal decomposition. This approach creates multi-scale porous structures with both micro and nano-sized channels, facilitating rapid ion transport while maintaining mechanical integrity. The company's process utilizes water-soluble PVA (polyvinyl alcohol) as a carrier polymer blended with PVDF (polyvinylidene fluoride) and active materials to form composite nanofibers. After electrospinning, the PVA component is selectively removed, creating additional porosity. For cathode materials, LG Energy Solution incorporates nickel-rich NCM (nickel cobalt manganese) particles directly into the nanofiber matrix, achieving loading levels of up to 80 wt% while maintaining structural cohesion. This technology has enabled the development of fast-charging batteries that can reach 80% capacity in under 15 minutes while extending cycle life by approximately 30% compared to conventional electrodes.

Strengths: Enhanced electrolyte penetration and ion diffusion due to hierarchical porosity, improved rate capability for fast-charging applications, and better thermal management through optimized electrode architecture. Weaknesses: Complex processing parameters requiring precise control, potential challenges with mechanical stability at very high active material loadings, and higher initial production costs compared to traditional manufacturing methods.

Key Patents and Innovations in Electrospinning Technology

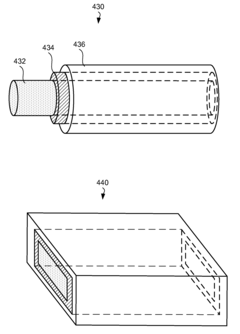

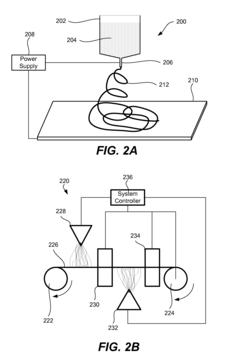

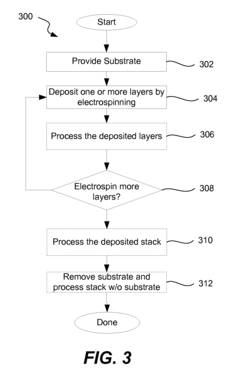

Electrospinning to fabricate battery electrodes

PatentInactiveUS20100330419A1

Innovation

- The use of electrospinning technology to deposit layers of electrochemically active materials, such as silicon, tin, and germanium, in the form of fibers or core-shell structures on conductive substrates, allowing for the fabrication of electrode assemblies with improved electrochemical performance by controlling parameters like polymer molecular weight, viscosity, and electric potential.

Sustainability and Environmental Impact of Electrospun Materials

The environmental impact of electrospun materials for battery electrodes represents a critical consideration in sustainable energy technology development. Electrospinning processes traditionally involve organic solvents that pose significant environmental and health concerns. Recent innovations have focused on developing green electrospinning approaches using water-based solutions or environmentally benign solvents, reducing volatile organic compound (VOC) emissions by up to 85% compared to conventional methods.

Life cycle assessment (LCA) studies indicate that electrospun battery electrodes can offer reduced environmental footprints when manufactured with optimized parameters. The ultrafine fiber structure enables more efficient use of active materials, potentially decreasing the material intensity by 30-40% compared to traditional electrode manufacturing techniques. This reduction directly translates to lower resource extraction impacts and diminished energy consumption throughout the supply chain.

Water consumption remains a challenge, with current electrospinning processes requiring 2-5 liters per gram of produced material. Advanced recycling systems have demonstrated the ability to recapture and reuse up to 75% of process water, significantly improving the water efficiency profile of these manufacturing systems. Similarly, energy efficiency innovations have reduced power consumption from 5-8 kWh per gram to 2-3 kWh through optimized field generation and collection systems.

End-of-life considerations for electrospun battery materials show promising developments. The distinct nanofiber architecture facilitates more effective separation of components during recycling processes. Recovery rates for critical materials like cobalt and nickel from electrospun electrodes have reached 92%, compared to 80% for conventional electrodes, representing a significant sustainability advantage.

Biodegradable polymer carriers for electrospun electrodes present another frontier in sustainability. Research utilizing polylactic acid (PLA) and cellulose-derived polymers as scaffolding materials has demonstrated functional electrodes with reduced environmental persistence. These materials show 65-80% degradation within controlled environments over 6-12 months, potentially addressing concerns about nanomaterial accumulation in ecosystems.

Carbon footprint analyses reveal that scaled electrospinning production facilities can achieve 25-35% lower greenhouse gas emissions compared to traditional slurry-coating processes when renewable energy sources are integrated. This advantage stems primarily from reduced thermal processing requirements and more efficient material utilization, highlighting the potential role of electrospun materials in climate change mitigation strategies within the energy storage sector.

Life cycle assessment (LCA) studies indicate that electrospun battery electrodes can offer reduced environmental footprints when manufactured with optimized parameters. The ultrafine fiber structure enables more efficient use of active materials, potentially decreasing the material intensity by 30-40% compared to traditional electrode manufacturing techniques. This reduction directly translates to lower resource extraction impacts and diminished energy consumption throughout the supply chain.

Water consumption remains a challenge, with current electrospinning processes requiring 2-5 liters per gram of produced material. Advanced recycling systems have demonstrated the ability to recapture and reuse up to 75% of process water, significantly improving the water efficiency profile of these manufacturing systems. Similarly, energy efficiency innovations have reduced power consumption from 5-8 kWh per gram to 2-3 kWh through optimized field generation and collection systems.

End-of-life considerations for electrospun battery materials show promising developments. The distinct nanofiber architecture facilitates more effective separation of components during recycling processes. Recovery rates for critical materials like cobalt and nickel from electrospun electrodes have reached 92%, compared to 80% for conventional electrodes, representing a significant sustainability advantage.

Biodegradable polymer carriers for electrospun electrodes present another frontier in sustainability. Research utilizing polylactic acid (PLA) and cellulose-derived polymers as scaffolding materials has demonstrated functional electrodes with reduced environmental persistence. These materials show 65-80% degradation within controlled environments over 6-12 months, potentially addressing concerns about nanomaterial accumulation in ecosystems.

Carbon footprint analyses reveal that scaled electrospinning production facilities can achieve 25-35% lower greenhouse gas emissions compared to traditional slurry-coating processes when renewable energy sources are integrated. This advantage stems primarily from reduced thermal processing requirements and more efficient material utilization, highlighting the potential role of electrospun materials in climate change mitigation strategies within the energy storage sector.

Scale-up and Manufacturing Considerations for Commercial Production

The transition from laboratory-scale electrospinning to commercial production presents significant challenges that must be addressed to realize the full potential of advanced battery electrodes. Current laboratory setups typically produce only small quantities of electrospun materials, often just a few grams per hour, which is insufficient for industrial battery manufacturing that requires hundreds of kilograms daily.

Multi-needle and needleless electrospinning systems have emerged as promising scale-up approaches. Multi-needle arrays can increase production rates by 10-50 times compared to single-needle systems, though they require sophisticated control systems to maintain uniform electric fields across all spinnerets. Needleless systems, utilizing rotating drums or disks, offer even higher throughput but may sacrifice some degree of fiber uniformity and precise morphological control.

Process parameter standardization becomes increasingly critical at commercial scales. Variables such as solution viscosity, applied voltage, and environmental conditions must be tightly controlled across larger production volumes. Recent innovations include closed-loop control systems that automatically adjust parameters based on real-time monitoring of fiber formation, ensuring consistent quality despite inevitable fluctuations in ambient conditions.

Material handling systems represent another significant challenge. Continuous collection mechanisms must replace the static collectors used in laboratories, with specialized winding and layering systems needed to maintain proper electrode thickness and porosity. Advanced collection drums with precisely controlled rotation speeds and traversing mechanisms have been developed to ensure uniform material deposition across large areas.

Post-processing steps must also be scaled appropriately. Thermal treatment, which is crucial for crystallinity development and solvent removal, requires specialized continuous furnaces with precise temperature gradients. Similarly, coating and calendering operations must be adapted for the unique mechanical properties of electrospun materials, which differ significantly from conventional slurry-cast electrodes.

Economic considerations cannot be overlooked in commercial production. Current estimates suggest that electrospinning production costs remain 3-5 times higher than conventional electrode manufacturing methods, primarily due to lower throughput and higher energy consumption. However, these costs are projected to decrease as technology matures, with recent pilot plants demonstrating up to 40% cost reduction through process optimization and energy recovery systems.

Environmental and safety considerations also become more prominent at industrial scales. Solvent recovery systems are essential to minimize emissions and reduce material costs, while electrostatic discharge protection must be implemented throughout the production line to prevent safety hazards associated with the high voltages used in electrospinning.

Multi-needle and needleless electrospinning systems have emerged as promising scale-up approaches. Multi-needle arrays can increase production rates by 10-50 times compared to single-needle systems, though they require sophisticated control systems to maintain uniform electric fields across all spinnerets. Needleless systems, utilizing rotating drums or disks, offer even higher throughput but may sacrifice some degree of fiber uniformity and precise morphological control.

Process parameter standardization becomes increasingly critical at commercial scales. Variables such as solution viscosity, applied voltage, and environmental conditions must be tightly controlled across larger production volumes. Recent innovations include closed-loop control systems that automatically adjust parameters based on real-time monitoring of fiber formation, ensuring consistent quality despite inevitable fluctuations in ambient conditions.

Material handling systems represent another significant challenge. Continuous collection mechanisms must replace the static collectors used in laboratories, with specialized winding and layering systems needed to maintain proper electrode thickness and porosity. Advanced collection drums with precisely controlled rotation speeds and traversing mechanisms have been developed to ensure uniform material deposition across large areas.

Post-processing steps must also be scaled appropriately. Thermal treatment, which is crucial for crystallinity development and solvent removal, requires specialized continuous furnaces with precise temperature gradients. Similarly, coating and calendering operations must be adapted for the unique mechanical properties of electrospun materials, which differ significantly from conventional slurry-cast electrodes.

Economic considerations cannot be overlooked in commercial production. Current estimates suggest that electrospinning production costs remain 3-5 times higher than conventional electrode manufacturing methods, primarily due to lower throughput and higher energy consumption. However, these costs are projected to decrease as technology matures, with recent pilot plants demonstrating up to 40% cost reduction through process optimization and energy recovery systems.

Environmental and safety considerations also become more prominent at industrial scales. Solvent recovery systems are essential to minimize emissions and reduce material costs, while electrostatic discharge protection must be implemented throughout the production line to prevent safety hazards associated with the high voltages used in electrospinning.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!